DESCRIPTION

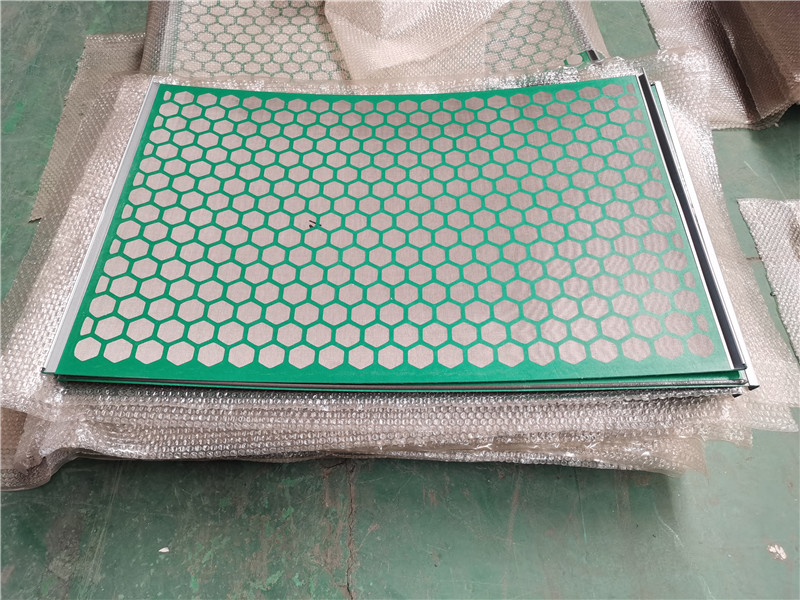

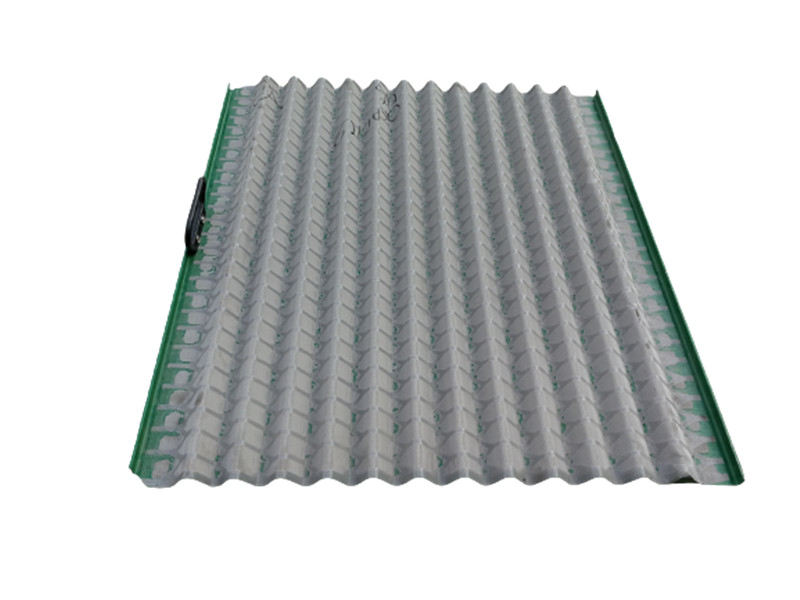

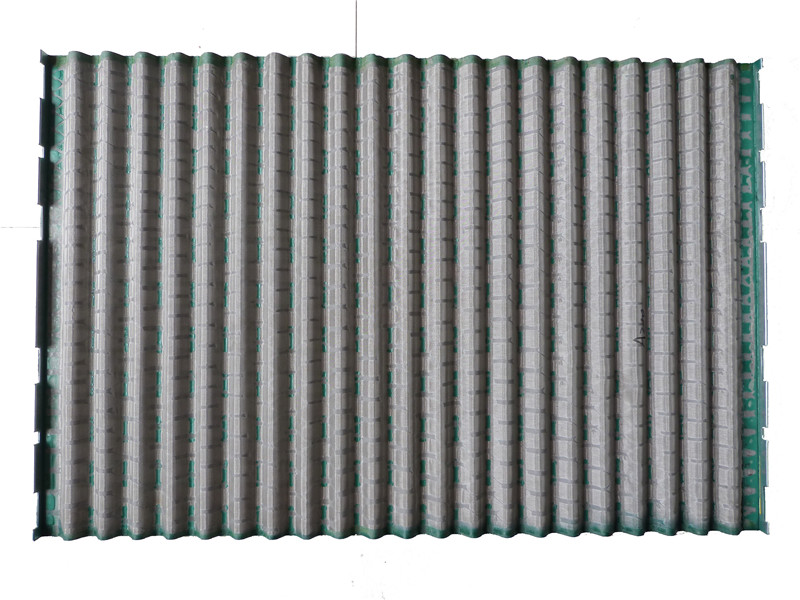

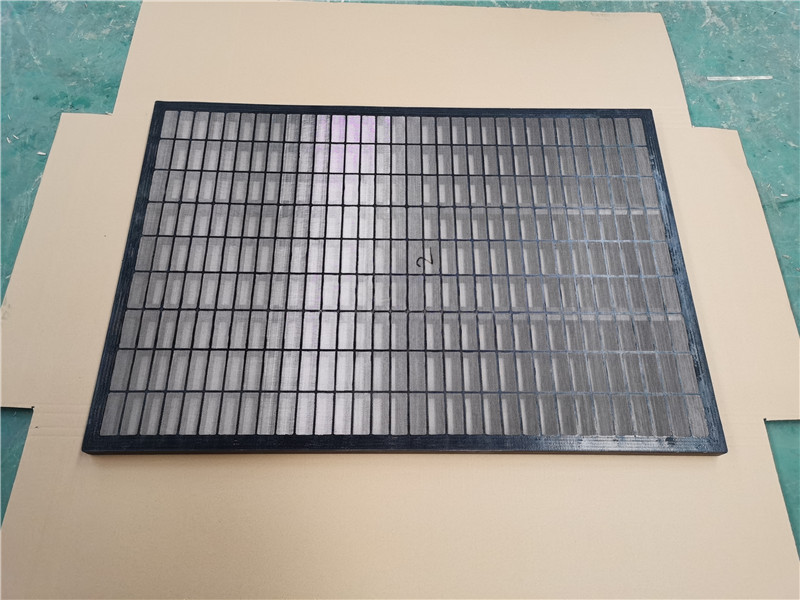

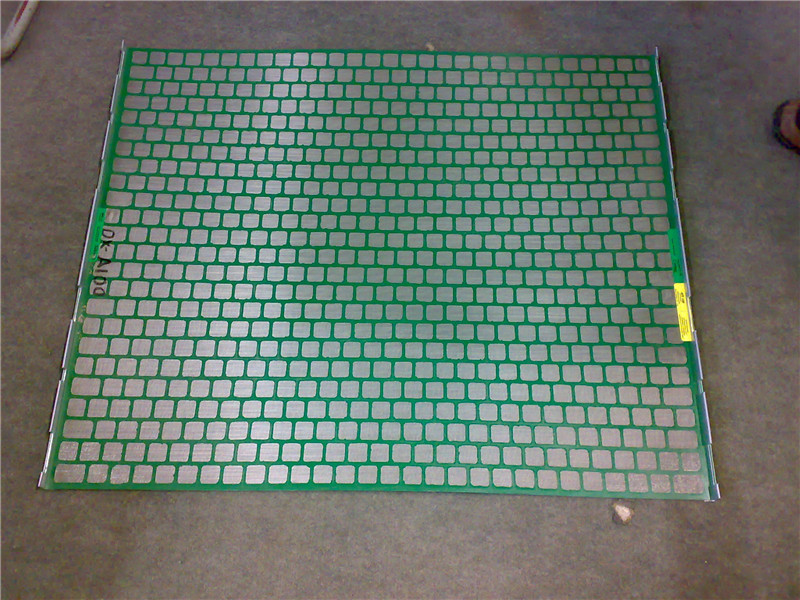

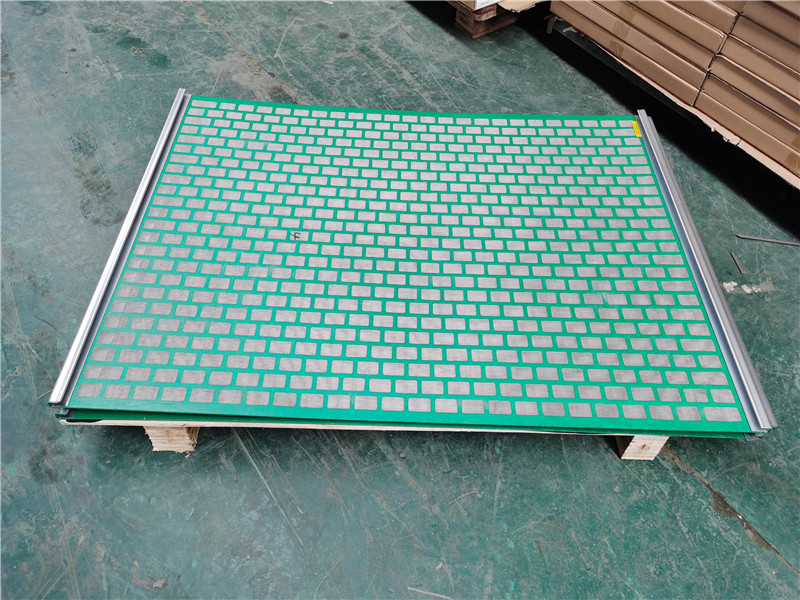

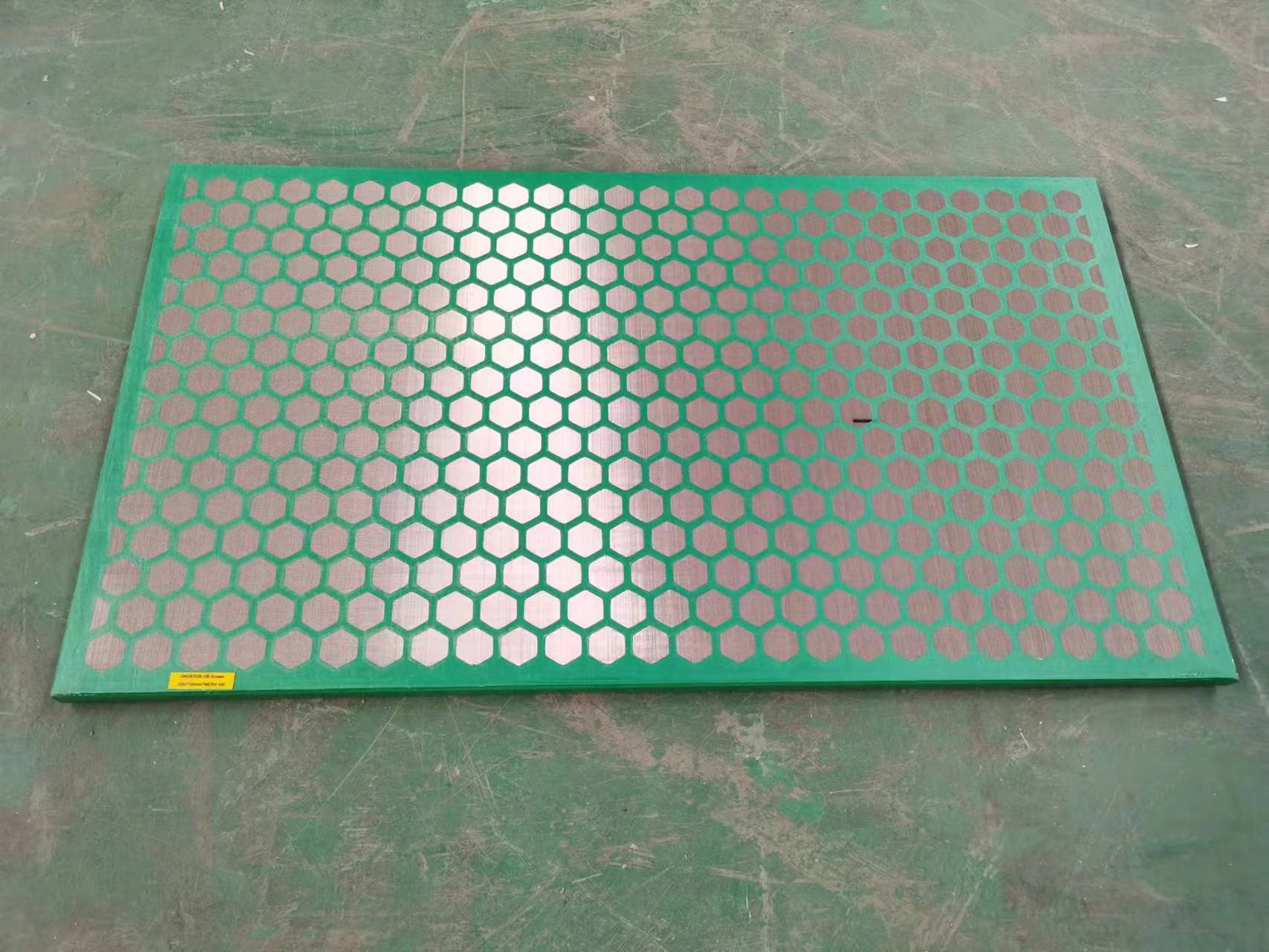

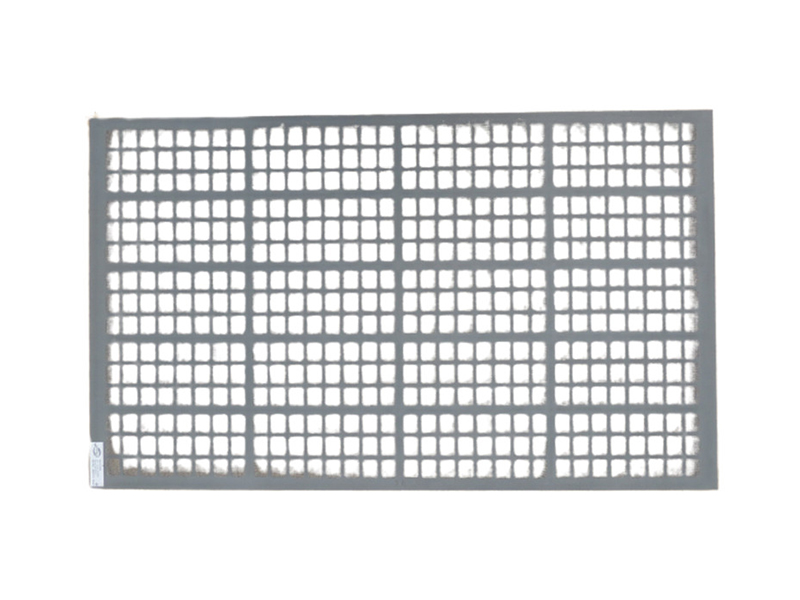

KET-S250 shale shaker screens, also famous known as S250 screens, are compatible with S250 series shale shakers. It is a hook strip flat type shaker screen, which is constructed of multiple stainless steel 304 or 316 wire mesh cloth