| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| KET-PWP 500-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 4.05 |

| KET-PWP 500-A270 | DF | API 270 | 0.67 | 57 | 2/3 | 4.05 |

| KET-PWP 500-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 4.05 |

| KET-PWP 500-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 4.05 |

| KET-PWP 500-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 4.05 |

| KET-PWP 500-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 4.05 |

| KET-PWP 500-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 4.05 |

| KET-PWP 500-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 4.05 |

| KET-PWP 500-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 4.05 |

| KET-PWP 500-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 4.05 |

| KET-PWP 500-A60 | DX | API 60 | 4.1. | 268 | 2/3 | 4.05 |

| KET-PWP 500-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 4.05 |

| KET-PWP 500-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 4.05 |

| KET-PWP 500-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 4.05 |

| KET-PWP 500-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 4.05 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

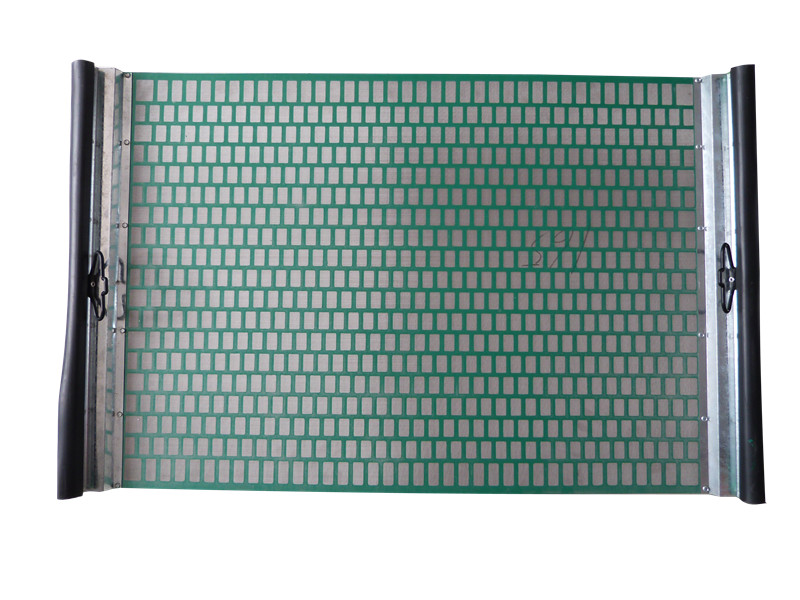

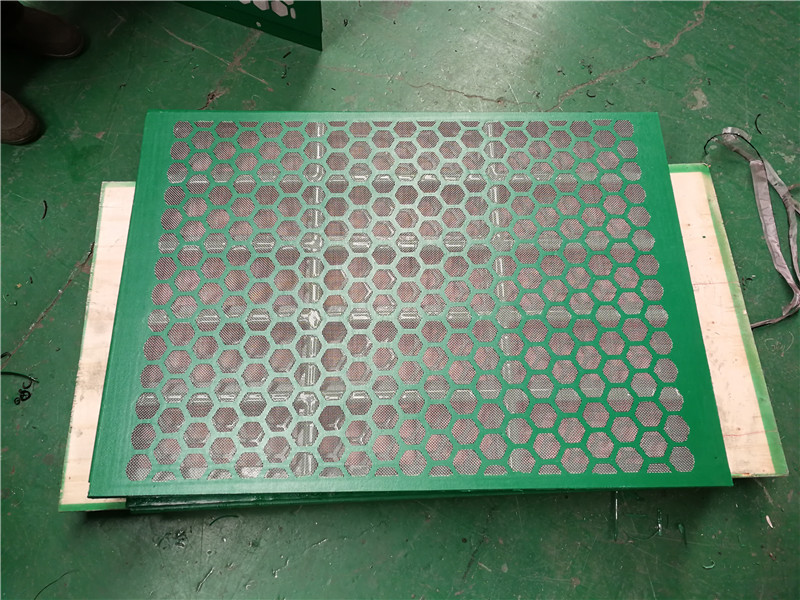

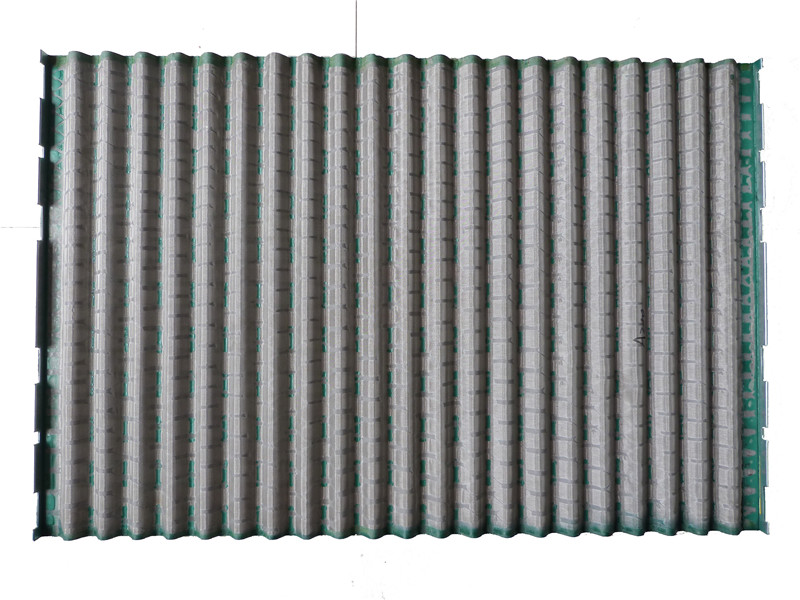

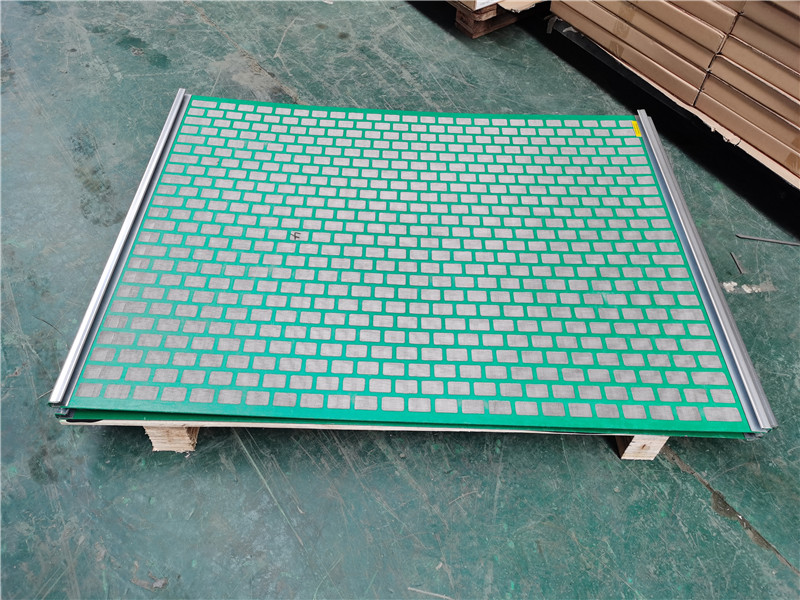

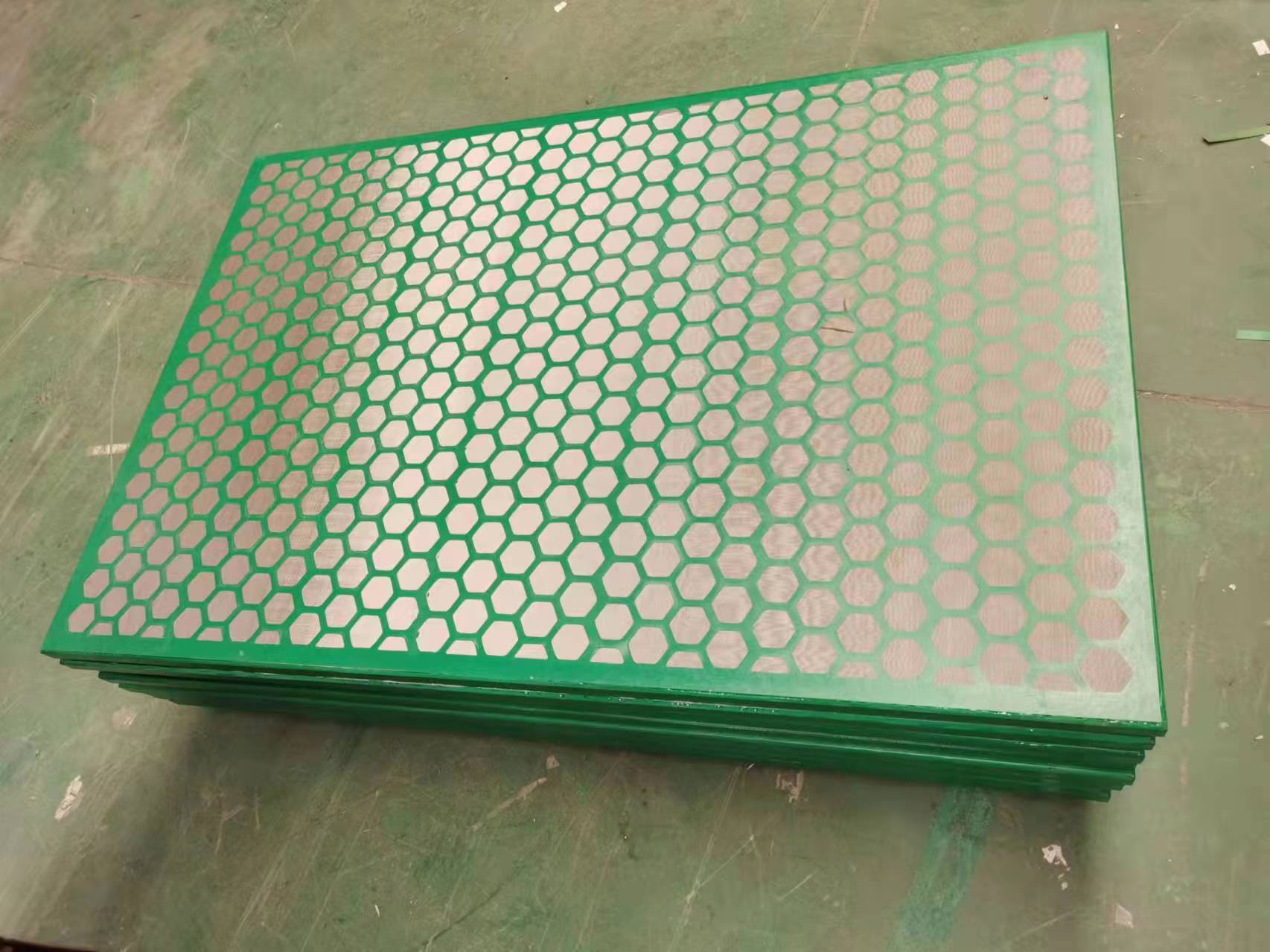

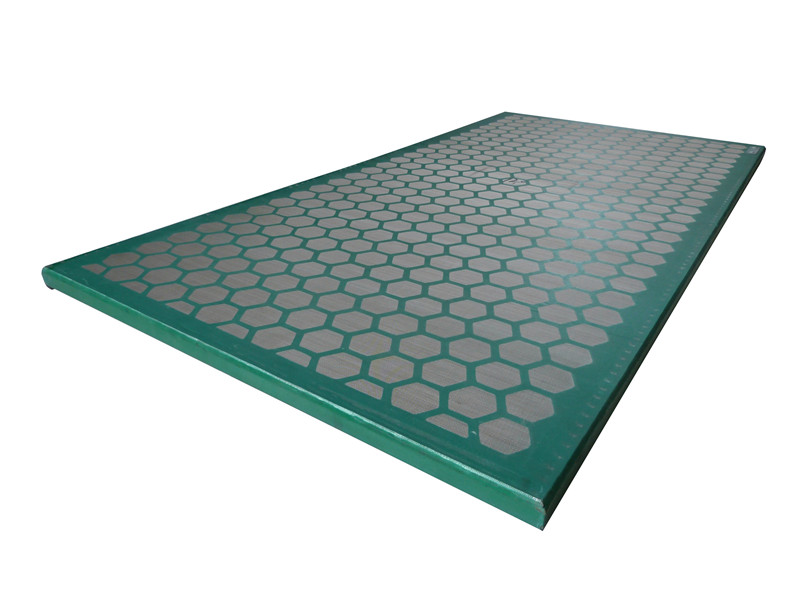

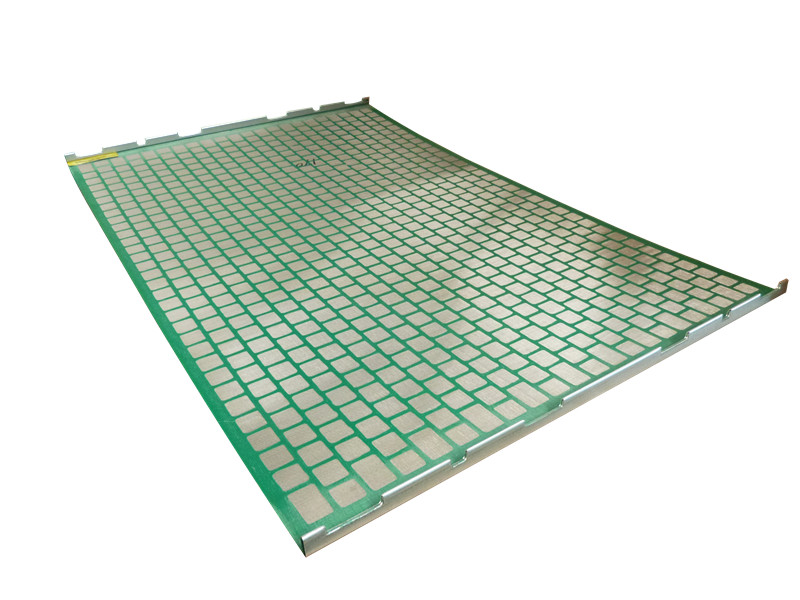

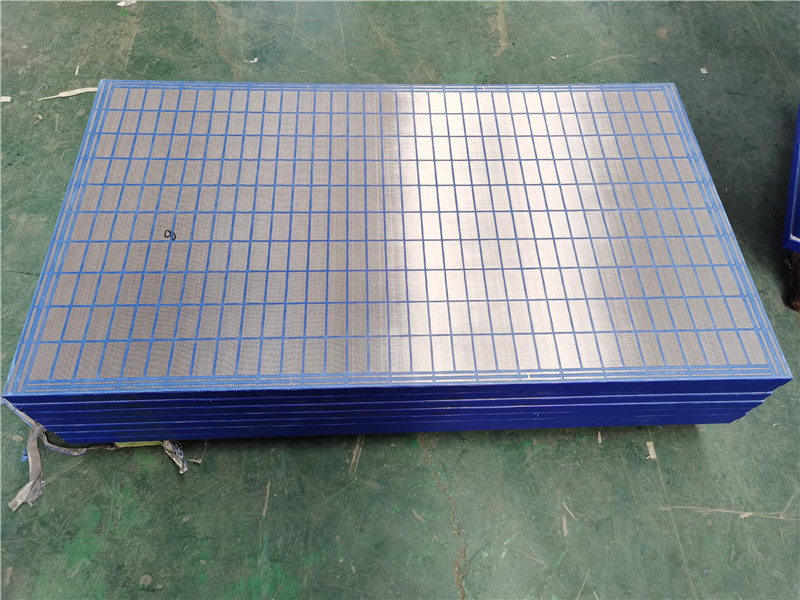

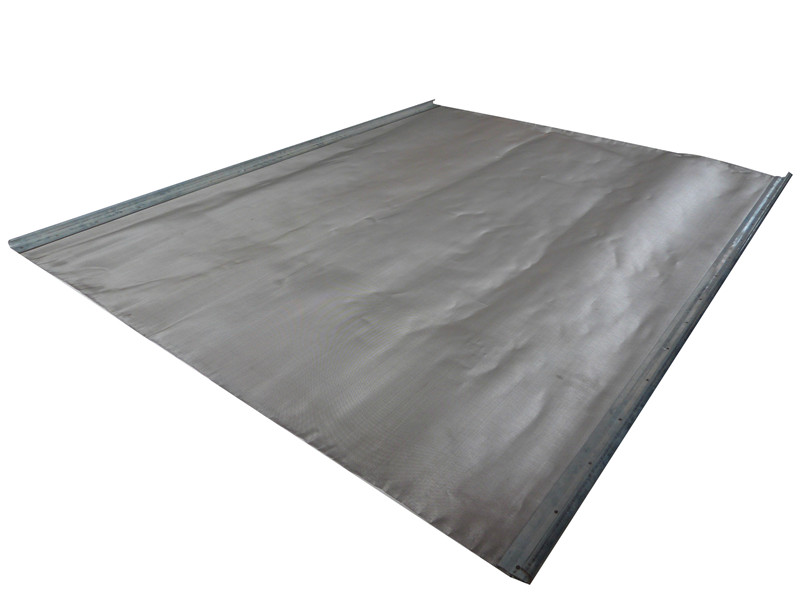

Replacement Screen for Derrock 500 PWP

Looking for a replacement screen for Derrock 500 PWP? Look no further! We are a factory specializing in manufacturing high-quality screens.

Request a QuotePRODUCTS DETAILS

Hot Products

Brandt VSM Multi-sizer Scapling

Replacement Screen for Polyurethane Screen

Replacement Screen for FLC 2000 48-30 PMD

Replacement Screen for BEM-3 PWP

Replacement Screen for Derrock Hyperpool PWP

05 GNZS-853 833

Replacement Screen for Brandt King CobraHybridVenom

Replacement Screen for FLC 2000 48-30 PWP

Replacement Screen for KEMTRON 28

Replacement Screen for Brandt 4 × 5 B40

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours