Ultimate Guide to Understanding the DFE Pyramid Screen

By:Admin

The DFE Pyramid Screen boasts a unique pyramid-shaped design that sets it apart from traditional flat screens. This innovative design not only enhances the visual appeal of the screen but also offers a more immersive viewing experience. The screen's pyramid shape creates a sense of depth and realism that is unmatched by any other display screen on the market.

In addition to its striking design, the DFE Pyramid Screen is equipped with state-of-the-art technology that delivers stunning visuals and unparalleled performance. The screen is capable of displaying high-definition content with remarkable clarity and detail, making it perfect for a wide range of applications including gaming, entertainment, and digital signage.

One of the key features of the DFE Pyramid Screen is its ability to display 3D content without the need for special glasses. This breakthrough technology opens up a whole new world of possibilities for visual content creators and allows viewers to enjoy immersive 3D experiences without any additional equipment.

Furthermore, the DFE Pyramid Screen is also equipped with advanced connectivity options, including HDMI, DisplayPort, and USB-C, making it compatible with a wide range of devices. This flexibility makes it an ideal choice for businesses, entertainment venues, and homes, where multiple devices need to be connected to the display screen.

The company behind the development of the DFE Pyramid Screen has a long history of innovation and excellence in the field of display technology. With a team of dedicated engineers and designers, the company has consistently pushed the boundaries of what is possible with display screens and has earned a reputation for delivering cutting-edge products that exceed customer expectations.

The launch of the DFE Pyramid Screen is a significant milestone for the company, as it represents a culmination of years of research and development. The screen has been met with enthusiastic reviews from industry experts and early adopters, who have praised its stunning visuals, innovative design, and seamless performance.

The company has also emphasized the environmental sustainability of the DFE Pyramid Screen, highlighting its energy-efficient design and commitment to reducing its carbon footprint. This focus on sustainability aligns with the company's broader corporate responsibility initiatives and underscores its dedication to creating products that are not only advanced and impressive but also environmentally conscious.

Looking ahead, the company is committed to further refining and expanding the capabilities of the DFE Pyramid Screen, with plans to introduce new features and enhancements in the near future. This ongoing commitment to innovation ensures that the screen will remain at the forefront of display technology and continue to set new standards for visual experiences.

Overall, the DFE Pyramid Screen represents a game-changing advancement in display technology, offering a captivating visual experience that is unmatched by any other screen on the market. With its striking design, advanced features, and commitment to sustainability, the DFE Pyramid Screen is poised to redefine the way we engage with visual content and is set to become a must-have for businesses, entertainment venues, and homes alike.

Company News & Blog

High-Quality BEM-650 Shaker Screen for OEM Equipment

Shaker screens are a crucial component in the oil and gas industry, used in the process of separating solids from drilling fluid. This allows for the efficient and cost-effective removal of solid particles from the fluid, which is essential for maintaining the quality and performance of the drilling operation. One company that has been at the forefront of developing high-quality shaker screens for the oil and gas industry is {company}.{Company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has a strong reputation for delivering innovative and reliable products that meet the needs of its customers. With a focus on quality and performance, {company} has become a trusted partner for many drilling operations around the world.One of the flagship products from {company} is the BEM-650 shaker screen. This shaker screen is designed to provide superior performance in the separation of solids from drilling fluid. The BEM-650 is known for its durability and efficiency, making it a popular choice among drilling operators.The BEM-650 shaker screen is designed to fit OEM Swaco shakers, making it a versatile and compatible option for many drilling operations. The screen features a high-quality mesh that is capable of effectively separating a wide range of solid particles from the drilling fluid. This is essential for maintaining the integrity of the fluid and ensuring that the drilling operation runs smoothly and efficiently.In addition to its superior performance, the BEM-650 shaker screen is also known for its durability. The screen is built to withstand the harsh conditions of the drilling environment, ensuring that it remains effective and reliable even in challenging circumstances. This level of reliability is crucial for drilling operators, who rely on their equipment to perform consistently in order to maintain the quality and efficiency of their operations.{Company} is committed to delivering high-quality products and exceptional customer service. The company works closely with its customers to understand their needs and develop solutions that meet their specific requirements. This customer-focused approach has helped {company} build strong and lasting relationships with its clients, who trust the company to deliver reliable and effective equipment for their drilling operations.With a track record of innovation and excellence, {company} continues to lead the way in the development of shaker screens and other equipment for the oil and gas industry. The company's dedication to quality, performance, and customer satisfaction has made it a trusted partner for drilling operators around the world.As the demand for reliable and efficient equipment in the oil and gas industry continues to grow, {company} is well-positioned to meet the needs of its customers. With its high-quality products and commitment to excellence, the company is poised to remain a leader in the development of shaker screens and other equipment for the drilling industry.In conclusion, {company} is a top manufacturer of shaker screens and other equipment for the oil and gas industry. The company's commitment to quality and performance is evident in its flagship product, the BEM-650 shaker screen. With its superior performance and durability, the BEM-650 is a popular choice among drilling operators. Combined with {company}'s dedication to customer service and innovation, the company is well-positioned to remain a leader in the development of equipment for the oil and gas industry.

