Shale Shaker Screen: Latest News and Updates

By:Admin

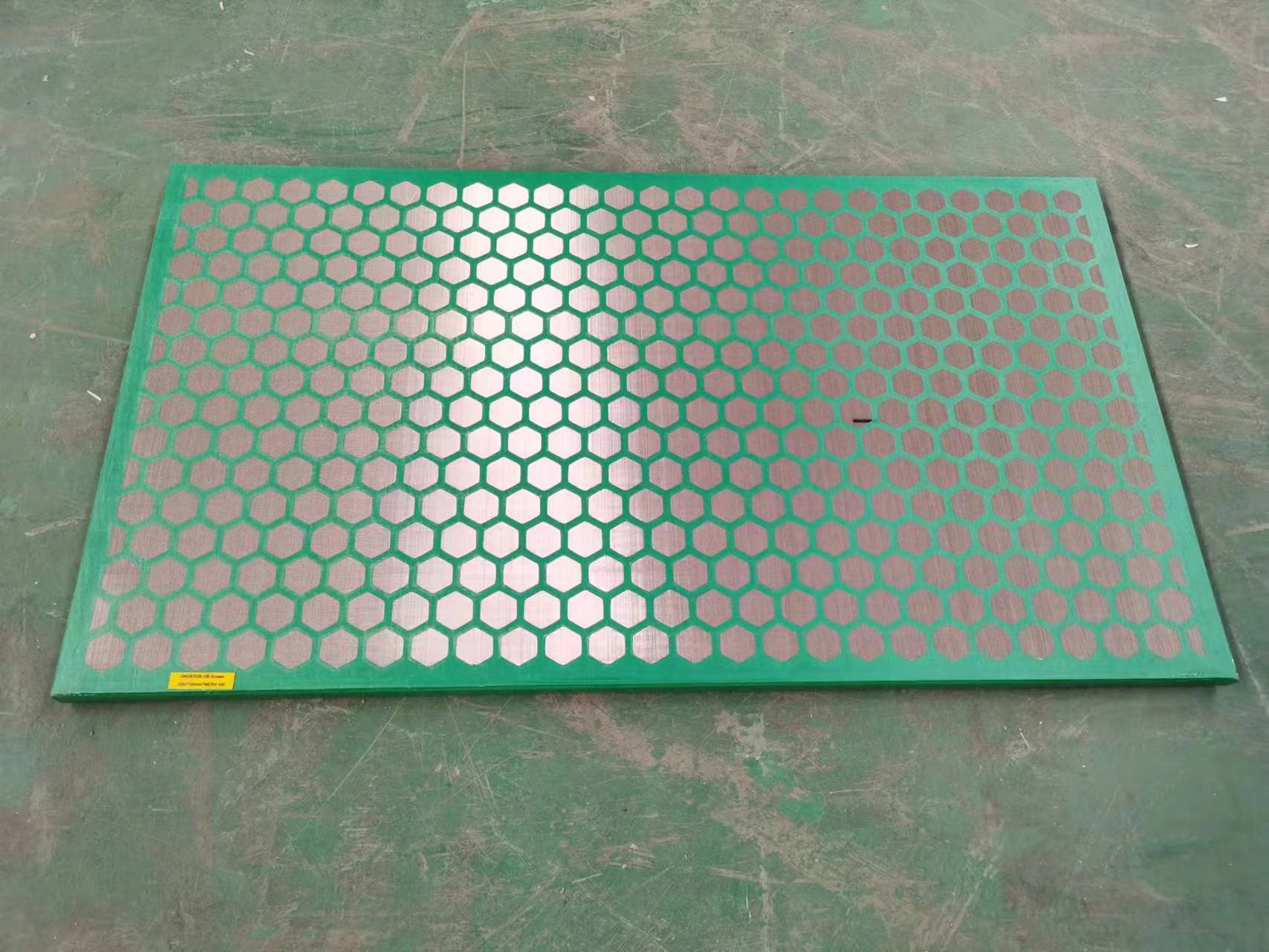

The Brandt Shale Shaker Screen is engineered to effectively separate solids from drilling mud, ensuring the smooth operation of the drilling process. Its high-quality stainless steel wire mesh and durable frame construction make it capable of withstanding the demanding conditions of drilling operations while delivering consistent performance.

In addition to its exceptional durability and reliability, the Brandt Shale Shaker Screen also offers a wide range of configurations to suit various drilling applications. It is available in different mesh sizes to accommodate different particle sizes and provide effective solids control. This flexibility in design makes it a versatile and adaptable solution for different drilling environments.

Furthermore, the Brandt Shale Shaker Screen is designed to be compatible with a range of shale shakers, making it a convenient and easily integrable option for drilling contractors. Its quick and simple installation process allows for minimal downtime, ensuring that drilling operations can resume swiftly and efficiently.

The company behind the Brandt Shale Shaker Screen has a long-standing reputation for delivering high-quality products and exceptional customer service. With a focus on continuous innovation and improvement, the company is committed to providing advanced solutions that meet the evolving needs of the oil and gas industry.

The company’s dedication to research and development has resulted in the creation of the Brandt Shale Shaker Screen, which has set a new standard for solids control in the drilling industry. Its advanced technology and superior performance have made it a preferred choice for drilling contractors and operators around the world.

Moreover, the company’s commitment to sustainability is reflected in the production of the Brandt Shale Shaker Screen. With a focus on environmental responsibility, the company ensures that its products are manufactured using eco-friendly processes and materials, minimizing their impact on the environment.

The Brandt Shale Shaker Screen has earned the trust and confidence of customers globally, thanks to its exceptional performance, reliability, and versatility. Its ability to enhance solids control and improve drilling efficiency has made it an indispensable component of drilling operations, contributing to increased productivity and reduced operational costs.

As the demand for efficient and reliable solids control solutions continues to grow in the oil and gas industry, the Brandt Shale Shaker Screen is well-positioned to meet the needs of drilling contractors and operators. With its proven track record and commitment to innovation, it is set to remain a leading choice for solids control in the years to come.

Company News & Blog

High-quality Shaker Screen for Swaco Mongoose/Meerkat Available

Swaco Mongoose/Meerkat Shaker Screen, a top-of-the-line shaker screen technology, has been making waves in the oilfield industry for its efficient and effective performance. The shaker screens are designed to provide superior solids control and separation, ensuring optimal efficiency and productivity in drilling operations.This innovative technology is the brainchild of a leading company in the oil and gas industry, which has been at the forefront of developing cutting-edge equipment and solutions for the energy sector. With a strong emphasis on research and development, the company has consistently delivered high-quality products that meet the evolving needs of oilfield operations.The Swaco Mongoose/Meerkat Shaker Screen is a testament to the company's commitment to excellence and innovation. It is engineered to deliver exceptional performance in terms of solids control and fluid handling, allowing for the efficient removal of drilled solids and ensuring the smooth operation of drilling equipment. With its durable construction and high-quality materials, the shaker screen is designed to withstand the demanding conditions of oilfield operations, delivering reliable performance in all types of drilling environments.One of the key features of the Swaco Mongoose/Meerkat Shaker Screen is its advanced technology that allows for effective solids control and fluid handling. The screen is designed to effectively separate solids from drilling fluids, ensuring that the drilling process is not hindered by the presence of contaminants. This results in improved drilling efficiency and reduced downtime, leading to significant cost savings for operators.In addition to its superior performance, the Swaco Mongoose/Meerkat Shaker Screen is also designed for easy installation and maintenance. Its user-friendly design allows for quick and hassle-free screen replacement, minimizing downtime and maximizing productivity. This makes it an ideal choice for operators looking to streamline their operations and improve overall efficiency.The company behind the Swaco Mongoose/Meerkat Shaker Screen has a strong reputation for providing top-quality products and exceptional customer service. With a global presence and a strong network of distributors and service centers, the company ensures that its customers receive the support they need, wherever they are located. This commitment to customer satisfaction has made the company a trusted partner for oilfield operators around the world.As the oil and gas industry continues to evolve and face new challenges, the demand for innovative and reliable equipment remains high. The Swaco Mongoose/Meerkat Shaker Screen is a clear example of the type of technology that is needed to meet these challenges, providing operators with a competitive edge and the confidence to tackle even the most demanding drilling environments.In conclusion, the Swaco Mongoose/Meerkat Shaker Screen is a game-changer in the oilfield industry, offering unmatched performance, durability, and ease of use. With the backing of a reputable and forward-thinking company, this innovative technology is set to become a staple in drilling operations around the world, helping operators achieve greater efficiency and productivity.

High-Quality FLC503 PWP Shaker Screen for Effective Filtering

Derrick Corporation is proud to announce the launch of its latest innovation – the FLC503 PWP Shaker Screen. This new product is poised to set a new standard in the industry with its unparalleled performance and durability.The FLC503 PWP Shaker Screen is designed to deliver exceptional solids control and liquid separation during the drilling process. It is engineered to withstand the harsh conditions of the oil and gas industry, ensuring reliable and efficient operation even in the most demanding applications.The key to the FLC503 PWP Shaker Screen's exceptional performance lies in its advanced design and high-quality materials. The screen features a patented composite frame that provides superior support and stability, ensuring that it can withstand the rigors of the drilling process. Additionally, the screen is constructed using high-quality stainless steel wire mesh that is resistant to corrosion and abrasion, making it a highly durable and long-lasting solution.In addition to its exceptional durability, the FLC503 PWP Shaker Screen also offers outstanding solids control and liquid separation capabilities. Its precise mesh openings and large open area ensure efficient filtration of drilling fluids, effectively removing solids and impurities to maintain the integrity of the drilling process. This results in improved performance, reduced downtime, and lower operating costs for our customers.The FLC503 PWP Shaker Screen is compatible with Derrick's FLC 500 series shale shakers, making it an easy and seamless upgrade for existing equipment. This compatibility ensures that customers can effortlessly integrate the FLC503 PWP Shaker Screen into their operations, unlocking its benefits without the need for significant investment in new infrastructure.At Derrick Corporation, we are committed to delivering exceptional solutions that meet the evolving needs of the industry. The introduction of the FLC503 PWP Shaker Screen is a testament to our dedication to innovation and excellence, as we continue to push the boundaries of what is possible in solids control and liquid separation technology.Our extensive experience and expertise in the field of solids control and liquid separation have allowed us to develop a comprehensive range of solutions that are trusted by industry professionals around the world. With the launch of the FLC503 PWP Shaker Screen, we are proud to further expand our offering and provide our customers with a cutting-edge solution that delivers unmatched performance and reliability.In conclusion, the FLC503 PWP Shaker Screen represents a new chapter in the evolution of solids control and liquid separation technology. Its advanced design, exceptional durability, and outstanding performance make it a game-changer for the industry, setting a new standard for efficiency and reliability. Derrick Corporation is excited to bring this innovative solution to the market, and we look forward to supporting our customers as they harness the benefits of the FLC503 PWP Shaker Screen in their operations.

Upgrading Your Shaker Screens: Tips for Replacing and Choosing the Right Screens

Replacement Shaker Screens Transforming the Oil and Gas IndustryIn the ever-evolving oil and gas industry, technological advancements play a crucial role in optimizing efficiency and productivity. And one company at the forefront of this transformation is a leading innovator in the field of replacement shaker screens. By combining cutting-edge technology with a deep understanding of industry needs, this company is revolutionizing the way drilling fluids are filtered and processed.With global demand for oil and gas continuing to rise, drilling operations have become more complex and challenging. The extraction process involves drilling deep into the earth's crust, often in harsh and remote locations. Consequently, drilling contractors face numerous challenges in order to maintain profitable operations. Ensuring efficient solid control systems is a critical aspect of successful drilling, as it directly impacts the overall performance and longevity of drilling equipment.Replacement shaker screens are an integral component of a drilling rig's solid control system. They are used to filter out unwanted solids from drilling fluids, a process known as shale shaker. Shaker screens play a vital role in maintaining the quality and integrity of the drilling fluids, as well as protecting downstream equipment such as centrifuges and pumps. Hence, the durability, effectiveness, and efficiency of these screens are of utmost importance.The innovator in question has a long-standing reputation for producing high-quality replacement shaker screens that surpass industry standards. Their commitment to continuous research and development has led to breakthrough technologies that address the industry's most pressing challenges. By leveraging advanced engineering techniques, this company has created screens that excel in terms of durability, efficiency, and performance.One of the key features that sets these replacement shaker screens apart is the utilization of composite materials. By combining carefully selected grades of stainless steel with engineered polymer frames, these screens exhibit enhanced resistance to wear and corrosion. This ensures a longer lifespan, resulting in reduced maintenance costs and increased overall productivity.Moreover, the company's innovative screen design maximizes the usable screen area, significantly improving fluid handling capacity. This not only facilitates faster drilling operations but also minimizes the chance of screen blinding, a common issue faced by drilling contractors. With decreased screen blinding, operators are able to maintain optimal fluid flow rates, enhancing the overall efficiency of the drilling process.Furthermore, these replacement screens are meticulously engineered to deliver accurate particle separation. They employ advanced mesh technology that enables precise cut points, ensuring that only the desired solids are filtered out. This level of finesse in separation allows drilling contractors to better manage the drilling fluids' composition, thereby delivering superior drilling performance.The company's commitment to customer satisfaction extends beyond the quality of their products. They provide comprehensive technical support and responsive customer service, ensuring that their clients' specific needs are met. In an industry where downtime can have costly repercussions, this level of support is invaluable.To further enhance their service offering, the company actively collaborates with drilling contractors to develop customized solutions. By understanding the unique challenges faced by each client, they are able to tailor their screens to specific drilling conditions, thereby optimizing performance and efficiency. This collaborative approach has earned the company a loyal customer base and cemented their position as a trusted partner in the oil and gas industry.With replacement shaker screens playing such a vital role in the oil and gas sector, the technological advancements offered by this innovative company are poised to transform the industry. By improving durability, maximizing fluid handling capacity, enhancing particle separation accuracy, and providing exceptional customer support, they are revolutionizing the solid control process. As drilling operations continue to evolve, these replacement shaker screens serve as a testament to the power of innovation in shaping the future of the oil and gas industry.

Shale Shaker Screen: Latest News and Updates

Brandt Shale Shaker Screen, one of the leading products in the oil drilling industry, has continue to make waves with its innovative technology and exceptional performance. With its advanced design and superior materials, the Brandt Shale Shaker Screen has become a game changer in the oil and gas sector, providing a reliable and efficient solution for solids control.The Brandt Shale Shaker Screen is engineered to effectively separate solids from drilling mud, ensuring the smooth operation of the drilling process. Its high-quality stainless steel wire mesh and durable frame construction make it capable of withstanding the demanding conditions of drilling operations while delivering consistent performance.In addition to its exceptional durability and reliability, the Brandt Shale Shaker Screen also offers a wide range of configurations to suit various drilling applications. It is available in different mesh sizes to accommodate different particle sizes and provide effective solids control. This flexibility in design makes it a versatile and adaptable solution for different drilling environments.Furthermore, the Brandt Shale Shaker Screen is designed to be compatible with a range of shale shakers, making it a convenient and easily integrable option for drilling contractors. Its quick and simple installation process allows for minimal downtime, ensuring that drilling operations can resume swiftly and efficiently.The company behind the Brandt Shale Shaker Screen has a long-standing reputation for delivering high-quality products and exceptional customer service. With a focus on continuous innovation and improvement, the company is committed to providing advanced solutions that meet the evolving needs of the oil and gas industry.The company’s dedication to research and development has resulted in the creation of the Brandt Shale Shaker Screen, which has set a new standard for solids control in the drilling industry. Its advanced technology and superior performance have made it a preferred choice for drilling contractors and operators around the world.Moreover, the company’s commitment to sustainability is reflected in the production of the Brandt Shale Shaker Screen. With a focus on environmental responsibility, the company ensures that its products are manufactured using eco-friendly processes and materials, minimizing their impact on the environment.The Brandt Shale Shaker Screen has earned the trust and confidence of customers globally, thanks to its exceptional performance, reliability, and versatility. Its ability to enhance solids control and improve drilling efficiency has made it an indispensable component of drilling operations, contributing to increased productivity and reduced operational costs.As the demand for efficient and reliable solids control solutions continues to grow in the oil and gas industry, the Brandt Shale Shaker Screen is well-positioned to meet the needs of drilling contractors and operators. With its proven track record and commitment to innovation, it is set to remain a leading choice for solids control in the years to come.

Discover the Benefits of Flat PWP Shaker Screens for Enhanced Performance

Title: Industry-Leading Flat PWP Shaker Screen Revolutionizes Oil Filtration ProcessIntroduction:In a world where efficiency and reliability reign supreme, the oil and gas industry continually seeks innovative solutions to enhance their operations. As a response to this need, Company XYZ has unveiled its industry-leading Flat PWP Shaker Screen, a revolutionary product that promises to transform the oil filtration process. By combining cutting-edge technology with years of experience, Company XYZ has once again positioned itself as a frontrunner in the market, delivering exceptional results to its clients.The Flat PWP Shaker Screen:Designed to optimize the oil filtration process, the Flat PWP Shaker Screen features a technologically advanced flat design that allows for better fluid handling, improved filtration efficiency, and extended operational lifespan. This groundbreaking development sets it apart from conventional shaker screens in terms of performance, durability, and reliability.Enhanced Fluid Handling:One of the key advantages of the Flat PWP Shaker Screen is its ability to provide superior fluid handling capabilities. The innovative flat design offers increased open area, facilitating smoother fluid flow throughout the screening process. This enables a higher throughput, reducing the likelihood of blockages and improving overall productivity. The advanced technology behind the Flat PWP Shaker Screen ensures consistent separation and particle filtration, irrespective of the feed conditions.Improved Filtration Efficiency:With its precision-engineered mesh, the Flat PWP Shaker Screen offers unmatched filtration efficiency. The mesh size and configuration of the screen are meticulously crafted to capture a wide range of particle sizes, ensuring that the extracted oil meets the desired quality standards. High-quality filtration not only leads to increased oil purity but also enhances the efficiency of downstream processes such as refining and purification.Extended Operational Lifespan:The Flat PWP Shaker Screen boasts exceptional durability and longevity, significantly minimizing downtime and replacement costs. Constructed using premium-quality materials and employing advanced manufacturing techniques, this screen can endure challenging operating conditions, including high temperatures and corrosive environments. Its robust design allows for continuous use, resulting in extended operational lifespan and reduced maintenance efforts. This longevity serves as a testament to the superior engineering and unrivaled commitment of Company XYZ.Company XYZ's Expertise:Company XYZ has been at the forefront of the oil and gas industry for several years, renowned for its dedication to innovation and customer satisfaction. The release of the Flat PWP Shaker Screen further exemplifies the company's commitment to enhancing operational efficiency, optimizing productivity, and providing comprehensive solutions to its clients.With an experienced team of engineers and researchers, Company XYZ has successfully developed and refined products that meet the most rigorous industry standards. Through partnerships with leading oil and gas companies, Company XYZ has gained unparalleled insights into the challenges faced by the industry. This knowledge, coupled with cutting-edge technology, ensures that the Flat PWP Shaker Screen is tailor-made to address the specific demands of the oil filtration process.Conclusion:As the oil and gas industry continue to evolve and demand higher standards, Company XYZ's Flat PWP Shaker Screen emerges as a game-changer. This revolutionary product pushes the boundaries of conventional shaker screens, offering enhanced fluid handling, improved filtration efficiency, and extended operational lifespan. With its commitment to innovation, expertise, and customer satisfaction, Company XYZ has once again positioned itself as a leader in the field, providing the industry with a reliable and efficient solution for optimizing the oil filtration process.

