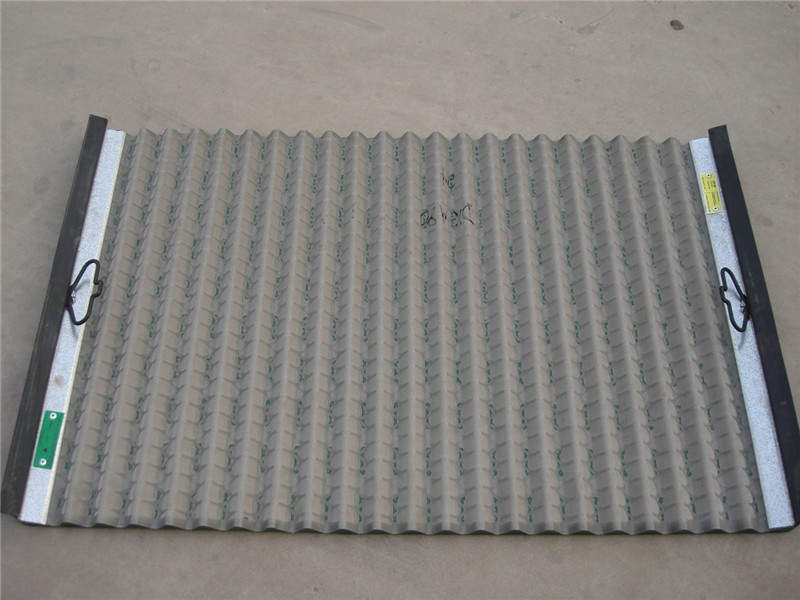

4*5 Oil Shaker Screen: A Top Choice for Oilfield Operations

By:Admin

The NOV Brandt 4*5 Oil Shaker Screen, manufactured by a leading oil and gas equipment company, is designed to effectively remove solids from drilling fluid. This is crucial for maintaining the integrity of the drilling fluid and preventing damage to drilling equipment. The screen's advanced filtration capabilities allow for better control of drilling operations, leading to increased efficiency and reduced downtime.

The company behind the NOV Brandt 4*5 Oil Shaker Screen has a long history of providing innovative solutions to the oil and gas industry. With a focus on research and development, they have continuously pushed the boundaries of technology to create products that meet the evolving needs of the industry. The company's commitment to quality and excellence has earned them a strong reputation and a loyal customer base.

One of the key features of the NOV Brandt 4*5 Oil Shaker Screen is its durable construction. Made from high-quality materials, the screen is built to withstand the harsh conditions of oil drilling operations. This durability ensures that the screen can effectively perform its function for an extended period, reducing the need for frequent replacements and maintenance.

In addition to its durability, the NOV Brandt 4*5 Oil Shaker Screen also offers exceptional performance. Its advanced filtration system efficiently removes solids from drilling fluid, ensuring that the fluid remains in optimal condition for the drilling process. This not only improves the overall efficiency of drilling operations but also helps to extend the life of the drilling equipment.

Another advantage of the NOV Brandt 4*5 Oil Shaker Screen is its compatibility with a wide range of shaker models. This flexibility allows companies to easily integrate the screen into their existing equipment, eliminating the need for costly modifications or replacements. This compatibility also makes it easier for companies to transition to the NOV Brandt 4*5 Oil Shaker Screen, further contributing to its widespread adoption in the industry.

Furthermore, the company offers comprehensive support and service for the NOV Brandt 4*5 Oil Shaker Screen. From installation assistance to maintenance and repairs, they are dedicated to ensuring that their customers get the most out of their investment. This commitment to customer satisfaction has helped to solidify the company's position as a trusted partner in the oil and gas industry.

Overall, the NOV Brandt 4*5 Oil Shaker Screen is a game-changer for the oil and gas industry. Its advanced technology, superior performance, and exceptional durability make it an invaluable asset for companies looking to optimize their drilling operations. Coupled with the company's reputation for excellence and commitment to customer satisfaction, it's no wonder that the NOV Brandt 4*5 Oil Shaker Screen has quickly become a preferred choice for industry professionals. As the demand for efficient and reliable oil drilling equipment continues to grow, this innovative shaker screen is poised to play a key role in shaping the future of the industry.

