High-quality Shaker Screen for Kemtron 48 - A Comprehensive Review

By:Admin

In the fast-paced world of oil and gas exploration, every second counts. From drilling to extraction, each step of the process requires precision and efficiency. A key aspect of this process is the management of solid control, which is essential for ensuring the smooth functioning of drilling operations. This is where the Kemtron 48 Shaker Screen comes in.

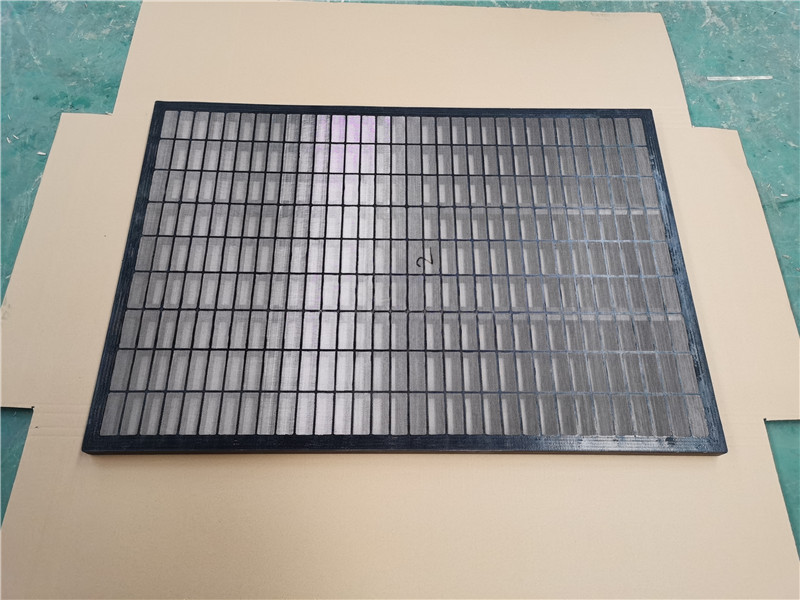

The Kemtron 48 Shaker Screen is a revolutionary product that has been designed to effectively manage solid control in the oil and gas industry. It is a vital component of the Kemtron 48 Shale Shaker, which is known for its high-performance and reliability. The shaker screen is made of high-quality stainless steel wire mesh and is designed to effectively separate solid particles from drilling fluid. This not only ensures the smooth functioning of drilling operations but also protects downstream equipment and reduces waste disposal costs.

One of the key features of the Kemtron 48 Shaker Screen is its superior durability. Made of high-quality materials, it is designed to withstand the harsh conditions of the oil and gas industry. It is also easy to install and maintain, making it a cost-effective solution for solid control. In addition, the screen has a large screening area, which allows for high capacity and efficiency. This means that operators can achieve optimal performance and productivity with the Kemtron 48 Shaker Screen.

The Kemtron 48 Shaker Screen is also designed with versatility in mind. It can be used with a wide range of drilling fluids and is compatible with various types of shakers. This means that it can be seamlessly integrated into existing operations, minimizing downtime and disruption. This is crucial in the oil and gas industry, where every minute of downtime can result in significant financial losses.

In addition to its technical capabilities, the Kemtron 48 Shaker Screen is also backed by exceptional customer support. The company behind the product is known for its commitment to customer satisfaction and has a team of experts who are dedicated to providing support and assistance to clients. This means that operators can rely on the company not only for top-of-the-line products but also for reliable service and support.

The Kemtron 48 Shaker Screen has already made a significant impact in the oil and gas industry. Its innovative design and superior performance have helped operators around the world achieve greater efficiency and productivity in their drilling operations. From onshore to offshore projects, the Kemtron 48 Shaker Screen has proven to be an indispensable tool for solid control.

Looking to the future, the company is committed to further enhancing the capabilities of the Kemtron 48 Shaker Screen. With ongoing research and development, the company aims to continually improve the product and adapt to the evolving needs of the industry. This includes exploring new materials, technologies, and designs to ensure that the Kemtron 48 Shaker Screen remains at the forefront of solid control solutions.

In conclusion, the Kemtron 48 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, superior durability, and exceptional performance make it the ultimate solution for solid control. Backed by a commitment to customer satisfaction and continuous innovation, the company behind the product has established itself as a leader in the industry. As the demand for efficient solid control solutions continues to grow, the Kemtron 48 Shaker Screen is poised to play a crucial role in shaping the future of the oil and gas industry.

Company News & Blog

High-Quality Shaker Screen for DFTS Available Now

The global oil and gas industry has been experiencing a significant growth in recent years, leading to a surge in demand for high-quality and efficient equipment. In response to this, [Company Name] has introduced a novel and advanced solution to the market – the DFTS Shaker Screen.[Company Name] is a leading provider of oilfield equipment and services, with a strong focus on innovation and customer satisfaction. The company has established itself as a reliable and superior provider of products that meet the ever-evolving needs of the industry.The DFTS Shaker Screen is designed to enhance the performance of shale shakers, which are essential in the process of separating solids from drilling fluids. This is an integral part of the drilling process as it ensures that the quality of the drilling fluid is maintained, leading to improved operational efficiency and reduced downtime.The DFTS Shaker Screen is built with cutting-edge technology and superior materials, ensuring its durability and reliability even in the most demanding drilling environments. The screen is designed to provide high-capacity and efficient solids removal, thereby offering significant cost savings to drilling operations. The innovative design of the screen also ensures a longer service life, reducing the frequency of replacements and maintenance.In addition to its performance benefits, the DFTS Shaker Screen is also environmentally friendly, as it helps in minimizing waste and improving the overall efficiency of drilling operations. This aligns with [Company Name]'s commitment to sustainability and responsible environmental practices.The introduction of the DFTS Shaker Screen underscores [Company Name]'s dedication to providing its customers with cutting-edge solutions that address their specific needs and challenges. The company's relentless focus on research and development has allowed it to stay ahead of the curve and continue to be a leader in the industry.The DFTS Shaker Screen has already garnered significant attention and positive feedback from industry professionals, who have praised its superior performance and cost-saving benefits. Its introduction to the market has further solidified [Company Name]'s position as a provider of high-quality and innovative solutions for the oil and gas industry.[Company Name] continues to be at the forefront of technological advancements in the oilfield equipment sector, and the DFTS Shaker Screen is a testament to its commitment to excellence and customer satisfaction. With its unrivaled performance and durability, the screen is set to make a significant impact on drilling operations worldwide.As the global demand for oil and gas continues to rise, the need for efficient and reliable equipment has never been more crucial. With the introduction of the DFTS Shaker Screen, [Company Name] has once again demonstrated its ability to meet the industry's evolving needs and provide solutions that drive operational excellence and profitability.In conclusion, the DFTS Shaker Screen is a game-changer in the oilfield equipment market, offering unmatched performance, reliability, and cost-saving benefits. With this latest innovation, [Company Name] has reinforced its position as a leader in providing cutting-edge solutions that empower the oil and gas industry to thrive in today's dynamic market.

