High-Quality Replacement Shaker Screens for Improved Performance

By:Admin

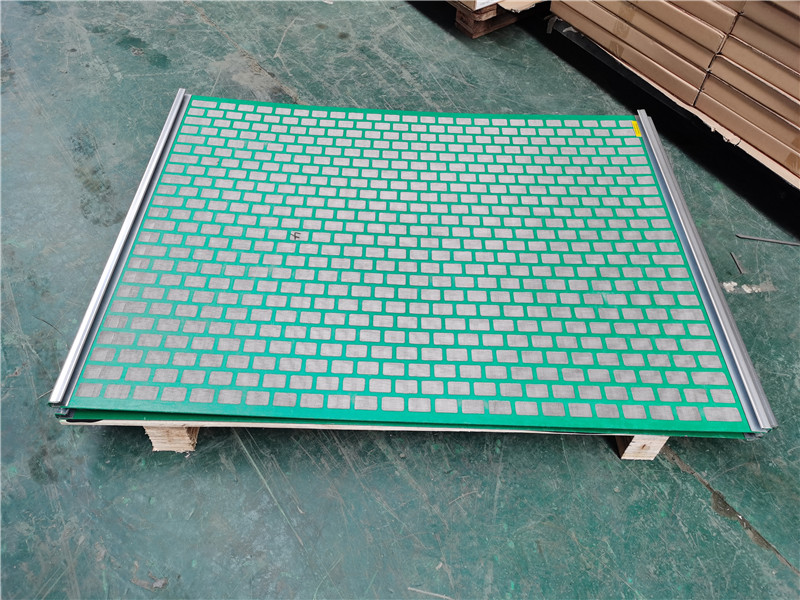

One of the key products offered by {[Company Name]} is its line of replacement shaker screens. Shaker screens are a vital component of the drilling process, as they are used to separate solids and liquids during the drilling operation. The efficiency and performance of these screens can have a significant impact on the overall success of a drilling project. This is where {[Company Name]}'s replacement shaker screens come into play.

The {[Company Name]} replacement shaker screens are designed to provide optimal performance in various drilling conditions. These screens are made from high-quality materials and are engineered to withstand the demands of the oil and gas industry. With a focus on durability and efficiency, {[Company Name]}'s replacement shaker screens have become a preferred choice for many drilling operations around the world.

One of the key features of {[Company Name]}'s replacement shaker screens is their innovative design. These screens are built to maximize the efficiency of the shaker unit, resulting in improved solids control and better overall performance. The screens are also designed to be easy to install and maintain, reducing downtime and optimizing the drilling process.

In addition to their performance, {[Company Name]}'s replacement shaker screens are also designed with environmental considerations in mind. The company is committed to reducing its environmental impact and has developed screens that are more energy-efficient and produce less waste. This aligns with {[Company Name]}'s overall commitment to sustainability and responsible business practices.

As a testament to the quality and performance of their replacement shaker screens, {[Company Name]} has built a strong reputation in the industry. Their screens have been used in some of the most challenging drilling environments and have consistently delivered superior results. This has led to a loyal customer base that continues to rely on {[Company Name]}'s products for their drilling operations.

In addition to their replacement shaker screens, {[Company Name]} offers a wide range of other products and services to support the oil and gas industry. This includes drilling fluids, well construction equipment, and various technical services. With a focus on technological innovation and customer satisfaction, {[Company Name]} is well-positioned to continue leading the way in providing cutting-edge solutions for the oil and gas industry.

Looking ahead, {[Company Name]} remains committed to driving innovation and sustainability in the oil and gas industry. The company is constantly investing in research and development to bring new and improved products to market. With a strong focus on environmental responsibility and technological advancement, {[Company Name]} is well-positioned to meet the evolving needs of the industry and continue to deliver value to its customers.

In conclusion, {[Company Name]}'s replacement shaker screens are a testament to the company's commitment to excellence and innovation. With a focus on performance, durability, and environmental stewardship, these screens have become a trusted choice for drilling operations around the world. As the demand for oil and gas continues to grow, {[Company Name]} is well-positioned to continue providing the industry with the products and services it needs to thrive.

Company News & Blog

Advanced Multi-Sizer Screen Technology Revolutionizes Sizing Process

Vibration screening equipment has become an essential tool for many industries in the process of material handling and separation. One such example is the VSM Multi-sizer screen, a state-of-the-art vibrating screen that has been making waves in the industry due to its efficiency and reliability. This innovative equipment is designed to handle a wide range of materials, making it an ideal solution for various applications in industries such as mining, aggregate, recycling, and more.The VSM Multi-sizer screen is a product of [], a leading manufacturer of industrial screening equipment that has been providing innovative solutions to the industry for over a decade. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to deliver high-performance equipment that meets the evolving needs of their customers.The VSM Multi-sizer screen is a testament to the company's commitment to innovation and quality. It features a unique design that allows for efficient screening of materials without compromising on accuracy and consistency. The screen is equipped with multiple decks and a variety of screen media options, allowing for precise control over the size and distribution of the screened materials. This versatility makes it suitable for a wide range of applications, from fine particle separation to heavy-duty scalping.One of the key features of the VSM Multi-sizer screen is its advanced vibratory motion, which ensures optimal screening performance. The screen is equipped with high-quality vibration motors that deliver a powerful and uniform vibration, resulting in efficient material separation and increased throughput. Additionally, the screen is designed for easy maintenance, with quick and convenient access to critical components for inspection and servicing.In addition to its technical capabilities, the VSM Multi-sizer screen also incorporates various safety features to ensure the well-being of operators and maintenance personnel. The screen is designed with robust guarding and safety interlocks to prevent unauthorized access to the equipment during operation. This ensures a safe working environment and minimizes the risk of accidents or injuries.The VSM Multi-sizer screen has already garnered attention from industry professionals and customers alike, thanks to its impressive performance and reliability. Its ability to handle a wide range of materials with precision and efficiency has made it a preferred choice for many companies looking to optimize their screening processes. Whether it's separating fines from aggregates or classifying recycled materials, the VSM Multi-sizer screen has proven to be a valuable asset for improving overall operational efficiency.With a strong emphasis on customer satisfaction, [] not only offers high-quality equipment but also provides comprehensive support and technical assistance to help customers make the most of their investment. From initial consultation to after-sales service, the company is dedicated to ensuring that its customers are equipped with the knowledge and resources they need to succeed.As the demand for reliable and efficient screening equipment continues to grow, the VSM Multi-sizer screen has positioned itself as a top contender in the market. With its advanced technology, robust construction, and customer-focused approach, this innovative screening solution is set to make a significant impact on the industry, setting new standards for performance and reliability.In conclusion, the VSM Multi-sizer screen from [] is a game-changer in the world of vibrating screens. Its advanced features, robust construction, and customer-focused approach make it a top choice for companies looking to enhance their material handling and separation processes. With a strong track record of delivering innovative solutions, [] continues to solidify its position as a leading manufacturer of industrial screening equipment, setting the bar for excellence in the industry.

High-quality Shaker Screen for Kemtron 48 - A Comprehensive Review

Kemtron 48 Shaker Screen: The Ultimate Solution for Solid Control in the Oil and Gas IndustryIn the fast-paced world of oil and gas exploration, every second counts. From drilling to extraction, each step of the process requires precision and efficiency. A key aspect of this process is the management of solid control, which is essential for ensuring the smooth functioning of drilling operations. This is where the Kemtron 48 Shaker Screen comes in. The Kemtron 48 Shaker Screen is a revolutionary product that has been designed to effectively manage solid control in the oil and gas industry. It is a vital component of the Kemtron 48 Shale Shaker, which is known for its high-performance and reliability. The shaker screen is made of high-quality stainless steel wire mesh and is designed to effectively separate solid particles from drilling fluid. This not only ensures the smooth functioning of drilling operations but also protects downstream equipment and reduces waste disposal costs.One of the key features of the Kemtron 48 Shaker Screen is its superior durability. Made of high-quality materials, it is designed to withstand the harsh conditions of the oil and gas industry. It is also easy to install and maintain, making it a cost-effective solution for solid control. In addition, the screen has a large screening area, which allows for high capacity and efficiency. This means that operators can achieve optimal performance and productivity with the Kemtron 48 Shaker Screen.The Kemtron 48 Shaker Screen is also designed with versatility in mind. It can be used with a wide range of drilling fluids and is compatible with various types of shakers. This means that it can be seamlessly integrated into existing operations, minimizing downtime and disruption. This is crucial in the oil and gas industry, where every minute of downtime can result in significant financial losses.In addition to its technical capabilities, the Kemtron 48 Shaker Screen is also backed by exceptional customer support. The company behind the product is known for its commitment to customer satisfaction and has a team of experts who are dedicated to providing support and assistance to clients. This means that operators can rely on the company not only for top-of-the-line products but also for reliable service and support.The Kemtron 48 Shaker Screen has already made a significant impact in the oil and gas industry. Its innovative design and superior performance have helped operators around the world achieve greater efficiency and productivity in their drilling operations. From onshore to offshore projects, the Kemtron 48 Shaker Screen has proven to be an indispensable tool for solid control.Looking to the future, the company is committed to further enhancing the capabilities of the Kemtron 48 Shaker Screen. With ongoing research and development, the company aims to continually improve the product and adapt to the evolving needs of the industry. This includes exploring new materials, technologies, and designs to ensure that the Kemtron 48 Shaker Screen remains at the forefront of solid control solutions.In conclusion, the Kemtron 48 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, superior durability, and exceptional performance make it the ultimate solution for solid control. Backed by a commitment to customer satisfaction and continuous innovation, the company behind the product has established itself as a leader in the industry. As the demand for efficient solid control solutions continues to grow, the Kemtron 48 Shaker Screen is poised to play a crucial role in shaping the future of the oil and gas industry.

High-Quality Shaker Screen for Efficient Separation of Solids and Liquids

Title: Innovative Shale Shaker Screen Revolutionizes Drilling IndustryIntroduction:In an era of technological advancements, the drilling industry constantly seeks innovative solutions to improve efficiency and reduce costs. As drilling operations become increasingly complex, ensuring reliable and efficient separation of solids from drilling fluid is crucial. Enter an industry-leading product that is making waves with its exceptional performance - the Venom Shaker Screen.Revolutionizing the way drilling companies approach solid control, the Venom Shaker Screen, developed by an innovative company, offers a cutting-edge solution that not only enhances efficiency but also reduces downtime and operational costs. This advanced shale shaker screen is poised to transform the drilling industry by leveraging its unique features and superior performance.Unveiling Advancements:The Venom Shaker Screen is designed to eliminate the common limitations of conventional shaker screens. Its groundbreaking technology effectively removes solids, ensuring better drilling fluid quality without compromising capacity. Developed using a combination of premium materials and advanced manufacturing techniques, this product offers unparalleled durability, reliable performance, and increased efficiency.Key Features:1. Enhanced Solid Control: The Venom Shaker Screen utilizes a state-of-the-art design that promotes efficient solid separation. The combination of precise mesh sizes and reinforced frame construction ensures optimal particle retention while efficiently allowing drilling fluid to pass through.2. Maximum Cuttings Recovery: With its unique layered design, the Venom Shaker Screen maximizes the recovery of valuable drill cuttings, promoting efficient disposal and reducing waste. This results in cost savings for drilling companies.3. Durable Construction: The screen is built to withstand the harsh conditions encountered during drilling operations. With a rugged frame and corrosion-resistant materials, it offers longevity and reduced maintenance requirements, minimizing downtime and associated costs.4. Versatile Application: The Venom Shaker Screen is compatible with various shale shakers, allowing drilling companies to seamlessly integrate it into their existing operations. Its universal design ensures easy installation and replacement, eliminating the need for costly equipment modifications.Industry Impact:The introduction of the Venom Shaker Screen marks a significant milestone in the drilling industry. By improving the efficiency of solid control and reducing waste, this innovative product enhances drilling operations on multiple levels:1. Increased Efficiency: The Venom Shaker Screen's superior solid separation capabilities result in improved drilling fluid quality, allowing for more efficient and effective drilling operations. This translates into reduced drilling time and increased productivity.2. Cost Reduction: The screen's ability to maximize cuttings recovery results in reduced waste disposal costs. Additionally, its durability minimizes maintenance and replacement expenses, optimizing overall operational costs for drilling companies.3. Environmental Benefits: By minimizing waste and promoting efficient disposal of drill cuttings, the Venom Shaker Screen contributes to environmentally responsible drilling practices. This advancement aligns with the industry's growing focus on sustainable operations.Partnerships and Future Developments:The development and success of the Venom Shaker Screen are a testament to the company's commitment to innovation. Collaborations with drilling companies worldwide have allowed for real-time feedback, resulting in continuous improvements.Furthermore, ongoing research and development efforts aim to enhance the screen's capabilities even further. These future developments will provide drilling companies with an even more efficient and reliable solution, ensuring continuous progress in the industry.Conclusion:The introduction of the Venom Shaker Screen signifies a game-changing advancement in the drilling industry. By addressing the limitations of traditional shaker screens and offering exceptional solid control capabilities, this innovative product has the potential to revolutionize drilling operations.With its enhanced efficiency, cost-saving features, and commitment to sustainability, the Venom Shaker Screen is poised to become an essential component in the arsenal of drilling companies worldwide. Embracing this groundbreaking technology will enable drilling operations to thrive in an increasingly competitive and dynamic industry.