Industry News: Upgraded Shale Shaker Screens for Efficient Solids Control on S250 Shakers

Shale Shaker Screen for S250: The New Breakthrough in Oil and Gas Drilling IndustryThe oil and gas drilling industry has been facing increasing pressure to improve its operational efficiency as the oil prices continue to fluctuate. With the need to maximize production and minimize costs, operators are consistently seeking new technology to improve the drilling process. One of the biggest challenges in the drilling industry is the proper handling of drilled cuttings and mud away from the borehole. This is where the shale shaker screen comes in.A shale shaker screen is an essential component of drilling equipment that is used to screen the drilling fluid and cuttings from the borehole. The shale shaker screen is designed to handle a high capacity of solids to ensure that the drilling fluid is well controlled and to extend the life of the drilling equipment through efficient solids removal. A new technology, the shale shaker screen for S250, has been developed to solve the problem of inefficient solids control during drilling operations.The S250 shale shaker screen is a breakthrough technology in the oil and gas industry. It is designed to replace the conventional screens and improve the shale shaker's performance with its advanced capabilities. The shale shaker screen for S250 is manufactured using advanced techniques to ensure its durability and longevity. It is made from high-quality stainless steel mesh, ensuring its resistance to wear and tear, and it has been tested under the harshest drilling conditions to ensure its efficiency in dealing with high-speed cuttings.The shale shaker screen for S250 provides significant operational and financial benefits. With its high-capacity performance, it reduces the overall cost of drilling operations by reducing the number of screens required for the operation. The shale shaker screen for S250 is also easy to install and replace, reducing the downtime of the drilling operation, which results in higher efficiency and faster drilling times.The company behind the development of the S250 shale shaker screen has a reputation for excellence. The company has been providing cutting-edge technology solutions for drilling, exploration, and production operations for more than a decade. Its mission is to provide customized solutions that optimize operational efficiency in the oil and gas industry. The S250 shale shaker screen is a testament to the company's commitment to providing innovative solutions that meet the needs of the industry.In conclusion, the shale shaker screen for S250 is a game-changer in the drilling industry. It is designed to improve the efficiency of the drilling operation by providing a high-capacity, durable and efficient solution for solids removal. Its advanced capabilities result in reduced screen usage and faster drilling times, leading to significant operational and financial benefits. The company behind the development of the S250 shale shaker screen is dedicated to delivering innovative technology solutions that help the drilling industry achieve peak performance. The future of the drilling industry is bright with advancements like the shale shaker screen for S250, and the industry can expect even more breakthroughs in the years to come as we continue to push the limits of innovation.

