VSM 300 Secondary Oil Shaker Screen: A Guide to Choosing the Best Option

By:Admin

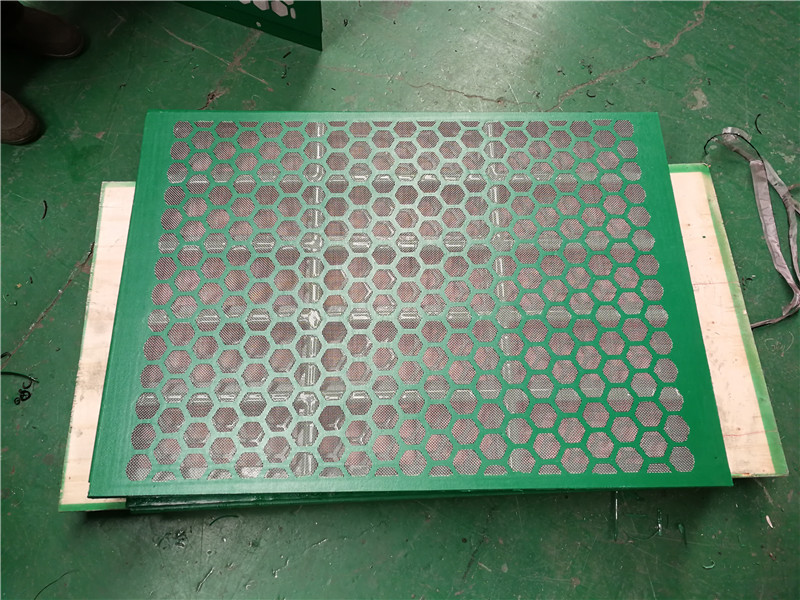

The VSM 300 Secondary Oil Shaker Screen is a high-quality replacement screen that is compatible with the VSM 300 shale shaker. It is designed to effectively remove solids from drilling fluid while ensuring maximum efficiency and durability. This new product is the result of extensive research and development, as well as feedback from our customers in the oil and gas industry.

One of the key features of the VSM 300 Secondary Oil Shaker Screen is its advanced composite frame, which provides increased strength and longer service life compared to traditional metal frames. This innovative design reduces the risk of screen failure and ensures that the screen can withstand the demanding conditions of oil drilling operations. Additionally, the screen is manufactured using high-quality materials that are resistant to corrosion and abrasion, further enhancing its longevity and performance.

In addition to its durability, the VSM 300 Secondary Oil Shaker Screen also offers superior solids control capabilities. The screen features a unique layered design that effectively separates solids from drilling fluid, allowing for the efficient removal of unwanted particles. This not only helps to maintain the quality of the drilling fluid but also reduces the wear and tear on downstream equipment, resulting in cost savings and improved operational efficiency.

Furthermore, the VSM 300 Secondary Oil Shaker Screen is engineered to provide a high conductance rate, ensuring that drilling fluid can flow through the screen at an optimal rate. This helps to prevent blockages and ensures that the drilling process can continue uninterrupted, ultimately leading to increased productivity and reduced downtime.

As a global leader in the oil and gas industry, Global Oil Shaker Screen Company is committed to providing high-quality products and exceptional service to our customers. Our team of experienced engineers and technicians are dedicated to developing innovative solutions that meet the evolving needs of the industry, and the VSM 300 Secondary Oil Shaker Screen is a testament to this commitment.

With the introduction of the VSM 300 Secondary Oil Shaker Screen, Global Oil Shaker Screen Company is continuing its legacy of excellence and innovation in the oil and gas industry. This new product showcases our dedication to providing superior solutions for solids control and fluid management, and we are confident that it will deliver exceptional performance in a wide range of drilling applications.

In conclusion, the VSM 300 Secondary Oil Shaker Screen is a testament to Global Oil Shaker Screen Company's dedication to innovation and excellence in the oil and gas industry. With its advanced design, superior durability, and unmatched performance, this new product is set to revolutionize solids control in oil drilling operations, providing our customers with a reliable and efficient solution for their fluid management needs. As we look to the future, Global Oil Shaker Screen Company remains committed to pushing the boundaries of innovation and delivering value to our customers around the world.

Company News & Blog

Introducing the Latest Innovation: Atl 1000 Shaker Screen Unveils Revolutionary Features

Title: Cutting-Edge Shaker Screen Revolutionizes Solid Control for the Oil and Gas IndustryIntroduction:The oil and gas industry plays a vital role in global energy production. To support the extraction process, cutting-edge equipment and technologies are continuously being introduced to improve efficiency and productivity. In this context, the Brandt Atl 1000 Shaker Screen is making a significant impact on solid control, serving as a game-changer for oil and gas drilling operations around the world.Revolutionizing Solid Control:Solid control is a crucial stage in drilling operations that involves the separation of drilling fluids from solid particles. The efficiency and reliability of solid control technology directly impact the overall drilling performance, environmental safety, and cost-effectiveness of oil and gas projects. The Brandt Atl 1000 Shaker Screen, developed by a renowned industry leader, is designed to optimize this process, offering improved performance, durability, and enhanced solids removal capacity.Enhanced Performance:The Atl 1000 Shaker Screen is designed with advanced engineering techniques to maximize performance. It boasts a larger usable screen area, allowing for higher throughput and improved fluid handling capabilities. The increased screen area enhances the shaker's ability to remove a higher volume of solid particles from drilling fluids, leading to enhanced drilling operations' efficiency and reduced downtime.Superior Build Quality:Durability is a key concern when choosing solid control equipment in the oil and gas industry. The Atl 1000 Shaker Screen is meticulously crafted using state-of-the-art materials and manufacturing processes. Its robust build quality ensures prolonged operational life, reducing the need for frequent replacements and enhancing cost-effectiveness. The shaker screens are engineered to withstand demanding drilling conditions, such as high temperatures, extreme pressure differentials, and abrasive drilling fluids, making them highly reliable and efficient.Optimized Solids Removal:Efficient solids separation is critical for maintaining drilling fluids' quality and minimizing environmental impact in oil and gas operations. The Brandt Atl 1000 Shaker Screen exhibits exceptional solids removal efficiency, thanks to its unique design features. Its innovative mesh configuration and mesh bonding technique provide superior resistance to blinding and plug formation, ensuring consistent performance and extended screen life. This results in cleaner drilling fluids, reduced waste disposal costs, and a smaller environmental footprint.Industry-Leading Technology:The Brandt Atl 1000 Shaker Screen is backed by extensive research, development, and testing processes conducted by a highly reputed company. The manufacturer combines years of industry experience, engineering expertise, and customer feedback to continually improve their product offerings. By incorporating the latest technological advancements, the Atl 1000 Shaker Screen sets a new industry standard for solid control solutions.Global Impact:With its exceptional performance and reliability, the Brandt Atl 1000 Shaker Screen has garnered significant attention and gained global recognition. Oil and gas operators across various geographic regions have embraced this innovative technology to streamline their drilling operations. The shaker screen's international adoption affirms its effectiveness in delivering optimized solid control and environmental compliance, translating into enhanced operational efficiency and profitability for drilling projects worldwide.Conclusion:As the oil and gas industry continues to evolve, the importance of advanced solid control solutions cannot be overstated. The Brandt Atl 1000 Shaker Screen, with its superior performance, durability, and optimized solids removal capacity, offers a compelling solution to the industry's needs. With its efficient particle separation capabilities, enhanced fluid handling, and reduced downtime, the Atl 1000 Shaker Screen sets a new benchmark, revolutionizing solid control in the oil and gas sector. As drilling operations strive for increased productivity, environmental protection, and cost-effectiveness, this cutting-edge technology serves as a significant asset, enabling oil and gas companies to achieve their goals efficiently and sustainably.

How Does a Shale Shaker Work and Why Is It Important in Oil and Gas Drilling Operations?

Shale Shaker has played a vital role in the oil and gas industry for decades, and it continues to be an essential piece of equipment for companies worldwide. The Shale Shaker has been designed and manufactured by a leading oil and gas equipment company, which has been in the business for over 20 years. The company is known for its commitment to providing high-quality products and exceptional customer service. In recent years, the company has seen a surge in demand for its Shale Shaker due to the increased focus on environmental sustainability and the need to maximize efficiency in oil and gas operations. The Shale Shaker is a crucial component in the process of separating drilling cuttings from drilling fluid, which is essential in maintaining the integrity of the drilling fluid and preventing pollution of the environment. The Shale Shaker is designed to effectively remove large solids from drilling fluid, which is vital for the smooth operation of downstream equipment such as desanders and desilters. This process not only ensures the quality of the drilling fluid but also reduces operational costs and minimizes environmental impact. The company's Shale Shaker is renowned for its durability, reliability, and performance. It is equipped with a high G-force linear motion to effectively remove solids from the drilling fluid, and its innovative design allows for easy maintenance and servicing. One of the key advantages of the Shale Shaker is its ability to adapt to different operational conditions. It can be customized with various screen options to suit different drilling requirements, and its adjustable deck angle allows for efficient handling of different types of drilling fluids. Furthermore, the company's Shale Shaker is designed with a focus on safety and efficiency. It is equipped with a range of features to ensure the safety of operators and maintenance personnel, and its compact design allows for easy transportation and installation on drilling rigs. The company's commitment to excellence extends beyond the design and manufacturing of the Shale Shaker. It provides comprehensive support and training for its customers to ensure the efficient and effective operation of the equipment. Furthermore, the company has a global network of service centers and parts distribution to provide timely support and maintenance for its Shale Shaker. As the oil and gas industry continues to evolve, the demand for high-quality and reliable equipment such as the Shale Shaker will only increase. The company's commitment to innovation and customer satisfaction ensures that its Shale Shaker will remain at the forefront of the industry for years to come. In conclusion, the Shale Shaker has proven to be an essential piece of equipment in the oil and gas industry, and the company behind its design and manufacturing has positioned itself as a leader in the field. With its focus on quality, performance, and customer support, the company's Shale Shaker is set to continue its legacy as a vital component in oil and gas operations worldwide.

Revolutionary Hyperpool Pyramid Screens Making Waves in News

In the world of oil and gas drilling, efficiency is key. The faster and more effectively a well can be drilled, the more profitable it is for the drilling company. To aid in this endeavor, companies like Derrick Corporation are constantly innovating new technology to improve wellsite operations. Recently, they unveiled a new product that promises to revolutionize how operators approach drilling fluid management.The Hyperpool Pyramid Screen is an advanced shale shaker screen designed to improve the performance of drilling fluids handling and recovery systems. The screen boasts a high-capacity of fine solids management, which makes it especially useful in unconventional drilling operations like well pads and hydraulic fracturing sites. It is designed to fit all Derrick shakers and can even be retrofitted to other brand shakers, providing an immediate increase in efficiency to those who adopt it.Hyperpool Pyramid Screen features a unique pyramid pattern that differs significantly from traditional flat-surface shale shakers. The pyramid design allows for increased surface area coverage and more significant solids retention, allowing the screen to perform better and last longer than its competitors. Its innovative design reduces the tendency of drilled solids to bypass, thereby increasing the operating life of the screen and improving the quality of drilling fluid for disposal or reuse.In addition to its superior performance, the Hyperpool Pyramid Screen reduces the environmental impact of drilling operations by improving the management and recycling of drilling fluids. With its increased capacity to retains fine solids, less waste is generated, thereby reducing the volume of waste materials required for disposal. As a result, the wellsite could experience fewer trips to dispose of drilling wastes, saving operators the time and money.Derrick Corporation's Hyperpool Pyramid Screen is a product of nearly 70 years of oilfield equipment manufacturing experience. Since 1951, the company has been pushing the boundaries of technological innovation to help oil and gas operators perform their duties more efficiently and effectively. Today, Derrick Corporation serves the global oil and gas industry with advanced high-performance equipment, including shale shakers, desanders, hydrocyclones, centrifuges, and more.More than just a leading manufacturer of drilling equipment, Derrick Corporation is also a trusted partner to the industry. They work closely with customers to ensure that every product they develop is tailored to meet reasonable and specific customer needs. The company's focus on customer satisfaction and innovation has made them one of the most respected names in the oil and gas industry, with operations in over 70 countries around the world.In conclusion, Derrick Corporation's Hyperpool Pyramid Screen is a game-changer for drilling fluids management in the oil and gas industry. With its advanced design, increased capacity, reduced environmental footprint, and easy adaptability, it provides the perfect solution for drilling companies looking to enhance their wellsite operations. Derrick's long-standing commitment to innovation and customer satisfaction ensures that the Hyperpool Pyramid Screen meets and exceeds the growing demands of the oil and gas industry. The product serves to demonstrate what is achievable when manufacturers and operators work together.

Replacement Shaker Screen for King Cobra/Hybrid

An industry-leading company, known for its innovative solutions to the oil and gas drilling industry, has just announced the launch of their new Replacement Shaker Screen for Brandt King Cobra/Hybrid. This new product is set to revolutionize shale shaker operations and provide exceptional performance in solids control. This announcement comes as a part of the company’s commitment to delivering high-quality products and services to their clients in the oil and gas industry.With over (number) years of experience in the industry, the company has established itself as a trusted partner for many drilling companies around the world. Their dedication to research and development has allowed them to continuously improve their products and stay ahead of the competition. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is the latest addition to their extensive product line and embodies their commitment to excellence.The new Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed to offer superior performance and durability compared to traditional screens currently on the market. It features a unique mesh design that allows for increased flow rates and better separation of solid particles, leading to a more efficient drilling process. In addition, the screen is engineered to withstand the harsh conditions of drilling operations, ensuring a longer lifespan and reduced maintenance costs for the end user.One of the key advantages of the Replacement Shaker Screen for Brandt King Cobra/Hybrid is its compatibility with existing equipment. The company has designed the screen to seamlessly fit into the Brandt King Cobra/Hybrid shale shaker, eliminating the need for any modifications or additional hardware. This allows for a hassle-free upgrade for drilling companies looking to improve the performance of their solids control systems.Furthermore, the company’s commitment to environmental responsibility is evident in the design of the new shaker screen. By using durable materials and optimizing the manufacturing process, they have minimized the environmental impact of the product, aligning with the industry’s push for sustainability.The launch of the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to the company’s dedication to meeting the evolving needs of the oil and gas industry. With a focus on innovation and customer satisfaction, they continue to set new standards for quality and performance in solids control equipment.In addition to their new product launch, the company is also known for their exceptional customer service and technical support. Their team of experts is available to provide assistance and guidance to clients, ensuring that the Replacement Shaker Screen for Brandt King Cobra/Hybrid is integrated seamlessly into their operations.As the oil and gas industry continues to evolve, the demand for efficient and reliable solids control solutions is greater than ever. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is poised to meet this demand and make a significant impact on drilling operations worldwide.With a track record of delivering innovative solutions and a dedication to customer satisfaction, the company stands out as a leader in the field of solids control equipment. Their new shaker screen is set to reinforce their position as a go-to provider for high-quality products in the oil and gas drilling industry.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

New Factory Screen Technology: Enhancing Productivity and Efficiency

The Zs/z-2 Factory has announced the launch of their latest innovative screen, revolutionizing the way businesses display content. This state-of-the-art screen is a game-changer and is set to transform the digital display industry.The Zs/z-2 Factory is a leading company in the display technology sector and has been at the forefront of innovation for many years. They specialize in creating cutting-edge display solutions for businesses in various industries. With a strong focus on research and development, the company is constantly striving to push the boundaries of what is possible in the world of display technology.The new screen from the Zs/z-2 Factory offers a range of features that set it apart from traditional displays. Its ultra-high resolution and crystal-clear image quality provide a stunning visual experience for viewers. The screen is also built to be incredibly durable, with a rugged design that can withstand the rigors of daily use in commercial settings.One of the most impressive aspects of the new screen is its versatility. It is designed to be fully customizable, allowing businesses to tailor the display to meet their specific needs. Whether it's a large-scale digital advertising campaign or a small-scale informational display, the Zs/z-2 Factory screen can handle it all with ease.In addition to its impressive technical capabilities, the Zs/z-2 Factory screen is also designed with ease of use in mind. It features an intuitive interface that makes it simple for businesses to manage and update their content. This user-friendly design ensures that businesses can make the most of their digital displays without the need for extensive technical expertise.The launch of this new screen has generated a lot of excitement within the industry. Many businesses are already expressing interest in integrating the Zs/z-2 Factory screen into their operations. With its exceptional quality and versatility, it is poised to become the go-to choice for businesses looking to enhance their digital displays."We are thrilled to introduce our latest screen to the market," said a spokesperson for the Zs/z-2 Factory. "We believe that this new product will redefine the standard for digital displays and provide businesses with a powerful tool for engaging with their audience. With its advanced features and user-friendly design, we are confident that it will be a game-changer for businesses in a wide range of industries."The Zs/z-2 Factory has a strong track record of delivering high-quality display solutions to businesses around the world. Their commitment to innovation and excellence has earned them a reputation as a trusted leader in the industry. With the launch of their new screen, they are further solidifying their position as a driving force in the world of display technology.As businesses continue to seek out effective ways to connect with their audience, the Zs/z-2 Factory screen is poised to play a key role in shaping the future of digital displays. Its exceptional quality, versatility, and user-friendly design make it an ideal choice for businesses looking to make a lasting impression with their digital content.With the launch of their latest screen, the Zs/z-2 Factory is once again demonstrating their dedication to pushing the boundaries of what is possible in the world of display technology. As the industry continues to evolve, their commitment to innovation will ensure that they remain at the forefront of the market, delivering cutting-edge solutions to businesses around the world.