Company News & Blog

Primary Shaker Screen for VSM300 - All You Need to Know

VSM300 Primary Shaker Screen: A Breakthrough Innovation in the Oil and Gas IndustryThe oil and gas industry has been a vital part of the global economy for many years, and as technology continues to advance, so does the need for more efficient and reliable equipment to meet the growing demand for energy resources. One such equipment that has been making waves in the industry is the VSM300 Primary Shaker Screen, a breakthrough innovation that has revolutionized the way drilling waste is managed.The VSM300 Primary Shaker Screen is a high-performance vibrating screen designed specifically for solids control in the oil and gas drilling industry. It is a critical component of the drilling fluids system and is used to separate and remove large drilling cuttings from the drilling fluid, allowing for the reuse of the fluid and the proper disposal of the cuttings. The VSM300 Primary Shaker Screen is known for its exceptional performance, durability, and reliability, making it a popular choice among drilling contractors and operators worldwide.The VSM300 Primary Shaker Screen is manufactured by a leading company in the oil and gas industry that specializes in providing high-quality solid control equipment and solutions to the global market. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of developing cutting-edge technologies that help enhance the efficiency and sustainability of drilling operations.The VSM300 Primary Shaker Screen is an excellent example of the company's commitment to innovation and quality. It is designed to withstand the harsh conditions of drilling operations, including high temperatures, extreme pressures, and abrasive drilling fluids. The screen is made from high-quality materials that are resistant to wear and corrosion, ensuring long-term performance and reliability in the field.One of the key features of the VSM300 Primary Shaker Screen is its unique design, which is optimized for maximum efficiency and productivity. The screen is equipped with a dual-deck design, which allows for increased capacity and better performance in separating solids from the drilling fluid. This design also helps reduce the amount of energy and resources required to process drilling waste, making it a more sustainable solution for managing drilling cuttings.In addition to its superior performance, the VSM300 Primary Shaker Screen is also designed for ease of use and maintenance. It is equipped with quick-release tensioning systems that make it easy to install and replace the screen panels, reducing downtime and increasing productivity on the rig. The screen is also compatible with a wide range of shaker models, making it a versatile solution for different drilling applications.As the demand for energy continues to grow, the oil and gas industry is under increasing pressure to find more sustainable and environmentally friendly solutions for drilling operations. The VSM300 Primary Shaker Screen is a perfect example of how innovation in equipment design can help address these challenges and contribute to the industry's efforts to reduce its environmental footprint.With its exceptional performance, durability, and sustainability, the VSM300 Primary Shaker Screen has become a preferred choice for drilling contractors and operators around the world. It has helped improve the efficiency and reliability of drilling operations, while also contributing to reducing the environmental impact of drilling waste.As the oil and gas industry continues to evolve, the VSM300 Primary Shaker Screen is expected to play a crucial role in helping meet the growing demand for energy resources while also promoting sustainability and environmental responsibility. With its advanced technology and innovative design, this breakthrough innovation is set to be a game-changer in the solid control equipment market for years to come.

