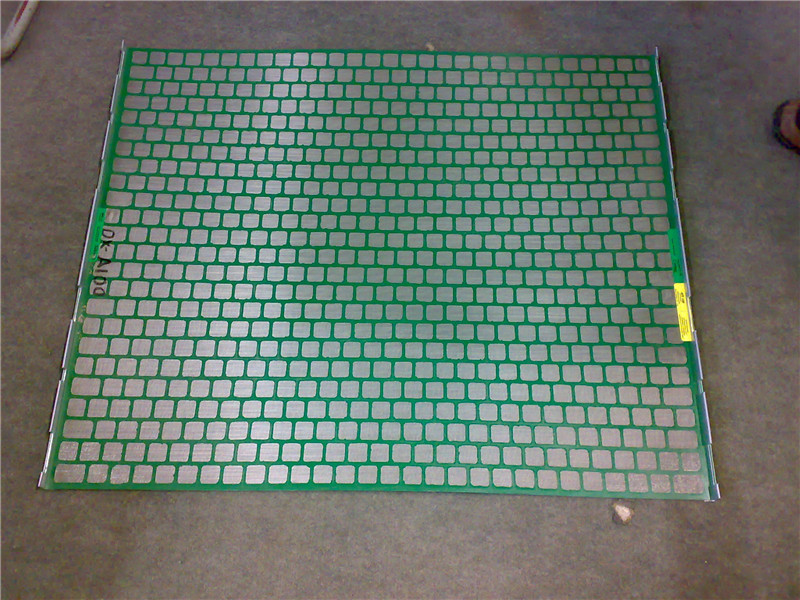

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) | |

|---|---|---|---|---|---|---|---|

| KET-LCM-2D-A325 | XR/XL | API 325 | 0.37 | 44 | 2/3 | 8.6 | |

| KET-LCM-2D-A200 | XR/XL | API 200 | 0.54 | 72 | 2/3 | 8.6 | |

| KET-LCM-2D-A170 | XR/XL | API 170 | 0.7 | 98 | 2/3 | 8.6 | |

| KET-LCM-2D-A140 | XR/XL | API 140 | 1.14 | 104 | 2/3 | 8.6 | |

| KET-LCM-2D-A120 | XR/XL | API 120 | 1.55 | 119 | 2/3 | 8.6 | |

| KET-LCM-2D-A100 | XR/XL | API 100 | 2.04 | 147 | 2/3 | 8.6 | |

| KET-LCM-2D-A80 | XR/XL | API 80 | 2.33 | 195 | 2/3 | 8.6 | |

| KET-LCM-2D-A70 | XR/XL | API 70 | 2.85 | 223 | 2/3 | 8.6 | |

| KET-LCM-2D-A60 | XR/XL | API 60 | 3.09 | 275 | 2/3 | 8.6 | |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | |||||||