Innovative Mixing Bottle for Health and Fitness Enthusiasts

Shaker bottles have become a popular item among fitness enthusiasts and health-conscious individuals, offering a convenient way to mix and enjoy protein shakes, meal replacements, and other nutritional beverages on the go. These innovative bottles feature a built-in mixing mechanism that ensures a smooth and lump-free drink, making them a must-have accessory for anyone leading an active lifestyle.One company that has been at the forefront of the shaker bottle industry is {Company Name}. With a strong commitment to quality, innovation, and customer satisfaction, {Company Name} has established itself as a leading provider of high-performance shaker bottles that are trusted by athletes, fitness professionals, and health enthusiasts around the world.Founded in [year], {Company Name} has quickly made a name for itself in the health and wellness industry by offering a wide range of shaker bottles that are not only functional but also stylish and durable. The company's dedication to excellence is evident in its use of high-quality materials, rigorous testing processes, and attention to detail, ensuring that each shaker bottle meets the highest standards of performance and reliability.One of the key features that set {Company Name}'s shaker bottles apart from the competition is their patented mixing technology, which effectively blends ingredients together without the need for additional tools or shaking. This innovative design has made {Company Name}'s shaker bottles a favorite among users who demand a hassle-free and consistent mixing experience.In addition to their superior performance, {Company Name}'s shaker bottles also stand out for their ergonomic design, leak-proof construction, and easy-to-use features. Whether it's the convenient carrying loop, the secure screw-on lid, or the wide mouth opening for effortless cleaning, every aspect of {Company Name}'s shaker bottles is engineered with the user's convenience and satisfaction in mind.Moreover, {Company Name} has been proactive in addressing the environmental impact of its products by incorporating sustainable and eco-friendly materials into its shaker bottles. The company's commitment to sustainability is reflected in its use of recyclable materials and its efforts to reduce waste throughout the production and distribution processes.To further enhance the customer experience, {Company Name} offers a range of customization options for its shaker bottles, allowing users to choose from a variety of colors, designs, and accessories to suit their individual preferences. This level of personalization has made {Company Name}'s shaker bottles a popular choice for personal use, promotional giveaways, and corporate branding initiatives.As part of its ongoing mission to promote health and wellness, {Company Name} has also partnered with fitness and nutrition experts to develop educational resources and content that inspire and empower individuals to make positive lifestyle choices. By sharing valuable insights, tips, and recipes, {Company Name} aims to support its customers on their journey to improved health and well-being.Looking ahead, {Company Name} remains dedicated to pushing the boundaries of innovation and setting new standards of excellence in the shaker bottle industry. With a focus on quality, sustainability, and customer satisfaction, {Company Name} is poised to continue its success as a trusted leader in providing premium shaker bottles for the health-conscious consumer.In conclusion, {Company Name} has undoubtedly made a significant impact on the market for shaker bottles, offering a comprehensive range of products that combine functionality, style, and sustainability. With a steadfast commitment to meeting the needs of its customers and promoting a healthy lifestyle, {Company Name} has solidified its position as a leading provider of high-performance shaker bottles that are trusted by consumers worldwide.

