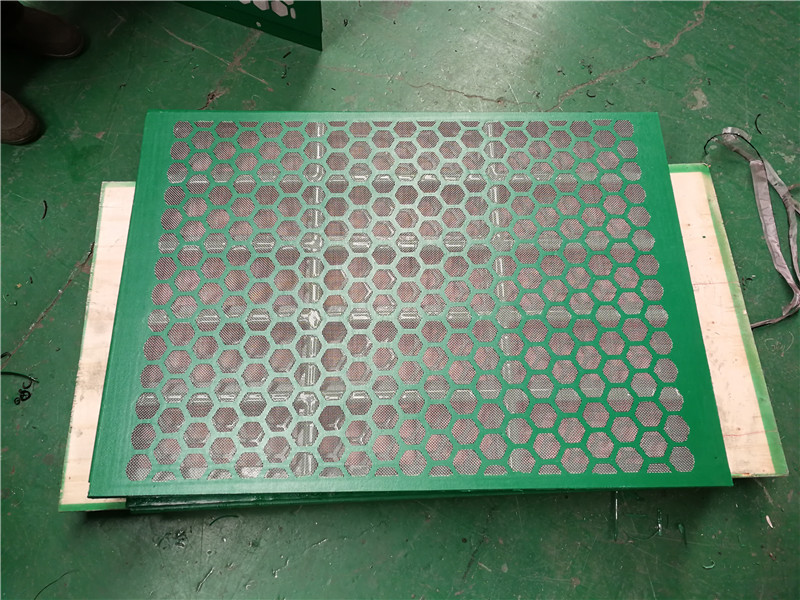

High-quality 28 Series Screen for Industrial Use

By:Admin

In today's fast-paced world, technological advancements are taking place at an unprecedented rate, revolutionizing the way we live and work. One such groundbreaking innovation is the newly launched 28 Series Screen by a leading provider in the industry. This cutting-edge product is now set to transform the way businesses and individuals engage with digital content, offering a plethora of features and capabilities that cater to a wide range of needs and preferences.

With its sleek design and state-of-the-art technology, the 28 Series Screen is designed to deliver an unparalleled viewing experience. One of its key highlights is the high-resolution display, which ensures crisp and clear visuals, allowing users to immerse themselves in their work or entertainment. Whether it's designing graphics, editing videos, or simply enjoying a movie, this screen promises to deliver stunning image quality that surpasses expectations.

Additionally, the screen also boasts a range of connectivity options, making it versatile and adaptable to various devices and systems. With multiple ports and compatibility with different interfaces, users can seamlessly connect their laptops, desktops, gaming consoles, and other devices to the screen, maximizing convenience and efficiency. This makes it an ideal choice for professionals and enthusiasts who require a flexible and dynamic display solution.

Furthermore, the 28 Series Screen is equipped with advanced features that enhance user experience and promote productivity. From customizable display settings to ergonomic design, every aspect of the product is meticulously crafted to cater to the diverse needs of modern-day users. Whether it's adjusting the screen tilt for optimal viewing angles or toggling between different modes for specific tasks, this screen is designed to adapt to the user's preferences and requirements.

In addition to its exceptional performance and functionality, the 28 Series Screen also prioritizes sustainability and energy efficiency. As an environmentally conscious brand, the company has incorporated eco-friendly materials and technologies into the screen's design, ensuring minimal environmental impact without compromising on quality or performance. This aligns with the company's commitment to corporate social responsibility and reflects its dedication to creating products that are not only innovative but also environmentally sustainable.

As a testament to its reliability and superior quality, the 28 Series Screen is backed by comprehensive support and warranty services. Customers can rest assured that they will receive prompt assistance and technical support in the unlikely event of any issues or concerns. This demonstrates the company's unwavering dedication to customer satisfaction and its confidence in the durability and longevity of the product.

Overall, the 28 Series Screen represents a significant leap forward in display technology, offering a blend of cutting-edge features, versatility, and sustainability. With its sleek design, immersive visuals, and user-centric functionality, it is poised to set new standards in the industry and cater to the evolving needs of consumers across various sectors. Whether it's for professional use, creative endeavors, or entertainment, this screen is set to redefine the way we engage with digital content, making it a must-have for anyone seeking a premium display solution.

Company News & Blog

High-quality Shaker Screen for Oil and Gas Industry Applications

Derrick Corporation, a global leader in separation technology, has recently unveiled its latest innovation in shale shaker screen technology, the HYP PWP Shaker Screen. This new product is designed to provide unparalleled efficiency and durability in the oil and gas industry, setting a new standard for oilfield solids control equipment.The HYP PWP Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced in shale shaker operations. This new generation of shaker screens offers a significant improvement in performance, with enhanced solids removal and increased fluid handling capacity. The innovative design of the HYP PWP Shaker Screen ensures a longer lifespan and reduced maintenance, resulting in cost savings for oil and gas operators.Derrick Corporation has long been recognized for its commitment to advancing separation technology, and the introduction of the HYP PWP Shaker Screen further solidifies its position as a leader in the industry. The company's dedication to quality and innovation is evident in the design and engineering of this new product, which is set to revolutionize shale shaker performance.With a global footprint and a strong presence in major oil and gas producing regions, Derrick Corporation is well-positioned to meet the growing demands of the industry. The company's extensive experience and expertise in solids control equipment make it a trusted partner for oilfield operators seeking reliable and efficient solutions. The HYP PWP Shaker Screen is yet another example of Derrick Corporation's commitment to delivering superior products that meet the evolving needs of the oil and gas sector.In addition to its innovative products, Derrick Corporation also offers comprehensive aftermarket support and service to ensure the optimal performance of its equipment. The company's team of experts provides technical assistance, training, and maintenance services to help customers maximize the value of their investment in Derrick products. This commitment to customer satisfaction further underscores Derrick Corporation's reputation as a reliable and trusted partner in the oil and gas industry.The launch of the HYP PWP Shaker Screen marks a significant milestone for Derrick Corporation, as it continues to lead the way in advancing separation technology for the oil and gas sector. This new product is set to deliver tangible benefits for oilfield operators, including improved efficiency, reduced maintenance costs, and enhanced drilling fluid performance. With its proven track record of innovation and excellence, Derrick Corporation is well-positioned to shape the future of solids control equipment and make a lasting impact on the oil and gas industry.