Discover Affordable and High-Quality Shaker Screens Available for Purchase

Shaker Screens for Sale: Enhanced Performance and Efficiency in Industrial ProcessesIn the rapidly evolving landscape of industrial processes, the demand for efficient and reliable machinery has never been higher. Among the various components used in industries such as oil and gas, mining, and wastewater management, shaker screens play a vital role in ensuring smooth operations and improved productivity. With a commitment to delivering high-quality equipment, {Company Name} has emerged as a trusted provider of shaker screens for sale, revolutionizing the way industries function.In an era where extracting resources from the earth has become increasingly complex, shaker screens have proven to be indispensable tools. These screens are primarily used in the drilling industry to extract valuable materials such as oil and gas from beneath the earth's surface. Shaker screens are installed on shale shakers, which vibrate at high frequencies to separate solids from drilling fluids or mud. By removing unwanted solids, shaker screens prevent clogging of drilling equipment, boost efficiency, and help maintain the integrity of drilling fluids.Recognizing the crucial role shaker screens play, {Company Name} has invested significant resources in research and development to create cutting-edge products that cater to the diverse needs of industries worldwide. Tapping into the expertise of a dedicated team of engineers and technicians, they have developed a range of shaker screens that offer enhanced performance and durability.One of the key innovations from {Company Name} is the use of advanced mesh technology in their shaker screens. These screens are constructed with precision-woven mesh, ensuring a uniform distribution of openings throughout the surface. This design feature allows for efficient filtration and separation of different particle sizes, leading to improved solids control. Additionally, the advanced mesh technology enhances screen life, reducing the frequency of replacements and thereby minimizing downtime.Moreover, {Company Name} understands the importance of customization in meeting the unique requirements of various industries. They offer an extensive range of shaker screens in different sizes and configurations, allowing customers to select the most suitable option for their specific applications. Whether it is a small-scale mining operation or a large-scale oil drilling project, {Company Name} has the capability to provide tailor-made solutions, ensuring optimal performance and cost-effectiveness.Furthermore, environmental sustainability has become a critical consideration for industries across the globe. Recognizing this, {Company Name} has incorporated eco-friendly practices into their manufacturing processes. They have implemented measures to reduce energy consumption and minimize waste generation. By using recyclable materials and adhering to stringent quality standards, {Company Name} ensures that their shaker screens not only enhance efficiency but also contribute to a greener future.In addition to providing industry-leading products, {Company Name} places great emphasis on customer satisfaction and after-sales support. Their team of technical experts is readily available to provide guidance and assistance, ensuring seamless integration of shaker screens into existing equipment. Furthermore, {Company Name} offers prompt delivery services and robust warranty programs to instill trust and confidence in their customers.As industries continue to evolve, shaker screens will remain essential components of various processes. With its commitment to innovation, customization, and sustainability, {Company Name} has emerged as a reputable and reliable provider of shaker screens for sale. By continually pushing the boundaries of technology, they empower industries to achieve higher levels of productivity, efficiency, and environmental responsibility.In conclusion, shaker screens have become indispensable for industries that rely on efficient solids control. {Company Name} has positioned itself as a leader in this sector by offering high-quality shaker screens that deliver improved performance, durability, and environmental sustainability. With their commitment to customer satisfaction and cutting-edge technology, {Company Name} continues to redefine the standards for shaker screens, driving progress in industrial processes worldwide.