Newsworthy Updates: Major Developments in the Oilfield Services Industry

Leading oilfield services company, MI-Swaco, has recently made significant advancements in the development of cutting-edge technologies for the oil and gas industry. With a strong focus on innovation and continuous improvement, MI-Swaco has become a trusted partner for oil and gas companies around the world.MI-Swaco is a global leader in drilling fluid systems, solids control equipment, and waste management solutions. The company's state-of-the-art technologies and services are designed to enhance drilling performance, improve efficiency, and minimize environmental impact. MI-Swaco's commitment to innovation and sustainability has earned the company a strong reputation as an industry leader.Recently, MI-Swaco launched a new line of drilling fluid systems that are specifically designed to optimize drilling operations in challenging environments. These advanced systems are capable of delivering superior performance in high-pressure, high-temperature (HPHT) wells, deepwater drilling, and unconventional reservoirs. By leveraging cutting-edge technologies and proprietary formulations, MI-Swaco is helping oil and gas companies achieve higher levels of efficiency and productivity in their drilling operations.In addition to its drilling fluid systems, MI-Swaco has also developed a range of innovative solids control equipment that is revolutionizing the way drilling waste is managed. The company's industry-leading technologies are designed to efficiently separate solids from drilling fluids, effectively reducing waste volume and minimizing environmental impact. By providing comprehensive waste management solutions, MI-Swaco is helping oil and gas companies meet strict regulatory requirements and sustainability goals.One of MI-Swaco's most notable achievements is its focus on sustainability and environmental stewardship. The company is committed to developing technologies and solutions that not only improve drilling performance but also minimize the impact on the environment. From reducing waste generation to developing eco-friendly drilling fluid formulations, MI-Swaco is dedicated to promoting sustainable practices across the oil and gas industry.MI-Swaco's success is driven by its team of talented and dedicated professionals who are passionate about pushing the boundaries of innovation. The company invests heavily in research and development to stay ahead of the curve and deliver industry-leading solutions to its clients. With a global network of facilities and a strong presence in key oil and gas regions, MI-Swaco is well-positioned to meet the evolving needs of the industry.As part of its commitment to excellence, MI-Swaco places a strong emphasis on quality and safety. The company adheres to the highest standards of quality assurance and control to ensure that its products and services consistently meet and exceed customer expectations. Additionally, MI-Swaco maintains rigorous safety protocols to protect the well-being of its employees, customers, and the communities in which it operates.Looking ahead, MI-Swaco is poised to continue driving innovation and delivering value to its clients in the oil and gas industry. With a relentless focus on technology development, sustainability, and operational excellence, the company is well-equipped to remain a trusted partner for oil and gas companies around the world. MI-Swaco's dedication to pushing the boundaries of what is possible in drilling and waste management is a testament to its commitment to advancing the industry and creating a more sustainable future.