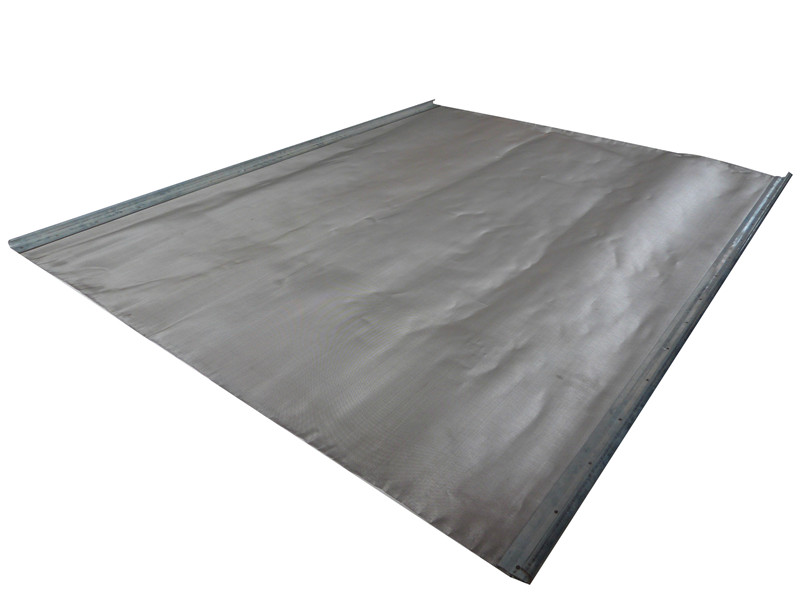

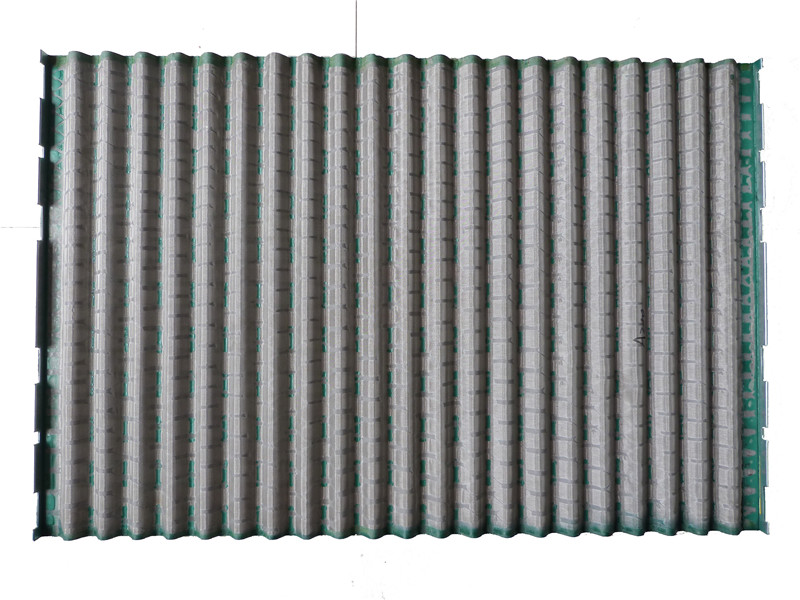

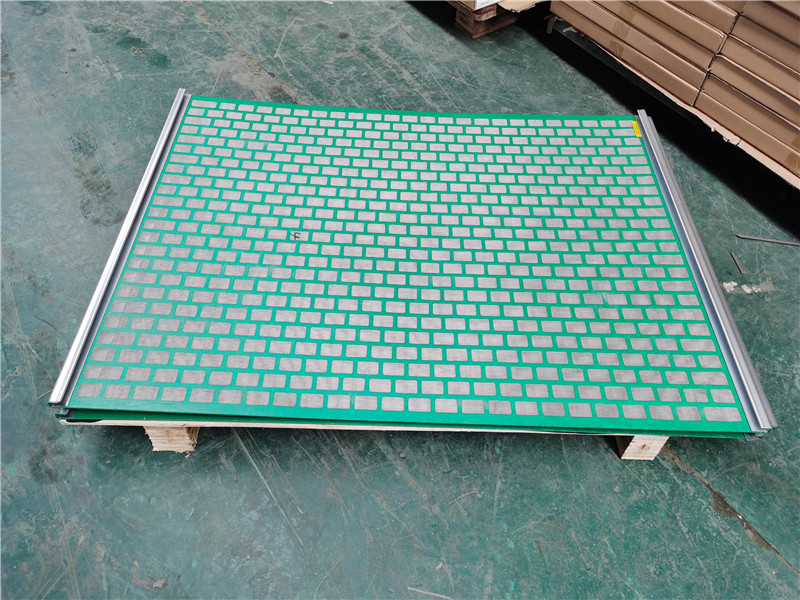

Replacement Screen for Brandt BLT-50LCM-2D

Get the best quality Replacement Screen for Brandt BLT-50LCM-2D at our factory. High-performance and durable screens for optimal viewing experience. Buy now!