How to Replace a Screen Frame: A Step-by-Step Guide

Screen Frame Replacement Offers New Solution for Damaged ScreensIn today's digital age, screens are an integral part of our everyday lives. Whether it's a smartphone, tablet, or computer monitor, we rely on screens to stay connected, work, and be entertained. However, these screens are not invulnerable to damage, and when they do get damaged, it can be a frustrating and costly experience. Fortunately, Screen Frame Replacement, a leading provider of screen repair solutions, is offering a new and innovative solution for damaged screens. The company's patented screen frame replacement technology is revolutionizing the way screens are repaired, making the process faster, more cost-effective, and environmentally friendly.Screen Frame Replacement has been in the business of screen repair for over a decade, and their team of experts has extensive experience in repairing a wide range of screens, including those for smartphones, tablets, laptops, and monitors. The company prides itself on delivering high-quality repairs with a quick turnaround time, so customers can get back to using their devices as soon as possible.Unlike traditional screen repair methods, which often involve replacing the entire screen assembly, Screen Frame Replacement's technology allows for the damaged frame to be removed and replaced with a new one, while leaving the screen itself intact. This not only reduces the cost of repairs but also minimizes electronic waste, making it an environmentally friendly solution.The process begins with a thorough assessment of the damaged screen, followed by the removal of the old frame and the installation of a new one. The entire process is carried out by skilled technicians who are trained to work with precision and attention to detail, ensuring that the repaired screen looks and functions as good as new.One of the key advantages of Screen Frame Replacement's technology is its versatility. The company is able to provide screen frame replacement for a wide variety of devices, regardless of make or model. Whether it's a cracked iPhone screen, a damaged Samsung tablet, or a broken laptop display, Screen Frame Replacement can provide a solution.Furthermore, the company understands the importance of convenience for its customers. To that end, they offer a variety of service options, including in-store repairs, mail-in services, and even on-site repairs for businesses. This flexibility ensures that customers have a convenient and hassle-free experience when getting their screens repaired.Screen Frame Replacement's commitment to quality and customer satisfaction has earned them a strong reputation in the screen repair industry. Thousands of satisfied customers have praised the company for its reliable and affordable services, making it the go-to choice for screen repair needs.In addition to its screen repair services, Screen Frame Replacement also offers a range of accessories and protective products to help customers keep their screens safe and secure. From screen protectors to protective cases, the company is dedicated to helping customers prolong the life of their devices and avoid future damage.As technology continues to play a central role in our lives, having a reliable and affordable solution for screen repair is more important than ever. With its innovative screen frame replacement technology, Screen Frame Replacement is leading the way in the industry, providing customers with the peace of mind that their damaged screens can be quickly and effectively repaired. Whether it's a cracked smartphone screen or a broken laptop display, customers can trust Screen Frame Replacement to deliver a solution that meets their needs.

High Performance Shaker Screen with FSI 5000 Technology

The oil and gas industry is constantly evolving, with new technologies and innovations driving the sector forward. One of the key components of the industry is the use of shale shakers to separate drilling cuttings from drilling fluid. This process is crucial in maintaining the efficiency and effectiveness of drilling operations.In this regard, the FSI 5000 Shaker Screen has been making waves in the industry. This cutting-edge technology has been designed to provide superior performance and durability, making it a game-changer in the field of shale shaker screens. The FSI 5000 Shaker Screen is engineered to meet the demanding requirements of the oil and gas industry, and its innovative design sets it apart from traditional shaker screens.The FSI 5000 Shaker Screen is manufactured by a leading company in the oil and gas sector, known for its commitment to quality and excellence. With a strong focus on research and development, this company has been at the forefront of technological advancements in the industry. The FSI 5000 Shaker Screen is a testament to their dedication to innovation and their relentless pursuit of excellence.One of the key features of the FSI 5000 Shaker Screen is its advanced composite frame, which provides exceptional strength and longevity. This not only enhances the performance of the shaker screen, but also reduces the overall cost of ownership for the end user. The innovative design of the FSI 5000 Shaker Screen is a result of extensive research and development, ensuring that it meets the highest standards of quality and reliability.In addition to its superior performance, the FSI 5000 Shaker Screen is also designed with ease of use in mind. Its user-friendly interface and simple maintenance procedures make it an ideal choice for busy drilling operations. This allows for seamless integration into existing shaker systems, minimizing downtime and maximizing efficiency.The FSI 5000 Shaker Screen has already garnered rave reviews from industry professionals who have praised its durability and effectiveness. Its ability to withstand the rigors of the oil and gas sector and deliver consistent performance has made it a popular choice among drilling contractors and operators.Furthermore, the company behind the FSI 5000 Shaker Screen is known for its commitment to customer satisfaction. They offer comprehensive support and service to ensure that their clients get the most out of their investment. This includes technical assistance, training, and ongoing maintenance programs to keep the FSI 5000 Shaker Screen operating at its peak performance.In conclusion, the FSI 5000 Shaker Screen is a groundbreaking innovation that is set to revolutionize the oil and gas industry. Its advanced design, superior performance, and exceptional durability make it a top choice for drilling operations around the world. Combined with the company's dedication to quality and customer satisfaction, the FSI 5000 Shaker Screen is poised to become an indispensable asset in the oil and gas sector.

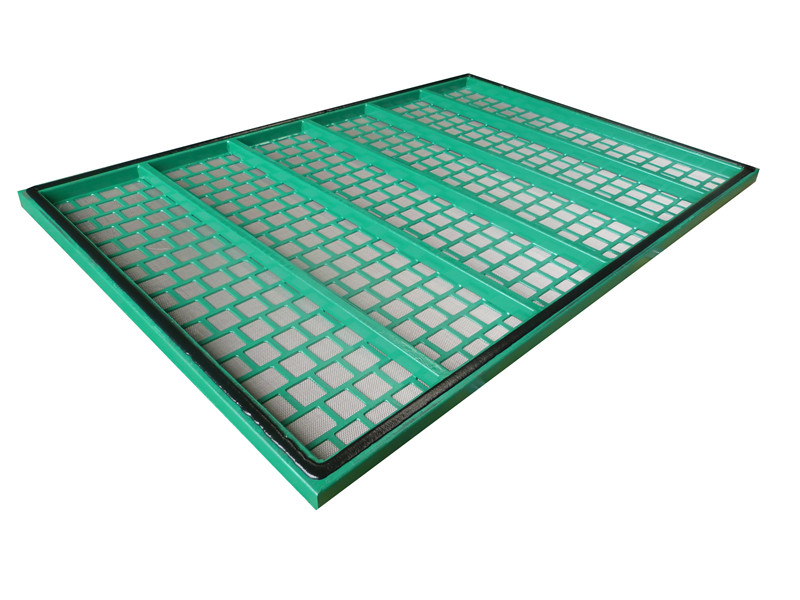

Steel Frame Shaker Screen with High Efficiency and Durability

Title: Cutting-Edge Steel Frame Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the fast-paced and demanding oil and gas industry, efficient drilling operations are crucial for maximizing productivity and profitability. One fundamental component of the drilling process is the shaker screen, which plays a critical role in separating drilling fluid from the drill cuttings. Recognizing the need for highly effective and durable shaker screens, {} has developed the groundbreaking GNZS-703 Steel Frame Shaker Screen. With exceptional efficiency and extended longevity, this game-changing technology is revolutionizing the way the industry operates.Part I: The Importance of Shaker Screens in Drilling Operations (150 words)To comprehend the significance of the GNZS-703 Steel Frame Shaker Screen, it is essential to understand the vital role shaker screens play in drilling operations. These screens act as the primary defense mechanism in the drilling process, separating undesirable solids from valuable drilling fluids. The efficiency and durability of shaker screens directly impact drilling operation costs, as ineffective screens lead to increased maintenance, decreased productivity, and elevated expenses. Thus, the development of advanced shaker screen technology holds immense potential in streamlining drilling operations.Part II: Introducing the GNZS-703 Steel Frame Shaker Screen (200 words)The GNZS-703 Steel Frame Shaker Screen is a cutting-edge innovation designed to optimize the performance and durability of shale shakers, improving overall drilling efficiency. Manufactured by {}, a renowned leader in oilfield equipment, this high-quality screen integrates innovative engineering, expert craftsmanship, and years of industry experience. The result is an exceptional product that surpasses industry standards in terms of efficiency, longevity, and cost-effectiveness.Constructed with precision-welded stainless steel wire mesh, the GNZS-703 Steel Frame Shaker Screen boasts excellent wear resistance, ensuring outstanding performance in the demanding drilling conditions. The frame is made from sturdy steel, providing robust structural support and extending service life. Additionally, the screen undergoes a specialized treatment process to enhance its corrosion resistance, enabling it to withstand harsh drilling fluids and adverse operating conditions.Part III: Key Advantages of the GNZS-703 Steel Frame Shaker Screen (250 words)The GNZS-703 Steel Frame Shaker Screen offers a multitude of advantages, making it a superior choice for drilling contractors and service providers. Firstly, its exceptional filtration efficiency guarantees the removal of a wide range of unwanted solids, preventing their reentry into the drilling fluid system. This not only enhances drilling fluid performance but also minimizes downtime related to fluid system maintenance.Moreover, the GNZS-703 Steel Frame Shaker Screen's long service life significantly reduces replacement costs, enhancing cost-effectiveness for drilling operations. The screen's heavy-duty construction ensures durability and reliability, enabling sustained performance even under heavy workloads. This translates into increased productivity and improved overall drilling efficiency.Furthermore, the upgraded design of the screen allows for easy installation and quick replacement, minimizing downtime and saving valuable operation hours. Its user-friendly nature simplifies maintenance, optimizing efficiency on-site.Conclusion (100 words)With the introduction of the GNZS-703 Steel Frame Shaker Screen, {} has raised the industry standard for shaker screen performance. By combining cutting-edge technology, superior materials, and expert engineering, this innovative product offers exceptional efficiency, extended service life, and substantial cost savings. The GNZS-703 Steel Frame Shaker Screen epitomizes the commitment of {} to providing the oil and gas industry with game-changing solutions that streamline drilling operations and increase profitability.

High-Quality 48-30 PWP Shaker Screen for Derrick FLC2000

Derrick Corporation is proud to announce the release of their latest innovation, the FLC2000 48-30 PWP Shaker Screen. This new product promises to revolutionize the way drilling operations are conducted, offering a more efficient and reliable solution for solids control in the oil and gas industry.The FLC2000 48-30 PWP Shaker Screen combines cutting-edge technology with Derrick's extensive experience in the field of solid control equipment. This results in a product that is not only highly effective in separating solids from drilling fluid, but also durable and long-lasting, even in the most demanding drilling environments.Derrick Corporation has been a leading provider of solid control equipment for over 70 years. The company's commitment to innovation and quality has earned them a reputation as a trusted partner for some of the largest and most respected oil and gas companies in the world. With the release of the FLC2000 48-30 PWP Shaker Screen, Derrick continues to demonstrate their dedication to providing solutions that improve the efficiency and effectiveness of drilling operations.The FLC2000 48-30 PWP Shaker Screen offers a number of key features that set it apart from other products on the market. Its high-quality construction and superior design ensure that it can withstand the rigorous demands of drilling operations, providing reliable performance in even the harshest conditions. Additionally, the screen's advanced technology allows for more efficient solid control, resulting in less downtime and increased productivity for drilling operations.One of the key advantages of the FLC2000 48-30 PWP Shaker Screen is its versatility. It is compatible with a wide range of shaker models, making it an ideal solution for both new installations and retrofitting existing equipment. This flexibility allows drilling companies to easily integrate the FLC2000 48-30 PWP Shaker Screen into their operations, without the need for extensive modifications or additional equipment.In addition to its superior performance and versatility, the FLC2000 48-30 PWP Shaker Screen also offers cost savings for drilling operations. Its durable construction and long lifespan reduce the need for frequent replacements, saving both time and money in the long run. Furthermore, its efficient solid control capabilities result in less wasted drilling fluid, further reducing operational costs for drilling companies.Derrick Corporation is confident that the FLC2000 48-30 PWP Shaker Screen will make a significant impact on the oil and gas industry. With its innovative design, superior performance, and cost-saving benefits, this new product is poised to become a game-changer for drilling operations around the world.As the oil and gas industry continues to evolve, Derrick Corporation remains committed to providing cutting-edge solutions that meet the evolving needs of their customers. The release of the FLC2000 48-30 PWP Shaker Screen is just the latest example of this commitment, and the company looks forward to continue leading the way in solid control equipment for years to come.

Latest Shale Shaker Screen Enhances Efficiency and Performance: A Detailed Report

In the world of oil and gas extraction, shale shaker screens are an essential part of the process. These screens are used to separate solids from drilling fluid and keep the drilling fluid clean and reusable. As technology advances, so do the capabilities of shale shaker screens. One of the latest advancements in this field comes from the production of Derrick FLC313 shale shaker screens.Derrick Corporation, a top provider of innovative solutions for the oil and gas industry, has introduced the Derrick FLC313 shale shaker screen. The company's vast experience and expertise in this industry are evident in the design and capabilities of these screens. The Derrick FLC313 screens offer significant benefits to drilling operations across the globe.The Derrick FLC313 shale shaker screen is engineered to deliver superior performance in a variety of drilling applications. The screen features a fully compliant, repairable screen panel design that maximizes operational uptime. The panel is constructed with a unique composite frame that is tough and durable, yet lightweight. This design reduces the screen's overall weight, making it easier to handle, and improves shaker performance.The screen's construction also includes a layer of high-strength steel reinforcement, providing added rigidity and strength to the screen panel. This layer prevents the screen mesh from sagging and reduces the risk of mesh failures, ensuring that the screen remains operational for longer periods.Derrick's FLC313 shale shaker screen incorporates several advanced features that enhance the performance of drilling operations. The screen uses the pyramid-shaped openings of the patented Pyramid Plus screen technology, which increases the surface area of the screen and reduces the amount of drilling fluid that is lost. The increased surface area provides more efficient solids removal and maximizes the drilling fluid's quality.Another significant advantage of the FLC313 shale shaker screen is its ability to handle high-volume solids processing. The screen's unique design and construction make it suitable for separating a higher volume of solids from drilling fluids, making it an ideal solution for demanding drilling applications.The FLC313 shale shaker screen is compatible with a wide range of shaker models, making it versatile and easy to install. The screen's universal design requires no modifications to the shaker, allowing for a simple installation process, reducing downtime, and increasing productivity.Derrick Corporation is committed to producing sustainable and environmentally-friendly solutions for the oil and gas industry. The company's FLC313 shale shaker screens are designed to minimize environmental impact and reduce waste. The screen's durable, lightweight construction and efficient solids control help to remediate drilling fluid and minimize waste disposal.In conclusion, Derrick Corporation's FLC313 shale shaker screen is a breakthrough innovation in the oil and gas industry. Its exceptional design, durability, and efficiency make it an ideal solution for demanding drilling applications. The screen's ability to handle high-volume solids processing and its compatibility with a wide range of shaker models offer unparalleled versatility and productivity. Derrick Corporation's commitment to sustainability and environmental consciousness ensures that the FLC313 shale shaker screen is also a responsible choice for the industry.

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

Efficient and Durable Oil Shaker Screen: Maximizing Oil Extraction

Houston, Texas – A leading provider of oil drilling equipment is proud to announce the release of their latest shaker screen, the S250. This new shaker screen is the perfect solution for oil and gas rig companies to sift through drilling mud and improve drilling efficiency.The S250 Oil Shaker Screen, which is designed to fit the popular brand of shale shakers, has been field-tested, and the results have been impressive. The screen's design allows for increased throughput capacity and better solids control, meaning that drilling companies will experience less downtime due to drilling mud inefficiencies, translating to lower costs and faster drilling times.The company, which has over two decades of experience in the oil drilling equipment industry, is known for its innovative approach to developing products and solutions that help improve efficiencies in the drilling process, making the process safer and more cost-effective for all parties involved."Drilling for oil and natural gas is a crucial part of the energy industry, and we understand the importance of providing drilling companies with the most advanced and effective equipment on the market," said a spokesperson for the company. "We are proud of our team of engineers and technicians who have worked tirelessly to develop the S250 Oil Shaker Screen. Their expertise and creativity have allowed us to provide a solution that is truly cutting edge."With the energy industry expected to continue its upward trajectory in the coming years, it is imperative for drilling companies to have access to equipment that is both efficient and reliable. The S250 Oil Shaker Screen is designed to meet these demands and help drilling companies prepare to meet the challenges of the future.About the CompanyThe company, which has been operating since 1999, specializes in providing a wide range of oil drilling equipment to companies in the energy industry. The company's mission is to provide drilling companies with the most advanced and reliable equipment on the market, helping to streamline the drilling process and improve safety and efficiency.The company takes pride in working with top-notch engineers and technicians to develop innovative solutions that meet the unique needs of their clients. From mud pumps to drilling rigs to shaker screens like the S250, they are committed to providing equipment that is of the highest quality and built to last.Their dedication to their customers' success has earned them a reputation as a trusted partner in the oil and gas drilling industry. With a commitment to excellence, the company will continue to push the boundaries of innovation in the years to come, helping drilling companies across the globe to safely and efficiently extract oil and natural gas from the earth.