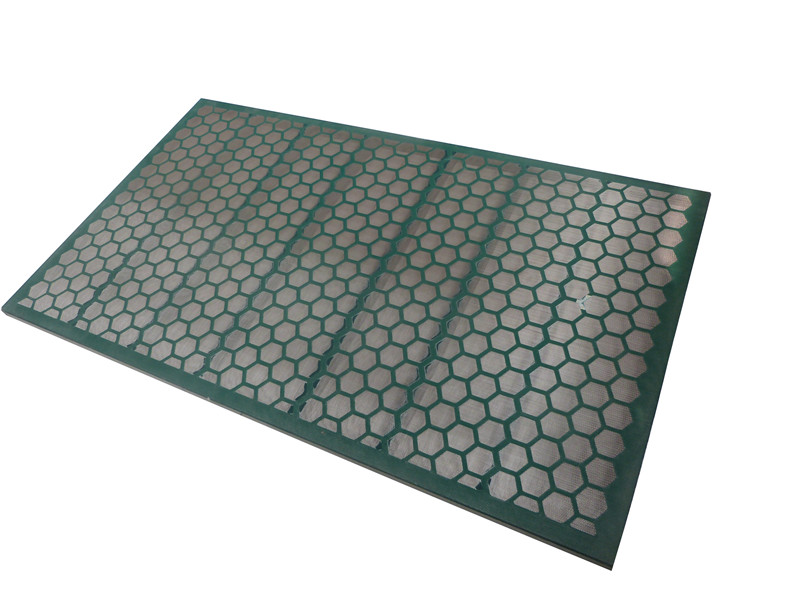

High-Quality Shale Shaker Screen KPT-48 for Effective Oil and Gas Drilling Operations

By:Admin

The Kemtron KPT-48 Shale Shaker Screen is manufactured by a well-established company with a strong reputation in the industry. The company has been providing high-quality drilling equipment and solutions for many years, catering to the needs of oil and gas companies around the world. With a commitment to innovation and excellence, the company has continuously pushed the boundaries of technology to develop cutting-edge products that meet the evolving demands of the industry.

The Kemtron KPT-48 Shale Shaker Screen is a testament to the company's dedication to delivering superior quality products. It is engineered to deliver optimal performance, ensuring efficient and reliable operation in demanding drilling environments. The screen is made from high-quality materials and is built to withstand the rigors of the drilling process, making it a dependable and long-lasting solution for oil and gas companies.

One of the key features of the Kemtron KPT-48 Shale Shaker Screen is its advanced design, which allows for effective solid particle separation. The screen is meticulously engineered to provide maximum efficiency in removing debris and solid particles from drilling fluid, helping to maintain the integrity of the fluid and enhance overall drilling performance.

In addition to its exceptional performance, the Kemtron KPT-48 Shale Shaker Screen is also designed with user-friendly features that make it easy to install and maintain. Its durable construction and easy-to-use design make it a practical and cost-effective solution for oil and gas companies seeking to optimize their drilling operations.

The Kemtron KPT-48 Shale Shaker Screen has already garnered rave reviews from industry professionals who have praised its high performance and reliability. Many companies have reported significant improvements in drilling efficiency and cost savings after implementing the screen into their operations. With its proven track record and positive feedback from users, the Kemtron KPT-48 Shale Shaker Screen is swiftly gaining traction as a preferred choice for oil and gas companies worldwide.

As the oil and gas industry continues to evolve, the demand for high-performance drilling equipment remains high. The Kemtron KPT-48 Shale Shaker Screen is well-positioned to meet this demand, offering a powerful solution that addresses the specific challenges of solid particle separation in drilling operations. Its top-notch quality, innovative design, and outstanding performance make it a standout choice for companies looking to enhance their drilling processes.