Newsworthy Updates: Major Developments in the Oilfield Services Industry

Leading oilfield services company, MI-Swaco, has recently made significant advancements in the development of cutting-edge technologies for the oil and gas industry. With a strong focus on innovation and continuous improvement, MI-Swaco has become a trusted partner for oil and gas companies around the world.MI-Swaco is a global leader in drilling fluid systems, solids control equipment, and waste management solutions. The company's state-of-the-art technologies and services are designed to enhance drilling performance, improve efficiency, and minimize environmental impact. MI-Swaco's commitment to innovation and sustainability has earned the company a strong reputation as an industry leader.Recently, MI-Swaco launched a new line of drilling fluid systems that are specifically designed to optimize drilling operations in challenging environments. These advanced systems are capable of delivering superior performance in high-pressure, high-temperature (HPHT) wells, deepwater drilling, and unconventional reservoirs. By leveraging cutting-edge technologies and proprietary formulations, MI-Swaco is helping oil and gas companies achieve higher levels of efficiency and productivity in their drilling operations.In addition to its drilling fluid systems, MI-Swaco has also developed a range of innovative solids control equipment that is revolutionizing the way drilling waste is managed. The company's industry-leading technologies are designed to efficiently separate solids from drilling fluids, effectively reducing waste volume and minimizing environmental impact. By providing comprehensive waste management solutions, MI-Swaco is helping oil and gas companies meet strict regulatory requirements and sustainability goals.One of MI-Swaco's most notable achievements is its focus on sustainability and environmental stewardship. The company is committed to developing technologies and solutions that not only improve drilling performance but also minimize the impact on the environment. From reducing waste generation to developing eco-friendly drilling fluid formulations, MI-Swaco is dedicated to promoting sustainable practices across the oil and gas industry.MI-Swaco's success is driven by its team of talented and dedicated professionals who are passionate about pushing the boundaries of innovation. The company invests heavily in research and development to stay ahead of the curve and deliver industry-leading solutions to its clients. With a global network of facilities and a strong presence in key oil and gas regions, MI-Swaco is well-positioned to meet the evolving needs of the industry.As part of its commitment to excellence, MI-Swaco places a strong emphasis on quality and safety. The company adheres to the highest standards of quality assurance and control to ensure that its products and services consistently meet and exceed customer expectations. Additionally, MI-Swaco maintains rigorous safety protocols to protect the well-being of its employees, customers, and the communities in which it operates.Looking ahead, MI-Swaco is poised to continue driving innovation and delivering value to its clients in the oil and gas industry. With a relentless focus on technology development, sustainability, and operational excellence, the company is well-equipped to remain a trusted partner for oil and gas companies around the world. MI-Swaco's dedication to pushing the boundaries of what is possible in drilling and waste management is a testament to its commitment to advancing the industry and creating a more sustainable future.