Request a QuotePRODUCTS DETAILS

Hot Products

Brandt VSM Multi-Sizer Primary

Replacement Screen for Brandt 4 × 5 B40

Replacement Screen for FLC 2000 48-30 PMD

Replacement Screen for FLC313M PWP

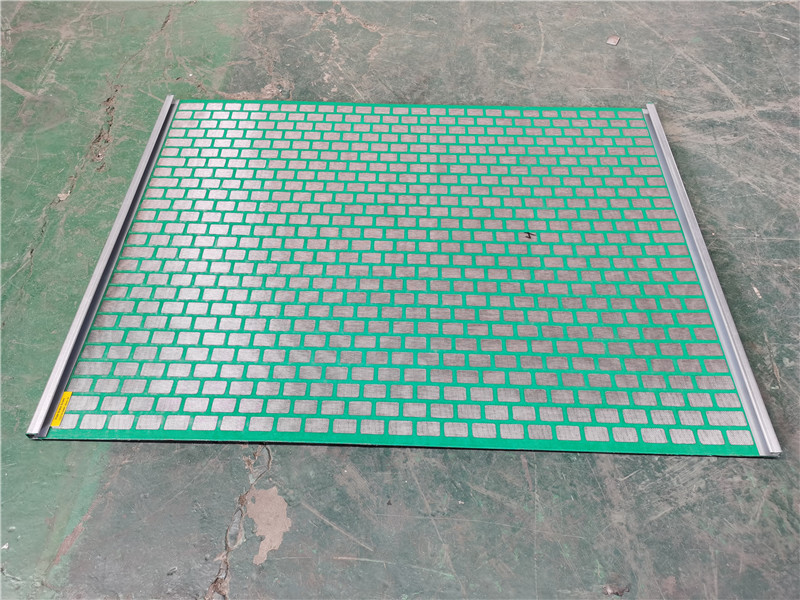

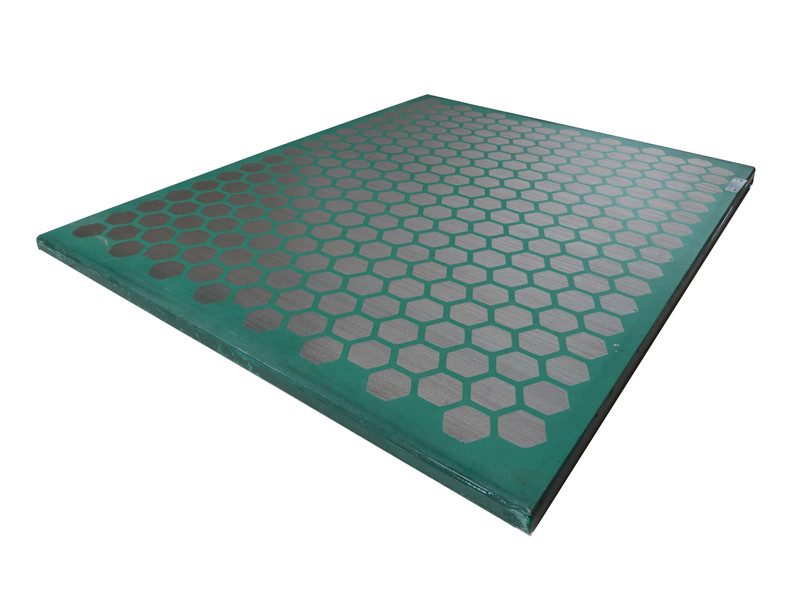

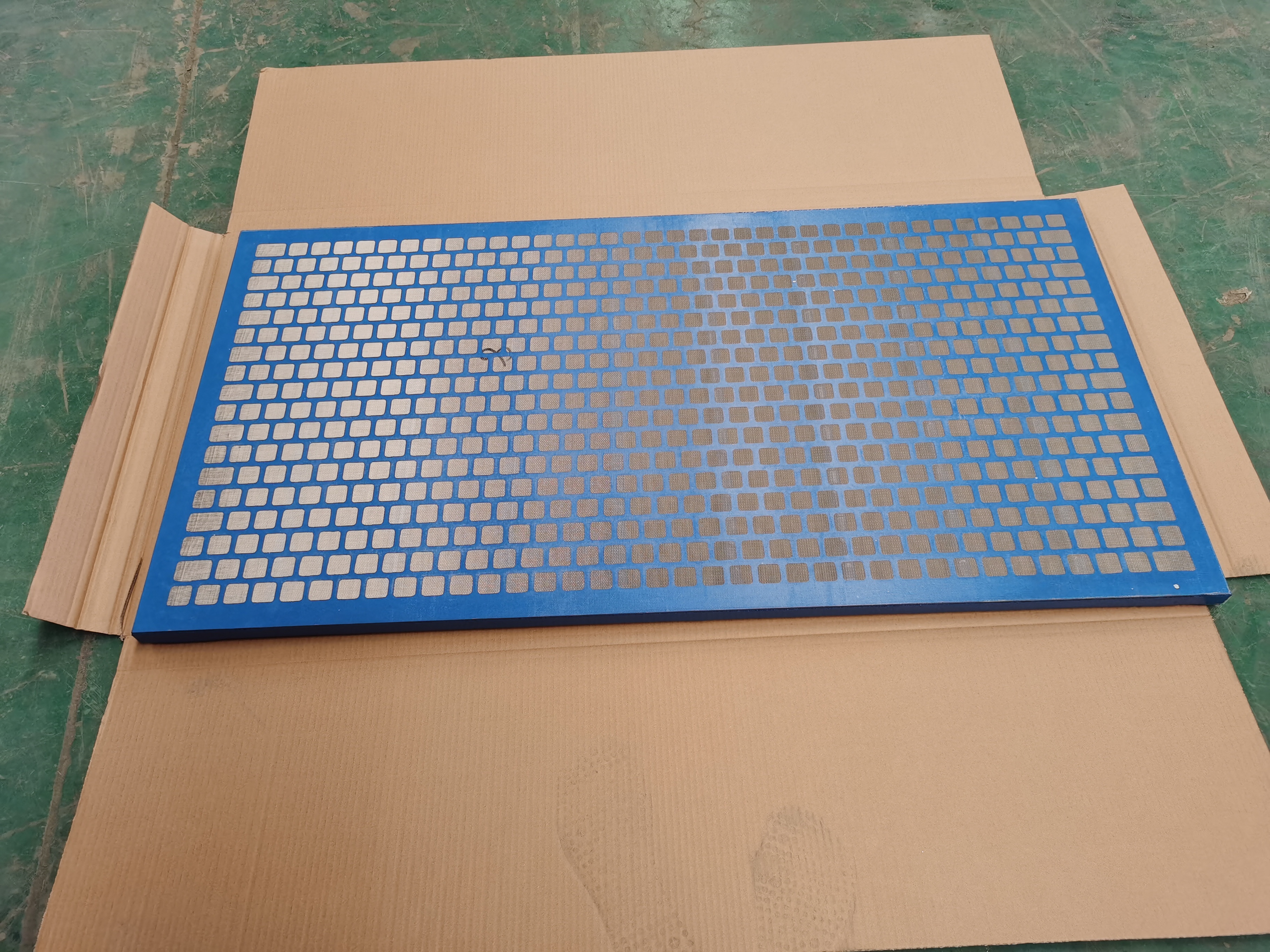