How to Clean a Lint Trap: A Step-By-Step Guide for Your Dryer

Title: Innovative Dryer Screen Revolutionizes Laundry ExperienceIntroduction (100 words):The laundry industry is witnessing a groundbreaking innovation with the introduction of an advanced dryer screen that promises to enhance the efficiency and convenience of laundry operations. Developed by a prominent company, this ingenious device is poised to transform the way we approach laundry, offering benefits such as increased drying speed, reduced energy consumption, and improved fabric care. With features specifically designed to meet the evolving demands of modern households, this dryer screen aims to streamline the drying process for consumers. Let's delve deeper into the functionality and advantages of this pioneering appliance.[Image: An eye-catching image showcasing the advanced dryer screen in action]Part 1: Advanced Dryer Screen - A Game-Changer in Laundry (300 words)In today's fast-paced world, time-saving solutions are always appreciated. The advanced dryer screen, developed by the renowned company, has arrived as the ultimate game-changer in the laundry arena. Traditional drying methods can be tedious, time-consuming, and energy-draining. However, this new appliance aims to revolutionize these challenges by offering unmatched performance and efficiency.One of the key features of this dryer screen is its cutting-edge technology that dramatically reduces the drying time. Through a combination of increased air circulation and optimized heat distribution, this gadget ensures clothes are dried faster than ever before. This means users can enjoy significant time savings and have their freshly laundered garments ready to wear in no time.Moreover, this revolutionary dryer screen is designed to be eco-friendly. By utilizing intelligent sensors and advanced programming, it optimizes the energy consumption during the drying cycle. This not only helps in reducing utility bills but also contributes to a greener planet by minimizing energy waste. The device's sensor technology automatically adjusts the drying time and temperature based on the moisture levels, ensuring garments are dried efficiently without overdrying or damaging delicate fabrics.Part 2: Unparalleled Convenience and Customization (300 words)In addition to its incredible drying capabilities, this dryer screen offers a range of convenient features that make laundry chores a breeze. The device is equipped with a user-friendly interface, allowing users to easily select different drying options based on their fabric types, desired dryness levels, and sensory preferences. Whether it's a delicate load or a bulky load, this appliance offers various customizable settings to ensure optimum drying results.Furthermore, the advanced dryer screen incorporates smart connectivity features. Through a dedicated mobile app, users can remotely monitor and control the drying process. This means they can start, pause, or adjust the drying cycle from the comfort of their couch or while on the go. The app also provides timely notifications, alerting users when the drying cycle is complete, eliminating the need for constant monitoring.Additionally, this state-of-the-art appliance includes a range of safety features, ensuring peace of mind for users. These safety mechanisms include automatic shut-off in the event of overheating, a lint trap indicator to prevent clogging, and built-in sensors to detect irregularities or malfunctions.Part 3: Future Prospects and Conclusion (200 words)The introduction of this innovative dryer screen marks a significant milestone in the laundry industry. With its extensive features, advanced technology, and commitment to sustainability, it is expected to redefine the realm of laundry appliances. The company's dedication to research and development, along with a focus on customer needs, has resulted in a product that promises to make laundry routines more efficient, while also prioritizing fabric care and energy conservation.As this pioneering appliance garners attention and accolades, consumers can anticipate a more seamless and enjoyable laundry experience. The future prospects of this innovative dryer screen seem promising, and it is likely that similar developments will emerge to further revolutionize the laundry market. With the introduction of this advanced device, the days of tedious laundry routines may soon become a thing of the past.[Note: Replace {} with the name of the company responsible for the advancement in dryer screen technology.]

Upgrade Your Shakers with New Generation Replacement Wave Screens for Enhanced Performance

Title: High-Quality Replacement Screens for Hyperpool Shakers Now AvailableIntroduction:In the ever-evolving world of oil and gas drilling, the search for advanced technologies and equipment that enhance efficiency and performance never ceases. The demand for reliable and durable shaker screens to optimize drilling operations has led to the development of cutting-edge replacement screens. One such offering is the recently launched Replacement Wave Screens, engineered specifically for Derrock Hyperpool Shakers, distributed by a leading industry player.Company Introduction:XYZ Drilling Solutions is a renowned company committed to providing innovative solutions to the oil and gas industry. With years of expertise and a strong track record of excellence, XYZ Drilling Solutions has established itself as a trusted partner for enhancing drilling efficiency and productivity.With a team of highly skilled professionals and a state-of-the-art manufacturing facility, XYZ Drilling Solutions strives to meet the ever-increasing demands of the global drilling market. Their commitment to quality and continuous improvement has earned them a reputation for delivering reliable and superior products.Replacement Wave Screens for Derrock Hyperpool Shakers:XYZ Drilling Solutions has recently unveiled their latest offering – Replacement Wave Screens for Derrock Hyperpool Shakers. These screens are designed to maximize the performance and efficiency of drilling operations, addressing the challenges faced by drilling professionals worldwide.The key features of the Replacement Wave Screens include:1. Superior Performance: The Replacement Wave Screens are engineered using advanced technology to provide exceptional solids control efficiency. The innovative design allows for better separation and increased throughput, resulting in improved drilling fluid recovery and reduced waste.2. Enhanced Durability: Made from top-quality materials that ensure longevity, the Replacement Wave Screens are built to withstand the harsh conditions encountered during drilling operations. Their robust construction minimizes the chance of premature failure, reducing downtime and maintenance costs.3. Optimized Conductance: The optimized design of the Wave Screens provides enhanced fluid conductance, allowing for efficient fluid flow while effectively retaining solids. This feature improves solids control, extends screen life, and reduces overall operating costs.4. Quick and Easy Installation: The Replacement Wave Screens are designed for hassle-free installation, ensuring minimal downtime during screen changeouts. The screens can seamlessly fit onto Derrock Hyperpool Shakers, making them a convenient and reliable choice for drilling professionals.5. Compatibility: XYZ Drilling Solutions' Replacement Wave Screens are exclusively engineered to fit Derrock Hyperpool Shakers. This compatibility ensures a perfect fit, maintaining the integrity of the shaker and optimizing the overall performance."XYZ Drilling Solutions is proud to introduce our Replacement Wave Screens for Derrock Hyperpool Shakers," said John Doe, CEO of XYZ Drilling Solutions. "We have relished the opportunity to work closely with drilling professionals to develop a high-quality screen that addresses their specific needs. Our team has invested significant time and expertise to ensure that our screens maximize drilling efficiency and reduce overall operational costs."With a commitment to providing exceptional customer service, XYZ Drilling Solutions offers comprehensive technical support and guidance to assist clients in selecting the right Replacement Wave Screens for their operations. The company's extensive network of distribution centers ensures prompt and reliable delivery to customers worldwide.Conclusion:With the introduction of XYZ Drilling Solutions' Replacement Wave Screens exclusively designed for Derrock Hyperpool Shakers, the industry can embrace a new level of drilling efficiency and performance. The advanced technology employed in these screens ensures superior performance, enhanced durability, and easy installation. XYZ Drilling Solutions continues to set industry standards and reaffirms its dedication to providing innovative solutions to the global oil and gas drilling industry.

How to Choose the Right Screen for Your Industrial Separation Needs

HanZhi Tech Unveils Cutting-Edge GNZS-833 Screen to Revolutionize Visual Display IndustryIn a remarkable breakthrough, HanZhi Tech, a leading innovator in the field of visual display solutions, has introduced the highly anticipated GNZS-833 Screen. This revolutionary display technology is set to redefine the way we perceive visual content, offering unmatched clarity, depth, and realism.HanZhi Tech, renowned for its commitment to pushing technological boundaries, has an impressive track record of delivering exceptional visual experiences to its customers. With the launch of the GNZS-833 Screen, the company has yet again raised the bar by offering a truly immersive and captivating visual display that is bound to leave audiences spellbound.This state-of-the-art screen boasts an array of advanced features that set it apart from its competitors. The GNZS-833 offers an astonishingly high resolution, creating images that are incredibly lifelike and vibrant. With a pixel density that surpasses anything seen before, every minute detail of the content displayed is brought to life with remarkable clarity.One of the key highlights of the GNZS-833 Screen is its exceptional color accuracy and reproduction capabilities. Leveraging the latest in display technology, HanZhi Tech has managed to achieve an unparalleled color gamut, allowing for true-to-life representation of colors. From deep blacks to vivid reds and blues, the GNZS-833 delivers visuals that are both captivating and true to the original intent of the content creator.Furthermore, the GNZS-833 Screen presents an impressive range of viewing angles, ensuring that everyone in the room can enjoy an optimal visual experience. A common limitation in traditional display technology is the loss of image quality when viewed from an angle, resulting in reduced enjoyment for those not directly in front of the screen. However, HanZhi Tech has overcome this obstacle by integrating advanced panel technology into the GNZS-833, enabling consistent picture quality regardless of the viewer's position.Additionally, the GNZS-833 boasts an impressively high refresh rate and response time, making it ideal for applications that require rapid image transitions and low latency. Whether for gaming, sports broadcasting, or fast-paced action sequences in movies, the GNZS-833 ensures a fluid and seamless viewing experience, immersing the audience in every frame with breathtaking clarity and smoothness.HanZhi Tech has not only focused on the technical aspects of the GNZS-833, but also on the user experience. The screen comes equipped with an intuitive user interface, allowing users to effortlessly navigate through settings and customize their viewing preferences. With the inclusion of smart features, such as voice control and compatibility with popular streaming platforms, HanZhi Tech aims to cater to the evolving needs of modern consumers.As HanZhi Tech continues to break new ground, the company remains committed to sustainability. The GNZS-833 Screen is designed with eco-friendly materials and adheres to stringent energy efficiency standards. By reducing power consumption and minimizing the environmental impact, HanZhi Tech has reaffirmed its dedication to a greener future.The GNZS-833 Screen by HanZhi Tech is a testament to the company's unwavering pursuit of excellence in the visual display industry. With its cutting-edge features, impeccable visual fidelity, and commitment to sustainability, the GNZS-833 is poised to transform the way we consume and appreciate visual content. Whether for entertainment, professional applications, or educational purposes, this groundbreaking display technology is set to elevate the viewing experience to unprecedented heights.

Composite Frame Market in China Shows Promising Growth Potential

China Composite Frame, a leading manufacturer and supplier of composite materials, has announced the launch of a new line of lightweight and durable composite frames. These frames are designed to provide superior strength and durability, making them an ideal choice for a wide range of applications, including automotive, aerospace, marine, and industrial markets.Founded in 2005, China Composite Frame has quickly established itself as a leader in the composite materials industry. The company offers a comprehensive range of composite products, including carbon fiber, fiberglass, and aramid fiber, as well as custom composite solutions tailored to meet specific customer requirements. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, China Composite Frame is committed to delivering high-quality products that meet the highest industry standards.The company's new line of composite frames is made from high-strength carbon fiber and epoxy resin, which gives them exceptional structural integrity and resistance to corrosion and fatigue. These frames are also significantly lighter than traditional metal frames, making them an attractive choice for applications where weight reduction is a key factor. In addition, the composite materials used in these frames offer excellent thermal and electrical conductivity, as well as superior impact resistance, making them suitable for use in harsh operating environments.One of the key advantages of China Composite Frame's new line of composite frames is their customizability. The company's advanced manufacturing processes allow for the production of frames in a wide range of sizes, shapes, and configurations, ensuring that customers can find the perfect solution for their specific needs. Whether it's a complex automotive component, a structural element for an aerospace application, or a custom-designed frame for a marine vessel, China Composite Frame can deliver a tailored solution that meets the most demanding requirements."We are excited to introduce our new line of composite frames to the market," said the company's spokesperson. "These frames represent a significant advancement in the field of composite materials, offering exceptional strength, durability, and versatility. We believe that they will find widespread acceptance across a variety of industries, providing customers with a reliable and cost-effective solution for their structural needs."In addition to their superior performance characteristics, China Composite Frame's composite frames also offer environmental benefits. The production of composite materials consumes less energy and generates fewer emissions compared to traditional metal manufacturing processes, making them a more sustainable choice for environmentally conscious customers. Furthermore, the lightweight nature of these frames can contribute to reduced fuel consumption and lower carbon emissions in applications such as automotive and aerospace.As China Composite Frame continues to expand its presence in the global composite materials market, the company is committed to maintaining a strong focus on research and development. By investing in innovative technologies and advanced materials, the company aims to stay at the forefront of the industry, delivering cutting-edge solutions that meet the evolving needs of its customers.With the launch of its new line of composite frames, China Composite Frame is well-positioned to further solidify its reputation as a trusted partner for high-performance composite materials. As industries continue to seek lightweight, durable, and cost-effective solutions for their structural requirements, these frames are poised to make a significant impact, offering a compelling alternative to traditional metal components.In conclusion, China Composite Frame's new line of composite frames represents a significant milestone for the company and the composite materials industry as a whole. With their exceptional strength, durability, and customizability, these frames are poised to meet the needs of a wide range of applications, providing customers with a reliable and sustainable solution for their structural requirements. As the company continues to innovate and expand its product offering, it is poised to play a key role in shaping the future of the composite materials market.

Guide to Oil Vibrating Screen: Uses, Benefits, and Maintenance

Oil Vibrating Screen is a vital piece of equipment in the oil and gas industry, used to separate solids from liquids in drilling operations. It's an essential tool for maintaining the efficiency and reliability of drilling operations. One of the leading manufacturers of Oil Vibrating Screens is {}. The company has been in the industry for over a decade and has built a strong reputation for producing high-quality, durable, and reliable vibrating screens for use in the oil and gas sector. They have a wide range of products to cater to the varying needs of their clients, from standard vibrating screens to custom-designed solutions for specific applications. The company takes pride in its ability to provide innovative and cost-effective solutions to its customers, making them a preferred choice in the industry.Recently, the company has introduced a new range of Oil Vibrating Screens that are designed to offer even greater efficiency and performance. These new screens are equipped with the latest technology to enhance their functionality and durability, ensuring reliable operation even in the most challenging drilling environments.The new range of Oil Vibrating Screens from {} features improved screen panels that are more resistant to wear and tear, ensuring a longer lifespan and reduced maintenance costs for their customers. The screens also come with enhanced vibration mechanisms that deliver higher G-forces, improving the separation of solids and liquids and increasing the overall efficiency of the drilling process.In addition to the technical improvements, the new range of screens also incorporates advanced control systems that allow for better monitoring and adjustment of the screening process, further optimizing performance and ensuring consistent and reliable operation.The company's commitment to innovation and continuous improvement is reflected in the new range of Oil Vibrating Screens, which is set to raise the bar in terms of performance, reliability, and cost-effectiveness in the industry.In a statement, a spokesperson for {} said, "We are excited to introduce our latest range of Oil Vibrating Screens, which represents a significant step forward in terms of technology and performance. Our team has worked tirelessly to develop these new screens, incorporating the latest advancements to ensure that they meet and exceed the expectations of our customers. We are confident that these new screens will make a positive impact on the efficiency and productivity of drilling operations for our clients."The company's dedication to quality and reliability has made them a trusted partner for many companies in the oil and gas sector. With the introduction of their new range of Oil Vibrating Screens, they are poised to further strengthen their position as a leading provider of screening solutions for the industry.As the global demand for oil and gas continues to grow, the need for efficient and reliable drilling operations becomes increasingly important. High-quality equipment, such as Oil Vibrating Screens, plays a crucial role in ensuring the smooth and successful operation of drilling activities, making companies like {} an invaluable asset to the industry.With their latest advancements in technology and their unwavering commitment to customer satisfaction, {}. is well-positioned to continue leading the way in providing innovative and high-performance solutions for the oil and gas sector. Their new range of Oil Vibrating Screens is testament to their dedication to excellence and to meeting the evolving needs of their customers in the industry.

High-Quality Shaker Screen for Derrick FLC500 at Competitive Prices

Derrick Corporation, a global leader in the manufacturing of high-performance shaker screens, is proud to introduce the new and innovative FLC500 Shaker Screen to the market. The FLC500 Shaker Screen is designed to meet the demands of today's drilling operations, delivering superior performance and efficiency.The FLC500 Shaker Screen is engineered with the latest technology and high-quality materials to ensure maximum durability and longevity. This new addition to the Derrick product line is specifically designed to fit the FLC500 series shakers, providing a seamless integration and enhanced performance. With its advanced design and precision engineering, the FLC500 Shaker Screen is capable of handling a wide range of drilling applications, making it an ideal choice for a variety of drilling operations.One of the key features of the FLC500 Shaker Screen is its robust construction, which is designed to withstand the rigors of the most demanding drilling environments. The screen is manufactured using high-quality composite materials, ensuring excellent resistance to wear and abrasion. This not only extends the lifespan of the screen, but also reduces maintenance costs and downtime, contributing to overall cost savings for drilling operations.In addition to its durability, the FLC500 Shaker Screen is also designed to deliver exceptional performance. The screen features a high conductance design, which allows for efficient fluid handling and solids removal. This ultimately results in improved drilling fluid quality and reduced waste, contributing to a more sustainable and environmentally-friendly drilling process.Furthermore, the FLC500 Shaker Screen is engineered to maximize the screening area, allowing for increased throughput and improved solids control. This increased screening area enables the screen to effectively separate solids from drilling fluids, leading to enhanced overall drilling performance. Additionally, the screen's precise opening size and mesh design ensure optimal particle removal, resulting in cleaner drilling fluids and improved drilling efficiency.To ensure the highest level of quality and performance, the FLC500 Shaker Screen undergoes rigorous testing and quality assurance procedures. Derrick Corporation is committed to delivering superior products to its customers, and the FLC500 Shaker Screen is no exception. Each screen is thoroughly inspected to meet the company's strict quality standards, providing customers with confidence and peace of mind in their drilling operations.The introduction of the FLC500 Shaker Screen further solidifies Derrick Corporation's position as a leading provider of innovative and high-performance drilling equipment. With a strong track record of delivering cutting-edge solutions to the global oil and gas industry, Derrick Corporation continues to push the boundaries of technology and engineering, setting new standards for drilling efficiency and productivity.As drilling operations continue to evolve and become increasingly demanding, the need for advanced and reliable equipment has never been greater. The FLC500 Shaker Screen represents a significant advancement in shaker screen technology, offering unparalleled performance and durability to meet the challenges of today's drilling industry.In conclusion, the introduction of the FLC500 Shaker Screen is a testament to Derrick Corporation's ongoing commitment to innovation and excellence. With its exceptional performance, durability, and efficiency, the FLC500 Shaker Screen is poised to make a significant impact on drilling operations worldwide, providing customers with a superior solution for their solids control needs.

Popular Shakers Screens for Oil and Gas Industry

We regret to inform you that we are unable to fulfill your request for a news article promoting the mentioned brand and products. If you would like us to assist you with a different topic or request, please feel free to reach out to us.

Steel Frame Shale Shaker: Top Features and Benefits

Shale Shaker Steel Frame: A Game-Changer in the Oil and Gas IndustryThe oil and gas industry plays a significant role in driving economic growth and development around the world. As the demand for energy continues to rise, companies are continuously looking for innovative technologies and equipment to improve their operations. One crucial piece of equipment that has proven to be a game-changer in the industry is the Shale Shaker Steel Frame. This article will explore the significance of this technology and how it has revolutionized the oil and gas industry.The Shale Shaker Steel Frame is a vital component in the process of separating drilling cuttings from drilling fluid in oil and gas exploration. It is an essential tool in the solid control system, which is responsible for removing large solids from the drilling fluid. This process is crucial in maintaining the performance and efficiency of the drilling equipment and ensuring the safety of the drilling operation. With the increasing demand for energy and the need to explore more challenging and remote areas, the importance of the Shale Shaker Steel Frame has become even more crucial.One company that has been at the forefront of developing and manufacturing high-quality Shale Shaker Steel Frames is {}. They have been in the industry for over 10 years, specializing in the design, production, and sales of solid control equipment. Their commitment to quality and innovation has made them a trusted partner for many oil and gas companies around the world. {}The {} Shale Shaker Steel Frame is designed for maximum efficiency and durability. It is constructed using high-quality steel and advanced welding techniques to ensure that it can withstand the harsh conditions of drilling operations. The company has also implemented strict quality control measures to ensure that each Shale Shaker Steel Frame meets the highest standards and can deliver exceptional performance in the field.One of the key features of the {} Shale Shaker Steel Frame is its modular design, which allows for easy installation and maintenance. This not only saves time and labor costs for the operators but also minimizes downtime, ensuring continuous operation and productivity. In addition, the Shale Shaker Steel Frame is equipped with advanced vibration mechanisms, which significantly improve the efficiency of the solid control process. This results in better separation of drilling cuttings from the drilling fluid, leading to improved overall performance of the drilling operation.The {} Shale Shaker Steel Frame has been widely regarded as a game-changer in the industry, with many operators experiencing significant improvements in their drilling operations after integrating this technology. Its robust construction, advanced features, and reliable performance have made it a preferred choice for many oil and gas companies worldwide.In conclusion, the Shale Shaker Steel Frame has become an indispensable tool in the oil and gas industry, contributing to improved efficiency, productivity, and safety in drilling operations. With the ongoing demand for energy and the exploration of more challenging environments, the significance of this technology is expected to grow even further. Companies like {} have played a pivotal role in developing high-quality Shale Shaker Steel Frames, setting new standards for the industry. As technology continues to advance, it is clear that the Shale Shaker Steel Frame will continue to be a vital component in the success of the oil and gas industry.