In conclusion, the Kemtron KPT-48 Shale Shaker Screen stands as a testament to the company's commitment to excellence and innovation. With its exceptional performance, advanced features, and user-friendly design, it has quickly established itself as a top contender in the market of shale shaker screens. Oil and gas companies looking to optimize their drilling operations would do well to consider the Kemtron KPT-48 Shale Shaker Screen as a reliable and efficient solution.

Company News & Blog

Oil Shale Shaker Screen GNZS-703: All you need to know about it

Oil and gas industry is a crucial part of the global economy. With the continuous development and progress, there is a growing demand for advanced equipment and technology to ensure efficient and safe operation. One of the crucial components in the oil and gas drilling process is the shale shaker screen.Recently, the GNZS-703 Oil Shale Shaker Screen, developed by a leading company in the industry, has been making waves in the market. This innovative product has been designed to improve the efficiency and performance of oil and gas drilling operations, setting a new standard for shale shaker screens.The GNZS-703 Oil Shale Shaker Screen is a result of extensive research and development by the company, which has been a pioneer in providing cutting-edge solutions for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a reliable and trusted partner for oil and gas companies around the world.The GNZS-703 Oil Shale Shaker Screen is engineered to deliver superior performance in separating and filtering drilling cuttings during the oil and gas drilling process. Its unique design and advanced technology ensure maximum efficiency and productivity, while also reducing downtime and maintenance costs for drilling operations.One of the key features of the GNZS-703 Oil Shale Shaker Screen is its durable and wear-resistant construction, which allows it to withstand the harsh conditions of drilling operations. This ensures a longer service life and lower replacement costs for oil and gas companies, contributing to overall cost savings and improved profitability.Additionally, the GNZS-703 Oil Shale Shaker Screen is designed for easy installation and maintenance, making it a practical and convenient solution for drilling operations. Its efficient performance and user-friendly design have garnered positive feedback from industry professionals, further solidifying its reputation as a leading product in the market.The company behind the GNZS-703 Oil Shale Shaker Screen has a rich history and extensive expertise in providing high-quality equipment and services for the oil and gas industry. With a strong commitment to continuous improvement and innovation, the company has been at the forefront of developing advanced solutions to meet the evolving needs of the industry.In addition to the GNZS-703 Oil Shale Shaker Screen, the company offers a comprehensive range of products and services, including shale shakers, mud cleaners, and other drilling equipment. Its commitment to excellence and customer satisfaction has earned the company a solid reputation as a reliable and trusted partner for oil and gas companies worldwide.The GNZS-703 Oil Shale Shaker Screen is just one example of the company's dedication to providing cutting-edge solutions for the oil and gas industry. With a focus on performance, reliability, and cost-effectiveness, the company continues to set new standards and push the boundaries of innovation in the industry.As the oil and gas industry continues to evolve and expand, the demand for advanced equipment and technology will only continue to grow. With its proven track record and commitment to excellence, the company is well-positioned to meet the ever-changing needs of the industry and play a key role in driving progress and success for oil and gas companies around the world.In conclusion, the GNZS-703 Oil Shale Shaker Screen, developed by a leading company in the industry, represents a new standard of excellence in the oil and gas drilling process. With its advanced technology, durable construction, and user-friendly design, this innovative product is set to make a significant impact on the efficiency and productivity of drilling operations. As the company continues to push the boundaries of innovation and provide cutting-edge solutions, it is poised to play a crucial role in driving progress and success for the oil and gas industry.

