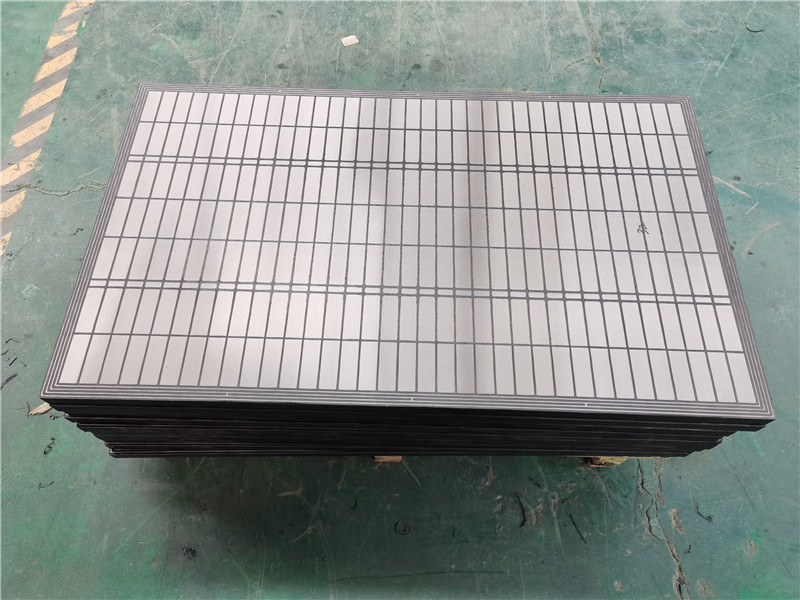

Durable Steel Frame Screen: A Reliable Solution for Screening Needs

By:Admin

The GNZS-752 Steel Frame Screen is a vital component of the company's comprehensive line of solids control equipment. It is designed to effectively remove solids and impurities from drilling fluids, ensuring that the fluids remain in optimal condition for the duration of the drilling process. The screen is constructed with high-quality steel frame and adheres to strict manufacturing standards, making it durable and long-lasting even in the most demanding drilling conditions.

One of the key features of the GNZS-752 Steel Frame Screen is its advanced composite frame technology. This technology allows for increased screen life and fluid-handling capacity, ultimately leading to improved solids control efficiency. Additionally, the screen is designed for quick and easy installation, reducing downtime and maximizing operational efficiency for drilling operations.

The GNZS-752 Steel Frame Screen is compatible with a wide range of shakers, allowing for seamless integration into existing solids control systems. This versatility makes it an ideal solution for drilling contractors and operators looking to enhance their solids control processes.

In addition to its innovative products, the company behind the GNZS-752 Steel Frame Screen is known for its commitment to customer satisfaction and technical support. The company's team of experienced professionals are dedicated to providing exceptional service and support to clients, ensuring that their solids control needs are met with the highest level of expertise and efficiency.

Furthermore, the company has established a global presence, with a network of distributors and partners spanning across the world. This global reach allows for quick and efficient access to the GNZS-752 Steel Frame Screen and other solids control equipment, regardless of the location of the drilling operation.

The GNZS-752 Steel Frame Screen has already garnered praise from industry professionals for its outstanding performance and reliability. Its advanced technology and durable construction have made it a preferred choice for drilling contractors and operators around the world.

With a proven track record of delivering high-quality solids control solutions, the company behind the GNZS-752 Steel Frame Screen has solidified its position as a leader in the industry. As the demand for efficient solids control and waste management solutions continues to grow, the company remains dedicated to providing innovative, reliable, and cost-effective solutions for the oil and gas industry.

In conclusion, the GNZS-752 Steel Frame Screen is a testament to the company's commitment to excellence and innovation in the field of solids control. With its advanced technology, durable construction, and global presence, the screen is set to continue making a significant impact in the industry, meeting the needs of drilling contractors and operators around the world.

Company News & Blog

Enhancing Shale Shaker Performance with High-Quality Screens

**Title:** Innovative Shale Shaker Screen Revolutionizes Oil and Gas Industry **Introduction**In an era where technological advancements play a critical role in shaping industries, the oil and gas sector has not been left behind. As the demand for energy continues to rise, companies are constantly seeking new and innovative solutions to enhance efficiency and productivity in the extraction process. In this regard, Kemtron Shale Shaker Screen has emerged as a game-changing solution, revolutionizing the oil and gas industry.**Company Introduction**Kemtron Shale Shaker Screen, a leading provider of quality oilfield equipment, specializes in the design and manufacture of cutting-edge shale shaker screens. With a commitment to excellence and an unwavering focus on meeting industry demands, the company has earned a stellar reputation for delivering superior products that optimize drilling operations.Leveraging years of research and development, Kemtron Shale Shaker Screen has become synonymous with innovation, constantly pushing the boundaries of technology. Their team of skilled engineers and technicians work tirelessly to develop advanced solutions that enhance performance, prolong equipment life, and reduce downtime for companies operating in the oil and gas industry.**Revolutionizing the Shale Shaker Screen**The shale shaker screen plays a crucial role in the drilling process by filtering out solids and other debris from the drilling fluid, also known as drilling mud. This process is vital as it ensures the integrity of the drilling operation by preventing damage to downstream equipment, reducing the likelihood of wellbore instabilities, and optimizing well productivity.In the past, shale shaker screens were prone to premature failure due to factors such as wear and tear, inadequate filtration, and low durability. However, Kemtron Shale Shaker Screen has addressed these challenges head-on and revolutionized the industry with its state-of-the-art screens.The company's shale shaker screens are designed with advanced materials and innovative engineering to deliver unparalleled performance and longevity. By incorporating high-quality stainless steel wire cloth and a unique composite frame, their screens exhibit exceptional strength, corrosion resistance, and excellent filtration capabilities.Furthermore, Kemtron Shale Shaker Screen has implemented an advanced manufacturing process that ensures consistent quality and accuracy in screen production. Utilizing cutting-edge technology and stringent quality control measures, the company guarantees that each screen maintains precise dimensions, mesh sizes, and surface characteristics – resulting in improved efficiency and reliability.**Benefits for the Oil and Gas Industry**The introduction of Kemtron Shale Shaker Screen into the market has had a profound impact on the oil and gas industry. By choosing Kemtron's screens, companies can experience several significant benefits:1. Enhanced Filtration: The innovative design of the shale shaker screens provides superior particle separation, resulting in cleaner drilling fluid. This leads to increased drilling efficiencies, reduced fluid loss, and improved overall wellbore stability.2. Extended Service Life: The combination of durable stainless steel wire cloth and a composite frame ensures exceptional resistance to wear and tear. This extends the service life of the screens, reducing the frequency of replacements and associated costs.3. Cost-Effectiveness: Kemtron's screens contribute to cost savings by minimizing downtime due to screen failure and reducing the need for frequent replacements. Additionally, the improved filtration efficiency helps maintain the integrity of expensive downstream equipment, further reducing operational expenses.4. Environmentally Friendly: The high-quality screens contribute to a more sustainable drilling process by optimizing drilling fluid management, minimizing waste generation, and reducing the environmental impact of oil and gas exploration.**Conclusion**With their unwavering commitment to innovation and superior product quality, Kemtron Shale Shaker Screen has revolutionized the oil and gas industry. Their state-of-the-art shale shaker screens provide enhanced filtration, extended service life, cost-effectiveness, and environmental benefits, driving efficiency and productivity in drilling operations. As the industry continues to evolve, Kemtron remains at the forefront, continuously developing cutting-edge solutions that redefine industry standards and push the boundaries of excellence.

Oil Shale Shaker Screen: Latest Updates and Developments in the Industry

Scomi Prima Oil Shale Shaker Screen, a leading company in the oil and gas industry, has recently introduced a new and innovative shaker screen that is set to revolutionize the way oil and gas drilling operations are conducted. The new shaker screen is designed to offer enhanced efficiency, durability, and performance, ultimately leading to significant cost savings for companies operating in the oil and gas sector.The company, with a strong commitment to research and development, has dedicated significant resources to the design and production of the new shale shaker screen. With a team of experienced engineers and industry experts, Scomi Prima Oil has been able to develop a product that meets the growing demands of the oil and gas industry.The new shaker screen features a state-of-the-art design that is aimed at maximizing the efficiency of the drilling process. With a focus on durability, the screen is built to withstand the harsh conditions typically encountered in drilling operations. This will result in reduced downtime and maintenance costs for oil and gas companies, leading to increased overall productivity.One of the key benefits of the new shaker screen is its ability to effectively separate drilling cuttings from the drilling fluid. This process is crucial in maintaining the quality of the drilling fluid, ultimately leading to improved wellbore stability and reduced environmental impact. Additionally, by effectively removing solid particles from the drilling fluid, the new shale shaker screen will contribute to a reduction in overall drilling waste, in line with the industry's increasing focus on sustainability and environmental responsibility.The enhanced performance of the new shale shaker screen is expected to result in significant cost savings for oil and gas companies. Through improved efficiency and reduced maintenance requirements, companies can expect to see a decrease in operating costs, leading to greater profitability in their drilling operations.Furthermore, the introduction of the new shaker screen demonstrates Scomi Prima Oil's commitment to providing innovative solutions for the oil and gas industry. The company has long been recognized for its dedication to continuous improvement and the development of cutting-edge technologies. With the launch of the new shale shaker screen, Scomi Prima Oil solidifies its position as a leader in the industry.The new shaker screen is set to be available for purchase in the coming months, and the industry is eagerly anticipating its release. With its promise of improved efficiency, durability, and cost savings, the new product is expected to be well-received by oil and gas companies around the world.In conclusion, Scomi Prima Oil's introduction of the new shale shaker screen represents a significant development in the oil and gas industry. With its focus on efficiency, durability, and performance, the new product is poised to make a substantial impact on drilling operations. As the industry continues to evolve, innovative solutions such as the new shale shaker screen will play a crucial role in driving progress and ensuring the sustainability of oil and gas operations. Scomi Prima Oil remains at the forefront of these advancements, demonstrating its ongoing commitment to providing the best possible solutions for its customers.

Innovative Screen Technology for Efficient Material Separation

Innovative New Screen Technology Set to Revolutionize the IndustryThe future of screening technology is here, and it's all thanks to a revolutionary new product that is set to change the game for industry professionals. The Vortex Screen, developed by a leading industry expert in screening solutions, is a cutting-edge product that promises to deliver unparalleled performance and efficiency for a wide range of applications.This innovative new screen technology utilizes a unique design that maximizes the flow of material through the screen, resulting in higher capacities, better separations, and lower energy consumption. The Vortex Screen is poised to disrupt the industry by providing a solution that is both cost-effective and environmentally friendly.The company behind this groundbreaking product, which has been a leader in the screening industry for over 30 years, is known for its commitment to delivering high-quality, innovative solutions to its customers. Their team of experts has developed the Vortex Screen with a focus on continuous improvement and customer satisfaction, ensuring that it meets and exceeds the needs of industry professionals.With its unparalleled performance and efficiency, the Vortex Screen is suitable for a wide range of applications, including mining, aggregate, recycling, and industrial minerals. The screen is designed to handle a variety of materials, from fine dry products to wet, sticky materials, making it a versatile and reliable solution for industry professionals.The Vortex Screen also boasts a modular design, which allows for easy installation and maintenance, saving both time and money for its users. This user-friendly design is a testament to the company's commitment to providing practical, customer-focused solutions that prioritize ease of use and operational efficiency.Furthermore, the Vortex Screen is designed to minimize environmental impact, with lower energy consumption and reduced carbon emissions compared to traditional screening technologies. This demonstrates the company's dedication to sustainability and responsible resource management, aligning with the growing focus on environmental stewardship within the industry.In addition to its impressive technical capabilities, the Vortex Screen comes with a comprehensive support package, including expert technical assistance, aftermarket services, and spare parts availability. This ensures that customers can rely on the company's ongoing support to maximize the performance and longevity of their screening equipment.The launch of the Vortex Screen marks a significant milestone for the company, solidifying its position as an industry leader in screening solutions. With its commitment to innovation, performance, and sustainability, the company continues to push the boundaries of what is possible in screening technology, setting a new standard for the industry.As industry professionals look to optimize their operations and minimize environmental impact, the Vortex Screen offers a compelling solution that delivers on performance, efficiency, and sustainability. With its user-friendly design, versatile applications, and comprehensive support package, the Vortex Screen is set to revolutionize the industry and empower its users to achieve new levels of productivity and resource efficiency.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Discover the High-Performance MD-3 Shaker Screen for Efficient Drilling Operations

Innovative New Shaker Screen Revolutionizes Drilling OperationsIntroducing the Next-Generation MD-3 Shaker ScreenDrilling operations are about to witness a technology revolution with the introduction of the state-of-the-art MD-3 Shaker Screen. Developed by a leading oilfield service company, this revolutionary shaker screen promises to enhance efficiency, improve performance, and revolutionize drilling operations across the industry.The MD-3 Shaker Screen, a product of cutting-edge engineering and research, is set to redefine the way drilling fluid is processed on-site. Designed to remove solid particles and impurities from drilling fluid during the wellbore operation, this innovative shaker screen offers unparalleled levels of performance and reliability.One of the standout features of the MD-3 Shaker Screen is its unique design. Crafted with meticulous attention to detail, the screen comprises a series of layers specifically engineered to maximize efficiency. With a higher number of layers than traditional shaker screens, the MD-3 offers improved filtration capabilities, thus delivering cleaner drilling fluid.The increased filtration efficiency of the MD-3 Shaker Screen translates into tangible benefits for drilling operations. By removing a higher percentage of solid particles from the drilling fluid, the screen significantly reduces maintenance costs and improves overall operational efficiency. Operators can now experience extended screen life, reduced downtime, and increased drilling productivity.Additionally, the improved filtration provided by the MD-3 Shaker Screen ensures the effective separation of cuttings from the drilling fluid. This ensures that the drilling fluid can be recycled and reused more efficiently, leading to significant cost savings and reduced environmental impact. The MD-3 Shaker Screen thus presents a viable solution for the oil and gas industry as it strives to meet increasing environmental regulations and sustainability goals.Notably, the MD-3 Shaker Screen is also designed to be seamlessly integrated with existing shaker systems, ensuring a hassle-free transition for drilling operators. Its compatibility with commonly used shaker systems makes it an attractive upgrade for drilling rigs across the industry.Furthermore, the MD-3 Shaker Screen boasts an extended lifespan compared to traditional screens. With its robust construction and advanced materials, this shaker screen provides exceptional durability and resistant to wear, delivering enhanced reliability in even the harshest drilling environments. This ensures that the screen can withstand the rigors of drilling operations, minimizing the need for frequent replacements and resulting in substantial cost savings.In light of its exceptional performance and reliability, the MD-3 Shaker Screen has quickly gained traction among industry leaders. Renowned drilling companies, both onshore and offshore, have reported remarkable improvements in operational efficiency and cost reduction since adopting this innovative technology. Initial feedback from these operators has been overwhelmingly positive, cementing the MD-3 Shaker Screen's reputation as the go-to solution for solid control in drilling operations.As the global energy landscape continues to evolve, the MD-3 Shaker Screen emerges as a game-changer in drilling operations. Its groundbreaking design, improved filtration efficiency, and enhanced durability set a new standard for shaker screens industry-wide. This innovative technology will undoubtedly enable drilling companies to optimize their operations, improve sustainability, and remain at the forefront of the evolving energy industry.In conclusion, the introduction of the MD-3 Shaker Screen marks a significant milestone in the oil and gas industry. Its exceptional performance, reliability, and compatibility make it an essential tool for drilling operations worldwide. With this innovative technology, drilling companies can now achieve unprecedented levels of efficiency, cost reduction, and environmental responsibility. The MD-3 Shaker Screen is poised to transform the future of drilling, and it's clear that the next-generation of shaker screens has arrived.

Quality Shaker Screens for Mongoose Shale Shakers

In recent news, (company name) has announced the release of their latest product, the (product name). This innovative screen is designed to provide improved efficiency and performance for the oil and gas industry, making it an essential tool for drilling operations.The (product name) is designed to fit the popular (product type) models and is constructed with high-quality materials to ensure durability in even the most demanding drilling environments. Its advanced technology allows for efficient solids control and fluid handling, making it a valuable asset for any drilling operation.The (product name) features a unique design that is engineered to maximize throughput and screen life, ultimately reducing the overall cost of operations. Its high-capacity composite frame provides increased support and resistance to wear and tear, making it a reliable and long-lasting solution for solids control.Furthermore, the (product name) is designed to offer quick and easy installation, reducing downtime and increasing productivity on the drilling site. Its superior performance and reliability make it an ideal choice for operators looking to improve their drilling efficiency and reduce overall operating costs.Additionally, (company name) has a long-standing reputation for delivering innovative and reliable products to the oil and gas industry. With a commitment to quality and customer satisfaction, they have become a trusted partner for drilling operations around the world.The company's extensive experience and expertise in the industry have allowed them to develop cutting-edge solutions that address the unique challenges faced by oil and gas operators. The introduction of the (product name) further demonstrates their dedication to providing industry-leading products and services.In addition to their exceptional product offerings, (company name) also provides comprehensive support and service to ensure that their customers receive the maximum benefit from their products. Their team of experts is available to provide technical assistance, training, and maintenance services to keep operations running smoothly.As the oil and gas industry continues to evolve, (company name) remains at the forefront of innovation, delivering solutions that meet the changing needs of the industry. The release of the (product name) further solidifies their position as a leader in the field of drilling equipment and technology.In conclusion, the (product name) from (company name) is a game-changing solution for the oil and gas industry, offering unmatched performance, reliability, and efficiency for drilling operations. With its advanced design and durable construction, it is sure to become an essential tool for operators looking to optimize their operations and reduce costs. As the industry continues to demand high-performance equipment, (company name) remains committed to providing the innovative solutions that operators need to succeed.

Mesh Shale Shaker Screen - The Latest Innovation in Oil and Gas Industry

In recent times, the oil and gas industry has witnessed increased demand for cutting-edge technologies to improve production efficiency and effectiveness. One of the essential tools for efficient drilling operations is the shale shaker screen. It separates solids and liquids, allowing drilling companies to recycle drilling fluids and save resources. Brandt Api All Mesh Shale Shaker Screen (brand name removed for confidentiality), is a premium quality product that offers highly efficient and reliable performance. The brand has built a reputation for producing high-quality shale shaker screens that meet the unique demands of drilling operations. The Brandt API All Mesh Shale Shaker Screen is designed to withstand the harsh conditions of drilling activities. It is made of high-quality materials that can withstand high temperatures, high pressure, and abrasive environments. The shaker screen is fully compliant with API RP 13C regulations, ensuring that it meets the highest standards for quality, reliability, and performance. The Brandt API All Mesh Shale Shaker Screen has several features that make it stand out in the market. First, it has a unique mesh design that enhances drilling fluid handling capacity. It can separate solids from fluids effectively, thereby boosting drilling efficiency. The shaker screen is optimized for fine particle separation, which means that it can efficiently handle drilling muds with a higher viscosity. Another selling point of the Brandt API All Mesh Shale Shaker Screen is its durability and long-lasting performance. The screen is made of advanced composite materials that offer excellent resistance to wear and tear. It has a longer lifespan than conventional metal screens, which require frequent replacements. This feature makes the Brandt API All Mesh Shale Shaker Screen a cost-effective solution for drilling companies looking to save money on operation and maintenance costs. Ease of installation is another advantage of the Brandt API All Mesh Shale Shaker Screen. It is designed to fit most shale shakers, making it easy to install and replace. The shaker screen requires minimal maintenance, and operators can replace it quickly, reducing downtime during drilling operations. The manufacturers of the Brandt API All Mesh Shale Shaker Screen have expressed their excitement about the product's performance and the prospects it offers the oil and gas exploration sector. Speaking during the product launch, the company's spokesperson stated that the company had invested heavily in research and development to produce a highly efficient and reliable shale shaker screen that meets the changing demands of the industry. "We are excited to introduce the Brandt API All Mesh Shale Shaker Screen to the market," said the spokesperson. "It is a product that demonstrates our commitment to innovation and excellence. We believe that the shale shaker screen's reliability, performance, and ease of installation make it a game-changer for the industry. We are confident that drilling companies will enjoy the benefits of this product, saving both time and money on operations and maintenance costs." The Brandt API All Mesh Shale Shaker Screen has already garnered positive reviews and feedback from some of the industry's leading operators. Companies that have used the product attest to its efficiency, durability, and long-lasting performance. Many drilling companies have reported high uptime rates and low maintenance costs since switching to the Brandt API All Mesh Shale Shaker Screen. In conclusion, the Brandt API All Mesh Shale Shaker Screen is a superior quality product that delivers excellent results for drilling operations. It is durable, efficient, and cost-effective, offering drilling companies a reliable solution to boost their operational efficiency. With the current high demand for drilling activities and the increasing need for sustainable practices, the Brandt API All Mesh Shale Shaker Screen is an essential tool for drilling operations seeking to optimize performance, reduce costs, and improve resource management.

Efficient Shaker Screen for Optimal Solids Separation

Title: Groundbreaking S250 Shaker Screen Sets New Standards in Oil and Gas IndustryIntroduction:In a world reliant on energy extraction, the oil and gas industry remains a vital player, constantly seeking innovative technologies to optimize drilling and production processes. Step forward the revolutionary S250 Shaker Screen, a cutting-edge solution developed by industry-leading experts, poised to reshape the landscape of oilfield equipment. This groundbreaking equipment promises improved performance, increased durability, and enhanced efficiency, cementing its position as a game-changer in the global market.Section 1: Evolution of Shaker Screens in the Oil and Gas IndustryThe oil and gas industry is known for its relentless pursuit of efficiency and cost-effectiveness. Over the years, there has been an evolution in shaker screens, which play a crucial role in filtering drilling fluids during extraction operations. The S250 Shaker Screen encompasses the latest innovations in material science and design, surpassing its predecessors in terms of longevity and performance.Section 2: Unparalleled Design and Superior PerformanceThe development team behind the S250 Shaker Screen focused on improving the efficiency of the screening process. By enhancing the screen's capacity to retain solids while allowing drilling fluid to pass through, the S250 ensures uninterrupted operation and reduces downtime. Its state-of-the-art design maximizes solids removal, leading to cleaner drilling fluids and increased productivity on-site.Section 3: Enhanced Durability and Cost-EffectivenessIn the oilfield, durability is of paramount importance. The S250 Shaker Screen guarantees exceptional longevity, enabling operators to optimize equipment performance while reducing overall maintenance costs. Manufactured using high-quality materials and employing advanced engineering techniques, this screen withstands the harshest operating conditions, making it an indispensable asset for drilling companies worldwide.Section 4: Eco-Friendly and Sustainable SolutionCorporate social responsibility has become a crucial aspect of the oil and gas industry. Recognizing this, the S250 Shaker Screen is designed with sustainability in mind. By ensuring optimal solids removal and minimizing waste, it significantly reduces environmental impact. Additionally, its extended lifespan and reduced maintenance contribute to minimizing the carbon footprint associated with equipment replacement.Section 5: Market Impact and Industry AdoptionThe launch of the S250 Shaker Screen has generated substantial excitement within the oil and gas industry. Major drilling companies are already adopting this cutting-edge technology, recognizing its potential to revolutionize their operations. With demand rising, manufacturers are increasing production capacity to meet global market needs and capitalize on the expanding customer base.Section 6: Testing and ValidationBefore its launch, the S250 Shaker Screen underwent rigorous testing to ensure it met the industry's stringent quality standards. Evaluation criteria included efficiency, durability, and compatibility with various drilling fluids. The results were overwhelmingly positive, confirming that this novel solution is ready to transform the industry.Conclusion:The S250 Shaker Screen stands as a testament to the relentless pursuit of innovation within the oil and gas industry. Its revolutionary design, exceptional performance, and unmatched durability set a new benchmark for shaker screens. With the global market embracing this game-changing technology, the stage is set for a more efficient and sustainable future in oil and gas extraction.

High-quality 28 Series Screen for Industrial Use

Introducing the New 28 Series ScreenIn today's fast-paced world, technological advancements are taking place at an unprecedented rate, revolutionizing the way we live and work. One such groundbreaking innovation is the newly launched 28 Series Screen by a leading provider in the industry. This cutting-edge product is now set to transform the way businesses and individuals engage with digital content, offering a plethora of features and capabilities that cater to a wide range of needs and preferences.With its sleek design and state-of-the-art technology, the 28 Series Screen is designed to deliver an unparalleled viewing experience. One of its key highlights is the high-resolution display, which ensures crisp and clear visuals, allowing users to immerse themselves in their work or entertainment. Whether it's designing graphics, editing videos, or simply enjoying a movie, this screen promises to deliver stunning image quality that surpasses expectations.Additionally, the screen also boasts a range of connectivity options, making it versatile and adaptable to various devices and systems. With multiple ports and compatibility with different interfaces, users can seamlessly connect their laptops, desktops, gaming consoles, and other devices to the screen, maximizing convenience and efficiency. This makes it an ideal choice for professionals and enthusiasts who require a flexible and dynamic display solution.Furthermore, the 28 Series Screen is equipped with advanced features that enhance user experience and promote productivity. From customizable display settings to ergonomic design, every aspect of the product is meticulously crafted to cater to the diverse needs of modern-day users. Whether it's adjusting the screen tilt for optimal viewing angles or toggling between different modes for specific tasks, this screen is designed to adapt to the user's preferences and requirements.In addition to its exceptional performance and functionality, the 28 Series Screen also prioritizes sustainability and energy efficiency. As an environmentally conscious brand, the company has incorporated eco-friendly materials and technologies into the screen's design, ensuring minimal environmental impact without compromising on quality or performance. This aligns with the company's commitment to corporate social responsibility and reflects its dedication to creating products that are not only innovative but also environmentally sustainable.As a testament to its reliability and superior quality, the 28 Series Screen is backed by comprehensive support and warranty services. Customers can rest assured that they will receive prompt assistance and technical support in the unlikely event of any issues or concerns. This demonstrates the company's unwavering dedication to customer satisfaction and its confidence in the durability and longevity of the product.Overall, the 28 Series Screen represents a significant leap forward in display technology, offering a blend of cutting-edge features, versatility, and sustainability. With its sleek design, immersive visuals, and user-centric functionality, it is poised to set new standards in the industry and cater to the evolving needs of consumers across various sectors. Whether it's for professional use, creative endeavors, or entertainment, this screen is set to redefine the way we engage with digital content, making it a must-have for anyone seeking a premium display solution.

High-performance Oil Shaker Screen for Derrick FLC500

Derrick Corporation Introduces Innovative FLC500 Oil Shaker ScreenDerrick Corporation, a global leader in innovative equipment for the oil and gas industry, recently announced the launch of their latest product, the FLC500 Oil Shaker Screen. This new addition to Derrick's extensive product line is designed to provide unparalleled performance and reliability in the field of solids control.The FLC500 Oil Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced by oil and gas operators in their efforts to efficiently separate solids from drilling fluids. Derrick Corporation's commitment to innovation and customer satisfaction is evident in the design and performance of this cutting-edge product.The FLC500 Oil Shaker Screen features a unique design that allows for increased throughput and finer solids separation. Its high-quality construction and advanced technology ensure durability and longevity, even in the most demanding operating conditions. This makes it an ideal choice for oil and gas operators looking to maximize efficiency and minimize downtime.One of the key features of the FLC500 Oil Shaker Screen is its ability to effectively handle a wide range of drilling fluids, including those with high viscosity and high solids content. This flexibility is essential for operators working in diverse geological formations and drilling environments, where the composition of drilling fluids can vary significantly.In addition to its exceptional performance, the FLC500 Oil Shaker Screen is also designed with ease of use and maintenance in mind. Derrick Corporation understands the importance of minimizing downtime and maximizing uptime for their customers, and this product reflects that commitment. Its simple and intuitive design allows for quick and easy installation, as well as efficient cleaning and maintenance.Furthermore, Derrick Corporation provides comprehensive support and service for the FLC500 Oil Shaker Screen, ensuring that customers have access to the expertise and resources they need to keep their equipment running at peak performance. This includes technical assistance, spare parts availability, and training programs to help operators make the most of their investment.The introduction of the FLC500 Oil Shaker Screen reinforces Derrick Corporation's position as a leading provider of innovative solutions for the oil and gas industry. With a proven track record of delivering high-quality products and outstanding customer service, Derrick Corporation continues to set the standard for excellence in solids control equipment."We are thrilled to introduce the FLC500 Oil Shaker Screen to the market," said a spokesperson for Derrick Corporation. "This product represents a significant advancement in solids control technology, and we are confident that it will make a positive impact for our customers. We remain committed to pushing the boundaries of innovation and setting new benchmarks for performance and reliability."Oil and gas operators who are interested in learning more about the FLC500 Oil Shaker Screen and its capabilities are encouraged to contact Derrick Corporation for additional information. With its impressive performance, durability, and ease of use, this product promises to deliver significant benefits for those in need of reliable solids control solutions.