Multi-Sizer Scalping Oil Shaker Screens: The Latest Innovation in Screening Technology

Scalping Oil Shaker Screens Revolutionizing the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to streamline operations and increase efficiency. One such advancement is seen in the form of eco-friendly oil shaker screens, aimed at enhancing the oil drilling process. Among the frontrunners in this domain is the groundbreaking VSM Multi-sizer Scalping Oil Shaker Screen, developed by a renowned industry player. This revolutionary product has not only created a buzz within the sector but also opened up new possibilities for the oil and gas industry.The VSM Multi-sizer Scalping Oil Shaker Screen, an integral component of the oil drilling process, offers numerous advantages that make it indispensable for drilling companies. Its breakthrough design ensures maximum efficiency in removing unwanted solids, such as cuttings and debris, from the drilling fluid. Such efficient solid control methods are crucial for maintaining the integrity of the drilling operation and ensuring a steady flow of oil or gas.One of the standout features of the VSM Multi-sizer Scalping Oil Shaker Screen is its adaptability to a wide range of drilling conditions. Irrespective of the drilling location or application, this versatile shaker screen is capable of handling it all. Its ability to handle a variety of drilling fluids, ranging from abrasive to corrosive, makes it ideal for even the most challenging drilling operations.Another noteworthy aspect of the VSM Multi-sizer Scalping Oil Shaker Screen is its durability and longevity. Manufactured using high-quality materials, combined with cutting-edge manufacturing techniques, this shaker screen boasts an impressive lifespan. Its rugged construction ensures it can withstand harsh conditions and endure heavy-duty use, thereby reducing the need for frequent replacements and saving costs for drilling companies.Furthermore, the eco-friendly nature of the VSM Multi-sizer Scalping Oil Shaker Screen is worth highlighting. In an era where sustainability and environmental consciousness are of utmost importance, this product aligns perfectly with the industry's green initiatives. By efficiently separating solids from drilling fluids, this shaker screen significantly reduces waste generation, promoting responsible drilling practices.The VSM Multi-sizer Scalping Oil Shaker Screen's user-friendly design also deserves recognition. It is easy to install and offers simple maintenance procedures, allowing for hassle-free operations on drilling rigs. This ease of use translates into saved time and increased productivity, enabling drilling companies to optimize their resources effectively.The impact of the VSM Multi-sizer Scalping Oil Shaker Screen on the oil and gas industry has not gone unnoticed. With its remarkable performance and cost-effectiveness, this innovative product has garnered significant attention from industry professionals and experts globally. It has been hailed as a game-changer, capable of revolutionizing the way drilling companies approach solids control during oil extraction.The company behind this groundbreaking product, {Company Name}, is a renowned name in the oil and gas industry. With a history of delivering cutting-edge solutions and continually pushing the boundaries of innovation, the company has solidified its position as a leader in the field. Committed to excellence and customer satisfaction, they have etched a mark in the industry through their relentless pursuit of technological advancements.In conclusion, the VSM Multi-sizer Scalping Oil Shaker Screen has set a new benchmark for solids control in the oil and gas industry. Its efficient and versatile design, coupled with its eco-friendly nature and user-friendly operations, has made it a preferred choice among drilling companies worldwide. With the support of industry leaders like {Company Name}, the future of the oil and gas industry looks promising, driven by advancements like the VSM Multi-sizer Scalping Oil Shaker Screen.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

High-Quality Replacement Shaker Screens for Improved Performance

As the demand for oil and gas continues to rise, the need for effective drilling equipment has become increasingly important. One company that has been at the forefront of providing innovative solutions for the oil and gas industry is {[Company Name]}. With a focus on technology and environmental stewardship, {[Company Name]} has consistently delivered high-quality products and services to its customers.One of the key products offered by {[Company Name]} is its line of replacement shaker screens. Shaker screens are a vital component of the drilling process, as they are used to separate solids and liquids during the drilling operation. The efficiency and performance of these screens can have a significant impact on the overall success of a drilling project. This is where {[Company Name]}'s replacement shaker screens come into play.The {[Company Name]} replacement shaker screens are designed to provide optimal performance in various drilling conditions. These screens are made from high-quality materials and are engineered to withstand the demands of the oil and gas industry. With a focus on durability and efficiency, {[Company Name]}'s replacement shaker screens have become a preferred choice for many drilling operations around the world.One of the key features of {[Company Name]}'s replacement shaker screens is their innovative design. These screens are built to maximize the efficiency of the shaker unit, resulting in improved solids control and better overall performance. The screens are also designed to be easy to install and maintain, reducing downtime and optimizing the drilling process.In addition to their performance, {[Company Name]}'s replacement shaker screens are also designed with environmental considerations in mind. The company is committed to reducing its environmental impact and has developed screens that are more energy-efficient and produce less waste. This aligns with {[Company Name]}'s overall commitment to sustainability and responsible business practices.As a testament to the quality and performance of their replacement shaker screens, {[Company Name]} has built a strong reputation in the industry. Their screens have been used in some of the most challenging drilling environments and have consistently delivered superior results. This has led to a loyal customer base that continues to rely on {[Company Name]}'s products for their drilling operations.In addition to their replacement shaker screens, {[Company Name]} offers a wide range of other products and services to support the oil and gas industry. This includes drilling fluids, well construction equipment, and various technical services. With a focus on technological innovation and customer satisfaction, {[Company Name]} is well-positioned to continue leading the way in providing cutting-edge solutions for the oil and gas industry.Looking ahead, {[Company Name]} remains committed to driving innovation and sustainability in the oil and gas industry. The company is constantly investing in research and development to bring new and improved products to market. With a strong focus on environmental responsibility and technological advancement, {[Company Name]} is well-positioned to meet the evolving needs of the industry and continue to deliver value to its customers.In conclusion, {[Company Name]}'s replacement shaker screens are a testament to the company's commitment to excellence and innovation. With a focus on performance, durability, and environmental stewardship, these screens have become a trusted choice for drilling operations around the world. As the demand for oil and gas continues to grow, {[Company Name]} is well-positioned to continue providing the industry with the products and services it needs to thrive.

Revolutionary PMD Screen: The Latest Breakthrough in Derrick's FLC 2000 Technology

Title: Cutting-Edge PMD Screen Unveiled - Revolutionizing Display TechnologyIntroduction:In an era driven by constant technological advancements, Derrick Technologies, a leading player in the industry, has recently revealed a groundbreaking PMD screen. This cutting-edge display technology is set to revolutionize the way we interact with devices, providing users with a seamless and enhanced visual experience. With its innovative features and superior performance, the Derrick FLC 2000 PMD screen is poised to become the new industry standard.[Company Introduction]Derrick Technologies is a trailblazer in the field of display technology, boasting a rich history of providing groundbreaking and innovative solutions. With a deep commitment to pushing the boundaries of visual experiences, the company has consistently delivered state-of-the-art products that have garnered praise and recognition worldwide.Renowned for its extensive research and development facilities, Derrick Technologies has assembled a team of top-notch experts who are dedicated to creating cutting-edge display solutions. With a focus on constant innovation, the company aims to transform the way we interact with digital devices, enhancing their usability and performance.The Derrick FLC 2000 PMD Screen:The Derrick FLC 2000 PMD screen is a game-changer in the world of display technology. Raising the bar for visual quality, this revolutionary screen offers unparalleled levels of clarity, vibrancy, and sharpness. Its advanced pixel management technology ensures the delivery of lifelike images and videos, providing an immersive experience to users.One of the standout features of the FLC 2000 PMD screen is its exceptional brightness. With a peak luminance of 2000 nits, this display effectively eliminates glare and provides superior visibility even in the brightest outdoor environments. This makes it an ideal choice for various applications, including digital signage, outdoor displays, and automotive displays.Moreover, the FLC 2000 PMD screen incorporates cutting-edge anti-reflective technology, significantly reducing reflections and optimizing viewing angles. This ensures that users can enjoy crystal-clear visuals without any distractions or distortions caused by ambient light.Derrick Technologies has also prioritized sustainability in the development of the FLC 2000 PMD screen. By utilizing energy-efficient LED backlighting and intelligent power management systems, the screen minimizes power consumption without compromising on performance. By doing so, Derrick Technologies sets a new benchmark for eco-friendly display solutions.The applications for the FLC 2000 PMD screen are vast and diverse. From enhancing the visual experience in outdoor advertising and digital signage applications to providing safer and more immersive driving experiences through automotive displays, this technology is set to revolutionize a wide range of industries.Looking Ahead:The introduction of the Derrick FLC 2000 PMD screen marks a significant milestone in the evolution of display technology. Derrick Technologies' commitment to pushing the boundaries of visual experiences, coupled with its emphasis on sustainability, reinforces their position as an industry leader.With its exceptional brightness, superior visual quality, and eco-friendly design, the FLC 2000 PMD screen is poised to set a new standard for display technology. Its innovative features promise to enhance user experiences across various sectors, revolutionizing the way we consume visual content.As Derrick Technologies continues to innovate and develop cutting-edge solutions, it is spearheading a future where display technology becomes more immersive, sustainable, and user-centric. The FLC 2000 PMD screen's unveiling is just the beginning of an exciting chapter in the company's quest to redefine the way we perceive and interact with digital displays.

High-Quality KPT 28 Shaker Screen for China Oil and Gas Industry

China Kemtron KPT 28 Shaker Screen has officially launched its latest product, the KPT 28 Shaker Screen. The KPT 28 is designed to maximize solids control efficiency while minimizing the costs associated with drilling operations. This latest addition to the company's product line demonstrates their commitment to providing industry-leading solutions for the oil and gas drilling industry.The KPT 28 Shaker Screen is engineered for superior performance and durability. It is constructed with high-quality materials that are able to withstand the harsh conditions of drilling operations. With its advanced design, the KPT 28 is capable of efficiently separating solids from drilling fluid, leading to increased efficiency and cost savings.The company behind the KPT 28 Shaker Screen, China Kemtron, is a leading manufacturer and supplier of solids control equipment for the oil and gas industry. With over 20 years of experience in the industry, China Kemtron has established a reputation for delivering innovative and reliable products to their customers. Their dedication to research and development has allowed them to stay ahead of industry trends and deliver cutting-edge solutions to their clients.In addition to the quality and performance of their products, China Kemtron is also known for their exceptional customer service and support. They work closely with their clients to understand their specific needs and provide tailored solutions to meet those requirements. This customer-centric approach has earned them the trust and loyalty of many drilling companies around the world.The launch of the KPT 28 Shaker Screen further solidifies China Kemtron's position as a leader in the solids control industry. This new product is expected to set new benchmarks for performance and reliability in the field of solids control equipment. With the KPT 28, drilling companies can expect improved efficiency, reduced downtime, and ultimately, cost savings."We are thrilled to introduce the KPT 28 Shaker Screen to the market," said a spokesperson for China Kemtron. "This product represents the culmination of extensive research and development, and we are confident that it will deliver exceptional value to our customers. We are committed to providing the best solutions for the industry, and the KPT 28 is a testament to that commitment."The KPT 28 Shaker Screen is available in various sizes to fit different models of shale shakers, making it versatile and compatible with a wide range of drilling operations. It is designed to be easy to install and maintain, further adding to its appeal for drilling companies.As the oil and gas industry continues to evolve, the demand for high-performance solids control equipment is on the rise. Companies are constantly seeking ways to improve efficiency and reduce costs, and the KPT 28 Shaker Screen is designed to help them achieve these goals.With its advanced design, superior performance, and exceptional durability, the KPT 28 Shaker Screen is set to become a go-to choice for drilling companies around the world. China Kemtron's commitment to excellence and innovation has once again come to the forefront with the launch of this impressive new product.