High-Quality Venom Shakers Screen for Effective Particle Separation

Shakers Screen: A Game-Changer in the Oil and Gas IndustryThe oil and gas industry continues to evolve and adapt with the advancement of technology. One such innovation that is making waves in the industry is the Shakers Screen, a key component in the process of separating solids and fluids during the drilling process. Among the leading brands in this space, the (remove brand name) Shakers Screen has gained widespread recognition for its efficiency and effectiveness in improving the overall operation of oil and gas drilling.The (remove brand name) Shakers Screen is a vital tool used in the drilling process to separate drilling fluid from the solids that are brought to the surface during the drilling of oil and gas wells. This separation process is essential to ensure the integrity of the well and to maintain proper drilling fluid properties. The Shakers Screen is designed to remove the solid particles from the drilling fluid, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner.The (remove brand name) Shakers Screen stands out from the competition due to its advanced design and high-quality materials. With a commitment to innovation and quality, the company has developed a range of screens that are durable, efficient, and cost-effective. The screens are designed to withstand the harsh conditions of drilling operations while providing reliable performance throughout the drilling process.The company prides itself on its dedication to research and development, continuously working to improve the design and functionality of the Shakers Screen. By listening to the needs of their customers, the company has been able to create screens that meet and exceed industry standards, providing a reliable solution for the challenges faced in the drilling process.In addition to its exceptional performance, the (remove brand name) Shakers Screen is also known for its ease of use and maintenance. The screens are designed for quick and simple installation, allowing for minimal downtime during the drilling process. Furthermore, the company provides comprehensive support and training for the maintenance and replacement of the screens, ensuring that they continue to operate at optimal efficiency.The impact of the Shakers Screen on the oil and gas industry cannot be overstated. By improving the efficiency of the drilling process, the screens help to reduce costs and increase overall productivity. This, in turn, has a positive impact on the bottom line for oil and gas companies, making the Shakers Screen a valuable investment for those in the industry.Furthermore, the screens play a crucial role in environmental sustainability. By allowing for the reuse of drilling fluid and the proper disposal of solids, the Shakers Screen helps to minimize the environmental impact of drilling operations. This aligns with the increasing emphasis on sustainable practices within the oil and gas industry, making the Shakers Screen a valuable tool for addressing environmental concerns.Looking ahead, the (remove brand name) Shakers Screen is poised to continue its upward trajectory in the oil and gas industry. With ongoing advancements in technology and a commitment to quality, the company is well-positioned to meet the evolving needs of the industry and provide innovative solutions for the challenges of drilling operations.In conclusion, the (remove brand name) Shakers Screen has emerged as a game-changer in the oil and gas industry, providing a reliable and efficient solution for the separation of solids and fluids during the drilling process. With its advanced design, high-quality materials, and commitment to innovation, the screens have significantly improved the operation of drilling operations, making them a valuable asset for oil and gas companies. As the industry continues to evolve, the Shakers Screen will undoubtedly play a vital role in driving efficiency, productivity, and sustainability in oil and gas drilling.

BEM-3 Pyramid Oil Shaker Screen for Swaco - News Update

Swaco BEM-3 Pyramid Oil Shaker Screen has been making waves in the oil and gas industry as a game-changing solution for efficient solids control. This innovative technology is paving the way for improved drilling operations, maximizing productivity and reducing environmental impact.The pyramid-shaped design of the shaker screen allows for increased fluid capacity and high fluid handling capacity, making it an ideal choice for challenging drilling environments. With a larger screen area and enhanced performance, the Swaco BEM-3 Pyramid Oil Shaker Screen is revolutionizing the way solids control is managed in the industry.The company behind this cutting-edge technology is a leading provider of innovative solutions for the oil and gas industry. With a strong focus on research and development, they are constantly pushing the boundaries of what is possible in solids control technology. Their commitment to excellence and dedication to providing top-quality products has earned them a solid reputation in the industry.The Swaco BEM-3 Pyramid Oil Shaker Screen is just one example of their commitment to innovation and performance. By developing advanced solutions that address the unique challenges of the oil and gas industry, they are helping companies around the world maximize efficiency and minimize environmental impact.In addition to their innovative products, the company also offers comprehensive support and service to ensure that their customers get the most out of their investment. With a team of experts standing by to provide technical support and guidance, they are dedicated to helping their clients achieve success in their operations.The performance and reliability of the Swaco BEM-3 Pyramid Oil Shaker Screen have been widely praised by industry professionals. Its ability to effectively separate solids from drilling fluids has contributed to significant improvements in overall drilling performance, leading to cost savings and increased productivity for companies using this technology.Moreover, the pyramid-shaped design of the shaker screen allows for easy cleaning and maintenance, reducing downtime and increasing the longevity of the equipment. This, combined with its exceptional performance, makes it a valuable asset for any drilling operation.The versatility of the Swaco BEM-3 Pyramid Oil Shaker Screen also makes it a valuable investment for companies operating in a variety of drilling environments. Whether it's onshore or offshore, this technology is adaptable and effective, making it a popular choice for companies looking to streamline their solids control processes.As the oil and gas industry continues to evolve, the demand for advanced solids control solutions is only going to increase. Companies that invest in innovative technology like the Swaco BEM-3 Pyramid Oil Shaker Screen are positioning themselves for success in a competitive and challenging market.In conclusion, the Swaco BEM-3 Pyramid Oil Shaker Screen is a testament to the commitment to excellence and innovation that defines the company behind it. With its game-changing design and exceptional performance, it is setting a new standard for solids control technology in the oil and gas industry. And as the industry continues to evolve, this technology will undoubtedly play a key role in driving efficiency and sustainability for drilling operations around the world.

Highly Efficient Multi-sizer Primary Screen for Versatile Screening Needs

VSM Multi-sizer Primary screen is a revolutionary new product that is set to change the way primary screening is conducted in the mining and aggregates industries. This innovative technology has been developed by a leading global provider of equipment and services for the mining and construction industries. With a strong commitment to innovation and sustainability, the company has a track record of developing cutting-edge solutions that improve the efficiency and productivity of its customers' operations.The VSM Multi-sizer Primary screen is designed to address the challenges of primary screening in the mining and aggregates industries. It offers a unique combination of high capacity, efficiency, and accuracy, making it an ideal solution for a wide range of applications. The screen is capable of handling large volumes of material, while also providing superior separation and classification capabilities. This allows operators to achieve higher throughput and better quality end products, ultimately leading to improved operational efficiency and profitability.One of the key features of the VSM Multi-sizer Primary screen is its modular design, which enables easy customization to suit the specific requirements of each application. This flexibility ensures that the screen can be tailored to meet the diverse needs of different operations, from small-scale quarries to large mining operations. Furthermore, the screen is equipped with advanced technologies that optimize the screening process, such as adjustable stroke and speed settings, as well as cushioned mounting for reduced vibration and noise levels.In addition to its technical capabilities, the VSM Multi-sizer Primary screen is also designed with sustainability in mind. It incorporates features that minimize environmental impact, such as low power consumption and reduced maintenance requirements. This aligns with the company's commitment to providing solutions that not only improve operational efficiency, but also contribute to a more sustainable future for the industry.The development of the VSM Multi-sizer Primary screen underscores the company's dedication to continuous innovation and customer-centric approach. By leveraging its expertise in screening technology and understanding of customer needs, the company has been able to deliver a product that sets new standards for primary screening in the mining and aggregates industries. This reflects the company's broader mission to drive progress through sustainable and efficient solutions that empower its customers to succeed in their respective fields.The VSM Multi-sizer Primary screen is already generating significant interest from the industry, with several installations planned in the coming months. Customers are eager to harness the benefits of this advanced screening technology, which promises to enhance their operations and deliver tangible results. With its proven track record of delivering high-quality solutions and its commitment to excellence, the company is well-positioned to meet the growing demand for the VSM Multi-sizer Primary screen and continue driving innovation in the mining and aggregates industries.Overall, the introduction of the VSM Multi-sizer Primary screen represents a significant milestone for the company and the industry as a whole. With its unrivaled combination of capacity, efficiency, and sustainability, this innovative technology is poised to reshape the landscape of primary screening and deliver lasting value to customers around the world. As the company continues to push the boundaries of what is possible, the VSM Multi-sizer Primary screen stands as a testament to its ongoing commitment to driving progress and empowering its customers for success.