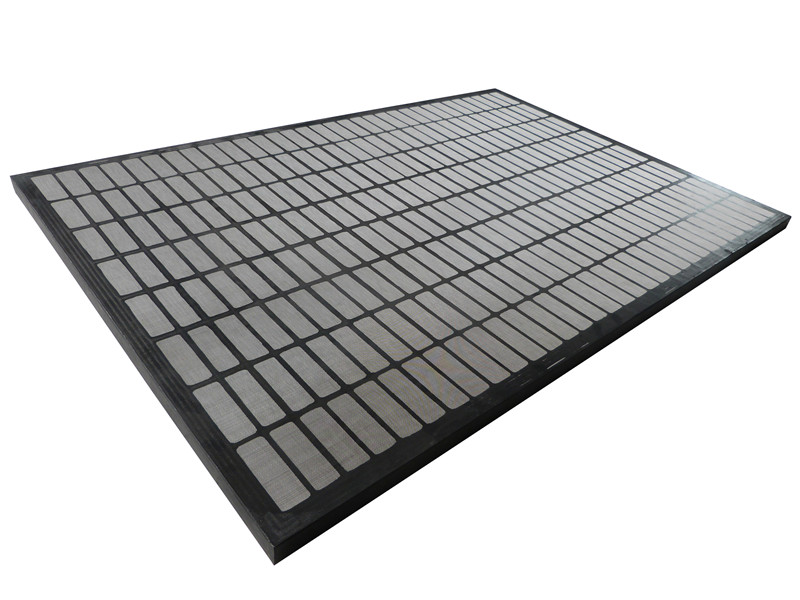

Replacement Screen for Brandt BLT-50LCM-2D

Replacement Screen for DFE

Brandt VSM 300 Primary

Replacement Screen for Vortex Screen/Vortex Shaker Screen

Replacement Screen for SWACO MAMUT

Replacement Screen for Derrick Hyperpool Pyramid

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours