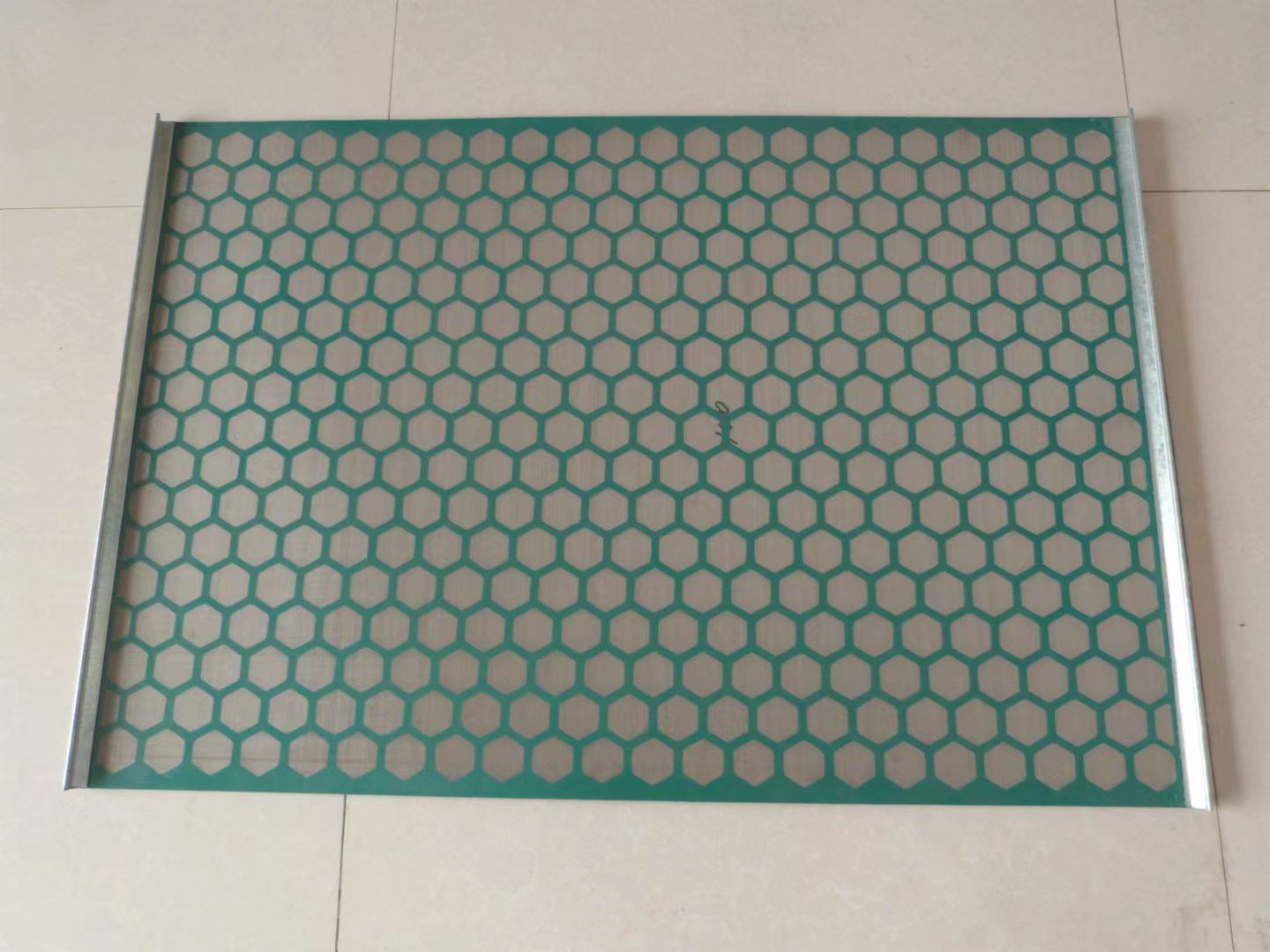

Composite Frame King Cobra Shale Shaker Screen for Oilfield Solids Control

By:Admin

The King Cobra Composite Frame Shale Shaker Screen is engineered to deliver exceptional efficiency and durability, making it an indispensable tool for operators seeking to maximize their drilling operations. With an advanced composite frame construction that provides superior resistance to corrosion and abrasion, this screen is built to withstand the harshest drilling environments, ensuring consistent performance and longevity.

One of the key features of our King Cobra Composite Frame Shale Shaker Screen is its optimized mesh design, which offers a greater open area for improved fluid handling and solids removal. This innovative design allows for increased flow rates and enhanced separation of drilling cuttings, resulting in higher efficiency and lower overall operating costs for our customers.

Furthermore, the use of high-quality composite materials in the construction of the screen frame ensures a lightweight yet robust structure that minimizes downtime and maintenance requirements. This contributes to a significant reduction in operational costs and enhances the overall productivity of drilling operations.

In addition to its exceptional performance and durability, the King Cobra Composite Frame Shale Shaker Screen is also designed for easy installation and compatibility with a wide range of shale shaker models, providing operators with greater flexibility and convenience. This ensures seamless integration into existing drilling systems, allowing for immediate improvements in efficiency and performance.

As a company dedicated to innovation and customer satisfaction, we have conducted rigorous testing and quality control measures to ensure that the King Cobra Composite Frame Shale Shaker Screen meets the highest industry standards and exceeds the expectations of our customers. We are confident that this groundbreaking product will set a new standard for shale shaker screens and make a significant impact on the oil and gas industry.

With the launch of the King Cobra Composite Frame Shale Shaker Screen, our company remains committed to delivering cutting-edge solutions that address the evolving needs of the oil and gas sector. We are proud to be at the forefront of technological advancements in the industry, and we will continue to invest in research and development to bring innovative products to market that drive efficiency, reliability, and cost savings for our customers.

In conclusion, the King Cobra Composite Frame Shale Shaker Screen represents a significant milestone for our company and the oil and gas industry as a whole. With its unrivaled performance, durability, and ease of use, this innovative product is poised to revolutionize drilling operations and set new benchmarks for excellence. We are excited to bring this game-changing technology to our customers and look forward to the positive impact it will have on their operations.

Company News & Blog

Guide to Oil Vibrating Screen: Uses, Benefits, and Maintenance

Oil Vibrating Screen is a vital piece of equipment in the oil and gas industry, used to separate solids from liquids in drilling operations. It's an essential tool for maintaining the efficiency and reliability of drilling operations. One of the leading manufacturers of Oil Vibrating Screens is {}. The company has been in the industry for over a decade and has built a strong reputation for producing high-quality, durable, and reliable vibrating screens for use in the oil and gas sector. They have a wide range of products to cater to the varying needs of their clients, from standard vibrating screens to custom-designed solutions for specific applications. The company takes pride in its ability to provide innovative and cost-effective solutions to its customers, making them a preferred choice in the industry.Recently, the company has introduced a new range of Oil Vibrating Screens that are designed to offer even greater efficiency and performance. These new screens are equipped with the latest technology to enhance their functionality and durability, ensuring reliable operation even in the most challenging drilling environments.The new range of Oil Vibrating Screens from {} features improved screen panels that are more resistant to wear and tear, ensuring a longer lifespan and reduced maintenance costs for their customers. The screens also come with enhanced vibration mechanisms that deliver higher G-forces, improving the separation of solids and liquids and increasing the overall efficiency of the drilling process.In addition to the technical improvements, the new range of screens also incorporates advanced control systems that allow for better monitoring and adjustment of the screening process, further optimizing performance and ensuring consistent and reliable operation.The company's commitment to innovation and continuous improvement is reflected in the new range of Oil Vibrating Screens, which is set to raise the bar in terms of performance, reliability, and cost-effectiveness in the industry.In a statement, a spokesperson for {} said, "We are excited to introduce our latest range of Oil Vibrating Screens, which represents a significant step forward in terms of technology and performance. Our team has worked tirelessly to develop these new screens, incorporating the latest advancements to ensure that they meet and exceed the expectations of our customers. We are confident that these new screens will make a positive impact on the efficiency and productivity of drilling operations for our clients."The company's dedication to quality and reliability has made them a trusted partner for many companies in the oil and gas sector. With the introduction of their new range of Oil Vibrating Screens, they are poised to further strengthen their position as a leading provider of screening solutions for the industry.As the global demand for oil and gas continues to grow, the need for efficient and reliable drilling operations becomes increasingly important. High-quality equipment, such as Oil Vibrating Screens, plays a crucial role in ensuring the smooth and successful operation of drilling activities, making companies like {} an invaluable asset to the industry.With their latest advancements in technology and their unwavering commitment to customer satisfaction, {}. is well-positioned to continue leading the way in providing innovative and high-performance solutions for the oil and gas sector. Their new range of Oil Vibrating Screens is testament to their dedication to excellence and to meeting the evolving needs of their customers in the industry.

High-Quality FLC313M Screen: What You Need to Know

Derrick Corporation, a leading global provider of high-quality separation and filtration equipment, has recently launched its latest innovation – the FLC313M screen. This new addition to the company’s extensive product line promises to revolutionize the way the oil and gas industry approaches solids control and dewatering.The FLC313M screen is designed to deliver superior performance and efficiency in separating solids from drilling fluid. Its advanced design features a unique combination of high-quality materials and innovative engineering, resulting in increased throughput and reduced operating costs for customers. With a focus on durability and reliability, this screen is built to withstand the demands of the most challenging drilling environments.One of the standout features of the FLC313M screen is its versatility. Suitable for both onshore and offshore applications, this screen excels in a wide range of operating conditions, including high temperature and high-pressure environments. Its ability to consistently deliver exceptional performance in such diverse settings sets it apart from other products currently available on the market.Furthermore, Derrick Corporation is committed to providing best-in-class customer service and support. The launch of the FLC313M screen is part of the company’s ongoing effort to meet the evolving needs of its global customer base. By offering innovative solutions that enhance efficiency and productivity, Derrick Corporation continues to solidify its position as a trusted partner to the oil and gas industry.In addition to the FLC313M screen, Derrick Corporation offers a comprehensive range of separation and filtration equipment, including shakers, hydrocyclones, and centrifuges. With a proven track record of delivering high-performance solutions, the company has established itself as a leader in the field of solids control and dewatering.The development and launch of the FLC313M screen underscore Derrick Corporation’s dedication to innovation and excellence. By staying at the forefront of technological advancements, the company remains well-positioned to address the evolving needs of the oil and gas industry. As the industry continues to seek more efficient and cost-effective solutions, Derrick Corporation is poised to provide the cutting-edge equipment required to meet these demands.In conclusion, the introduction of the FLC313M screen represents a significant milestone for Derrick Corporation. With its unmatched performance, durability, and versatility, this new addition to the company’s product line is set to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to push the boundaries of innovation, customers can expect to benefit from the superior quality and reliability that have become synonymous with the company’s brand.About Derrick Corporation:Derrick Corporation is a global provider of high-quality separation and filtration equipment for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner to its global customer base. Derrick Corporation is committed to delivering best-in-class equipment and solutions that enhance efficiency and productivity in solids control and dewatering applications.

Latest Oil Shale Shaker Screen Delivers Optimal Performance and Efficiency

Oil Shale Shaker Screen Provides Enhanced Efficiency and Performance for Oil and Gas IndustryOil and gas exploration is a complex and demanding process that relies on a variety of advanced technologies to extract hydrocarbons from the earth's surface. One of the most critical components of the process is the oil shale shaker screen, which separates the rock and mud from the liquid oil in the drilling process. GNZS-752 Oil Shale Shaker Screen is a new product from one of the leading suppliers of oilfield equipment and services. The shale shaker screen delivers high-quality performance and increased efficiency in oil and gas exploration.The GNZS-752 Oil Shale Shaker Screen is a revolutionary product for the oil and gas industry. This product is designed to withstand the toughest and most challenging drilling conditions and improve drilling efficiency. The shale shaker screen is known for its ability to remove impurities from drilling liquids, making it ideal for oilfield applications. The screen is designed to filter out the solid waste material and allow only the fluid to pass through.The GNZS-752 Oil Shale Shaker Screen is designed to provide an exceptional user experience that is efficient, durable, and cost-effective. The screen is made from high-quality materials, including High Tensile Steel and Stainless Steel, and is constructed using advanced welding techniques, adding to its durability and overall quality. The GNZS-752 Oil Shale Shaker Screen comes with various mesh types to choose from, from coarse to fine mesh, providing flexibility and versatility for different drilling applications.Apart from the technical specifications of the product, the company's attention to detail in the manufacturing process is worth highlighting. The Company has a unique quality control system that ensures consistent performance and reliability of their products. Sophisticated testing equipment verifies all the products are of the highest quality. The Company uses state-of-the-art manufacturing processes to create products that not only meet but exceed industry standards and provide exceptional results to their customers.The GNZS-752 Oil Shale Shaker Screen is designed to be compatible with most drilling equipment used in the oil and gas industry, guaranteeing a smooth integration into the entire system. The product improves the efficiency of the drilling process, reducing costs and time for the oil and gas companies that use it. The shale shaker screen is environmentally friendly, and the reusable material makes it easier to comply with responsible waste management practices.The GNZS-752 Oil Shale Shaker Screen is ideal for various applications in conventional and unconventional drilling. The screen excels in removing large and small solids from the drilling fluids during the drilling process. The product is designed to be flexible, durable and maintain its effectiveness in high-pressure drilling environments where the drilling fluids cross the shaker screens on multiple occasions. The company behind the development, design, and production of the GNZS-752 Oil Shale Shaker Screen is a leader in the supply of oilfield equipment and services. The Company serves the international market and has a presence in several countries worldwide. The Company provides a variety of options, including mud cleaner, centrifugal pumps, mixing hoppers, and mud tanks, among others, that are essential in the oil and gas industry.The Company has a reputation for excellent customer service. Their customer service is standardized, providing customers with the same level of quality across all their worldwide locations. They offer their customers personalized service, providing detailed guidance on their products and materials. They also provide the necessary after-sales support through their dedicated and experienced technical support team.In conclusion, the GNZS-752 Oil Shale Shaker Screen provides the oil and gas industry with a reliable, efficient, and cost-effective solution. The screen is designed to enhance the drilling process and improve overall productivity, providing valuable benefits to oil and gas companies. The company's customer service, coupled with their technical support team, ensures that their clients receive the necessary information to make the best decision for their drilling operations. As the oil and gas industry continues to evolve, the GNZS-752 Oil Shale Shaker Screen is poised to play an even more critical role in helping companies to achieve their objectives with increased efficiency and profitability.

VSM 300 Secondary Oil Shaker Screen: A Guide to Choosing the Best Option

Global Oil Shaker Screen Company is proud to announce its latest innovation, the VSM 300 Secondary Oil Shaker Screen. This new product is designed to offer superior performance and efficiency in the oil drilling and extraction process, further solidifying our position as a leader in the industry.The VSM 300 Secondary Oil Shaker Screen is a high-quality replacement screen that is compatible with the VSM 300 shale shaker. It is designed to effectively remove solids from drilling fluid while ensuring maximum efficiency and durability. This new product is the result of extensive research and development, as well as feedback from our customers in the oil and gas industry.One of the key features of the VSM 300 Secondary Oil Shaker Screen is its advanced composite frame, which provides increased strength and longer service life compared to traditional metal frames. This innovative design reduces the risk of screen failure and ensures that the screen can withstand the demanding conditions of oil drilling operations. Additionally, the screen is manufactured using high-quality materials that are resistant to corrosion and abrasion, further enhancing its longevity and performance.In addition to its durability, the VSM 300 Secondary Oil Shaker Screen also offers superior solids control capabilities. The screen features a unique layered design that effectively separates solids from drilling fluid, allowing for the efficient removal of unwanted particles. This not only helps to maintain the quality of the drilling fluid but also reduces the wear and tear on downstream equipment, resulting in cost savings and improved operational efficiency.Furthermore, the VSM 300 Secondary Oil Shaker Screen is engineered to provide a high conductance rate, ensuring that drilling fluid can flow through the screen at an optimal rate. This helps to prevent blockages and ensures that the drilling process can continue uninterrupted, ultimately leading to increased productivity and reduced downtime.As a global leader in the oil and gas industry, Global Oil Shaker Screen Company is committed to providing high-quality products and exceptional service to our customers. Our team of experienced engineers and technicians are dedicated to developing innovative solutions that meet the evolving needs of the industry, and the VSM 300 Secondary Oil Shaker Screen is a testament to this commitment.With the introduction of the VSM 300 Secondary Oil Shaker Screen, Global Oil Shaker Screen Company is continuing its legacy of excellence and innovation in the oil and gas industry. This new product showcases our dedication to providing superior solutions for solids control and fluid management, and we are confident that it will deliver exceptional performance in a wide range of drilling applications.In conclusion, the VSM 300 Secondary Oil Shaker Screen is a testament to Global Oil Shaker Screen Company's dedication to innovation and excellence in the oil and gas industry. With its advanced design, superior durability, and unmatched performance, this new product is set to revolutionize solids control in oil drilling operations, providing our customers with a reliable and efficient solution for their fluid management needs. As we look to the future, Global Oil Shaker Screen Company remains committed to pushing the boundaries of innovation and delivering value to our customers around the world.

High Performance Mongoose Screen and Shaker Screen for Efficient Solids Control

Global oil and gas demand continues to rise, and with it the need for efficient and reliable drilling equipment. We are proud to announce the launch of our newest innovation in the oil and gas industry – the state-of-the-art Mongoose Shaker Screen. This cutting-edge technology is designed to improve the efficiency and performance of drilling operations, providing a cost-effective solution for our clients.The Mongoose Shaker Screen is a high-quality, durable and reliable product that is designed to withstand the most demanding drilling conditions. Its advanced design and construction ensure that it provides superior performance and longevity, reducing downtime and increasing productivity on the drilling site. Our commitment to quality and innovation is evident in every aspect of the Mongoose Shaker Screen, from its superior materials to its precise manufacturing processes.The Mongoose Shaker Screen is engineered to deliver exceptional performance in a wide range of drilling applications, including both onshore and offshore operations. Its innovative design allows for more efficient separation of drilling fluid and solids, reducing waste and improving overall drilling performance. The result is a cleaner, more efficient drilling process that saves time and money for our clients.In addition to its superior performance, the Mongoose Shaker Screen is also designed with ease of use and maintenance in mind. Its user-friendly design allows for quick and simple installation, while its durable construction ensures long-lasting performance with minimal maintenance requirements. This means that our clients can focus on their drilling operations with confidence, knowing that they have a reliable and efficient solution in place.Furthermore, our commitment to environmental sustainability is reflected in the design of the Mongoose Shaker Screen. By reducing the amount of drilling waste and improving drilling efficiency, our product helps to minimize the environmental impact of drilling operations. This aligns with our company's values and commitment to responsible and sustainable business practices.At [Company Name], we are dedicated to delivering the highest quality products and services to our clients. The launch of the Mongoose Shaker Screen is a testament to our ongoing dedication to innovation and excellence in the oil and gas industry. We are confident that this new product will deliver exceptional value to our clients, helping them to improve their drilling operations and achieve greater success in their business endeavors.In conclusion, the Mongoose Shaker Screen represents a significant advancement in drilling technology, designed to enhance efficiency, reliability, and sustainability in drilling operations. With its superior performance, ease of use, and environmental benefits, it is set to become a leading solution in the oil and gas industry. We are excited to bring this innovative product to our clients and look forward to the positive impact it will have on their drilling operations.

