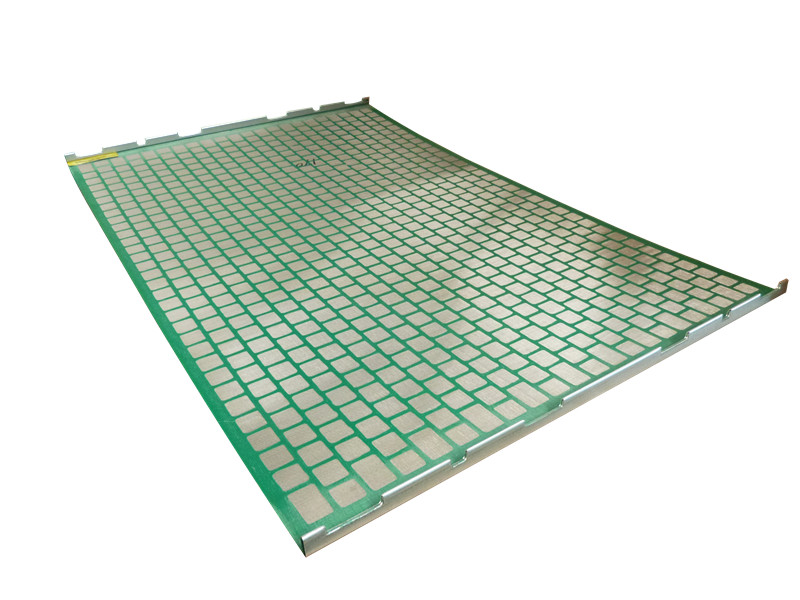

VSM 100 Secondary Oil Shaker Screen for Effective Oil Filtration

By:Admin

The new VSM 100 secondary oil shaker screen is designed to work seamlessly with the primary shaker screen, providing a two-step process for removing solids from the drilling fluid. This innovative design ensures that the drilling fluid is properly cleaned and recycled, ultimately reducing the overall cost and improving the efficiency of the drilling operation.

The NOV-brandt VSM 100 secondary oil shaker screen is made from high-quality materials that are capable of withstanding the harsh conditions of the drilling operation. The screen is durable, corrosion-resistant, and designed to perform consistently in demanding environments. This ensures that the screen will continue to provide reliable performance, even in the most challenging drilling conditions.

Moreover, the VSM 100 secondary oil shaker screen is easy to install and maintain, making it an ideal choice for oil drilling operations of all sizes. Its user-friendly design allows for quick and simple installation, and its low maintenance requirements help to minimize downtime and maximize productivity.

One of the key features of the VSM 100 secondary oil shaker screen is its high capacity for solids removal. The screen is capable of efficiently separating a wide range of solids, including large and small particles, ensuring that the drilling fluid is properly cleaned and ready for reuse. This not only helps to reduce waste and environmental impact but also improves overall drilling efficiency.

The VSM 100 secondary oil shaker screen is also designed to maximize the performance of the primary shaker screen, ensuring that the entire solids control system operates at peak efficiency. By working in tandem with the primary screen, the secondary screen helps to extend the lifespan of the primary screen, reducing the need for frequent replacements and maintenance.

In addition to its solid-removal capabilities, the VSM 100 secondary oil shaker screen is designed to enhance fluid handling and ensure a consistent flow of drilling fluid throughout the operation. This helps to improve overall drilling performance, minimize downtime, and reduce the risk of equipment damage caused by fluid-related issues.

As a leading provider of innovative solutions for the oil and gas industry, {COMPANY NAME} is proud to introduce the NOV-brandt VSM 100 secondary oil shaker screen. With its advanced technology, durable construction, and superior performance, the VSM 100 secondary screen is poised to set a new standard for solids control in oil drilling operations.

{COMPANY NAME} has a long history of delivering high-quality products and services to the oil and gas industry. With a focus on innovation, reliability, and customer satisfaction, {COMPANY NAME} is committed to providing solutions that meet the evolving needs of the industry.