Latest Developments in Shale Shaker Screen Technology Discussed in Recent News

Title: DFE PWP Shale Shaker Screen Revolutionizes Drilling OperationsIntroduction:DFE PWP Shale Shaker Screen, manufactured by an industry-leading company (name removed), is making significant strides in the oil and gas industry. With its cutting-edge technology and superior performance, this revolutionary shale shaker screen is transforming drilling operations across the globe. By combining innovative design with enhanced durability, it promises to improve the efficiency and productivity of oil and gas exploration activities. In this news article, we will delve into the key features of the DFE PWP Shale Shaker Screen and explore its impact on the industry.1. High-Quality Design and Functionality:The DFE PWP Shale Shaker Screen boasts an exceptional design that sets it apart from traditional screens. Crafted with precision using top-grade materials, this screen offers unparalleled filtration efficiency and durability. The advanced technology integrated into its construction promotes optimal solids removal, ensuring efficient mud separation during the drilling process. By facilitating effective drilling fluid management, the DFE PWP Shale Shaker Screen significantly minimizes waste and decreases operational costs.2. Extended Service Life:One of the standout features of the DFE PWP Shale Shaker Screen is its extended service life. The screen is equipped with wear-resistant composite materials that can withstand rigorous drilling conditions and abrasive substances. This enhanced durability translates into lower replacement costs and reduced downtime for maintenance, benefiting drilling companies of all sizes. The prolonged service life of the DFE PWP Shale Shaker Screen ultimately leads to improved operational efficiency and higher profitability.3. Increased Operational Efficiency:The DFE PWP Shale Shaker Screen's innovative design contributes to enhanced efficiency in drilling operations. It promotes faster and more efficient mud filtration, preventing blockage and ensuring continuous drilling progress. The screen's increased open area and precise particle separation minimize the loss of valuable drilling fluid, optimizing the overall drilling process. With this screen, operators can achieve higher penetration rates, reduced non-productive time, and improved wellbore stability, ultimately leading to significant cost savings.4. Compatibility and Versatility:The DFE PWP Shale Shaker Screen offers compatibility with various shale shaker models, ensuring versatility and ease of integration within existing drilling rigs. This versatility makes it a versatile and practical solution for drilling companies operating globally. The screen's easy installation and compatibility reduce downtime during screen replacement and enhance overall operational efficiency.5. Sustainable and Environmentally Friendly:Recognizing the importance of sustainable practices in the oil and gas industry, the DFE PWP Shale Shaker Screen is designed with environmental considerations in mind. By improving the efficiency of solids control and mud management, this screen reduces waste generation and helps minimize the environmental impact of drilling activities. The use of top-grade materials in its construction ensures its long-lasting durability, further contributing to sustainable drilling operations.Conclusion:The DFE PWP Shale Shaker Screen has emerged as a game-changer in the oil and gas industry, offering a range of benefits that significantly enhance drilling operations. Its advanced filtration technology, extended service life, increased efficiency, compatibility, and sustainable qualities make it an ideal choice for drilling companies looking to optimize productivity and reduce costs. As the oil and gas industry continues to evolve, the DFE PWP Shale Shaker Screen plays a crucial role in driving progress and setting new standards for excellence in drilling operations.

Discover the Importance of Vibrating Screen Frequency for Optimal Efficiency

Vibrating Screen Frequency Advancements Revolutionize the Screening ProcessInnovative Technology Sets New Standards for Efficiency and Productivity[City], [Country] - The global industrial equipment market has witnessed tremendous growth over the years, driven by advancements in technology and increasing demand for efficient and sustainable solutions. One company at the forefront of this revolution is [Company Name], a leader in the development and manufacturing of vibrating screens. Their latest breakthrough, the new Vibrating Screen Frequency, is set to revolutionize the screening process.The traditional vibrating screens have been widely used in various industries such as mining, construction, and recycling. However, these screens often encounter challenges in terms of efficiency and productivity, hampering the overall effectiveness of the screening process. Recognizing these limitations, [Company Name] invested heavily in research and development to create the Vibrating Screen Frequency – a cutting-edge technology that promises to address these issues head-on.What sets the Vibrating Screen Frequency apart from its predecessors is its superior operating frequency. By increasing the frequency at which the screen vibrates, the screening efficiency is significantly improved. This means that more material can be processed in a shorter amount of time, leading to higher productivity and reduced operational costs. Additionally, the increased frequency allows for better separation of particles, resulting in higher quality end products.The Vibrating Screen Frequency also boasts enhanced versatility. It can be easily adjusted to accommodate different materials and particle sizes, making it suitable for a wide range of applications. Whether it is separating aggregates in the mining industry, classifying plastics in recycling processes, or grading sand in the construction field, the Vibrating Screen Frequency delivers accurate and precise results every time.Furthermore, the new technology offers advanced customization options. [Company Name] understands that different industries have specific screening requirements, and the Vibrating Screen Frequency can be tailored to meet these needs. With adjustable parameters such as amplitude and vibration direction, operators can optimize the screen's performance for their specific applications, maximizing efficiency and throughput.Another key advantage of the Vibrating Screen Frequency is its durability and reliability. Manufactured using high-quality materials and state-of-the-art engineering techniques, this innovative product is built to withstand the toughest operating conditions. It boasts a longer lifespan compared to conventional screens, reducing maintenance costs and downtime, ensuring uninterrupted production.In addition to its impressive technical features, [Company Name] is renowned for its commitment to sustainability. The Vibrating Screen Frequency aligns with their philosophy of providing eco-friendly solutions to the industry. By optimizing screening efficiency, this technology enables companies to reduce energy consumption and minimize their environmental footprint.[Company Name] has already received positive feedback from early adopters of the Vibrating Screen Frequency. Several companies have reported significant improvements in their screening processes, with increased productivity and higher-quality output. In fact, one mining company claims that the Vibrating Screen Frequency has helped them achieve a 20% increase in overall efficiency, translating into substantial cost savings and improved profitability.As global industries continue to prioritize efficiency and sustainability, groundbreaking technologies like the Vibrating Screen Frequency will play a crucial role in boosting productivity and reducing environmental impact. With its exceptional performance, versatility, and reliability, the Vibrating Screen Frequency is set to reshape the future of the screening process across various sectors.About [Company Name]:[Company Name] is a globally recognized leader in the development, manufacturing, and supply of industrial equipment. With a strong focus on innovation, they continuously strive to deliver cutting-edge solutions that enhance efficiency, productivity, and sustainability. Through their superior products and unwavering commitment to customer satisfaction, [Company Name] has established itself as a trusted partner for businesses worldwide.For more information about [Company Name] and their revolutionary Vibrating Screen Frequency, please visit their official website or contact their customer service department.Media Contact:[Contact Name][Company Name][Phone Number][Email Address]