Durable Steel Frame Screen for Swaco Mamut Shakers" - Removed Brand Name

Swaco Mamut Steel Frame Screen (SWM) continues to demonstrate its commitment to innovation and excellence in the oil and gas industry, as it further establishes itself as a top provider of high-quality, durable, and efficient screens for the sector. SWM's steel frame screens have been praised for their reliability and performance, making them a top choice for companies looking to optimize their operations.A key factor that sets SWM apart from its competitors is its dedication to research and development. The company invests heavily in this area, constantly seeking new ways to improve its products and stay ahead of the curve in the industry. SWM also places a strong emphasis on customer feedback, using it to drive product improvements and ensure that its screens continue to meet the evolving demands of its clients.SWM's steel frame screens are designed to withstand the harshest conditions found in oil and gas operations. These screens are built to last, with a focus on durability and performance. This is critical in an industry where equipment needs to be able to endure extreme temperatures, high pressure, and corrosive materials. SWM's screens have been rigorously tested and proven to meet these demanding requirements.One of the key advantages of SWM's steel frame screens is their versatility. They can be used in a wide range of applications, from primary shale shakers to mud cleaners and desanders. This flexibility makes them a valuable asset for companies looking to streamline their operations and reduce downtime. The ability to use the same high-quality screens across multiple processes helps companies save time and money while maintaining a high level of efficiency.In addition to their durability and versatility, SWM's steel frame screens are also known for their exceptional performance. They are designed to provide effective solid-liquid separation, ensuring that drilling operations can run smoothly and efficiently. This is crucial for maximizing productivity and minimizing waste in the extraction process. SWM's screens have a proven track record of delivering these critical benefits, further solidifying their status as a top choice for oil and gas companies.SWM's commitment to excellence extends beyond its products to its customer service. The company has a team of dedicated professionals who are ready to provide support and assistance to clients, ensuring that they get the most out of their screens. Whether it's troubleshooting, maintenance, or general advice, SWM's experts are there to help every step of the way. This level of support is yet another reason why SWM has earned a reputation as a trusted and reliable partner in the industry.Looking to the future, SWM remains dedicated to pushing the boundaries of what is possible in the oil and gas sector. The company's ongoing investment in research and development will continue to drive innovation and lead to the introduction of new and improved products. SWM is committed to staying at the forefront of the industry, providing its clients with the tools they need to succeed in an ever-changing and demanding market.In conclusion, SWM's steel frame screens have firmly established themselves as a top choice for oil and gas companies seeking reliable, durable, and high-performance equipment. With a focus on innovation, quality, and customer service, SWM has proven itself to be a valuable partner in the industry. As the company continues to invest in its products and support services, it is well-positioned to remain a leader in the sector for years to come.

Discover the High-Performance MD-3 Shaker Screen for Efficient Drilling Operations

Innovative New Shaker Screen Revolutionizes Drilling OperationsIntroducing the Next-Generation MD-3 Shaker ScreenDrilling operations are about to witness a technology revolution with the introduction of the state-of-the-art MD-3 Shaker Screen. Developed by a leading oilfield service company, this revolutionary shaker screen promises to enhance efficiency, improve performance, and revolutionize drilling operations across the industry.The MD-3 Shaker Screen, a product of cutting-edge engineering and research, is set to redefine the way drilling fluid is processed on-site. Designed to remove solid particles and impurities from drilling fluid during the wellbore operation, this innovative shaker screen offers unparalleled levels of performance and reliability.One of the standout features of the MD-3 Shaker Screen is its unique design. Crafted with meticulous attention to detail, the screen comprises a series of layers specifically engineered to maximize efficiency. With a higher number of layers than traditional shaker screens, the MD-3 offers improved filtration capabilities, thus delivering cleaner drilling fluid.The increased filtration efficiency of the MD-3 Shaker Screen translates into tangible benefits for drilling operations. By removing a higher percentage of solid particles from the drilling fluid, the screen significantly reduces maintenance costs and improves overall operational efficiency. Operators can now experience extended screen life, reduced downtime, and increased drilling productivity.Additionally, the improved filtration provided by the MD-3 Shaker Screen ensures the effective separation of cuttings from the drilling fluid. This ensures that the drilling fluid can be recycled and reused more efficiently, leading to significant cost savings and reduced environmental impact. The MD-3 Shaker Screen thus presents a viable solution for the oil and gas industry as it strives to meet increasing environmental regulations and sustainability goals.Notably, the MD-3 Shaker Screen is also designed to be seamlessly integrated with existing shaker systems, ensuring a hassle-free transition for drilling operators. Its compatibility with commonly used shaker systems makes it an attractive upgrade for drilling rigs across the industry.Furthermore, the MD-3 Shaker Screen boasts an extended lifespan compared to traditional screens. With its robust construction and advanced materials, this shaker screen provides exceptional durability and resistant to wear, delivering enhanced reliability in even the harshest drilling environments. This ensures that the screen can withstand the rigors of drilling operations, minimizing the need for frequent replacements and resulting in substantial cost savings.In light of its exceptional performance and reliability, the MD-3 Shaker Screen has quickly gained traction among industry leaders. Renowned drilling companies, both onshore and offshore, have reported remarkable improvements in operational efficiency and cost reduction since adopting this innovative technology. Initial feedback from these operators has been overwhelmingly positive, cementing the MD-3 Shaker Screen's reputation as the go-to solution for solid control in drilling operations.As the global energy landscape continues to evolve, the MD-3 Shaker Screen emerges as a game-changer in drilling operations. Its groundbreaking design, improved filtration efficiency, and enhanced durability set a new standard for shaker screens industry-wide. This innovative technology will undoubtedly enable drilling companies to optimize their operations, improve sustainability, and remain at the forefront of the evolving energy industry.In conclusion, the introduction of the MD-3 Shaker Screen marks a significant milestone in the oil and gas industry. Its exceptional performance, reliability, and compatibility make it an essential tool for drilling operations worldwide. With this innovative technology, drilling companies can now achieve unprecedented levels of efficiency, cost reduction, and environmental responsibility. The MD-3 Shaker Screen is poised to transform the future of drilling, and it's clear that the next-generation of shaker screens has arrived.