In conclusion, the introduction of the NOV-brandt VSM 100 secondary oil shaker screen represents a significant advancement in solids control technology for oil drilling operations. With its exceptional performance, durability, and efficiency, the VSM 100 secondary screen is poised to make a positive impact on the industry, improving overall drilling operations and reducing environmental impact. By working seamlessly with the primary shaker screen, the VSM 100 secondary screen is set to revolutionize solids control in the oil and gas industry, establishing a new standard for performance and reliability.

Company News & Blog

VSM 100 Secondary Oil Shaker Screen for Effective Oil Filtration

NOV-brandt VSM 100 secondary oil shaker screen is the latest product innovation in the oil and gas industry. This new technology promises to revolutionize the oil drilling process by providing a more efficient and effective way of separating solids from liquids during the drilling operation.The new VSM 100 secondary oil shaker screen is designed to work seamlessly with the primary shaker screen, providing a two-step process for removing solids from the drilling fluid. This innovative design ensures that the drilling fluid is properly cleaned and recycled, ultimately reducing the overall cost and improving the efficiency of the drilling operation.The NOV-brandt VSM 100 secondary oil shaker screen is made from high-quality materials that are capable of withstanding the harsh conditions of the drilling operation. The screen is durable, corrosion-resistant, and designed to perform consistently in demanding environments. This ensures that the screen will continue to provide reliable performance, even in the most challenging drilling conditions.Moreover, the VSM 100 secondary oil shaker screen is easy to install and maintain, making it an ideal choice for oil drilling operations of all sizes. Its user-friendly design allows for quick and simple installation, and its low maintenance requirements help to minimize downtime and maximize productivity.One of the key features of the VSM 100 secondary oil shaker screen is its high capacity for solids removal. The screen is capable of efficiently separating a wide range of solids, including large and small particles, ensuring that the drilling fluid is properly cleaned and ready for reuse. This not only helps to reduce waste and environmental impact but also improves overall drilling efficiency.The VSM 100 secondary oil shaker screen is also designed to maximize the performance of the primary shaker screen, ensuring that the entire solids control system operates at peak efficiency. By working in tandem with the primary screen, the secondary screen helps to extend the lifespan of the primary screen, reducing the need for frequent replacements and maintenance.In addition to its solid-removal capabilities, the VSM 100 secondary oil shaker screen is designed to enhance fluid handling and ensure a consistent flow of drilling fluid throughout the operation. This helps to improve overall drilling performance, minimize downtime, and reduce the risk of equipment damage caused by fluid-related issues.As a leading provider of innovative solutions for the oil and gas industry, {COMPANY NAME} is proud to introduce the NOV-brandt VSM 100 secondary oil shaker screen. With its advanced technology, durable construction, and superior performance, the VSM 100 secondary screen is poised to set a new standard for solids control in oil drilling operations.{COMPANY NAME} has a long history of delivering high-quality products and services to the oil and gas industry. With a focus on innovation, reliability, and customer satisfaction, {COMPANY NAME} is committed to providing solutions that meet the evolving needs of the industry.In conclusion, the introduction of the NOV-brandt VSM 100 secondary oil shaker screen represents a significant advancement in solids control technology for oil drilling operations. With its exceptional performance, durability, and efficiency, the VSM 100 secondary screen is poised to make a positive impact on the industry, improving overall drilling operations and reducing environmental impact. By working seamlessly with the primary shaker screen, the VSM 100 secondary screen is set to revolutionize solids control in the oil and gas industry, establishing a new standard for performance and reliability.

Ultimate Guide to High-Performance Shaker Screens (FSI 5000) Revealed!