Multi-Sizer Scalping Oil Shaker Screens: The Latest Innovation in Screening Technology

Scalping Oil Shaker Screens Revolutionizing the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to streamline operations and increase efficiency. One such advancement is seen in the form of eco-friendly oil shaker screens, aimed at enhancing the oil drilling process. Among the frontrunners in this domain is the groundbreaking VSM Multi-sizer Scalping Oil Shaker Screen, developed by a renowned industry player. This revolutionary product has not only created a buzz within the sector but also opened up new possibilities for the oil and gas industry.The VSM Multi-sizer Scalping Oil Shaker Screen, an integral component of the oil drilling process, offers numerous advantages that make it indispensable for drilling companies. Its breakthrough design ensures maximum efficiency in removing unwanted solids, such as cuttings and debris, from the drilling fluid. Such efficient solid control methods are crucial for maintaining the integrity of the drilling operation and ensuring a steady flow of oil or gas.One of the standout features of the VSM Multi-sizer Scalping Oil Shaker Screen is its adaptability to a wide range of drilling conditions. Irrespective of the drilling location or application, this versatile shaker screen is capable of handling it all. Its ability to handle a variety of drilling fluids, ranging from abrasive to corrosive, makes it ideal for even the most challenging drilling operations.Another noteworthy aspect of the VSM Multi-sizer Scalping Oil Shaker Screen is its durability and longevity. Manufactured using high-quality materials, combined with cutting-edge manufacturing techniques, this shaker screen boasts an impressive lifespan. Its rugged construction ensures it can withstand harsh conditions and endure heavy-duty use, thereby reducing the need for frequent replacements and saving costs for drilling companies.Furthermore, the eco-friendly nature of the VSM Multi-sizer Scalping Oil Shaker Screen is worth highlighting. In an era where sustainability and environmental consciousness are of utmost importance, this product aligns perfectly with the industry's green initiatives. By efficiently separating solids from drilling fluids, this shaker screen significantly reduces waste generation, promoting responsible drilling practices.The VSM Multi-sizer Scalping Oil Shaker Screen's user-friendly design also deserves recognition. It is easy to install and offers simple maintenance procedures, allowing for hassle-free operations on drilling rigs. This ease of use translates into saved time and increased productivity, enabling drilling companies to optimize their resources effectively.The impact of the VSM Multi-sizer Scalping Oil Shaker Screen on the oil and gas industry has not gone unnoticed. With its remarkable performance and cost-effectiveness, this innovative product has garnered significant attention from industry professionals and experts globally. It has been hailed as a game-changer, capable of revolutionizing the way drilling companies approach solids control during oil extraction.The company behind this groundbreaking product, {Company Name}, is a renowned name in the oil and gas industry. With a history of delivering cutting-edge solutions and continually pushing the boundaries of innovation, the company has solidified its position as a leader in the field. Committed to excellence and customer satisfaction, they have etched a mark in the industry through their relentless pursuit of technological advancements.In conclusion, the VSM Multi-sizer Scalping Oil Shaker Screen has set a new benchmark for solids control in the oil and gas industry. Its efficient and versatile design, coupled with its eco-friendly nature and user-friendly operations, has made it a preferred choice among drilling companies worldwide. With the support of industry leaders like {Company Name}, the future of the oil and gas industry looks promising, driven by advancements like the VSM Multi-sizer Scalping Oil Shaker Screen.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Lcm-3d Screen: A Breakthrough in Display Technology