Efficient and Durable Oil Shaker Screen: Maximizing Oil Extraction

Houston, Texas – A leading provider of oil drilling equipment is proud to announce the release of their latest shaker screen, the S250. This new shaker screen is the perfect solution for oil and gas rig companies to sift through drilling mud and improve drilling efficiency.The S250 Oil Shaker Screen, which is designed to fit the popular brand of shale shakers, has been field-tested, and the results have been impressive. The screen's design allows for increased throughput capacity and better solids control, meaning that drilling companies will experience less downtime due to drilling mud inefficiencies, translating to lower costs and faster drilling times.The company, which has over two decades of experience in the oil drilling equipment industry, is known for its innovative approach to developing products and solutions that help improve efficiencies in the drilling process, making the process safer and more cost-effective for all parties involved."Drilling for oil and natural gas is a crucial part of the energy industry, and we understand the importance of providing drilling companies with the most advanced and effective equipment on the market," said a spokesperson for the company. "We are proud of our team of engineers and technicians who have worked tirelessly to develop the S250 Oil Shaker Screen. Their expertise and creativity have allowed us to provide a solution that is truly cutting edge."With the energy industry expected to continue its upward trajectory in the coming years, it is imperative for drilling companies to have access to equipment that is both efficient and reliable. The S250 Oil Shaker Screen is designed to meet these demands and help drilling companies prepare to meet the challenges of the future.About the CompanyThe company, which has been operating since 1999, specializes in providing a wide range of oil drilling equipment to companies in the energy industry. The company's mission is to provide drilling companies with the most advanced and reliable equipment on the market, helping to streamline the drilling process and improve safety and efficiency.The company takes pride in working with top-notch engineers and technicians to develop innovative solutions that meet the unique needs of their clients. From mud pumps to drilling rigs to shaker screens like the S250, they are committed to providing equipment that is of the highest quality and built to last.Their dedication to their customers' success has earned them a reputation as a trusted partner in the oil and gas drilling industry. With a commitment to excellence, the company will continue to push the boundaries of innovation in the years to come, helping drilling companies across the globe to safely and efficiently extract oil and natural gas from the earth.

PWP Screens: Unveiling the Impressive Derrick 2000 Series Design

Derrick 2000 Series PWP Screens Revolutionize the Oil and Gas IndustryWith the constant advancements in technology, the oil and gas industry is constantly evolving. One of the latest breakthroughs in the industry is the introduction of the Derrick 2000 Series PWP Screens. These innovative screens have revolutionized the way oil and gas is extracted and processed, leading to increased efficiency and productivity in the field.The Derrick 2000 Series PWP Screens, developed by a leading global provider of solids control and fine screening equipment, are known for their exceptional performance and durability. These screens are used in various applications, including shale shakers, desanders, desilters, and mud cleaners. They have been designed to withstand the demanding conditions of the oil and gas industry, ensuring optimum performance and reliability in any drilling operation.One of the key features of the Derrick 2000 Series PWP Screens is their superior cut point integrity. The screens are constructed with a unique ribbed design that provides enhanced strength and durability. This prevents the screens from sagging or bending under high pressure, ensuring a consistent cut point throughout their lifespan. The screens also feature a patented crown design, which increases the screen's surface area and improves fluid handling capacity.In addition to their exceptional durability, the Derrick 2000 Series PWP Screens are also highly efficient. They are created using advanced manufacturing techniques and high-quality materials, ensuring precise and accurate separation of solids from liquids. This results in cleaner fluids and higher-quality drilling mud, which in turn leads to improved wellbore stability and increased oil and gas production.Furthermore, the Derrick 2000 Series PWP Screens are designed for easy installation and maintenance. They are compatible with various shale shaker models and can be quickly and easily replaced when needed. This allows operators to minimize downtime and maximize operational efficiency. The screens are also engineered to minimize blinding and plugging, reducing the need for frequent cleaning and replacement.The introduction of the Derrick 2000 Series PWP Screens has garnered significant attention and praise within the oil and gas industry. Several major oil companies have already adopted these screens in their operations and have reported significant improvements in productivity and cost savings. The screens have been particularly effective in shale drilling applications, where precise separation of cuttings from drilling fluid is crucial for efficient drilling operations.The benefits of the Derrick 2000 Series PWP Screens extend beyond operational efficiency and cost savings. With their advanced solid control technology, these screens also contribute to environmental sustainability. By effectively removing solids from drilling fluid, the screens reduce the environmental impact of drilling operations, minimizing the discharge of contaminated fluids into the environment.In conclusion, the Derrick 2000 Series PWP Screens have revolutionized the oil and gas industry with their exceptional performance and durability. These screens have proven to be highly efficient, reliable, and easy to maintain, resulting in increased productivity and cost savings for oil and gas companies. With their advanced solid control technology, they also contribute to environmental sustainability, making them a valuable asset in the industry's ongoing efforts to minimize its environmental footprint. As more companies recognize the benefits of these screens, their adoption is expected to become widespread, further transforming the way oil and gas extraction is conducted.

Composite Frame Market in China Shows Promising Growth Potential

China Composite Frame, a leading manufacturer and supplier of composite materials, has announced the launch of a new line of lightweight and durable composite frames. These frames are designed to provide superior strength and durability, making them an ideal choice for a wide range of applications, including automotive, aerospace, marine, and industrial markets.Founded in 2005, China Composite Frame has quickly established itself as a leader in the composite materials industry. The company offers a comprehensive range of composite products, including carbon fiber, fiberglass, and aramid fiber, as well as custom composite solutions tailored to meet specific customer requirements. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, China Composite Frame is committed to delivering high-quality products that meet the highest industry standards.The company's new line of composite frames is made from high-strength carbon fiber and epoxy resin, which gives them exceptional structural integrity and resistance to corrosion and fatigue. These frames are also significantly lighter than traditional metal frames, making them an attractive choice for applications where weight reduction is a key factor. In addition, the composite materials used in these frames offer excellent thermal and electrical conductivity, as well as superior impact resistance, making them suitable for use in harsh operating environments.One of the key advantages of China Composite Frame's new line of composite frames is their customizability. The company's advanced manufacturing processes allow for the production of frames in a wide range of sizes, shapes, and configurations, ensuring that customers can find the perfect solution for their specific needs. Whether it's a complex automotive component, a structural element for an aerospace application, or a custom-designed frame for a marine vessel, China Composite Frame can deliver a tailored solution that meets the most demanding requirements."We are excited to introduce our new line of composite frames to the market," said the company's spokesperson. "These frames represent a significant advancement in the field of composite materials, offering exceptional strength, durability, and versatility. We believe that they will find widespread acceptance across a variety of industries, providing customers with a reliable and cost-effective solution for their structural needs."In addition to their superior performance characteristics, China Composite Frame's composite frames also offer environmental benefits. The production of composite materials consumes less energy and generates fewer emissions compared to traditional metal manufacturing processes, making them a more sustainable choice for environmentally conscious customers. Furthermore, the lightweight nature of these frames can contribute to reduced fuel consumption and lower carbon emissions in applications such as automotive and aerospace.As China Composite Frame continues to expand its presence in the global composite materials market, the company is committed to maintaining a strong focus on research and development. By investing in innovative technologies and advanced materials, the company aims to stay at the forefront of the industry, delivering cutting-edge solutions that meet the evolving needs of its customers.With the launch of its new line of composite frames, China Composite Frame is well-positioned to further solidify its reputation as a trusted partner for high-performance composite materials. As industries continue to seek lightweight, durable, and cost-effective solutions for their structural requirements, these frames are poised to make a significant impact, offering a compelling alternative to traditional metal components.In conclusion, China Composite Frame's new line of composite frames represents a significant milestone for the company and the composite materials industry as a whole. With their exceptional strength, durability, and customizability, these frames are poised to meet the needs of a wide range of applications, providing customers with a reliable and sustainable solution for their structural requirements. As the company continues to innovate and expand its product offering, it is poised to play a key role in shaping the future of the composite materials market.

Top 5 Must-Have Tools for Efficient Oilfield Operations

Title: Oilfield Equipment Supplier Embraces Innovation and Continues to Thrive in the MarketIntroduction:Oilfield Equipment, an industry-leading supplier of high-quality oilfield equipment and services, has been a driving force in the oil and gas sector for over a decade. With a strong commitment to innovation, cutting-edge technology, and exceptional customer service, Oilfield Equipment has successfully carved a niche for itself in the competitive market. This article explores the key factors contributing to the company's success and highlights its dedication to providing top-of-the-line equipment and solutions to the oil and gas industry.Growing Amidst Technological Advancements:As the oil and gas sector continues to evolve and adapt to the growing demands of the global market, Oilfield Equipment has remained at the forefront of technological advancements. The company consistently invests in research and development to offer state-of-the-art equipment that not only enhances efficiency but also ensures greater safety measures for the workforce in the field.By collaborating with leading technology providers, Oilfield Equipment has successfully integrated automation and data analytics into its product offerings, enabling clients to optimize their operational performance. Through the use of advanced sensors, real-time data monitoring, and artificial intelligence-driven systems, the company's equipment enables oilfield operators to make informed, data-driven decisions, resulting in improved productivity and reduced downtime.Commitment to Quality and Reliability:Oilfield Equipment's unwavering commitment to delivering high-quality and reliable products has cemented its position as a trusted supplier in the industry. The company adheres to strict manufacturing standards, leveraging its extensive expertise to design and engineer equipment that meets the specific requirements of oilfield operations.Stringent quality control measures are implemented throughout the production process, ensuring that every piece of equipment that bears the Oilfield Equipment name is built to withstand the demanding conditions of the oilfield environment. This dedication to quality has earned the company a loyal customer base who rely on their products to enhance their operational efficiency and profitability.Customer-Centric Approach:Recognizing the importance of building strong and lasting partnerships with clients, Oilfield Equipment maintains a customer-centric approach in all aspects of its business. The company works closely with its customers to understand their unique needs and challenges, providing tailored solutions that address their specific requirements.Oilfield Equipment's team of highly skilled professionals offers comprehensive support from initial consultation to delivery and beyond. Their technical expertise and prompt customer service ensure that clients receive all the assistance they need, be it equipment selection, installation, maintenance, or troubleshooting.Sustainable Solutions and Environmental Responsibility:In line with the growing global focus on sustainability, Oilfield Equipment has integrated environmentally responsible practices into its operations. The company is committed to minimizing its ecological footprint by developing energy-efficient equipment and exploring alternative energy solutions.Furthermore, the company ensures adherence to all relevant environmental regulations and continues to invest in innovative technologies that reduce emissions and optimize resource utilization. By prioritizing sustainability, Oilfield Equipment not only contributes to the long-term viability of the oil and gas industry but also demonstrates its commitment to preserving the planet for future generations.Future Prospects and Outlook:Looking ahead, Oilfield Equipment is poised to leverage its extensive industry experience and robust technological capabilities to capture new opportunities in emerging markets. The company's solid reputation, commitment to innovation, and customer-centric approach position it favorably within the industry, ensuring continued growth and success.In conclusion, Oilfield Equipment stands as a leading supplier of high-quality oilfield equipment and services, driven by innovation, reliability, customer focus, and sustainability. Through its constant pursuit of excellence, the company has established a strong foothold within the oil and gas sector, and its future prospects remain promising in an ever-evolving industry.

High-Quality and Efficient FLC504 Shaker Screen for Improved Productivity

Title: Industry-Leading Shaker Screen Reinvents Solid Control EfficiencyIntroduction:In today's dynamic global oil and gas drilling industry, efficient solid control systems are integral to optimizing drilling operations. Recognizing this need, leading industry specialist PWP has introduced its groundbreaking FLC504 Shaker Screen. Engineered to provide unmatched performance and longevity, this state-of-the-art screen is set to revolutionize solid control operations in oil and gas drilling.Developed by PWP, a renowned manufacturer known for delivering cutting-edge solutions, the FLC504 Shaker Screen offers a range of significant advantages that will undoubtedly enhance drilling efficiency, reduce costs, and ensure maximum productivity.Stunning Technical Features:The FLC504 Shaker Screen incorporates advanced technology and innovative design elements. Its unique structure enables it to effectively separate solids from drilling fluid, presenting a robust solution that significantly improves solid control efficiency.1. Superior Durability: The FLC504 Shaker Screen is constructed using high-quality materials that guarantee outstanding durability and reliability even under the most demanding drilling conditions. This durability translates into improved overall service life and reduced operational downtime.2. Enhanced Sieve Performance: The screen features a mesh configuration specifically designed to maximize its solids control capabilities, allowing for accurate separation and efficient removal of solids from drilling fluid. This results in cleaner drilling fluid, optimized drilling performance, and ultimately higher financial returns on drilling investments.3. Optimal Conductance: Engineered with precise aperture sizes and patterns, the FLC504 Shaker Screen offers excellent flow capacity without compromising drilling fluid quality. Its exceptional conductance delivers increased drilling efficiency, lower operating costs, and improved environmental sustainability.4. Easy Installation and Maintenance: Designed with user convenience in mind, the FLC504 Shaker Screen ensures quick and hassle-free installation. In addition, its streamlined design facilitates efficient cleaning and maintenance, saving valuable time and resources for drilling operations.Company Commitment and Support:PWP, with its unwavering commitment to providing top-notch solutions, believes in offering comprehensive support to its clients. Its dedicated team of experts offers extensive technical assistance, professional guidance, and prompt after-sales service. With a global reach and an impressive track record, PWP has become a trusted partner for numerous oil and gas industry stakeholders.The PWP Advantage:As a market leader, PWP has consistently delivered high-quality products, making it a trusted name in the industry. The introduction of the FLC504 Shaker Screen reinforces PWP's commitment to innovation and ongoing improvement. PWP is more than just a manufacturer; it is a provider of reliable, practical, and efficient solutions that empower its clients to achieve operational excellence.Environmental Commitment:PWP's commitment to sustainable practices is deeply ingrained in its corporate ethos. The FLC504 Shaker Screen significantly reduces waste generation, contributing to a greener and more environmentally conscious drilling industry. By maximizing solids control efficiency, PWP mitigates environmental impacts and reduces the overall carbon footprint of drilling operations.Market Prospects and Future Outlook:With the launch of the FLC504 Shaker Screen, PWP is poised to capture a significant share of the solid control market. The impressive technical features and proven performance of the screen make it an attractive proposition for drilling professionals seeking to streamline their operations and optimize productivity.PWP's continuous research and development efforts ensure that future iterations of the FLC504 Shaker Screen will incorporate further refinements and advancements. With a strong focus on customer satisfaction and industry-leading solutions, PWP sets itself apart as a global leader in the solid control systems sector.Conclusion:PWP's FLC504 Shaker Screen marks a breakthrough in solid control efficiency. By combining cutting-edge technology with unparalleled performance, this industry-leading screen offers improved drilling fluid management, reduced operational costs, and enhanced environmental sustainability. With PWP's unwavering commitment to delivering excellence, the FLC504 Shaker Screen is set to transform the way oil and gas drilling operations are conducted, ensuring increased efficiency, productivity, and success in the years ahead.

Advanced Multi-Sizer Screen Technology Revolutionizes Sizing Process

Vibration screening equipment has become an essential tool for many industries in the process of material handling and separation. One such example is the VSM Multi-sizer screen, a state-of-the-art vibrating screen that has been making waves in the industry due to its efficiency and reliability. This innovative equipment is designed to handle a wide range of materials, making it an ideal solution for various applications in industries such as mining, aggregate, recycling, and more.The VSM Multi-sizer screen is a product of [], a leading manufacturer of industrial screening equipment that has been providing innovative solutions to the industry for over a decade. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to deliver high-performance equipment that meets the evolving needs of their customers.The VSM Multi-sizer screen is a testament to the company's commitment to innovation and quality. It features a unique design that allows for efficient screening of materials without compromising on accuracy and consistency. The screen is equipped with multiple decks and a variety of screen media options, allowing for precise control over the size and distribution of the screened materials. This versatility makes it suitable for a wide range of applications, from fine particle separation to heavy-duty scalping.One of the key features of the VSM Multi-sizer screen is its advanced vibratory motion, which ensures optimal screening performance. The screen is equipped with high-quality vibration motors that deliver a powerful and uniform vibration, resulting in efficient material separation and increased throughput. Additionally, the screen is designed for easy maintenance, with quick and convenient access to critical components for inspection and servicing.In addition to its technical capabilities, the VSM Multi-sizer screen also incorporates various safety features to ensure the well-being of operators and maintenance personnel. The screen is designed with robust guarding and safety interlocks to prevent unauthorized access to the equipment during operation. This ensures a safe working environment and minimizes the risk of accidents or injuries.The VSM Multi-sizer screen has already garnered attention from industry professionals and customers alike, thanks to its impressive performance and reliability. Its ability to handle a wide range of materials with precision and efficiency has made it a preferred choice for many companies looking to optimize their screening processes. Whether it's separating fines from aggregates or classifying recycled materials, the VSM Multi-sizer screen has proven to be a valuable asset for improving overall operational efficiency.With a strong emphasis on customer satisfaction, [] not only offers high-quality equipment but also provides comprehensive support and technical assistance to help customers make the most of their investment. From initial consultation to after-sales service, the company is dedicated to ensuring that its customers are equipped with the knowledge and resources they need to succeed.As the demand for reliable and efficient screening equipment continues to grow, the VSM Multi-sizer screen has positioned itself as a top contender in the market. With its advanced technology, robust construction, and customer-focused approach, this innovative screening solution is set to make a significant impact on the industry, setting new standards for performance and reliability.In conclusion, the VSM Multi-sizer screen from [] is a game-changer in the world of vibrating screens. Its advanced features, robust construction, and customer-focused approach make it a top choice for companies looking to enhance their material handling and separation processes. With a strong track record of delivering innovative solutions, [] continues to solidify its position as a leading manufacturer of industrial screening equipment, setting the bar for excellence in the industry.