Introducing a High-Quality Shale Shaker Screen for Optimal Efficiency and Performance

Title: Innovation in Shale Shaker Screen Technology Revolutionizes the Drilling IndustryIntroduction:Shale shaker screens play a vital role in the oil and gas drilling industry. They are designed to efficiently filter out solid particles from drilling fluids, allowing for the retrieval of valuable resources. One company that has made significant strides in shale shaker screen innovation is Kemtron, a leading manufacturer and supplier of drilling equipment and accessories. With their latest technological breakthrough, the KTL-26 Shale Shaker Screen, Kemtron is revolutionizing the drilling industry by improving separation efficiency, reducing downtime, and optimizing drilling operations.Opening Paragraph:The KTL-26 Shale Shaker Screen, developed by Kemtron, represents a leap forward in drilling equipment technology. This state-of-the-art shale shaker screen is designed to deliver unparalleled performance, setting new industry standards for separation efficiency and cost-effectiveness. By effectively removing solid particles from drilling fluids, the KTL-26 ensures smooth operations, higher productivity, and increased profitability for drilling companies worldwide.Efficient Separation and Improved Downtime:The key advantage of the KTL-26 Shale Shaker Screen lies in its enhanced separation capabilities. With an intricate mesh design and advanced material composition, this screen offers superior filtration efficiency, effectively separating fine particles from drilling fluids. Its robust construction and high-quality materials ensure longevity and durability, reducing downtime due to frequent replacements and repairs.Additionally, the KTL-26's innovative design minimizes blinding and plugging, a common issue faced by traditional shale shaker screens. Its self-cleaning mechanism efficiently clears blockages, maintaining a consistent flow of drilling fluids and preventing disruptions to drilling operations. This unique feature significantly reduces downtime and increases the efficiency of drilling activities, ultimately saving time and costs for drilling companies.Optimized Drilling Operations:The KTL-26 Shale Shaker Screen is engineered to optimize drilling operations by delivering improved drilling fluid processing capabilities. The screen's precise particle separation not only eliminates harmful solids from drilling fluids, but also ensures the retention of valuable additives. This allows drilling companies to maintain the desired fluid properties, leading to improved drilling efficiency and higher quality wellbores.Furthermore, the KTL-26's design offers flexibility in adjusting the screen’s drying capacity and cut point, catering to varying drilling conditions. Drilling operations can now adapt to different formations, improving overall drilling performance and reducing the risk of outage due to unforeseen challenges.Environmental Sustainability:In addition to its impeccable performance, the KTL-26 Shale Shaker Screen also prioritizes environmental sustainability. Made from environmentally friendly materials and manufactured using eco-conscious processes, this screen reduces the carbon footprint typically associated with drilling activities. Kemtron's commitment to sustainable solutions aligns with the growing industry demand for eco-friendly practices, making the KTL-26 a responsible choice for environmentally conscious drilling companies.Conclusion:Kemtron's KTL-26 Shale Shaker Screen represents a significant advancement in shale shaker screen technology. Its improved separation efficiency, reduced downtime, and optimized drilling operations provide a competitive edge to drilling companies worldwide. By setting new industry standards, Kemtron continues to lead the way in enhancing drilling processes while prioritizing environmental sustainability. The KTL-26 Shale Shaker Screen is a testament to Kemtron's commitment to innovation, efficiency, and long-term success in the oil and gas drilling industry.