High-performance 48 PMD Shaker Screen for Effective Material Separation

Derrick Corporation is pleased to announce the launch of the Derrick 48 PMD Shaker Screen, the latest addition to its high-quality range of shale shaker screens for the oil and gas industry. This new product exemplifies Derrick's commitment to providing innovative solutions that meet the ever-evolving needs of its customers.The 48 PMD Shaker Screen offers superior performance and durability, making it the ideal choice for operators looking to enhance the efficiency of their drilling operations. With its advanced design and construction, this shaker screen is capable of handling high fluid capacities while effectively removing solid particles from drilling fluids. This not only improves the overall efficiency of the drilling process but also helps to minimize waste and reduce environmental impact.Derrick Corporation has a long-standing reputation for delivering cutting-edge solutions that set industry standards. With a strong focus on research and development, the company continuously works to improve its products and develop new technologies that address the challenges faced by its customers. The 48 PMD Shaker Screen is a testament to Derrick's dedication to innovation and excellence.In addition to its superior performance, the 48 PMD Shaker Screen is designed for easy installation and maintenance, allowing operators to maximize uptime and minimize downtime. This is especially crucial in the oil and gas industry, where every minute of lost time can translate to significant financial losses. By choosing Derrick's shaker screens, operators can be confident in the reliability and efficiency of their equipment.Derrick Corporation is known for its unwavering commitment to customer satisfaction. The company provides comprehensive support and service to ensure that its customers get the most out of their equipment. Whether it's technical assistance, training, or spare parts, Derrick's team of experts is always ready to help customers overcome any challenges they may encounter.Derrick's dedication to quality extends beyond its products and services. The company places a strong emphasis on safety and environmental responsibility, ensuring that its operations and products adhere to the highest standards. The 48 PMD Shaker Screen is no exception, as it is designed to meet strict safety and environmental regulations, giving operators peace of mind knowing that they are using a product that prioritizes the well-being of both people and the planet.As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, driving innovation and setting new benchmarks for performance and reliability. The launch of the 48 PMD Shaker Screen is yet another example of Derrick's commitment to meeting the needs of its customers and empowering them to achieve success in their operations.In conclusion, Derrick Corporation's introduction of the 48 PMD Shaker Screen marks a significant milestone in the company's dedication to providing top-of-the-line solutions for the oil and gas industry. With its advanced design, superior performance, and unwavering commitment to customer satisfaction, this new product is set to make a lasting impact in the field of shale shaker screens. Derrick Corporation continues to set the standard for excellence, and the launch of the 48 PMD Shaker Screen is a clear demonstration of the company's ongoing commitment to driving innovation and delivering value to its customers.