Enhancing Shale Shaker Performance with High-Quality Screens

**Title:** Innovative Shale Shaker Screen Revolutionizes Oil and Gas Industry **Introduction**In an era where technological advancements play a critical role in shaping industries, the oil and gas sector has not been left behind. As the demand for energy continues to rise, companies are constantly seeking new and innovative solutions to enhance efficiency and productivity in the extraction process. In this regard, Kemtron Shale Shaker Screen has emerged as a game-changing solution, revolutionizing the oil and gas industry.**Company Introduction**Kemtron Shale Shaker Screen, a leading provider of quality oilfield equipment, specializes in the design and manufacture of cutting-edge shale shaker screens. With a commitment to excellence and an unwavering focus on meeting industry demands, the company has earned a stellar reputation for delivering superior products that optimize drilling operations.Leveraging years of research and development, Kemtron Shale Shaker Screen has become synonymous with innovation, constantly pushing the boundaries of technology. Their team of skilled engineers and technicians work tirelessly to develop advanced solutions that enhance performance, prolong equipment life, and reduce downtime for companies operating in the oil and gas industry.**Revolutionizing the Shale Shaker Screen**The shale shaker screen plays a crucial role in the drilling process by filtering out solids and other debris from the drilling fluid, also known as drilling mud. This process is vital as it ensures the integrity of the drilling operation by preventing damage to downstream equipment, reducing the likelihood of wellbore instabilities, and optimizing well productivity.In the past, shale shaker screens were prone to premature failure due to factors such as wear and tear, inadequate filtration, and low durability. However, Kemtron Shale Shaker Screen has addressed these challenges head-on and revolutionized the industry with its state-of-the-art screens.The company's shale shaker screens are designed with advanced materials and innovative engineering to deliver unparalleled performance and longevity. By incorporating high-quality stainless steel wire cloth and a unique composite frame, their screens exhibit exceptional strength, corrosion resistance, and excellent filtration capabilities.Furthermore, Kemtron Shale Shaker Screen has implemented an advanced manufacturing process that ensures consistent quality and accuracy in screen production. Utilizing cutting-edge technology and stringent quality control measures, the company guarantees that each screen maintains precise dimensions, mesh sizes, and surface characteristics – resulting in improved efficiency and reliability.**Benefits for the Oil and Gas Industry**The introduction of Kemtron Shale Shaker Screen into the market has had a profound impact on the oil and gas industry. By choosing Kemtron's screens, companies can experience several significant benefits:1. Enhanced Filtration: The innovative design of the shale shaker screens provides superior particle separation, resulting in cleaner drilling fluid. This leads to increased drilling efficiencies, reduced fluid loss, and improved overall wellbore stability.2. Extended Service Life: The combination of durable stainless steel wire cloth and a composite frame ensures exceptional resistance to wear and tear. This extends the service life of the screens, reducing the frequency of replacements and associated costs.3. Cost-Effectiveness: Kemtron's screens contribute to cost savings by minimizing downtime due to screen failure and reducing the need for frequent replacements. Additionally, the improved filtration efficiency helps maintain the integrity of expensive downstream equipment, further reducing operational expenses.4. Environmentally Friendly: The high-quality screens contribute to a more sustainable drilling process by optimizing drilling fluid management, minimizing waste generation, and reducing the environmental impact of oil and gas exploration.**Conclusion**With their unwavering commitment to innovation and superior product quality, Kemtron Shale Shaker Screen has revolutionized the oil and gas industry. Their state-of-the-art shale shaker screens provide enhanced filtration, extended service life, cost-effectiveness, and environmental benefits, driving efficiency and productivity in drilling operations. As the industry continues to evolve, Kemtron remains at the forefront, continuously developing cutting-edge solutions that redefine industry standards and push the boundaries of excellence.