Top performance PMD Shaker screen for Derrick Hyperpool

By:Admin

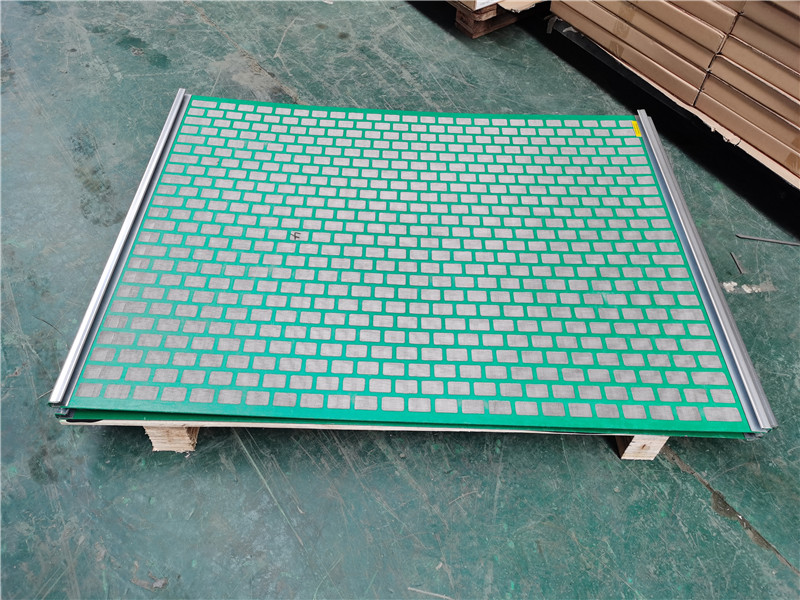

The Hyperpool PMD Shaker screen is designed to provide exceptional solids removal and fluid handling capabilities, making it the ideal solution for challenging drilling operations. With its unique, patented design, the screen is able to effectively separate solids from drilling fluids, leading to improved drilling efficiency and reduced operating costs.

The key to the Hyperpool PMD Shaker screen's exceptional performance lies in its advanced composite frame and ultra-fine mesh, which are engineered to maximize screen life and provide superior particle separation. This not only results in cleaner drilling fluids, but also minimizes the environmental impact of drilling operations by reducing waste and enhancing recycling efforts.

Derrick Corporation has a long-standing reputation for delivering innovative and reliable solutions to the oil and gas industry. With over 70 years of experience, the company has become a trusted partner for major oil and gas companies around the world, providing them with state-of-the-art equipment and exceptional customer service.

The Hyperpool PMD Shaker screen is just one example of Derrick Corporation's commitment to advancing the oil and gas industry through technological innovation. The company continuously invests in research and development to create products that address the evolving needs of the industry and contribute to improved operational efficiency and environmental sustainability.

In addition to its cutting-edge technology, Derrick Corporation is also known for its customer-focused approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique challenges. This collaborative approach has made Derrick Corporation a preferred partner for many leading oil and gas companies, enabling them to achieve their production goals and optimize their drilling operations.

The introduction of the Hyperpool PMD Shaker screen is set to further strengthen Derrick Corporation's position as a market leader in the solids control and waste management sector. The screen's exceptional performance, coupled with the company's reputation for reliability and innovation, is expected to drive its adoption across the oil and gas industry, leading to improved operational efficiencies and cost savings for drilling operators.

As the global demand for oil and gas continues to grow, the need for efficient and sustainable drilling practices has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen represents a significant step forward in advancing the industry's capabilities, and is poised to make a positive impact on drilling operations around the world.

In conclusion, Derrick Corporation's introduction of the Hyperpool PMD Shaker screen is a testament to the company's ongoing commitment to innovation and excellence in the oil and gas industry. With its cutting-edge technology and customer-driven approach, Derrick Corporation is well-positioned to continue leading the way in providing advanced solutions for solids control and fluid management in drilling operations.