Title: Cutting-edge LCM-3D Screen Technology Revolutionizes End-User ExperienceIntroduction:Innovations in screen display technology have been at the forefront of the electronics industry, constantly aiming to enhance the user experience through improved visual quality and engagement. One of the latest breakthroughs in this domain is the cutting-edge LCM-3D screen, developed by a leading technology company (Company XYZ). The LCM-3D screen not only elevates the visual experience but also redefines the way users engage with their electronic devices. This article will explore the key features of the LCM-3D screen and its potential implications for various industries.1. Enhanced Visual Quality:The LCM-3D screen features state-of-the-art display capabilities that deliver exceptional visual quality, surpassing traditional screens in terms of resolution, color vibrancy, and contrast. By employing advanced pixel technology and innovative backlighting solutions, the LCM-3D screen guarantees a more immersive and realistic viewing experience. Its ability to accurately reproduce colors and provide high pixel density ensures that users can enjoy crystal-clear details, whether they are watching movies, playing games, or editing photos and videos.2. Revolutionary 3D Experience:With its 3D functionality, the LCM-3D screen raises the bar for immersive viewing experiences. By incorporating cutting-edge parallax barrier technology, this screen eliminates the need for bulky and uncomfortable 3D glasses. Users can now enjoy stunning 3D content without any external accessories, allowing for a more convenient and natural viewing experience. The LCM-3D screen also provides adjustable depth control, enabling users to customize the level of 3D effect according to their preferences, thus further enhancing the depth and realism of the displayed content.3. Adaptive Display Technology:Unlike conventional screens, the LCM-3D offers adaptive display technology, which maximizes visual efficiency and comfort. This technology intelligently adjusts various display parameters, such as brightness and color temperature, based on ambient lighting conditions. This ensures optimal visual comfort while reducing eye strain, especially in low-light or high-glare environments. The adaptive display technology of the LCM-3D screen optimizes the viewing experience across different usage scenarios, making it suitable for a diverse range of applications.4. Applications across Multiple Industries:The LCM-3D screen's groundbreaking features hold tremendous potential for various industries. In gaming, it brings virtual worlds to life with its immersive 3D capabilities, offering gamers an unparalleled level of engagement. Architects and designers can benefit from the screen's ability to showcase 3D models with accurate depth perception, enabling them to visualize their creations more effectively. Additionally, the LCM-3D screen's vibrant colors and high resolution make it ideal for content creators, as it accurately displays the intricacies of their work.5. Environmental Responsibility:In line with the company's commitment to environmental sustainability, the LCM-3D screen incorporates energy-efficient technologies. It utilizes advanced power-saving features and materials to minimize power consumption, reducing its carbon footprint. This socially responsible approach not only benefits the environment but also provides cost savings for end-users by lowering energy bills.Conclusion:The LCM-3D screen represents a significant milestone in screen display technology, revolutionizing the way users engage with their electronic devices. Its enhanced visual quality, revolutionary 3D experience, adaptive display technology, and applications across multiple industries make it a game-changer in the market. With a commitment to environmental responsibility, the LCM-3D screen sets a new standard for immersive, sustainable, and visually stunning displays. As this technology continues to evolve and integrate into various devices, users can expect a more captivating and user-friendly experience across a wide range of industries.