Durable Vibrating Screen for Mining Machine

Mining Machine Vibrating Screen Revolutionizes the IndustryIn the fast-paced world of mining and construction, the need for efficient and reliable equipment has never been greater. With the demand for raw materials at an all-time high, mining companies are constantly seeking innovative solutions to improve their operations. One such solution comes in the form of the revolutionary Mining Machine Vibrating Screen, a game-changing piece of equipment that is set to transform the industry.The Mining Machine Vibrating Screen, developed by an industry-leading company, has quickly established itself as a vital tool in the extraction of minerals and aggregates. Its advanced technology and robust design make it an essential asset for any mining or construction operation. The vibrating screen is capable of efficiently separating and sorting a wide range of materials, making it an invaluable tool for any company looking to streamline their processes and increase productivity.The key to the success of the Mining Machine Vibrating Screen lies in its innovative design and cutting-edge technology. The screen is equipped with high-quality mesh panels that can be easily changed to meet the specific requirements of different materials. This flexibility allows for the efficient processing of a wide range of materials, from fine sand to large rocks. Additionally, the vibrating screen is equipped with powerful vibratory motors that ensure consistent and reliable performance, even under the most challenging conditions.One of the most impressive features of the Mining Machine Vibrating Screen is its user-friendly interface. Designed with the needs of operators in mind, the screen is easy to operate and maintain, reducing downtime and increasing efficiency. Additionally, the machine is equipped with advanced safety features to ensure the well-being of operators and prevent accidents in the workplace.The impact of the Mining Machine Vibrating Screen on the mining and construction industry cannot be overstated. With its ability to efficiently separate and sort materials, this revolutionary piece of equipment has drastically improved the productivity and profitability of countless companies. By streamlining the process of extracting and processing raw materials, the vibrating screen has become an essential tool for companies looking to stay ahead of the competition and maximize their output.In addition to its impressive technical capabilities, the Mining Machine Vibrating Screen is also designed with environmental sustainability in mind. By minimizing waste and maximizing the efficiency of material processing, this innovative equipment helps to reduce the environmental impact of mining and construction operations. This commitment to sustainability has earned the vibrating screen recognition and acclaim from industry experts and environmental organizations alike.As the demand for raw materials continues to grow, the need for efficient and reliable equipment has never been greater. The Mining Machine Vibrating Screen has quickly become an indispensable tool for companies looking to meet this demand and stay ahead of the competition. With its advanced technology, user-friendly design, and commitment to sustainability, this revolutionary piece of equipment is set to transform the mining and construction industry for years to come.In conclusion, the Mining Machine Vibrating Screen represents a significant advancement in the field of material processing. Its innovative design, cutting-edge technology, and commitment to sustainability make it an invaluable asset for any mining or construction operation. By streamlining the process of extracting and processing raw materials, this revolutionary piece of equipment has become a game-changer for the industry, and its impact is undeniable. As the demand for raw materials continues to rise, the Mining Machine Vibrating Screen is poised to play a pivotal role in the future of mining and construction.

Primary Shaker Screen for VSM300 - Key Features and Benefits

Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen has taken the oil and gas industry by storm with its innovative and efficient technology. This revolutionary shaker screen is designed to improve the overall performance and efficiency of the drilling process, making it an essential tool for oil and gas companies around the world.The primary function of the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is to remove solids from drilling fluid during the drilling process. This is important because the presence of solids can greatly affect the overall efficiency and productivity of the drilling operation. By effectively removing solids, the shaker screen helps to maintain the quality of the drilling fluid, leading to better wellbore stability and improved drilling performance.The key to the success of the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen lies in its advanced design and construction. It is made with high-quality materials that are durable and long-lasting, making it ideal for use in the challenging and demanding conditions of the oil and gas industry. The screen is also engineered to provide maximum efficiency in the removal of solids, ensuring that drilling operations can continue without any interruptions or delays.In addition to its superior performance, the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is also designed for ease of use and maintenance. Its innovative design allows for quick and easy installation and removal, saving valuable time and effort for the operators. Furthermore, the screen is designed to be highly resistant to wear and tear, reducing the need for frequent replacements and repairs.One of the main advantages of the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is its ability to improve the overall efficiency and cost-effectiveness of drilling operations. By removing solids from the drilling fluid, the screen helps to reduce the wear and tear on drilling equipment and tools, leading to longer lifespans and reduced maintenance costs. Additionally, the improved quality of the drilling fluid leads to better wellbore stability and reduced risks of issues such as stuck pipe or lost circulation, ultimately saving time and money for oil and gas companies.The Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is manufactured by a reputable company with a strong presence in the oil and gas industry. With years of experience and expertise in developing innovative solutions for the drilling process, the company has established itself as a leader in providing high-quality equipment and technology for oil and gas operations. The company is committed to providing reliable and efficient solutions that meet the needs of its customers, and the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is a testament to this commitment.In conclusion, the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, efficiency, and cost-effectiveness make it an essential tool for improving the overall performance of drilling operations. With its proven track record and the backing of a reputable company, the Brandt & VSM300 Primary /62735 FOTD089 Shaker Screen is set to revolutionize the way drilling operations are carried out, setting a new standard for efficiency and productivity in the oil and gas industry.

