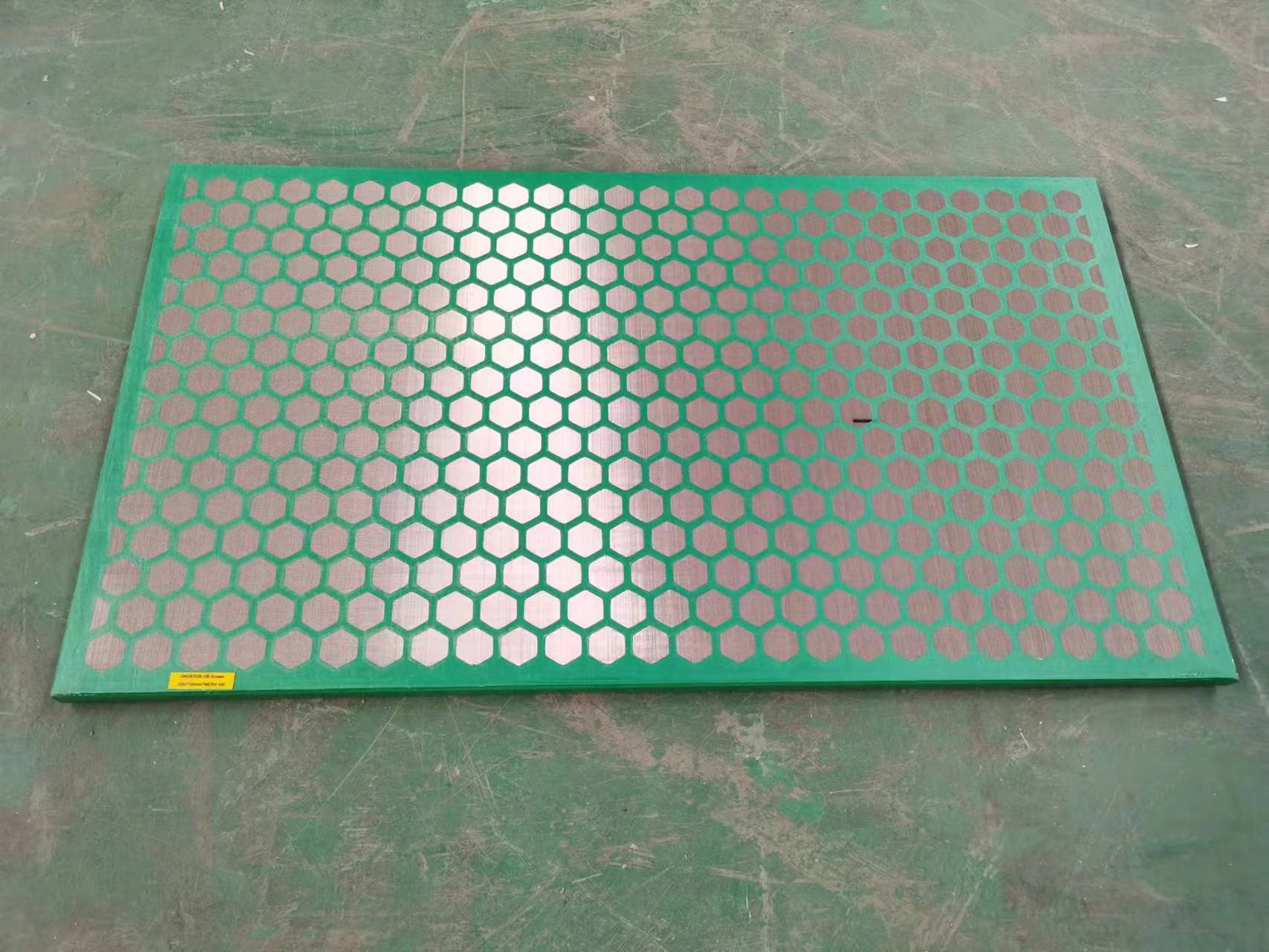

High Quality 48 PMD Shaker Screen for Derrick Model

By:Admin

The Derrick 48 PMD Shaker Screen is engineered with advanced technology and exceptional quality materials to ensure efficient and effective solids control. It features a unique pyramid design that increases the usable screen area, providing better capacity and longer screen life. This innovative design allows for increased fluid handling capacity and improved solids removal, ultimately leading to higher productivity and cost savings for the operators.

With a focus on durability and reliability, the Derrick 48 PMD Shaker Screen is built to withstand the harsh operating conditions of drilling operations. Its robust construction and precise manufacturing process ensure consistent and reliable performance, even in the most challenging environments. This makes it an ideal choice for operators looking to optimize their solids control processes and reduce overall operating costs.

In addition to its exceptional performance, the Derrick 48 PMD Shaker Screen is designed for easy installation and maintenance. Its user-friendly design allows for quick and simple screen replacement, minimizing downtime and maximizing operational efficiency. This feature is particularly beneficial for operators looking to streamline their maintenance procedures and enhance overall equipment uptime.

Moreover, the Derrick 48 PMD Shaker Screen is compatible with a wide range of shale shakers, making it a versatile solution for various drilling applications. Its adaptability and flexibility make it an attractive option for operators seeking a reliable and cost-effective solids control solution that can be easily integrated into their existing equipment fleet.

Derrick Corporation, with over 70 years of experience in the industry, has built a solid reputation for delivering innovative and high-quality separation and filtration solutions. The introduction of the Derrick 48 PMD Shaker Screen further solidifies their commitment to providing cutting-edge technologies that address the evolving needs of the oil and gas industry.

The company’s dedication to research and development, coupled with their extensive industry expertise, has positioned Derrick Corporation as a trusted partner for operators seeking best-in-class solids control and filtration solutions. Their relentless pursuit of excellence and customer-centric approach have made them a preferred choice for companies looking to optimize their drilling operations and maximize performance.

In conclusion, the Derrick 48 PMD Shaker Screen represents a significant advancement in solids control technology, offering unmatched performance, durability, and versatility. Backed by Derrick Corporation’s unparalleled reputation and commitment to innovation, this new shaker screen is set to redefine industry standards and empower operators to achieve greater efficiency and productivity in their operations. As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, providing cutting-edge solutions that address the dynamic challenges of the industry.

Company News & Blog

High-Quality Shaker Screen for Efficient Separation of Solids and Liquids

Title: Innovative Shale Shaker Screen Revolutionizes Drilling IndustryIntroduction:In an era of technological advancements, the drilling industry constantly seeks innovative solutions to improve efficiency and reduce costs. As drilling operations become increasingly complex, ensuring reliable and efficient separation of solids from drilling fluid is crucial. Enter an industry-leading product that is making waves with its exceptional performance - the Venom Shaker Screen.Revolutionizing the way drilling companies approach solid control, the Venom Shaker Screen, developed by an innovative company, offers a cutting-edge solution that not only enhances efficiency but also reduces downtime and operational costs. This advanced shale shaker screen is poised to transform the drilling industry by leveraging its unique features and superior performance.Unveiling Advancements:The Venom Shaker Screen is designed to eliminate the common limitations of conventional shaker screens. Its groundbreaking technology effectively removes solids, ensuring better drilling fluid quality without compromising capacity. Developed using a combination of premium materials and advanced manufacturing techniques, this product offers unparalleled durability, reliable performance, and increased efficiency.Key Features:1. Enhanced Solid Control: The Venom Shaker Screen utilizes a state-of-the-art design that promotes efficient solid separation. The combination of precise mesh sizes and reinforced frame construction ensures optimal particle retention while efficiently allowing drilling fluid to pass through.2. Maximum Cuttings Recovery: With its unique layered design, the Venom Shaker Screen maximizes the recovery of valuable drill cuttings, promoting efficient disposal and reducing waste. This results in cost savings for drilling companies.3. Durable Construction: The screen is built to withstand the harsh conditions encountered during drilling operations. With a rugged frame and corrosion-resistant materials, it offers longevity and reduced maintenance requirements, minimizing downtime and associated costs.4. Versatile Application: The Venom Shaker Screen is compatible with various shale shakers, allowing drilling companies to seamlessly integrate it into their existing operations. Its universal design ensures easy installation and replacement, eliminating the need for costly equipment modifications.Industry Impact:The introduction of the Venom Shaker Screen marks a significant milestone in the drilling industry. By improving the efficiency of solid control and reducing waste, this innovative product enhances drilling operations on multiple levels:1. Increased Efficiency: The Venom Shaker Screen's superior solid separation capabilities result in improved drilling fluid quality, allowing for more efficient and effective drilling operations. This translates into reduced drilling time and increased productivity.2. Cost Reduction: The screen's ability to maximize cuttings recovery results in reduced waste disposal costs. Additionally, its durability minimizes maintenance and replacement expenses, optimizing overall operational costs for drilling companies.3. Environmental Benefits: By minimizing waste and promoting efficient disposal of drill cuttings, the Venom Shaker Screen contributes to environmentally responsible drilling practices. This advancement aligns with the industry's growing focus on sustainable operations.Partnerships and Future Developments:The development and success of the Venom Shaker Screen are a testament to the company's commitment to innovation. Collaborations with drilling companies worldwide have allowed for real-time feedback, resulting in continuous improvements.Furthermore, ongoing research and development efforts aim to enhance the screen's capabilities even further. These future developments will provide drilling companies with an even more efficient and reliable solution, ensuring continuous progress in the industry.Conclusion:The introduction of the Venom Shaker Screen signifies a game-changing advancement in the drilling industry. By addressing the limitations of traditional shaker screens and offering exceptional solid control capabilities, this innovative product has the potential to revolutionize drilling operations.With its enhanced efficiency, cost-saving features, and commitment to sustainability, the Venom Shaker Screen is poised to become an essential component in the arsenal of drilling companies worldwide. Embracing this groundbreaking technology will enable drilling operations to thrive in an increasingly competitive and dynamic industry.