PWP Screens: Unveiling the Impressive Derrick 2000 Series Design

Derrick 2000 Series PWP Screens Revolutionize the Oil and Gas IndustryWith the constant advancements in technology, the oil and gas industry is constantly evolving. One of the latest breakthroughs in the industry is the introduction of the Derrick 2000 Series PWP Screens. These innovative screens have revolutionized the way oil and gas is extracted and processed, leading to increased efficiency and productivity in the field.The Derrick 2000 Series PWP Screens, developed by a leading global provider of solids control and fine screening equipment, are known for their exceptional performance and durability. These screens are used in various applications, including shale shakers, desanders, desilters, and mud cleaners. They have been designed to withstand the demanding conditions of the oil and gas industry, ensuring optimum performance and reliability in any drilling operation.One of the key features of the Derrick 2000 Series PWP Screens is their superior cut point integrity. The screens are constructed with a unique ribbed design that provides enhanced strength and durability. This prevents the screens from sagging or bending under high pressure, ensuring a consistent cut point throughout their lifespan. The screens also feature a patented crown design, which increases the screen's surface area and improves fluid handling capacity.In addition to their exceptional durability, the Derrick 2000 Series PWP Screens are also highly efficient. They are created using advanced manufacturing techniques and high-quality materials, ensuring precise and accurate separation of solids from liquids. This results in cleaner fluids and higher-quality drilling mud, which in turn leads to improved wellbore stability and increased oil and gas production.Furthermore, the Derrick 2000 Series PWP Screens are designed for easy installation and maintenance. They are compatible with various shale shaker models and can be quickly and easily replaced when needed. This allows operators to minimize downtime and maximize operational efficiency. The screens are also engineered to minimize blinding and plugging, reducing the need for frequent cleaning and replacement.The introduction of the Derrick 2000 Series PWP Screens has garnered significant attention and praise within the oil and gas industry. Several major oil companies have already adopted these screens in their operations and have reported significant improvements in productivity and cost savings. The screens have been particularly effective in shale drilling applications, where precise separation of cuttings from drilling fluid is crucial for efficient drilling operations.The benefits of the Derrick 2000 Series PWP Screens extend beyond operational efficiency and cost savings. With their advanced solid control technology, these screens also contribute to environmental sustainability. By effectively removing solids from drilling fluid, the screens reduce the environmental impact of drilling operations, minimizing the discharge of contaminated fluids into the environment.In conclusion, the Derrick 2000 Series PWP Screens have revolutionized the oil and gas industry with their exceptional performance and durability. These screens have proven to be highly efficient, reliable, and easy to maintain, resulting in increased productivity and cost savings for oil and gas companies. With their advanced solid control technology, they also contribute to environmental sustainability, making them a valuable asset in the industry's ongoing efforts to minimize its environmental footprint. As more companies recognize the benefits of these screens, their adoption is expected to become widespread, further transforming the way oil and gas extraction is conducted.

How to Choose the Right Screen for Your Industrial Separation Needs

HanZhi Tech Unveils Cutting-Edge GNZS-833 Screen to Revolutionize Visual Display IndustryIn a remarkable breakthrough, HanZhi Tech, a leading innovator in the field of visual display solutions, has introduced the highly anticipated GNZS-833 Screen. This revolutionary display technology is set to redefine the way we perceive visual content, offering unmatched clarity, depth, and realism.HanZhi Tech, renowned for its commitment to pushing technological boundaries, has an impressive track record of delivering exceptional visual experiences to its customers. With the launch of the GNZS-833 Screen, the company has yet again raised the bar by offering a truly immersive and captivating visual display that is bound to leave audiences spellbound.This state-of-the-art screen boasts an array of advanced features that set it apart from its competitors. The GNZS-833 offers an astonishingly high resolution, creating images that are incredibly lifelike and vibrant. With a pixel density that surpasses anything seen before, every minute detail of the content displayed is brought to life with remarkable clarity.One of the key highlights of the GNZS-833 Screen is its exceptional color accuracy and reproduction capabilities. Leveraging the latest in display technology, HanZhi Tech has managed to achieve an unparalleled color gamut, allowing for true-to-life representation of colors. From deep blacks to vivid reds and blues, the GNZS-833 delivers visuals that are both captivating and true to the original intent of the content creator.Furthermore, the GNZS-833 Screen presents an impressive range of viewing angles, ensuring that everyone in the room can enjoy an optimal visual experience. A common limitation in traditional display technology is the loss of image quality when viewed from an angle, resulting in reduced enjoyment for those not directly in front of the screen. However, HanZhi Tech has overcome this obstacle by integrating advanced panel technology into the GNZS-833, enabling consistent picture quality regardless of the viewer's position.Additionally, the GNZS-833 boasts an impressively high refresh rate and response time, making it ideal for applications that require rapid image transitions and low latency. Whether for gaming, sports broadcasting, or fast-paced action sequences in movies, the GNZS-833 ensures a fluid and seamless viewing experience, immersing the audience in every frame with breathtaking clarity and smoothness.HanZhi Tech has not only focused on the technical aspects of the GNZS-833, but also on the user experience. The screen comes equipped with an intuitive user interface, allowing users to effortlessly navigate through settings and customize their viewing preferences. With the inclusion of smart features, such as voice control and compatibility with popular streaming platforms, HanZhi Tech aims to cater to the evolving needs of modern consumers.As HanZhi Tech continues to break new ground, the company remains committed to sustainability. The GNZS-833 Screen is designed with eco-friendly materials and adheres to stringent energy efficiency standards. By reducing power consumption and minimizing the environmental impact, HanZhi Tech has reaffirmed its dedication to a greener future.The GNZS-833 Screen by HanZhi Tech is a testament to the company's unwavering pursuit of excellence in the visual display industry. With its cutting-edge features, impeccable visual fidelity, and commitment to sustainability, the GNZS-833 is poised to transform the way we consume and appreciate visual content. Whether for entertainment, professional applications, or educational purposes, this groundbreaking display technology is set to elevate the viewing experience to unprecedented heights.