High-Quality Composite Replacement Screen for King Cobra/Hybrid - Latest News

Composite Replacement Screen for King Cobra/Hybrid Shale Shaker Available NowThe oil and gas industry is constantly evolving and demands high-quality equipment to ensure efficient operations. In this regard, the introduction of composite replacement screens for the King Cobra/Hybrid shale shaker is a significant development. These screens are now available to provide superior performance and durability, meeting the industry's stringent requirements.The composite replacement screens are designed to fit the King Cobra/Hybrid shale shaker, a widely used equipment for solids control in drilling operations. With their advanced construction and innovative materials, these screens offer improved efficiency and reliability compared to traditional metal screens. Their enhanced durability also translates to cost savings, as they have a longer lifespan and require less frequent replacement.One of the key advantages of the composite replacement screens is their superior resistance to wear and damage. This is particularly important in the demanding conditions of oil and gas exploration, where equipment is exposed to abrasive solids and high vibration levels. The advanced composite materials used in these screens are specifically chosen for their durability, ensuring consistent performance and screen integrity even in the harshest environments.In addition to their resilience, the composite replacement screens are designed to provide better filtration, leading to cleaner drilling fluid and improved solids removal. This is crucial for maintaining drilling efficiency and protecting downstream equipment. By effectively separating solids from the drilling fluid, these screens contribute to overall operational efficiency and cost reduction.The introduction of these composite replacement screens is a testament to [Company Name]'s commitment to innovation and excellence in providing solutions for the oil and gas industry. With years of experience in designing and manufacturing drilling equipment and components, [Company Name] has established itself as a trusted partner for oil and gas companies worldwide.[Company Name] is known for its dedication to quality and customer satisfaction, and the development of the composite replacement screens is a reflection of this commitment. The company's team of engineers and technical experts has worked tirelessly to create a product that not only meets industry standards but also exceeds expectations in terms of performance and durability.The composite replacement screens for the King Cobra/Hybrid shale shaker are the latest addition to [Company Name]'s extensive range of products for solids control and waste management in drilling operations. With a focus on technological advancement and continuous improvement, the company aims to provide its customers with cutting-edge solutions that address their specific needs and challenges.In line with [Company Name]'s principles of environmental responsibility, the composite replacement screens are also designed to contribute to sustainable drilling practices. By optimizing solids control and reducing waste, these screens support efforts to minimize the environmental impact of oil and gas exploration. This aligns with the industry's increasing focus on sustainability and corporate social responsibility.The availability of the composite replacement screens for the King Cobra/Hybrid shale shaker represents a significant advancement in solids control technology. With their superior durability, filtration efficiency, and environmental benefits, these screens are poised to set a new standard for performance in the oil and gas industry. As [Company Name] continues to lead the way in innovation, the future looks promising for the development of advanced solutions that drive productivity and sustainability in drilling operations.

Latest Shale Shaker Screen Enhances Efficiency and Performance: A Detailed Report

In the world of oil and gas extraction, shale shaker screens are an essential part of the process. These screens are used to separate solids from drilling fluid and keep the drilling fluid clean and reusable. As technology advances, so do the capabilities of shale shaker screens. One of the latest advancements in this field comes from the production of Derrick FLC313 shale shaker screens.Derrick Corporation, a top provider of innovative solutions for the oil and gas industry, has introduced the Derrick FLC313 shale shaker screen. The company's vast experience and expertise in this industry are evident in the design and capabilities of these screens. The Derrick FLC313 screens offer significant benefits to drilling operations across the globe.The Derrick FLC313 shale shaker screen is engineered to deliver superior performance in a variety of drilling applications. The screen features a fully compliant, repairable screen panel design that maximizes operational uptime. The panel is constructed with a unique composite frame that is tough and durable, yet lightweight. This design reduces the screen's overall weight, making it easier to handle, and improves shaker performance.The screen's construction also includes a layer of high-strength steel reinforcement, providing added rigidity and strength to the screen panel. This layer prevents the screen mesh from sagging and reduces the risk of mesh failures, ensuring that the screen remains operational for longer periods.Derrick's FLC313 shale shaker screen incorporates several advanced features that enhance the performance of drilling operations. The screen uses the pyramid-shaped openings of the patented Pyramid Plus screen technology, which increases the surface area of the screen and reduces the amount of drilling fluid that is lost. The increased surface area provides more efficient solids removal and maximizes the drilling fluid's quality.Another significant advantage of the FLC313 shale shaker screen is its ability to handle high-volume solids processing. The screen's unique design and construction make it suitable for separating a higher volume of solids from drilling fluids, making it an ideal solution for demanding drilling applications.The FLC313 shale shaker screen is compatible with a wide range of shaker models, making it versatile and easy to install. The screen's universal design requires no modifications to the shaker, allowing for a simple installation process, reducing downtime, and increasing productivity.Derrick Corporation is committed to producing sustainable and environmentally-friendly solutions for the oil and gas industry. The company's FLC313 shale shaker screens are designed to minimize environmental impact and reduce waste. The screen's durable, lightweight construction and efficient solids control help to remediate drilling fluid and minimize waste disposal.In conclusion, Derrick Corporation's FLC313 shale shaker screen is a breakthrough innovation in the oil and gas industry. Its exceptional design, durability, and efficiency make it an ideal solution for demanding drilling applications. The screen's ability to handle high-volume solids processing and its compatibility with a wide range of shaker models offer unparalleled versatility and productivity. Derrick Corporation's commitment to sustainability and environmental consciousness ensures that the FLC313 shale shaker screen is also a responsible choice for the industry.