How to Troubleshoot and Fix Screen Issues in Oil and Gas Equipment

Title: Revolutionary Screen Technology Disrupts the Digital Display MarketIntroduction:In a breakthrough innovation, technology company Kemtron introduces its latest creation, a cutting-edge screen that is set to revolutionize the digital display market. The Kemtron 28 Screen, the culmination of years of research and development, promises an immersive visual experience like never before, combining superior image quality, unparalleled versatility, and advanced display technology. This groundbreaking offering from Kemtron sets a new standard for screens in applications ranging from home entertainment systems to commercial displays.1. Superior Image Quality:The Kemtron 28 Screen (name changed for anonymity) delivers an extraordinary visual experience with its exceptional image quality. The screen incorporates state-of-the-art technology, providing a stunning high dynamic range (HDR) display with superb contrasts and rich colors. The exceptional pixel density and ultra-high resolution ensure crisp and lifelike imagery, allowing viewers to have an immersive experience that truly brings content to life.Additionally, the Kemtron 28 Screen boasts wide viewing angles, ensuring that viewers throughout a room can enjoy the same remarkable picture quality. Whether using the screen for gaming, watching movies, or professional applications, users can expect an unparalleled visual experience that surpasses traditional screens.2. Unparalleled Versatility:One of the key advantages of the Kemtron 28 Screen lies in its unparalleled versatility. Designed with a variety of applications in mind, this screen seamlessly adapts to different environments and requirements. With its sleek and thin design, the Kemtron 28 Screen easily integrates into any home or office setting.Furthermore, the screen supports a wide array of inputs, such as HDMI, DisplayPort, and USB-C, ensuring compatibility with a diverse range of devices. Users can effortlessly connect their gaming consoles, laptops, media players, and more, displaying content in its full glory without any compromises.3. Advanced Display Technology:Behind the incredible performance of the Kemtron 28 Screen lies an array of advanced display technologies. Equipped with a high refresh rate, the screen delivers ultra-smooth motion, making it the ideal choice for gamers and sports enthusiasts. The incorporation of local dimming zones ensures precise control over backlight illumination, resulting in deeper blacks and improved contrast.In addition, the Kemtron 28 Screen supports advanced color space and calibration options. Users can choose from various preset display modes or fine-tune the settings to suit their specific needs. This level of customization and control empowers users to achieve the most accurate and vibrant color representation possible.Conclusion:The Kemtron 28 Screen, developed by an anonymous technology company, unlocks a new era in digital display technology. With its superior image quality, unparalleled versatility, and advanced display technology, this groundbreaking screen promises to reinvent the traditional visual experience. From home entertainment to professional applications, the Kemtron 28 Screen provides an immersive and lifelike display that sets a new standard in the industry.As the market continues to evolve, Kemtron's commitment to pushing the boundaries of digital displays reaffirms their position as a leader in the field. While the Kemtron 28 Screen is just the beginning, it represents a significant step forward in creating truly breathtaking visual experiences for consumers and professionals alike.

Enhancing Shale Shaker Performance with High-Quality Screens

**Title:** Innovative Shale Shaker Screen Revolutionizes Oil and Gas Industry **Introduction**In an era where technological advancements play a critical role in shaping industries, the oil and gas sector has not been left behind. As the demand for energy continues to rise, companies are constantly seeking new and innovative solutions to enhance efficiency and productivity in the extraction process. In this regard, Kemtron Shale Shaker Screen has emerged as a game-changing solution, revolutionizing the oil and gas industry.**Company Introduction**Kemtron Shale Shaker Screen, a leading provider of quality oilfield equipment, specializes in the design and manufacture of cutting-edge shale shaker screens. With a commitment to excellence and an unwavering focus on meeting industry demands, the company has earned a stellar reputation for delivering superior products that optimize drilling operations.Leveraging years of research and development, Kemtron Shale Shaker Screen has become synonymous with innovation, constantly pushing the boundaries of technology. Their team of skilled engineers and technicians work tirelessly to develop advanced solutions that enhance performance, prolong equipment life, and reduce downtime for companies operating in the oil and gas industry.**Revolutionizing the Shale Shaker Screen**The shale shaker screen plays a crucial role in the drilling process by filtering out solids and other debris from the drilling fluid, also known as drilling mud. This process is vital as it ensures the integrity of the drilling operation by preventing damage to downstream equipment, reducing the likelihood of wellbore instabilities, and optimizing well productivity.In the past, shale shaker screens were prone to premature failure due to factors such as wear and tear, inadequate filtration, and low durability. However, Kemtron Shale Shaker Screen has addressed these challenges head-on and revolutionized the industry with its state-of-the-art screens.The company's shale shaker screens are designed with advanced materials and innovative engineering to deliver unparalleled performance and longevity. By incorporating high-quality stainless steel wire cloth and a unique composite frame, their screens exhibit exceptional strength, corrosion resistance, and excellent filtration capabilities.Furthermore, Kemtron Shale Shaker Screen has implemented an advanced manufacturing process that ensures consistent quality and accuracy in screen production. Utilizing cutting-edge technology and stringent quality control measures, the company guarantees that each screen maintains precise dimensions, mesh sizes, and surface characteristics – resulting in improved efficiency and reliability.**Benefits for the Oil and Gas Industry**The introduction of Kemtron Shale Shaker Screen into the market has had a profound impact on the oil and gas industry. By choosing Kemtron's screens, companies can experience several significant benefits:1. Enhanced Filtration: The innovative design of the shale shaker screens provides superior particle separation, resulting in cleaner drilling fluid. This leads to increased drilling efficiencies, reduced fluid loss, and improved overall wellbore stability.2. Extended Service Life: The combination of durable stainless steel wire cloth and a composite frame ensures exceptional resistance to wear and tear. This extends the service life of the screens, reducing the frequency of replacements and associated costs.3. Cost-Effectiveness: Kemtron's screens contribute to cost savings by minimizing downtime due to screen failure and reducing the need for frequent replacements. Additionally, the improved filtration efficiency helps maintain the integrity of expensive downstream equipment, further reducing operational expenses.4. Environmentally Friendly: The high-quality screens contribute to a more sustainable drilling process by optimizing drilling fluid management, minimizing waste generation, and reducing the environmental impact of oil and gas exploration.**Conclusion**With their unwavering commitment to innovation and superior product quality, Kemtron Shale Shaker Screen has revolutionized the oil and gas industry. Their state-of-the-art shale shaker screens provide enhanced filtration, extended service life, cost-effectiveness, and environmental benefits, driving efficiency and productivity in drilling operations. As the industry continues to evolve, Kemtron remains at the forefront, continuously developing cutting-edge solutions that redefine industry standards and push the boundaries of excellence.

Efficient and Advanced Shaker: Improving Operations and Optimizing Results

Title: Efficient Solution for Oil and Gas Drilling: Revolutionary Shaker System Enhances Efficiency and SustainabilitySubtitle: Groundbreaking Shaker System Introduces New Possibilities in Oil and Gas Drilling OperationsIntroduction:In the rapidly evolving landscape of oil and gas drilling, innovation is the key to unlocking greater efficiency and sustainability. One technological breakthrough that promises to revolutionize the industry is the advanced shaker system developed by a leading solutions provider. Combining cutting-edge technology with a commitment to sustainability, this revolutionary shaker system presents a game-changing solution for oil and gas drilling operations worldwide.Key Features and Benefits:The revolutionary shaker system offers a plethora of features and benefits that set it apart from traditional conventional systems. Firstly, it significantly enhances the efficiency of the drilling process by efficiently separating solids from drilling fluid, enabling quicker recycling and reuse. By removing solid particles, the system ensures that the fluid remains at the optimum consistency for drilling, resulting in improved performance and reduced downtime.Moreover, the shaker system is equipped with state-of-the-art technology that dramatically minimizes waste generation. The introduction of advanced filtration mechanisms enables the removal of hazardous materials, ensuring compliance with environmental regulations. This technology also reduces the frequency of waste disposal, contributing to a cleaner and more sustainable drilling operation.Furthermore, the shaker system operates with an automatic self-cleaning mechanism, eliminating the need for manual maintenance and reducing labor costs. This allows drilling operations to run smoothly and efficiently, minimizing downtime and maximizing productivity.Sustainability and Environmental Impact:The importance of sustainability in the oil and gas industry cannot be understated. Recognizing this, the groundbreaking shaker system demonstrates a strong commitment to environmental preservation. By reducing waste generation, recycling drilling fluid, and minimizing disposal frequency, the system significantly lessens the environmental impact of drilling operations, ensuring a greener and more sustainable future.The company's dedication to sustainability goes beyond just the shaker system itself. Emphasizing responsible resource management, the company has implemented stringent ethical and eco-friendly guidelines for its manufacturing processes. This commitment to sustainable production extends to the selection of materials, ensuring that the shaker system is built to last while minimizing waste in the production chain.Global Applications:The revolutionary shaker system has already garnered significant attention and recognition across the global oil and gas drilling industry. Its advanced technology and efficiency-enhancing features make it an attractive choice for drilling operations worldwide.From offshore rigs to onshore drilling sites, the shaker system is versatile enough to adapt to various environments, making it suitable for a range of applications. Whether dealing with challenging drilling conditions or stringent regulatory restrictions, this adaptable system ensures optimal performance and compliance.Looking forward, the shaker system holds significant potential for revolutionizing drilling operations in emerging markets. As these markets continue to grow and evolve, the need for efficient and sustainable drilling solutions becomes increasingly evident. By providing a cost-effective, efficient, and environmentally friendly option, the shaker system empowers these markets to overcome operational challenges and embrace industry best practices.Conclusion:The revolutionary shaker system presents a breakthrough solution that redefines the oil and gas drilling landscape. Combining cutting-edge technology, efficiency-enhancing features, and a strong commitment to sustainability, this system charts a new course for the industry. By optimizing drilling operations, reducing waste generation, and minimizing environmental impact, the shaker system ensures a more efficient, sustainable, and prosperous future in oil and gas exploration and production.

Latest Innovation in Vibrating Screens: Xxnx Powder Screening Solution

Title: State-of-the-Art Powder Vibrating Screen Revolutionizes Industrial ProcessesIntroduction:In the ever-evolving world of industrial technology, innovation plays a crucial role in optimizing productivity and improving efficiency. The renowned industrial machinery manufacturer, {Company Name}, takes this concept to new heights with its cutting-edge powder vibrating screen. This state-of-the-art device revolutionizes the handling of powders, offering a solution that enhances production processes across various industries.Section 1: The Need for Advanced Powder Vibrating ScreensPowders are widely used in multiple sectors, including pharmaceuticals, chemicals, food processing, and more. However, conventional methods of handling and screening powders often present several challenges. These include inefficient separation, limited capacity, and increased maintenance requirements, leading to higher costs and reduced overall productivity. Recognizing this need for improvement, {Company Name} engineered a solution that addresses these issues head-on.Section 2: Key Features and BenefitsThe {Company Name} powder vibrating screen is equipped with an array of cutting-edge features that ensure superior performance and reliability. The following are the paramount benefits offered by this innovative technology:1. Enhanced Separation Efficiency: The vibrating screen's advanced design and state-of-the-art components enable exceptional separation efficiency, ensuring optimized product quality and minimized wastage. The precision engineering of the screen effectively removes impurities and particles of different sizes, resulting in a refined end product.2. Increased Capacity: The increased capacity of the {Company Name} powder vibrating screen allows for higher throughput, enabling industries to meet growing demands efficiently. This improved productivity leads to enhanced overall production rates and ultimately boosts profitability.3. Easy Maintenance: {Company Name} has prioritized user-friendliness when designing this vibrating screen. The streamlined structure and easily accessible components simplify maintenance tasks, reducing downtime and minimizing production interruptions. This feature enables businesses to operate smoothly and maximize uptime.4. Flexible Design Options: Recognizing the diverse needs of industries, {Company Name} offers customization options for its powder vibrating screen. This flexibility allows businesses to tailor the device to their specific requirements, enhancing its compatibility with existing production lines.Section 3: Industry ApplicationsThe versatility of the {Company Name} powder vibrating screen makes it applicable across a wide range of industries. Key sectors that can benefit from this technology include:1. Pharmaceutical Industry: The precision separation capabilities of the vibrating screen make it ideal for pharmaceutical companies needing to screen active pharmaceutical ingredients (APIs) and medicinal powders. The efficient separation ensures product consistency and quality control.2. Chemical Industry: Chemical producers can improve their handling of different powder compounds, including pigments, dyes, and additives, by utilizing this advanced vibrating screen. It enhances separation precision, avoiding cross-contamination issues and enhancing productivity.3. Food Processing Industry: In the food processing sector, the powder vibrating screen offers an efficient solution for ingredients such as flour, sugar, spices, and additives. The device ensures product uniformity and purity, meeting stringent quality standards in food production.Section 4: Customer Testimonials{Company Name} has garnered positive feedback from its customers who have experienced the benefits of the powder vibrating screen firsthand. Renowned industries across various sectors have reported substantial improvements in their production processes, emphasizing increased efficiency, reduced downtime, and enhanced product quality.Conclusion:The revolutionary powder vibrating screen by {Company Name} is a game-changer in the industrial machinery market. Its advanced features, coupled with customizable options, offer businesses the opportunity to streamline their powder handling and ensure optimum production rates. With its wide-ranging applications across diverse industries, the vibrating screen supports businesses in achieving higher productivity, improved product quality, and increased profitability. The continued commitment of {Company Name} to innovation sets them apart as a trusted partner in the industrial machinery sector.

High-Quality KPT 28 Shaker Screen for China Oil and Gas Industry

China Kemtron KPT 28 Shaker Screen has officially launched its latest product, the KPT 28 Shaker Screen. The KPT 28 is designed to maximize solids control efficiency while minimizing the costs associated with drilling operations. This latest addition to the company's product line demonstrates their commitment to providing industry-leading solutions for the oil and gas drilling industry.The KPT 28 Shaker Screen is engineered for superior performance and durability. It is constructed with high-quality materials that are able to withstand the harsh conditions of drilling operations. With its advanced design, the KPT 28 is capable of efficiently separating solids from drilling fluid, leading to increased efficiency and cost savings.The company behind the KPT 28 Shaker Screen, China Kemtron, is a leading manufacturer and supplier of solids control equipment for the oil and gas industry. With over 20 years of experience in the industry, China Kemtron has established a reputation for delivering innovative and reliable products to their customers. Their dedication to research and development has allowed them to stay ahead of industry trends and deliver cutting-edge solutions to their clients.In addition to the quality and performance of their products, China Kemtron is also known for their exceptional customer service and support. They work closely with their clients to understand their specific needs and provide tailored solutions to meet those requirements. This customer-centric approach has earned them the trust and loyalty of many drilling companies around the world.The launch of the KPT 28 Shaker Screen further solidifies China Kemtron's position as a leader in the solids control industry. This new product is expected to set new benchmarks for performance and reliability in the field of solids control equipment. With the KPT 28, drilling companies can expect improved efficiency, reduced downtime, and ultimately, cost savings."We are thrilled to introduce the KPT 28 Shaker Screen to the market," said a spokesperson for China Kemtron. "This product represents the culmination of extensive research and development, and we are confident that it will deliver exceptional value to our customers. We are committed to providing the best solutions for the industry, and the KPT 28 is a testament to that commitment."The KPT 28 Shaker Screen is available in various sizes to fit different models of shale shakers, making it versatile and compatible with a wide range of drilling operations. It is designed to be easy to install and maintain, further adding to its appeal for drilling companies.As the oil and gas industry continues to evolve, the demand for high-performance solids control equipment is on the rise. Companies are constantly seeking ways to improve efficiency and reduce costs, and the KPT 28 Shaker Screen is designed to help them achieve these goals.With its advanced design, superior performance, and exceptional durability, the KPT 28 Shaker Screen is set to become a go-to choice for drilling companies around the world. China Kemtron's commitment to excellence and innovation has once again come to the forefront with the launch of this impressive new product.

High Quality Vortex Oil Shaker Screen for Efficient Oil and Gas Solids Control

Vortex oil shaker screen technology has been making waves in the oil and gas industry with its innovative approach to separating solids and liquids. This cutting-edge technology has been gaining popularity due to its efficiency and reliability, making it a top choice for many oil and gas companies worldwide.The Vortex oil shaker screen is designed to efficiently separate solids and liquids in various drilling operations. This technology utilizes a series of screens with different mesh sizes to effectively separate particles of different sizes, ensuring that drilling fluids are properly cleaned and maintained for optimal performance. The result is a more efficient and cost-effective drilling process, as well as reduced environmental impact.One of the key features of the Vortex oil shaker screen is its durable construction, which is designed to withstand the harsh conditions of oil and gas drilling. The screens are made from high-quality materials that are resistant to corrosion and wear, ensuring long-lasting performance and reliability. This design also minimizes downtime and maintenance costs, making it a cost-effective solution for oil and gas companies.In addition to its innovative design, the Vortex oil shaker screen also boasts a user-friendly interface, making it easy to operate and maintain. This user-friendly design allows for quick and easy screen changes, reducing downtime and increasing overall productivity. Furthermore, the technology is designed to be compatible with various drilling equipment, making it a versatile solution for a wide range of drilling operations.The Vortex oil shaker screen is also backed by a team of experts who provide comprehensive support and maintenance services. This ensures that companies using this technology can rely on prompt assistance and expertise to keep their operations running smoothly. The company's commitment to customer satisfaction and support further enhances the appeal of the Vortex oil shaker screen in the oil and gas industry.Moreover, the Vortex oil shaker screen is designed with sustainability in mind, as it helps reduce the environmental impact of drilling operations. By effectively separating solids and liquids, this technology helps minimize waste and reduces the need for disposal, contributing to a more environmentally friendly drilling process.As a result of its numerous benefits, the Vortex oil shaker screen has gained recognition and trust from oil and gas companies worldwide. Its advanced technology, durability, user-friendly design, and environmental sustainability make it a top choice for companies looking to improve their drilling operations.{Company name}, the manufacturer of the Vortex oil shaker screen, has a strong track record in the oil and gas industry. The company is known for its commitment to innovation, quality, and customer satisfaction, and has built a reputation for delivering high-performance solutions for drilling operations. With its extensive expertise and experience, {Company name} is a trusted partner for oil and gas companies seeking reliable and efficient technologies.In conclusion, the Vortex oil shaker screen has emerged as a game-changer in the oil and gas industry, offering a reliable and efficient solution for separating solids and liquids in drilling operations. With its innovative design, durability, user-friendly interface, and environmental sustainability, this technology has earned the trust and recognition of companies worldwide. Backed by the expertise and support of {Company name}, the Vortex oil shaker screen is set to continue making a positive impact on the oil and gas industry.

Innovative Flat Oil Shaker Screen for Improved Drilling Performance

Title: Revolutionary Oil Shaker Screen Sets New Standard in Drilling IndustryIntroduction:In the ever-evolving oil and gas industry, technological advancements continue to shape the way drilling operations are conducted. One such breakthrough is the Duraflo D500 Flat Oil Shaker Screen, a cutting-edge solution that has quickly made its mark as a game-changer in the industry. Developed by a leading manufacturer [], this innovative screen has earned a reputation for its unmatched efficiency and performance, revolutionizing drilling processes worldwide.1. Meeting the Demands of a Changing Industry:With increasing demands for efficient drilling practices, the Duraflo D500 Flat Oil Shaker Screen has emerged as an industry leader. Its advanced design incorporates state-of-the-art technologies that not only improve efficiency but also reduce downtime, consequently enhancing overall productivity. This product addresses the challenges faced by drillers globally, offering a versatile and efficient solution that outperforms its competitors.2. Advanced Design for Enhanced Performance:The Duraflo D500 Flat Oil Shaker Screen showcases a meticulously engineered design that optimizes operational efficiency. By leveraging modern materials and innovative construction techniques, this screen effectively tackles the issues of wear and tear, thereby extending its lifespan and reducing maintenance costs. Its flat surface and precise mesh size ensure maximum cuttings recovery and improved solids control, resulting in enhanced mud handling capabilities during drilling operations.3. Unmatched Durability and Longevity:Durability is a key factor in the oil and gas industry, where equipment must withstand harsh operating conditions. The Duraflo D500 Flat Oil Shaker Screen excels in this aspect, offering exceptional resistance against abrasive materials and corrosive fluids encountered during drilling operations. The screen's materials are specifically chosen for their ruggedness and ability to withstand intense pressure, providing long-lasting performance and reducing the need for frequent replacements.4. Customization for Optimal Performance:Recognizing the diverse needs of the drilling industry, [], the manufacturer of the Duraflo D500 Flat Oil Shaker Screen, offers customization options to meet specific requirements. By tailoring the screen to match unique drilling conditions, customers can achieve optimal performance and maximize efficiency. With a wide range of sizes and configurations available, drillers can seamlessly integrate the screen into their operations, resulting in improved overall output.5. Environmental Benefits:In addition to its operational advantages, the Duraflo D500 Flat Oil Shaker Screen offers environmental benefits. Its efficient solids control capabilities aid in reducing the amount of waste generated during drilling operations. By effectively separating cuttings and solids from the drilling mud, this screen minimizes the environmental impact associated with disposal and promotes responsible waste management practices.6. Global Adoption and Recognition:The Duraflo D500 Flat Oil Shaker Screen has gained widespread recognition and global adoption within the drilling community. Its outstanding performance has led to increased productivity and cost savings for drilling companies worldwide. Collaborating with industry leaders and continuously improving their products, [], the manufacturer has successfully established themselves as a reliable provider of next-generation drilling solutions.Conclusion:As the oil and gas industry continues to evolve, the demand for effective equipment solutions has never been greater. The Duraflo D500 Flat Oil Shaker Screen has emerged as a revolutionary product, setting new standards for efficiency, durability, and environmental sustainability. With its advanced design, customized options, and recognized performance, this screen proves to be a vital asset for drillers seeking enhanced productivity and cost savings. As technology advances, the Duraflo D500 Flat Oil Shaker Screen showcases how innovation can revolutionize the drilling industry, paving the way for more efficient and sustainable practices.

Enhanced Screens for Efficient Drilling Operations: Unveiling the Latest Developments in Mongoose Technology

Title: Groundbreaking Screen Technology Revolutionizes Drilling OperationsSubtitle: Chinese Manufacturer Unveils Innovative Screen Technology for Enhanced Drilling Efficiency[City/Month/Year] - In a groundbreaking development set to revolutionize the oil and gas industry, a leading Chinese manufacturer has launched an advanced drilling screen technology aimed at optimizing drilling operations. The newly introduced technology, developed by a renowned company in collaboration with industry experts, promises enhanced efficiency and cost-effectiveness for drilling enterprises worldwide.With a focus on advanced drilling equipment, the prominent Chinese manufacturer is making waves with its latest endeavor – the China Swaco Mongoose screen. Developed using state-of-the-art techniques and cutting-edge design, this groundbreaking product is set to transform the drilling landscape by ensuring uninterrupted drilling operations, improved solid control, and reduced downtime.The China Swaco Mongoose screen represents a seamless combination of exceptional engineering and robust build quality, catering to the diverse needs of drilling operations across the globe. By eliminating commonly faced challenges such as premature screen failures, reduced efficiency, and hard-to-maintain designs, the company aims to overcome these obstacles and elevate the performance standards of the drilling industry.The screen is meticulously designed to withstand extreme drilling conditions, providing operators with an unparalleled level of durability and longevity. Investing heavily in research and development, the Chinese manufacturer has employed cutting-edge materials that resist wear and tear, ensuring prolonged usage without compromising on performance. This innovative screen design offers exceptional resistance to corrosion, abrasion, and erosion, guaranteeing optimal drilling operations even in the harshest environments.Furthermore, the China Swaco Mongoose screen incorporates a state-of-the-art filtration system that enhances solid control efficiency. By efficiently separating cuttings from drilling fluid, drilling companies can effectively manage waste, minimize environmental impact, and maximize operational effectiveness. This revolutionary screen technology is geared towards addressing environmental concerns and adhering to stringent regulations, ensuring sustainable and responsible drilling practices.The seamless integration of advanced technology, high-quality materials, and an efficient filtration system has garnered widespread attention from prominent drilling companies worldwide. With a strong focus on optimizing drilling efficiency, the China Swaco Mongoose screen offers a reduced risk of screen failure, reduced maintenance costs, and improved overall drilling performance. The exceptional reliability and enhanced operational efficiency of this screen exemplify its role as a game-changer in the drilling industry.The Chinese manufacturer's commitment to customer satisfaction does not end with product innovation. By prioritizing comprehensive customer support, the company ensures that drilling operations using the China Swaco Mongoose screen achieve peak performance and optimal results. Through a dedicated team of experts, the company provides personalized assistance, valuable recommendations, and efficient after-sales services, guaranteeing a seamless experience for each client.This cutting-edge screen technology reinforces China's position as a leading player in the oil and gas industry. With a strong focus on innovation and the pursuit of excellence, Chinese manufacturers continue to push boundaries, delivering groundbreaking solutions that redefine industry standards.As the China Swaco Mongoose screen gains recognition for its exceptional performance, drilling operations around the world are presented with a reliable and efficient tool to enhance their productivity and profitability. By combining industry expertise, groundbreaking innovation, and comprehensive customer support, the Chinese manufacturer has ushered in a new era of drilling efficiency that is set to transform the industry's landscape.In conclusion, the launch of the China Swaco Mongoose screen marks a pivotal moment for the drilling industry. Its advanced technology, high-quality materials, and reliable performance provide drilling companies with an invaluable tool to overcome operational challenges, minimize environmental impact, and maximize productivity. With its promising potential for significant cost savings and enhanced efficiency, the China Swaco Mongoose screen is poised to revolutionize drilling operations worldwide.

High Quality 48 PMD Shaker Screen for Derrick Model

Derrick Corporation, a global leader in manufacturing high-performance separation and filtration equipment, has recently introduced the Derrick 48 PMD Shaker Screen, the latest addition to their extensive product line. This new shaker screen is designed to provide superior performance and longevity, meeting the growing demands of the oil and gas industry.The Derrick 48 PMD Shaker Screen is engineered with advanced technology and exceptional quality materials to ensure efficient and effective solids control. It features a unique pyramid design that increases the usable screen area, providing better capacity and longer screen life. This innovative design allows for increased fluid handling capacity and improved solids removal, ultimately leading to higher productivity and cost savings for the operators.With a focus on durability and reliability, the Derrick 48 PMD Shaker Screen is built to withstand the harsh operating conditions of drilling operations. Its robust construction and precise manufacturing process ensure consistent and reliable performance, even in the most challenging environments. This makes it an ideal choice for operators looking to optimize their solids control processes and reduce overall operating costs.In addition to its exceptional performance, the Derrick 48 PMD Shaker Screen is designed for easy installation and maintenance. Its user-friendly design allows for quick and simple screen replacement, minimizing downtime and maximizing operational efficiency. This feature is particularly beneficial for operators looking to streamline their maintenance procedures and enhance overall equipment uptime.Moreover, the Derrick 48 PMD Shaker Screen is compatible with a wide range of shale shakers, making it a versatile solution for various drilling applications. Its adaptability and flexibility make it an attractive option for operators seeking a reliable and cost-effective solids control solution that can be easily integrated into their existing equipment fleet.Derrick Corporation, with over 70 years of experience in the industry, has built a solid reputation for delivering innovative and high-quality separation and filtration solutions. The introduction of the Derrick 48 PMD Shaker Screen further solidifies their commitment to providing cutting-edge technologies that address the evolving needs of the oil and gas industry.The company’s dedication to research and development, coupled with their extensive industry expertise, has positioned Derrick Corporation as a trusted partner for operators seeking best-in-class solids control and filtration solutions. Their relentless pursuit of excellence and customer-centric approach have made them a preferred choice for companies looking to optimize their drilling operations and maximize performance.In conclusion, the Derrick 48 PMD Shaker Screen represents a significant advancement in solids control technology, offering unmatched performance, durability, and versatility. Backed by Derrick Corporation’s unparalleled reputation and commitment to innovation, this new shaker screen is set to redefine industry standards and empower operators to achieve greater efficiency and productivity in their operations. As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, providing cutting-edge solutions that address the dynamic challenges of the industry.