How Shaker Screen Plugs Can Impact Your Screening Efficiency

Title: Enhanced Efficiency and Durability: Introducing Next-Generation Shaker Screen PlugsIntroduction:In the continually evolving field of oil and gas exploration and production, technological advancements play a crucial role in improving efficiency and productivity. One such innovation is the development of shaker screen plugs, essential components of shale shaker systems. These plugs are designed to optimize the performance of the shaker screens by offering enhanced durability, efficiency, and cost-effectiveness. This article will shed light on this next-generation shaker screen plug technology, exploring its features, benefits, and the company behind its development.Company Background:(Insert company name) is a leading manufacturer and supplier of advanced drilling solutions to the oil and gas industry. With a proven track record of innovation and technical expertise, they have dedicated their efforts to developing cutting-edge products that aim to revolutionize the drilling process. Their commitment to research and development has earned them a reputation for reliability and efficiency, making them a trusted partner for oil and gas companies worldwide.Features of Next-Generation Shaker Screen Plugs:1. Improved Construction: The next-generation shaker screen plugs utilize state-of-the-art materials and engineering techniques to ensure robustness and longevity. They are manufactured using high-quality polymers, metals, or composites, resulting in excellent resistance to abrasion, corrosion, and impact.2. Enhanced Sealing Capability: These shaker screen plugs feature advanced sealing mechanisms that prevent fluid bypass, ensuring maximum efficiency during the separation process. The improved sealing capability minimizes screen blinding, reducing downtime and increasing the lifespan of the shaker screens.3. Customizable Designs: The company offers a wide range of shaker screen plug designs, catering to various shale shaker systems and specific drilling requirements. This customization ensures compatibility and seamless integration, further enhancing the overall performance and effectiveness of the drilling operation.4. Anti-Vibration Technology: Additionally, the shaker screen plugs are engineered with anti-vibration technology, which significantly reduces noise and vibrations during operation. The reduced vibration not only improves the working environment for personnel but also extends the life of the shaker screens and other vital components.Benefits of Next-Generation Shaker Screen Plugs:1. Increased Efficiency: By minimizing fluid bypass, the enhanced sealing capability of these shaker screen plugs enhances the efficiency of the separation process. This leads to improved overall drilling performance, reduced wastage of valuable drilling fluids, and lower maintenance costs.2. Extended Lifespan: The durable construction and superior sealing mechanism of these plugs contribute to increased durability and reduced wear and tear on the shaker screens. This extends their lifespan, reducing the frequency of replacement requirements and enhancing cost-effectiveness in the long run.3. Enhanced Environmental Compliance: With the reduction of screen blinding, these shaker screen plugs minimize the discharge of fine cuttings and drilling waste into the environment. This aligns with evolving environmental regulations and promotes sustainable drilling practices.4. Enhanced Operational Safety: The incorporation of anti-vibration technology in these plugs reduces noise and vibration levels during drilling operations. This improves the work environment for personnel, minimizing fatigue and potential health risks associated with prolonged exposure to high noise levels.Conclusion:As the oil and gas industry seeks new ways to improve operational efficiency and sustainability, the introduction of next-generation shaker screen plugs offers significant advantages. The advanced features, enhanced sealing capability, and customizable designs make them a powerful asset for drilling operations. With their extensive industry expertise and commitment to innovative solutions, (Insert company name) is poised to revolutionize the drilling process and set new standards for efficiency, durability, and sustainability.Note: Please remove all {} tags and insert appropriate company information before publication.