High-efficient Rotary Vibrating Screen Shaker for Screening Applications

Rotary Vibrating Screen Shaker (name removed for privacy reasons) is a highly efficient and innovative screening solution that has revolutionized the way companies in various industries process materials. With its advanced design and state-of-the-art technology, this shaker has become a preferred choice for many businesses looking to improve their screening processes.The (name removed) Rotary Vibrating Screen Shaker is designed to efficiently separate and remove oversized particles from materials such as chemicals, minerals, plastics, and more. Its unique rotary motion and high-frequency vibration allow for a more precise and effective screening process, resulting in higher product quality and reduced downtime.The key features of the (name removed) Rotary Vibrating Screen Shaker include its compact design, easy operation, and low maintenance requirements. This makes it an ideal solution for companies looking to streamline their screening operations without compromising on performance.In addition to its technical capabilities, (name removed) is also committed to providing excellent customer service and support. The company's team of experienced professionals is dedicated to helping customers find the right screening solution for their specific needs, and its extensive network of distributors ensures that customers have access to reliable and responsive support wherever they are located.Furthermore, (name removed) takes pride in its commitment to environmental sustainability. The Rotary Vibrating Screen Shaker is designed with energy efficiency in mind, helping companies reduce their carbon footprint while improving their overall screening processes. This aligns with (name removed)'s mission to provide eco-friendly solutions that benefit both businesses and the environment.The (name removed) Rotary Vibrating Screen Shaker has already been adopted by a wide range of industries, including pharmaceuticals, food and beverage, ceramics, and more. Its versatility and adaptability make it a valuable asset for companies looking to enhance their material processing capabilities.Customer testimonials speak to the effectiveness and reliability of the (name removed) Rotary Vibrating Screen Shaker. Many companies have reported significant improvements in their screening processes after implementing this innovative solution, leading to increased productivity and cost savings.Looking ahead, (name removed) is continuously exploring ways to enhance the performance and capabilities of the Rotary Vibrating Screen Shaker. The company is committed to staying at the forefront of technological advancements in the screening industry, ensuring that its customers always have access to the most efficient and reliable solutions.In conclusion, the (name removed) Rotary Vibrating Screen Shaker has set a new standard for screening technology in various industries. Its advanced design, efficiency, and commitment to customer satisfaction have made it a preferred choice for companies worldwide. With a focus on innovation and sustainability, (name removed) continues to lead the way in providing cutting-edge solutions for material processing and screening needs.