layers. And then bonded to a rectangular or hexagonal perforated metal plate for added support and facilitation of repair. Adaptable Shale Shaker Model KET-S250 shaker screens are used as the substitute screen for ● S250 3-panel shaker. ● S250 4-panel shaker. ● S250 series mud cleaners. ● S250 Plus, FLC with AWD, HI-G dryer.Competitive Advantage

● Manufactured according to the API RP 13C (ISO 13501). ● Top quality stainless steel wire mesh for longevity. ● Increase shaker capacity and reduce mud loss. ● Scientific & reasonable cost control system for competitive price. ● Higher flow rates without sacrificing cut point integrity. ● Adequate inventory in the shortest time to meet customers' demand. ● Warranty Period: 1 year. ● Working Life: 400-450 hours.Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

| KET-S250-A325 | DF | API 325 | 0.29 | 44 | 2/3 | 5.5 |

| KET-S250-A270 | DF | API 270 | 0.31 | 57 | 2/3 | 5.5 |

| KET-S250-A230 | DF | API 230 | 0.59 | 68 | 2/3 | 5.5 |

| KET-S250-A200 | DX | API 200 | 0.73 | 73 | 2/3 | 5.5 |

| KET-S250-A170 | DX | API 170 | 0.85 | 83 | 2/3 | 5.5 |

| KET-S250-A140 | DX | API 140 | 1.43 | 101 | 2/3 | 5.5 |

| KET-S250-A120 | DX | API 120 | 1.46 | 134 | 2/3 | 5.5 |

| KET-S250-A100 | DX | API 100 | 1.8 | 164 | 2/3 | 5.5 |

| KET-S250-A80 | DX | API 80 | 2.48 | 193 | 2/3 | 5.5 |

| KET-S250-A70 | DX | API 70 | 2.67 | 203 | 2/3 | 5.5 |

| KET-S250-A60 | DX | API 60 | 3.56 | 268 | 2/3 | 5.5 |

| KET-S250-A50 | DX | API 50 | 4.19 | 285 | 2/3 | 5.5 |

| KET-S250-A40 | DX | API 40 | 6.77 | 439 | 2/3 | 5.5 |

| KET-S250-A35 | DX | API 35 | 7.24 | 538 | 2/3 | 5.5 |

| KET-S250-A20 | DF | API 20 | 14.35 | 809 | 2/3 | 5.5 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||