High-Quality MD-2 Shaker Screen for Efficient Solid Control

In a dynamic market environment where the demand for high-quality oilfield equipment is on the rise, the [Company Name] has been consistently delivering top-notch products to meet the evolving needs of the industry. The company, with its commitment to innovation and excellence, has been a leading provider of oilfield equipment, and its latest offering, the Swaco MD-2 Shaker Screen, is set to make waves in the industry.The Swaco MD-2 Shaker Screen is a critical component in the solids control process in the oil and gas industry. It is designed to separate solids from drilling fluid, ensuring that the fluid remains in optimal condition for the drilling operation. The efficiency and reliability of the shaker screen are crucial to the overall performance of the solids control system, and the Swaco MD-2 Shaker Screen delivers on both fronts.One of the key features of the Swaco MD-2 Shaker Screen is its superior screen mesh design, which allows for maximum throughput while maintaining accurate particle separation. This results in improved overall efficiency of the solids control process, leading to cost savings and enhanced drilling performance. Additionally, the shaker screen is built to withstand the harsh operating conditions encountered in the oilfield, ensuring long-lasting performance and minimal downtime.The Swaco MD-2 Shaker Screen is also a testament to [Company Name]'s commitment to sustainability and environmental responsibility. The screen is designed to minimize waste and reduce the environmental impact of drilling operations. By effectively separating solids from the drilling fluid, the shaker screen contributes to the overall reduction of waste and promotes responsible environmental stewardship in the oil and gas industry.As a leading provider of oilfield equipment, [Company Name] has built a solid reputation for delivering products of the highest quality. The company's team of experienced engineers and technical experts have worked tirelessly to ensure that the Swaco MD-2 Shaker Screen meets and exceeds the industry's stringent standards. Rigorous testing and quality control processes have been implemented to guarantee the reliability and performance of the shaker screen, giving customers the confidence that they are investing in a superior product.Moreover, [Company Name] takes pride in its customer-centric approach, offering comprehensive support and technical assistance to ensure that customers are able to maximize the benefits of the Swaco MD-2 Shaker Screen. The company's dedicated team is always on hand to provide guidance and assistance, from the initial selection of the shaker screen to ongoing maintenance and support throughout its operational life.The launch of the Swaco MD-2 Shaker Screen marks a significant milestone for [Company Name], further solidifying its position as a trusted provider of innovative and reliable oilfield equipment. With a relentless focus on customer satisfaction, product excellence, and environmental stewardship, the company is well-poised to meet the evolving needs of the oil and gas industry and set new benchmarks for performance and reliability.In conclusion, the Swaco MD-2 Shaker Screen is a testament to [Company Name]'s unwavering commitment to delivering exceptional products that drive efficiency, sustainability, and performance in the oilfield. With its advanced features, superior quality, and comprehensive support, the shaker screen is set to become the go-to choice for operators looking to optimize their solids control process and achieve superior drilling performance. As the industry continues to evolve, [Company Name] remains at the forefront, setting new standards and raising the bar for excellence in oilfield equipment.

High Performance Shaker Screen with FSI 5000 Technology

The oil and gas industry is constantly evolving, with new technologies and innovations driving the sector forward. One of the key components of the industry is the use of shale shakers to separate drilling cuttings from drilling fluid. This process is crucial in maintaining the efficiency and effectiveness of drilling operations.In this regard, the FSI 5000 Shaker Screen has been making waves in the industry. This cutting-edge technology has been designed to provide superior performance and durability, making it a game-changer in the field of shale shaker screens. The FSI 5000 Shaker Screen is engineered to meet the demanding requirements of the oil and gas industry, and its innovative design sets it apart from traditional shaker screens.The FSI 5000 Shaker Screen is manufactured by a leading company in the oil and gas sector, known for its commitment to quality and excellence. With a strong focus on research and development, this company has been at the forefront of technological advancements in the industry. The FSI 5000 Shaker Screen is a testament to their dedication to innovation and their relentless pursuit of excellence.One of the key features of the FSI 5000 Shaker Screen is its advanced composite frame, which provides exceptional strength and longevity. This not only enhances the performance of the shaker screen, but also reduces the overall cost of ownership for the end user. The innovative design of the FSI 5000 Shaker Screen is a result of extensive research and development, ensuring that it meets the highest standards of quality and reliability.In addition to its superior performance, the FSI 5000 Shaker Screen is also designed with ease of use in mind. Its user-friendly interface and simple maintenance procedures make it an ideal choice for busy drilling operations. This allows for seamless integration into existing shaker systems, minimizing downtime and maximizing efficiency.The FSI 5000 Shaker Screen has already garnered rave reviews from industry professionals who have praised its durability and effectiveness. Its ability to withstand the rigors of the oil and gas sector and deliver consistent performance has made it a popular choice among drilling contractors and operators.Furthermore, the company behind the FSI 5000 Shaker Screen is known for its commitment to customer satisfaction. They offer comprehensive support and service to ensure that their clients get the most out of their investment. This includes technical assistance, training, and ongoing maintenance programs to keep the FSI 5000 Shaker Screen operating at its peak performance.In conclusion, the FSI 5000 Shaker Screen is a groundbreaking innovation that is set to revolutionize the oil and gas industry. Its advanced design, superior performance, and exceptional durability make it a top choice for drilling operations around the world. Combined with the company's dedication to quality and customer satisfaction, the FSI 5000 Shaker Screen is poised to become an indispensable asset in the oil and gas sector.