High-Quality D380 Shaker Screen for Efficient Solid Control Operations

Shale shakers are essential tools used in the oil and gas industry for separating solids from drilling fluid. They play a crucial role in the drilling process by removing large solids from the drilling fluid, allowing the fluid to be recycled and reused. Therefore, the quality and efficiency of shale shaker screens are of utmost importance in ensuring smooth and productive drilling operations.In this regard, the Swaco D380 shaker screen has gained widespread recognition for its exceptional performance and durability. Manufactured by a leading company in the industry, this shaker screen is designed to withstand the most demanding drilling conditions while delivering consistent and reliable performance.The Swaco D380 shaker screen features a high-quality stainless steel wire mesh that is tightly woven to ensure maximum filtration efficiency. The screen is further reinforced with multiple layers of support mesh and a durable frame to withstand the high levels of vibration and impact encountered during drilling operations. This robust construction not only enhances the longevity of the screen but also ensures consistent performance in separating solids from the drilling fluid.One of the key advantages of the Swaco D380 shaker screen is its ability to provide a larger effective screening area, allowing for increased throughput and improved solids removal. This is particularly beneficial in high-volume drilling operations where the efficient removal of solids is critical to maintaining the integrity of the drilling fluid and the overall success of the operation.Additionally, the Swaco D380 shaker screen is designed for compatibility with a wide range of shale shaker models, making it a versatile and cost-effective solution for drilling contractors and operators. This compatibility ensures that the screen can be easily integrated into existing equipment, minimizing downtime and optimizing operational efficiency.Furthermore, the company behind the Swaco D380 shaker screen is committed to upholding the highest quality standards in its manufacturing processes. With state-of-the-art facilities and a team of experienced engineers and technicians, the company ensures that each screen meets strict quality control measures, resulting in a product that consistently meets and exceeds industry requirements.In line with its commitment to quality, the company also provides comprehensive technical support and assistance to its customers, ensuring that the Swaco D380 shaker screen is installed and maintained correctly for optimal performance. This level of support is indicative of the company's dedication to customer satisfaction and its understanding of the critical role that the shaker screen plays in the overall drilling process.As the oil and gas industry continues to evolve and demand grows for more efficient and reliable drilling technologies, the Swaco D380 shaker screen remains a trusted solution for operators seeking to enhance their drilling operations. Its superior performance, durability, and compatibility make it an indispensable tool for achieving maximum solids control and fluid management.In conclusion, the Swaco D380 shaker screen, manufactured by a leading company in the industry, stands as a testament to the commitment to quality, innovation, and customer satisfaction. With its exceptional performance and reliability, this shaker screen continues to set the standard for excellence in the field of solids control, contributing to the success of drilling operations worldwide.

High-Quality FLC313M Screen: What You Need to Know

Derrick Corporation, a leading global provider of high-quality separation and filtration equipment, has recently launched its latest innovation – the FLC313M screen. This new addition to the company’s extensive product line promises to revolutionize the way the oil and gas industry approaches solids control and dewatering.The FLC313M screen is designed to deliver superior performance and efficiency in separating solids from drilling fluid. Its advanced design features a unique combination of high-quality materials and innovative engineering, resulting in increased throughput and reduced operating costs for customers. With a focus on durability and reliability, this screen is built to withstand the demands of the most challenging drilling environments.One of the standout features of the FLC313M screen is its versatility. Suitable for both onshore and offshore applications, this screen excels in a wide range of operating conditions, including high temperature and high-pressure environments. Its ability to consistently deliver exceptional performance in such diverse settings sets it apart from other products currently available on the market.Furthermore, Derrick Corporation is committed to providing best-in-class customer service and support. The launch of the FLC313M screen is part of the company’s ongoing effort to meet the evolving needs of its global customer base. By offering innovative solutions that enhance efficiency and productivity, Derrick Corporation continues to solidify its position as a trusted partner to the oil and gas industry.In addition to the FLC313M screen, Derrick Corporation offers a comprehensive range of separation and filtration equipment, including shakers, hydrocyclones, and centrifuges. With a proven track record of delivering high-performance solutions, the company has established itself as a leader in the field of solids control and dewatering.The development and launch of the FLC313M screen underscore Derrick Corporation’s dedication to innovation and excellence. By staying at the forefront of technological advancements, the company remains well-positioned to address the evolving needs of the oil and gas industry. As the industry continues to seek more efficient and cost-effective solutions, Derrick Corporation is poised to provide the cutting-edge equipment required to meet these demands.In conclusion, the introduction of the FLC313M screen represents a significant milestone for Derrick Corporation. With its unmatched performance, durability, and versatility, this new addition to the company’s product line is set to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to push the boundaries of innovation, customers can expect to benefit from the superior quality and reliability that have become synonymous with the company’s brand.About Derrick Corporation:Derrick Corporation is a global provider of high-quality separation and filtration equipment for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner to its global customer base. Derrick Corporation is committed to delivering best-in-class equipment and solutions that enhance efficiency and productivity in solids control and dewatering applications.