Title: Industry-leading Shaker Screen Enhances Efficiency and Reliability in Drilling OperationsIntroduction:In the highly competitive oil and gas industry, efficiency and reliability are paramount for successful drilling operations. To address these challenges, renowned industry leader FSI has introduced its latest innovation, the FSI 5000 Shaker Screen. With its cutting-edge technology and superior performance, this groundbreaking product is set to revolutionize drilling processes, offering enhanced efficiency, improved oil recovery, and reduced operational costs.Efficiency and Reliability at the Forefront: FSI, a global leader in innovative oil and gas equipment manufacturing, has been at the forefront of delivering solutions aimed at optimizing drilling efficiency and reliability. With an unwavering commitment to continuous improvement and cutting-edge technology, FSI consistently sets industry standards and exceeds customer expectations.Revolutionary FSI 5000 Shaker Screen: The FSI 5000 Shaker Screen is built on FSI's decades of experience and expertise in addressing the challenges faced by drilling operators. Engineered to withstand rigorous conditions, this exceptional product delivers unmatched reliability, durability, and performance.Featuring Advanced Technology: At the heart of the FSI 5000 Shaker Screen lies its advanced mesh technology, which ensures efficient separation and accurate particle sizing. The use of high-quality materials further enhances the screen's longevity, reducing downtime and maintenance costs.Optimized Fluid Handling: The FSI 5000 Shaker Screen's innovative design enhances fluid handling capabilities, resulting in improved solid control while minimizing wastage. This not only boosts drilling efficiency but also reduces environmental impact.Superior Solid Control: By efficiently removing drilled solids and debris from the drilling fluid, the FSI 5000 Shaker Screen plays a critical role in maintaining wellbore stability and preventing equipment damage. Its mesh technology accurately separates particles, allowing for increased oil recovery and reduced waste.Enhanced Operational Performance: With its high throughput capacity and exceptional separation efficiency, the FSI 5000 Shaker Screen significantly improves drilling performance. By reducing the volume of drilled cuttings and solids, operators can minimize mud losses, optimize flow rates, and achieve faster penetration rates.Cost-Effective Solution: The FSI 5000 Shaker Screen proves to be a cost-effective investment for drilling operators, as it reduces downtime, maintenance costs, and the need for frequent mesh replacements. With its exceptional durability, this screen ensures extended service life and maximizes return on investment.Commitment to Quality and Customer Satisfaction: FSI's commitment to providing top-quality products is demonstrated through rigorous testing and quality control processes. The FSI 5000 Shaker Screen adheres to stringent industry standards, ensuring optimal performance, longevity, and customer satisfaction.The Path to a Greener Future: In addition to enhancing drilling operations, the FSI 5000 Shaker Screen contributes to sustainable practices within the oil and gas industry. Its efficient solid control system minimizes waste and enables environmentally responsible drilling practices.The FSI Advantage:FSI's longstanding reputation for innovation, reliability, and exceptional customer service sets it apart in the industry. With its extensive product portfolio, including the groundbreaking FSI 5000 Shaker Screen, FSI continues to revolutionize drilling operations, enabling operators to achieve greater efficiency, reduced costs, and maximum oil recovery.Conclusion:The introduction of the FSI 5000 Shaker Screen marks a significant milestone in the oil and gas industry. With its advanced technology, exceptional performance, and commitment to sustainability, FSI redefines the standards for drilling efficiency and reliability. The FSI 5000 Shaker Screen ensures optimized oil recovery, reduced environmental impact, and improved operational performance, positioning drilling operators for long-term success in an ever-evolving industry.

New Study Reveals Surprising Results in Screen Time Study

Introducing: Innovative Screen Technology revolutionizes the way we interact with digital displays. This cutting-edge company, known for its advancements in screen technology, has developed a revolutionary new product that is set to change the way we interact with digital displays.The new technology, which is being hailed as a game-changer in the industry, uses a combination of high-resolution screens and advanced touch technology to create a more immersive and intuitive user experience. This means that users can now interact with digital displays in a way that was previously not possible, opening up new possibilities for a wide range of applications, from interactive retail displays to immersive entertainment experiences.One of the key features of this new technology is its ability to accurately detect touch input, allowing for a more natural and intuitive interaction with digital content. This means that users can now swipe, pinch, and zoom with greater precision and accuracy, making for a more seamless and enjoyable user experience.In addition to its advanced touch capabilities, the new technology also offers unparalleled image quality, with vibrant colors and crisp details that bring digital content to life. This means that the technology is perfectly suited for a wide range of applications, from high-resolution digital signage to immersive virtual reality experiences.Furthermore, the company's commitment to sustainability is reflected in its manufacturing processes. By using energy-efficient materials and reducing waste, the company's products have a lower environmental impact than traditional screens, making this innovation not only advanced but also environmentally friendly.The impact of this new technology is already being felt in the industry, with major players taking notice and incorporating the technology into their own products and experiences. This speaks to the potential for this technology to become a standard feature in the digital display market, further solidifying the company's position as a leader in the industry.In conclusion, the new screen technology developed by the company is set to revolutionize the way we interact with digital displays, offering an unparalleled combination of advanced touch capabilities, high-resolution image quality, and sustainability. With its potential to become a standard feature in the industry, this innovation is poised to change the way we engage with digital content, opening up new possibilities for a wide range of applications. As the company continues to push the boundaries of screen technology, it is clear that the future of digital displays is brighter than ever.

Efficient Replacement Shaker Screens for Mongoose Models – Get Unmatched Performance

Title: Industry-Leading Shaker Screens by Mi-Swaco Revolutionize Solids Control SystemsIntroduction (85 words):Solids control technology plays a vital role in the efficient and cost-effective drilling of oil and gas wells. In this regard, Mi-Swaco, an industry-leading provider of innovative solutions, has recently unveiled their latest shaker screens designed to deliver unparalleled performance in solids control. With a commitment to continually revolutionize drilling operations, Mi-Swaco's technologically advanced shaker screens are set to enhance operational efficiency while reducing downtime and maintenance costs.Section 1: The Significance of Solids Control in Drilling Operations (150 words)Efficient solids control is crucial during the drilling process, as it helps to remove drill cuttings and other solid particles from drilling mud, ensuring its integrity and functionality. Effective solids control systems prevent drill bits from becoming excessively worn or damaged, optimize drilling performance, and protect downstream equipment. By adopting cutting-edge technologies and innovative designs, Mi-Swaco has emerged as a leading provider of solids control solutions that improve drilling operations across the industry.Section 2: The Pioneering Technology Behind Mi-Swaco's Shaker Screens (180 words)Mi-Swaco's latest breakthrough comes in the form of their technologically advanced shaker screens. These screens incorporate state-of-the-art materials and unique design features that maximize separation efficiency while extending their operational lifespan. The brand has engineered these screens using an innovative composite frame that enhances durability, resists corrosion, and prolongs screen performance.Moreover, Mi-Swaco's shaker screens utilize a specialized mesh configuration, featuring precise wire weaves, to achieve optimal filtration accuracy. This advanced technology ensures superior solids removal and improved fluid handling, guaranteeing an optimized drilling process. The screens' hassle-free installation and maintenance procedures further enhance their appeal, reducing downtime and increasing overall operational efficiency.Section 3: Mi-Swaco's Commitment to Continuous Innovation (130 words)Mi-Swaco has a robust track record of innovation in the drilling industry, driven by a commitment to enhancing solids control systems. Their team of experts consistently pushes the boundaries of technology to develop products that address specific industry challenges. With extensive research and development efforts, they continue to refine and optimize their shaker screens, aiming to make them the gold standard in the industry.Section 4: Operational and Economic Benefits of Mi-Swaco Shaker Screens (180 words)The implementation of Mi-Swaco's shaker screens provides a range of operational and cost benefits. By effectively separating solids from drilling mud, the screens improve drilling fluid properties, thereby increasing drilling efficiency and reducing the risk of equipment failure. Improved separation efficiency translates to reduced mud consumption and less waste disposal, resulting in significant cost savings for drilling operators.Additionally, the durability and extended lifespan of Mi-Swaco's shaker screens contribute to economies of scale. Reduced screen replacement frequency and minimal maintenance requirements lead to decreased downtime, ensuring uninterrupted drilling operations. This increased uptime, combined with the screens' innovative design features, ultimately leads to substantial cost savings over the long term.Conclusion (75 words):Mi-Swaco's innovative shaker screens are set to revolutionize solids control systems in the drilling industry. With their commitment to continuous improvement and cutting-edge technology, Mi-Swaco has developed a range of shaker screens that deliver superior performance, increased operational efficiency, and significant cost savings for drilling operators. By utilizing these advanced screens, drilling companies can optimize solids control, enhance drilling productivity, and ultimately drive success in the oil and gas industry.

High-quality Oil Shaker Screen for FLC2000 Shakers

The oil and gas industry is a complex and demanding sector that requires cutting-edge technology and equipment to ensure smooth operations. One such essential piece of equipment is the FLC2000 Shaker screen, a vital component in the drilling process.The FLC2000 Shaker screen is a high-performance vibrating screen used to separate solids from liquids in the drilling mud. It is designed to efficiently remove solid particles from drilling fluids, which is a crucial step in the drilling process to ensure the integrity of the wellbore and protect downstream equipment.The FLC2000 Shaker screen, manufactured by a leading oilfield equipment company, is known for its durability, efficiency, and reliability. With a strong focus on quality and performance, the company has positioned itself as a trusted provider of drilling equipment and solutions to the oil and gas industry.The company behind the FLC2000 Shaker screen has a solid reputation for delivering innovative and high-quality products that meet the demanding requirements of the oil and gas sector. With a strong emphasis on research and development, the company has continuously improved and enhanced its product offerings to meet the evolving needs of the industry.In addition to the FLC2000 Shaker screen, the company also offers a comprehensive range of drilling equipment, including shale shakers, mud cleaners, centrifuges, and other solids control equipment. These products are designed to optimize drilling performance, reduce downtime, and minimize environmental impact, making them essential for efficient and sustainable drilling operations.The company's commitment to quality and customer satisfaction is evident in its rigorous testing and certification processes, ensuring that its products meet the highest industry standards. This dedication to excellence has earned the company the trust and confidence of leading oil and gas companies worldwide.Furthermore, the company's expertise in providing custom solutions and technical support sets it apart as a reliable partner for the oil and gas industry. Its team of experienced engineers and technicians are readily available to provide installation, maintenance, and troubleshooting services, ensuring that its customers' operations run smoothly and efficiently.With a global network of distribution and service centers, the company is well-positioned to provide timely support and reliable delivery of its products to customers around the world. This extensive network underscores the company's commitment to being a valuable and dependable partner to the oil and gas industry.In conclusion, the FLC2000 Shaker screen, combined with the company's extensive experience, technical expertise, and commitment to quality, exemplifies the essential role of advanced technology and equipment in the oil and gas industry. By consistently delivering reliable and innovative solutions, the company has established itself as a trusted provider of drilling equipment and solutions, contributing to the efficiency and sustainability of the oil and gas sector.

Lcm-3d Screen: A Breakthrough in Display Technology

Title: Cutting-edge LCM-3D Screen Technology Revolutionizes End-User ExperienceIntroduction:Innovations in screen display technology have been at the forefront of the electronics industry, constantly aiming to enhance the user experience through improved visual quality and engagement. One of the latest breakthroughs in this domain is the cutting-edge LCM-3D screen, developed by a leading technology company (Company XYZ). The LCM-3D screen not only elevates the visual experience but also redefines the way users engage with their electronic devices. This article will explore the key features of the LCM-3D screen and its potential implications for various industries.1. Enhanced Visual Quality:The LCM-3D screen features state-of-the-art display capabilities that deliver exceptional visual quality, surpassing traditional screens in terms of resolution, color vibrancy, and contrast. By employing advanced pixel technology and innovative backlighting solutions, the LCM-3D screen guarantees a more immersive and realistic viewing experience. Its ability to accurately reproduce colors and provide high pixel density ensures that users can enjoy crystal-clear details, whether they are watching movies, playing games, or editing photos and videos.2. Revolutionary 3D Experience:With its 3D functionality, the LCM-3D screen raises the bar for immersive viewing experiences. By incorporating cutting-edge parallax barrier technology, this screen eliminates the need for bulky and uncomfortable 3D glasses. Users can now enjoy stunning 3D content without any external accessories, allowing for a more convenient and natural viewing experience. The LCM-3D screen also provides adjustable depth control, enabling users to customize the level of 3D effect according to their preferences, thus further enhancing the depth and realism of the displayed content.3. Adaptive Display Technology:Unlike conventional screens, the LCM-3D offers adaptive display technology, which maximizes visual efficiency and comfort. This technology intelligently adjusts various display parameters, such as brightness and color temperature, based on ambient lighting conditions. This ensures optimal visual comfort while reducing eye strain, especially in low-light or high-glare environments. The adaptive display technology of the LCM-3D screen optimizes the viewing experience across different usage scenarios, making it suitable for a diverse range of applications.4. Applications across Multiple Industries:The LCM-3D screen's groundbreaking features hold tremendous potential for various industries. In gaming, it brings virtual worlds to life with its immersive 3D capabilities, offering gamers an unparalleled level of engagement. Architects and designers can benefit from the screen's ability to showcase 3D models with accurate depth perception, enabling them to visualize their creations more effectively. Additionally, the LCM-3D screen's vibrant colors and high resolution make it ideal for content creators, as it accurately displays the intricacies of their work.5. Environmental Responsibility:In line with the company's commitment to environmental sustainability, the LCM-3D screen incorporates energy-efficient technologies. It utilizes advanced power-saving features and materials to minimize power consumption, reducing its carbon footprint. This socially responsible approach not only benefits the environment but also provides cost savings for end-users by lowering energy bills.Conclusion:The LCM-3D screen represents a significant milestone in screen display technology, revolutionizing the way users engage with their electronic devices. Its enhanced visual quality, revolutionary 3D experience, adaptive display technology, and applications across multiple industries make it a game-changer in the market. With a commitment to environmental responsibility, the LCM-3D screen sets a new standard for immersive, sustainable, and visually stunning displays. As this technology continues to evolve and integrate into various devices, users can expect a more captivating and user-friendly experience across a wide range of industries.

High-performance 48 PMD Shaker Screen for Effective Material Separation

Derrick Corporation is pleased to announce the launch of the Derrick 48 PMD Shaker Screen, the latest addition to its high-quality range of shale shaker screens for the oil and gas industry. This new product exemplifies Derrick's commitment to providing innovative solutions that meet the ever-evolving needs of its customers.The 48 PMD Shaker Screen offers superior performance and durability, making it the ideal choice for operators looking to enhance the efficiency of their drilling operations. With its advanced design and construction, this shaker screen is capable of handling high fluid capacities while effectively removing solid particles from drilling fluids. This not only improves the overall efficiency of the drilling process but also helps to minimize waste and reduce environmental impact.Derrick Corporation has a long-standing reputation for delivering cutting-edge solutions that set industry standards. With a strong focus on research and development, the company continuously works to improve its products and develop new technologies that address the challenges faced by its customers. The 48 PMD Shaker Screen is a testament to Derrick's dedication to innovation and excellence.In addition to its superior performance, the 48 PMD Shaker Screen is designed for easy installation and maintenance, allowing operators to maximize uptime and minimize downtime. This is especially crucial in the oil and gas industry, where every minute of lost time can translate to significant financial losses. By choosing Derrick's shaker screens, operators can be confident in the reliability and efficiency of their equipment.Derrick Corporation is known for its unwavering commitment to customer satisfaction. The company provides comprehensive support and service to ensure that its customers get the most out of their equipment. Whether it's technical assistance, training, or spare parts, Derrick's team of experts is always ready to help customers overcome any challenges they may encounter.Derrick's dedication to quality extends beyond its products and services. The company places a strong emphasis on safety and environmental responsibility, ensuring that its operations and products adhere to the highest standards. The 48 PMD Shaker Screen is no exception, as it is designed to meet strict safety and environmental regulations, giving operators peace of mind knowing that they are using a product that prioritizes the well-being of both people and the planet.As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, driving innovation and setting new benchmarks for performance and reliability. The launch of the 48 PMD Shaker Screen is yet another example of Derrick's commitment to meeting the needs of its customers and empowering them to achieve success in their operations.In conclusion, Derrick Corporation's introduction of the 48 PMD Shaker Screen marks a significant milestone in the company's dedication to providing top-of-the-line solutions for the oil and gas industry. With its advanced design, superior performance, and unwavering commitment to customer satisfaction, this new product is set to make a lasting impact in the field of shale shaker screens. Derrick Corporation continues to set the standard for excellence, and the launch of the 48 PMD Shaker Screen is a clear demonstration of the company's ongoing commitment to driving innovation and delivering value to its customers.