Top 5 Must-Have Tools for Efficient Oilfield Operations

Title: Oilfield Equipment Supplier Embraces Innovation and Continues to Thrive in the MarketIntroduction:Oilfield Equipment, an industry-leading supplier of high-quality oilfield equipment and services, has been a driving force in the oil and gas sector for over a decade. With a strong commitment to innovation, cutting-edge technology, and exceptional customer service, Oilfield Equipment has successfully carved a niche for itself in the competitive market. This article explores the key factors contributing to the company's success and highlights its dedication to providing top-of-the-line equipment and solutions to the oil and gas industry.Growing Amidst Technological Advancements:As the oil and gas sector continues to evolve and adapt to the growing demands of the global market, Oilfield Equipment has remained at the forefront of technological advancements. The company consistently invests in research and development to offer state-of-the-art equipment that not only enhances efficiency but also ensures greater safety measures for the workforce in the field.By collaborating with leading technology providers, Oilfield Equipment has successfully integrated automation and data analytics into its product offerings, enabling clients to optimize their operational performance. Through the use of advanced sensors, real-time data monitoring, and artificial intelligence-driven systems, the company's equipment enables oilfield operators to make informed, data-driven decisions, resulting in improved productivity and reduced downtime.Commitment to Quality and Reliability:Oilfield Equipment's unwavering commitment to delivering high-quality and reliable products has cemented its position as a trusted supplier in the industry. The company adheres to strict manufacturing standards, leveraging its extensive expertise to design and engineer equipment that meets the specific requirements of oilfield operations.Stringent quality control measures are implemented throughout the production process, ensuring that every piece of equipment that bears the Oilfield Equipment name is built to withstand the demanding conditions of the oilfield environment. This dedication to quality has earned the company a loyal customer base who rely on their products to enhance their operational efficiency and profitability.Customer-Centric Approach:Recognizing the importance of building strong and lasting partnerships with clients, Oilfield Equipment maintains a customer-centric approach in all aspects of its business. The company works closely with its customers to understand their unique needs and challenges, providing tailored solutions that address their specific requirements.Oilfield Equipment's team of highly skilled professionals offers comprehensive support from initial consultation to delivery and beyond. Their technical expertise and prompt customer service ensure that clients receive all the assistance they need, be it equipment selection, installation, maintenance, or troubleshooting.Sustainable Solutions and Environmental Responsibility:In line with the growing global focus on sustainability, Oilfield Equipment has integrated environmentally responsible practices into its operations. The company is committed to minimizing its ecological footprint by developing energy-efficient equipment and exploring alternative energy solutions.Furthermore, the company ensures adherence to all relevant environmental regulations and continues to invest in innovative technologies that reduce emissions and optimize resource utilization. By prioritizing sustainability, Oilfield Equipment not only contributes to the long-term viability of the oil and gas industry but also demonstrates its commitment to preserving the planet for future generations.Future Prospects and Outlook:Looking ahead, Oilfield Equipment is poised to leverage its extensive industry experience and robust technological capabilities to capture new opportunities in emerging markets. The company's solid reputation, commitment to innovation, and customer-centric approach position it favorably within the industry, ensuring continued growth and success.In conclusion, Oilfield Equipment stands as a leading supplier of high-quality oilfield equipment and services, driven by innovation, reliability, customer focus, and sustainability. Through its constant pursuit of excellence, the company has established a strong foothold within the oil and gas sector, and its future prospects remain promising in an ever-evolving industry.

Discover the Benefits of Secondary Screens for the VSM 300

VSM 300 Secondary Screen Enhances Efficiency in Oil and Gas Drilling OperationsOil and gas drilling operations require high-performance equipment to ensure maximum efficiency and productivity. The VSM 300 Secondary Screen, developed by a leading global provider of oilfield equipment, has been gaining recognition for its exceptional performance in the industry.The VSM 300 Secondary Screen is designed to be used in combination with a primary shale shaker in drilling operations. Its advanced technology and innovative design make it an essential component for separating solids from drilling fluid, also known as mud, in order to maintain the desired properties of the mud and to prevent environmental contamination.One of the key features of the VSM 300 Secondary Screen is its superior screening capacity, which allows for the efficient removal of fine solids and impurities from the drilling fluid. This capability significantly reduces the risk of equipment damage and improves overall drilling efficiency.In addition, the VSM 300 Secondary Screen is constructed with durable and reliable materials, ensuring its longevity and minimal maintenance requirements. This reliability is essential for drilling operations, as any downtime can result in considerable financial losses.Furthermore, the VSM 300 Secondary Screen is designed to be easy to install and operate, minimizing the need for specialized training and expertise. This user-friendly approach is highly valued in the industry, where operational simplicity is crucial for maintaining a smooth and efficient workflow.The VSM 300 Secondary Screen has also been engineered to be compatible with a wide range of drilling fluids, making it a versatile solution for various drilling operations. Its adaptability and flexibility have contributed to its widespread adoption across the oil and gas industry.Moreover, the company behind the VSM 300 Secondary Screen has a strong track record of providing high-quality equipment and solutions for the oil and gas sector. With a commitment to innovation and customer satisfaction, the company has earned a reputation as a trusted and reliable partner for drilling operators worldwide.In addition to the VSM 300 Secondary Screen, the company offers a comprehensive range of products and services to support drilling operations, including primary shale shakers, mud cleaners, centrifuges, and other essential equipment. This integrated approach allows drilling operators to source all their requirements from a single, reputable supplier, streamlining their procurement process and ensuring seamless compatibility between various components.Furthermore, the company has a global presence, with a network of service centers and support facilities strategically located in key regions. This extensive coverage enables the company to provide timely assistance and technical support to its customers, ensuring the uninterrupted operation of their equipment and the continuity of their drilling activities.The company also places a strong emphasis on research and development, continuously striving to enhance the performance and efficiency of its products. This commitment to innovation ensures that its offerings remain at the forefront of technological advancements in the oil and gas industry, meeting the evolving needs and challenges of drilling operations.In conclusion, the VSM 300 Secondary Screen, developed by a reputed provider of oilfield equipment, stands out as a high-performance and reliable solution for enhancing efficiency in oil and gas drilling operations. With its advanced technology, durability, ease of use, and compatibility with various drilling fluids, the VSM 300 Secondary Screen has earned its place as a trusted and valuable asset for the industry.As drilling activities continue to expand and evolve, the VSM 300 Secondary Screen and the company behind it are well-positioned to support the sector's ongoing success, contributing to the achievement of operational excellence and environmental stewardship.