Discover the Benefits of Flat PWP Shaker Screens for Enhanced Performance

Title: Industry-Leading Flat PWP Shaker Screen Revolutionizes Oil Filtration ProcessIntroduction:In a world where efficiency and reliability reign supreme, the oil and gas industry continually seeks innovative solutions to enhance their operations. As a response to this need, Company XYZ has unveiled its industry-leading Flat PWP Shaker Screen, a revolutionary product that promises to transform the oil filtration process. By combining cutting-edge technology with years of experience, Company XYZ has once again positioned itself as a frontrunner in the market, delivering exceptional results to its clients.The Flat PWP Shaker Screen:Designed to optimize the oil filtration process, the Flat PWP Shaker Screen features a technologically advanced flat design that allows for better fluid handling, improved filtration efficiency, and extended operational lifespan. This groundbreaking development sets it apart from conventional shaker screens in terms of performance, durability, and reliability.Enhanced Fluid Handling:One of the key advantages of the Flat PWP Shaker Screen is its ability to provide superior fluid handling capabilities. The innovative flat design offers increased open area, facilitating smoother fluid flow throughout the screening process. This enables a higher throughput, reducing the likelihood of blockages and improving overall productivity. The advanced technology behind the Flat PWP Shaker Screen ensures consistent separation and particle filtration, irrespective of the feed conditions.Improved Filtration Efficiency:With its precision-engineered mesh, the Flat PWP Shaker Screen offers unmatched filtration efficiency. The mesh size and configuration of the screen are meticulously crafted to capture a wide range of particle sizes, ensuring that the extracted oil meets the desired quality standards. High-quality filtration not only leads to increased oil purity but also enhances the efficiency of downstream processes such as refining and purification.Extended Operational Lifespan:The Flat PWP Shaker Screen boasts exceptional durability and longevity, significantly minimizing downtime and replacement costs. Constructed using premium-quality materials and employing advanced manufacturing techniques, this screen can endure challenging operating conditions, including high temperatures and corrosive environments. Its robust design allows for continuous use, resulting in extended operational lifespan and reduced maintenance efforts. This longevity serves as a testament to the superior engineering and unrivaled commitment of Company XYZ.Company XYZ's Expertise:Company XYZ has been at the forefront of the oil and gas industry for several years, renowned for its dedication to innovation and customer satisfaction. The release of the Flat PWP Shaker Screen further exemplifies the company's commitment to enhancing operational efficiency, optimizing productivity, and providing comprehensive solutions to its clients.With an experienced team of engineers and researchers, Company XYZ has successfully developed and refined products that meet the most rigorous industry standards. Through partnerships with leading oil and gas companies, Company XYZ has gained unparalleled insights into the challenges faced by the industry. This knowledge, coupled with cutting-edge technology, ensures that the Flat PWP Shaker Screen is tailor-made to address the specific demands of the oil filtration process.Conclusion:As the oil and gas industry continue to evolve and demand higher standards, Company XYZ's Flat PWP Shaker Screen emerges as a game-changer. This revolutionary product pushes the boundaries of conventional shaker screens, offering enhanced fluid handling, improved filtration efficiency, and extended operational lifespan. With its commitment to innovation, expertise, and customer satisfaction, Company XYZ has once again positioned itself as a leader in the field, providing the industry with a reliable and efficient solution for optimizing the oil filtration process.

Sugar Sieve Shaker Offers Efficient Filtering: Discover its Benefits Today!