Revolutionary PMD Screen: The Latest Breakthrough in Derrick's FLC 2000 Technology

Title: Cutting-Edge PMD Screen Unveiled - Revolutionizing Display TechnologyIntroduction:In an era driven by constant technological advancements, Derrick Technologies, a leading player in the industry, has recently revealed a groundbreaking PMD screen. This cutting-edge display technology is set to revolutionize the way we interact with devices, providing users with a seamless and enhanced visual experience. With its innovative features and superior performance, the Derrick FLC 2000 PMD screen is poised to become the new industry standard.[Company Introduction]Derrick Technologies is a trailblazer in the field of display technology, boasting a rich history of providing groundbreaking and innovative solutions. With a deep commitment to pushing the boundaries of visual experiences, the company has consistently delivered state-of-the-art products that have garnered praise and recognition worldwide.Renowned for its extensive research and development facilities, Derrick Technologies has assembled a team of top-notch experts who are dedicated to creating cutting-edge display solutions. With a focus on constant innovation, the company aims to transform the way we interact with digital devices, enhancing their usability and performance.The Derrick FLC 2000 PMD Screen:The Derrick FLC 2000 PMD screen is a game-changer in the world of display technology. Raising the bar for visual quality, this revolutionary screen offers unparalleled levels of clarity, vibrancy, and sharpness. Its advanced pixel management technology ensures the delivery of lifelike images and videos, providing an immersive experience to users.One of the standout features of the FLC 2000 PMD screen is its exceptional brightness. With a peak luminance of 2000 nits, this display effectively eliminates glare and provides superior visibility even in the brightest outdoor environments. This makes it an ideal choice for various applications, including digital signage, outdoor displays, and automotive displays.Moreover, the FLC 2000 PMD screen incorporates cutting-edge anti-reflective technology, significantly reducing reflections and optimizing viewing angles. This ensures that users can enjoy crystal-clear visuals without any distractions or distortions caused by ambient light.Derrick Technologies has also prioritized sustainability in the development of the FLC 2000 PMD screen. By utilizing energy-efficient LED backlighting and intelligent power management systems, the screen minimizes power consumption without compromising on performance. By doing so, Derrick Technologies sets a new benchmark for eco-friendly display solutions.The applications for the FLC 2000 PMD screen are vast and diverse. From enhancing the visual experience in outdoor advertising and digital signage applications to providing safer and more immersive driving experiences through automotive displays, this technology is set to revolutionize a wide range of industries.Looking Ahead:The introduction of the Derrick FLC 2000 PMD screen marks a significant milestone in the evolution of display technology. Derrick Technologies' commitment to pushing the boundaries of visual experiences, coupled with its emphasis on sustainability, reinforces their position as an industry leader.With its exceptional brightness, superior visual quality, and eco-friendly design, the FLC 2000 PMD screen is poised to set a new standard for display technology. Its innovative features promise to enhance user experiences across various sectors, revolutionizing the way we consume visual content.As Derrick Technologies continues to innovate and develop cutting-edge solutions, it is spearheading a future where display technology becomes more immersive, sustainable, and user-centric. The FLC 2000 PMD screen's unveiling is just the beginning of an exciting chapter in the company's quest to redefine the way we perceive and interact with digital displays.

How Does a Shale Shaker Work and Why Is It Important in Oil and Gas Drilling Operations?

Shale Shaker has played a vital role in the oil and gas industry for decades, and it continues to be an essential piece of equipment for companies worldwide. The Shale Shaker has been designed and manufactured by a leading oil and gas equipment company, which has been in the business for over 20 years. The company is known for its commitment to providing high-quality products and exceptional customer service. In recent years, the company has seen a surge in demand for its Shale Shaker due to the increased focus on environmental sustainability and the need to maximize efficiency in oil and gas operations. The Shale Shaker is a crucial component in the process of separating drilling cuttings from drilling fluid, which is essential in maintaining the integrity of the drilling fluid and preventing pollution of the environment. The Shale Shaker is designed to effectively remove large solids from drilling fluid, which is vital for the smooth operation of downstream equipment such as desanders and desilters. This process not only ensures the quality of the drilling fluid but also reduces operational costs and minimizes environmental impact. The company's Shale Shaker is renowned for its durability, reliability, and performance. It is equipped with a high G-force linear motion to effectively remove solids from the drilling fluid, and its innovative design allows for easy maintenance and servicing. One of the key advantages of the Shale Shaker is its ability to adapt to different operational conditions. It can be customized with various screen options to suit different drilling requirements, and its adjustable deck angle allows for efficient handling of different types of drilling fluids. Furthermore, the company's Shale Shaker is designed with a focus on safety and efficiency. It is equipped with a range of features to ensure the safety of operators and maintenance personnel, and its compact design allows for easy transportation and installation on drilling rigs. The company's commitment to excellence extends beyond the design and manufacturing of the Shale Shaker. It provides comprehensive support and training for its customers to ensure the efficient and effective operation of the equipment. Furthermore, the company has a global network of service centers and parts distribution to provide timely support and maintenance for its Shale Shaker. As the oil and gas industry continues to evolve, the demand for high-quality and reliable equipment such as the Shale Shaker will only increase. The company's commitment to innovation and customer satisfaction ensures that its Shale Shaker will remain at the forefront of the industry for years to come. In conclusion, the Shale Shaker has proven to be an essential piece of equipment in the oil and gas industry, and the company behind its design and manufacturing has positioned itself as a leader in the field. With its focus on quality, performance, and customer support, the company's Shale Shaker is set to continue its legacy as a vital component in oil and gas operations worldwide.

Durable Steel Frame Screen: A Reliable Solution for Screening Needs

GNZS-752 Steel Frame Screen has been making waves in the oil and gas industry with its innovative and efficient solution for solids control and waste management. The company, which was established in 2010, has quickly risen to become a leading provider of high-quality solids control equipment and services.The GNZS-752 Steel Frame Screen is a vital component of the company's comprehensive line of solids control equipment. It is designed to effectively remove solids and impurities from drilling fluids, ensuring that the fluids remain in optimal condition for the duration of the drilling process. The screen is constructed with high-quality steel frame and adheres to strict manufacturing standards, making it durable and long-lasting even in the most demanding drilling conditions.One of the key features of the GNZS-752 Steel Frame Screen is its advanced composite frame technology. This technology allows for increased screen life and fluid-handling capacity, ultimately leading to improved solids control efficiency. Additionally, the screen is designed for quick and easy installation, reducing downtime and maximizing operational efficiency for drilling operations.The GNZS-752 Steel Frame Screen is compatible with a wide range of shakers, allowing for seamless integration into existing solids control systems. This versatility makes it an ideal solution for drilling contractors and operators looking to enhance their solids control processes.In addition to its innovative products, the company behind the GNZS-752 Steel Frame Screen is known for its commitment to customer satisfaction and technical support. The company's team of experienced professionals are dedicated to providing exceptional service and support to clients, ensuring that their solids control needs are met with the highest level of expertise and efficiency.Furthermore, the company has established a global presence, with a network of distributors and partners spanning across the world. This global reach allows for quick and efficient access to the GNZS-752 Steel Frame Screen and other solids control equipment, regardless of the location of the drilling operation.The GNZS-752 Steel Frame Screen has already garnered praise from industry professionals for its outstanding performance and reliability. Its advanced technology and durable construction have made it a preferred choice for drilling contractors and operators around the world.With a proven track record of delivering high-quality solids control solutions, the company behind the GNZS-752 Steel Frame Screen has solidified its position as a leader in the industry. As the demand for efficient solids control and waste management solutions continues to grow, the company remains dedicated to providing innovative, reliable, and cost-effective solutions for the oil and gas industry.In conclusion, the GNZS-752 Steel Frame Screen is a testament to the company's commitment to excellence and innovation in the field of solids control. With its advanced technology, durable construction, and global presence, the screen is set to continue making a significant impact in the industry, meeting the needs of drilling contractors and operators around the world.