High-quality 28 Series Screen for Industrial Use

Introducing the New 28 Series ScreenIn today's fast-paced world, technological advancements are taking place at an unprecedented rate, revolutionizing the way we live and work. One such groundbreaking innovation is the newly launched 28 Series Screen by a leading provider in the industry. This cutting-edge product is now set to transform the way businesses and individuals engage with digital content, offering a plethora of features and capabilities that cater to a wide range of needs and preferences.With its sleek design and state-of-the-art technology, the 28 Series Screen is designed to deliver an unparalleled viewing experience. One of its key highlights is the high-resolution display, which ensures crisp and clear visuals, allowing users to immerse themselves in their work or entertainment. Whether it's designing graphics, editing videos, or simply enjoying a movie, this screen promises to deliver stunning image quality that surpasses expectations.Additionally, the screen also boasts a range of connectivity options, making it versatile and adaptable to various devices and systems. With multiple ports and compatibility with different interfaces, users can seamlessly connect their laptops, desktops, gaming consoles, and other devices to the screen, maximizing convenience and efficiency. This makes it an ideal choice for professionals and enthusiasts who require a flexible and dynamic display solution.Furthermore, the 28 Series Screen is equipped with advanced features that enhance user experience and promote productivity. From customizable display settings to ergonomic design, every aspect of the product is meticulously crafted to cater to the diverse needs of modern-day users. Whether it's adjusting the screen tilt for optimal viewing angles or toggling between different modes for specific tasks, this screen is designed to adapt to the user's preferences and requirements.In addition to its exceptional performance and functionality, the 28 Series Screen also prioritizes sustainability and energy efficiency. As an environmentally conscious brand, the company has incorporated eco-friendly materials and technologies into the screen's design, ensuring minimal environmental impact without compromising on quality or performance. This aligns with the company's commitment to corporate social responsibility and reflects its dedication to creating products that are not only innovative but also environmentally sustainable.As a testament to its reliability and superior quality, the 28 Series Screen is backed by comprehensive support and warranty services. Customers can rest assured that they will receive prompt assistance and technical support in the unlikely event of any issues or concerns. This demonstrates the company's unwavering dedication to customer satisfaction and its confidence in the durability and longevity of the product.Overall, the 28 Series Screen represents a significant leap forward in display technology, offering a blend of cutting-edge features, versatility, and sustainability. With its sleek design, immersive visuals, and user-centric functionality, it is poised to set new standards in the industry and cater to the evolving needs of consumers across various sectors. Whether it's for professional use, creative endeavors, or entertainment, this screen is set to redefine the way we engage with digital content, making it a must-have for anyone seeking a premium display solution.