Introducing: A Revolutionary Sugar Sieve Shaker Enhancing Efficiency and Precision in Sugar ProcessingSugar processing, a crucial step in the food and beverage industry, has now received a notable upgrade with the introduction of an innovative sugar sieve shaker. This groundbreaking technology has been developed by a leading company in the field of food manufacturing equipment, whose dedication to enhancing efficiency and precision has revolutionized sugar processing.With an unwavering commitment to quality and continuous improvement, this esteemed company has become a key player in the industry. Their expertise lies in designing and manufacturing cutting-edge equipment that meets the ever-evolving needs of food producers worldwide.The new sugar sieve shaker has been meticulously designed and engineered to optimize the sugar processing workflow. By leveraging state-of-the-art technology, this device offers unparalleled efficiency and precision in separating sugar crystals of different sizes. The shaker's unique design allows for a controlled and uniform sieving process, ensuring that only the desired particle sizes make their way through.One of the standout features of this sugar sieve shaker is its ability to handle a high throughput, significantly boosting overall productivity. Equipped with a powerful motor, it can handle large quantities of sugar with ease, avoiding downtime and delays that can occur with traditional methods. Additionally, this advanced shaker operates with minimal noise, creating a more pleasant working environment for operators.To further enhance efficiency and precision, the company has integrated advanced automation capabilities into the sugar sieve shaker. By implementing precise controls and monitoring systems, the device can automatically adjust sieve settings based on predefined parameters. This automation reduces the risk of operator error and ensures a consistently high-quality end product.Another crucial aspect of the sugar sieve shaker is its versatility. Designed to cater to the diverse requirements of the sugar processing industry, this device can be customized to fit a range of needs. Whether it's adapting to different sugar crystal sizes or accommodating unique sieving processes, the shaker can be fine-tuned to meet specific demands.Furthermore, the company's relentless focus on sustainability shines through in the development of this state-of-the-art sugar sieve shaker. By optimizing energy consumption and maximizing efficiency, this device has made significant strides in reducing the environmental impact of sugar processing operations.The company's commitment to customer satisfaction is evident not only in the performance of their equipment but also in their exceptional customer service. Their dedicated team of experts works closely with clients to understand their needs and provide tailored solutions that meet and exceed expectations. From initial consultations to ongoing technical support, this company stands as a reliable partner throughout the entire process.In conclusion, the introduction of this revolutionary sugar sieve shaker marks a new era in sugar processing. With its unrivaled efficiency, precision, and adaptability, this breakthrough technology has the potential to transform the industry. Backed by a company renowned for its expertise and commitment to customer satisfaction, this sugar sieve shaker is set to redefine sugar processing standards worldwide.

VSM300 Primary Screen: Key Details and Updates

Houston, TX – The primary screen from one of the leading shale shaker manufacturers has been making waves in the oil and gas industry. The VSM300 Primary Screen, designed to meet the demanding requirements of the industry, has been a game changer in the field of shale shaker technology.The {Company Name} has been at the forefront of providing innovative solutions for the oil and gas industry. With a focus on research and development, the company has continuously pushed the boundaries of what is possible in the field of shale shaker technology. Their commitment to quality and customer satisfaction has made them a trusted name in the industry.The VSM300 Primary Screen is the latest offering from {Company Name}, and it has quickly gained a reputation for its exceptional performance and durability. The screen is designed to be used with the VSM300 shale shaker, a popular choice for many drilling operations. It is engineered to provide efficient and reliable solids control, allowing for the efficient separation of solids from drilling fluids.One of the key features of the VSM300 Primary Screen is its durability. It is constructed using high-quality materials that can withstand the harsh conditions of drilling operations. This means that operators can rely on the screen to perform consistently, even in the most demanding environments. The screen is also designed for easy installation and maintenance, which helps to minimize downtime and maximize productivity.Another important aspect of the VSM300 Primary Screen is its superior performance. The screen is engineered to provide high-capacity separation of solids from drilling fluids, ensuring that the fluids remain in optimal condition for the drilling process. This helps to improve overall drilling efficiency and reduce costs associated with fluid management.In addition to its exceptional performance and durability, the VSM300 Primary Screen also offers flexibility. It is available in a range of mesh sizes, allowing operators to customize the screen to meet their specific operational requirements. This flexibility makes the screen suitable for a wide range of drilling applications, further enhancing its value to operators.The success of the VSM300 Primary Screen can be attributed to {Company Name}'s commitment to innovation and excellence. The company has a team of experienced engineers and researchers who are dedicated to developing cutting-edge solutions for the oil and gas industry. Through their expertise and dedication, they have been able to create a product that is truly a game changer in the field of shale shaker technology.As the oil and gas industry continues to evolve, the demand for reliable and efficient solids control solutions will only continue to grow. The VSM300 Primary Screen from {Company Name} is well-positioned to meet this demand, thanks to its exceptional performance, durability, and flexibility. It is clear that this innovative product will play a significant role in shaping the future of shale shaker technology.In conclusion, the VSM300 Primary Screen from {Company Name} is a prime example of their commitment to providing innovative solutions for the oil and gas industry. This product has set a new standard for shale shaker technology, and its impact is being felt across the industry. With its exceptional performance, durability, and flexibility, it is evident that the VSM300 Primary Screen is here to stay and will continue to have a significant impact on drilling operations for years to come.