Company News & Blog

Efficient Shaker Screen for Optimal Solids Separation

Title: Groundbreaking S250 Shaker Screen Sets New Standards in Oil and Gas IndustryIntroduction:In a world reliant on energy extraction, the oil and gas industry remains a vital player, constantly seeking innovative technologies to optimize drilling and production processes. Step forward the revolutionary S250 Shaker Screen, a cutting-edge solution developed by industry-leading experts, poised to reshape the landscape of oilfield equipment. This groundbreaking equipment promises improved performance, increased durability, and enhanced efficiency, cementing its position as a game-changer in the global market.Section 1: Evolution of Shaker Screens in the Oil and Gas IndustryThe oil and gas industry is known for its relentless pursuit of efficiency and cost-effectiveness. Over the years, there has been an evolution in shaker screens, which play a crucial role in filtering drilling fluids during extraction operations. The S250 Shaker Screen encompasses the latest innovations in material science and design, surpassing its predecessors in terms of longevity and performance.Section 2: Unparalleled Design and Superior PerformanceThe development team behind the S250 Shaker Screen focused on improving the efficiency of the screening process. By enhancing the screen's capacity to retain solids while allowing drilling fluid to pass through, the S250 ensures uninterrupted operation and reduces downtime. Its state-of-the-art design maximizes solids removal, leading to cleaner drilling fluids and increased productivity on-site.Section 3: Enhanced Durability and Cost-EffectivenessIn the oilfield, durability is of paramount importance. The S250 Shaker Screen guarantees exceptional longevity, enabling operators to optimize equipment performance while reducing overall maintenance costs. Manufactured using high-quality materials and employing advanced engineering techniques, this screen withstands the harshest operating conditions, making it an indispensable asset for drilling companies worldwide.Section 4: Eco-Friendly and Sustainable SolutionCorporate social responsibility has become a crucial aspect of the oil and gas industry. Recognizing this, the S250 Shaker Screen is designed with sustainability in mind. By ensuring optimal solids removal and minimizing waste, it significantly reduces environmental impact. Additionally, its extended lifespan and reduced maintenance contribute to minimizing the carbon footprint associated with equipment replacement.Section 5: Market Impact and Industry AdoptionThe launch of the S250 Shaker Screen has generated substantial excitement within the oil and gas industry. Major drilling companies are already adopting this cutting-edge technology, recognizing its potential to revolutionize their operations. With demand rising, manufacturers are increasing production capacity to meet global market needs and capitalize on the expanding customer base.Section 6: Testing and ValidationBefore its launch, the S250 Shaker Screen underwent rigorous testing to ensure it met the industry's stringent quality standards. Evaluation criteria included efficiency, durability, and compatibility with various drilling fluids. The results were overwhelmingly positive, confirming that this novel solution is ready to transform the industry.Conclusion:The S250 Shaker Screen stands as a testament to the relentless pursuit of innovation within the oil and gas industry. Its revolutionary design, exceptional performance, and unmatched durability set a new benchmark for shaker screens. With the global market embracing this game-changing technology, the stage is set for a more efficient and sustainable future in oil and gas extraction.

Innovative Flat Oil Shaker Screen for Improved Drilling Performance

Title: Revolutionary Oil Shaker Screen Sets New Standard in Drilling IndustryIntroduction:In the ever-evolving oil and gas industry, technological advancements continue to shape the way drilling operations are conducted. One such breakthrough is the Duraflo D500 Flat Oil Shaker Screen, a cutting-edge solution that has quickly made its mark as a game-changer in the industry. Developed by a leading manufacturer [], this innovative screen has earned a reputation for its unmatched efficiency and performance, revolutionizing drilling processes worldwide.1. Meeting the Demands of a Changing Industry:With increasing demands for efficient drilling practices, the Duraflo D500 Flat Oil Shaker Screen has emerged as an industry leader. Its advanced design incorporates state-of-the-art technologies that not only improve efficiency but also reduce downtime, consequently enhancing overall productivity. This product addresses the challenges faced by drillers globally, offering a versatile and efficient solution that outperforms its competitors.2. Advanced Design for Enhanced Performance:The Duraflo D500 Flat Oil Shaker Screen showcases a meticulously engineered design that optimizes operational efficiency. By leveraging modern materials and innovative construction techniques, this screen effectively tackles the issues of wear and tear, thereby extending its lifespan and reducing maintenance costs. Its flat surface and precise mesh size ensure maximum cuttings recovery and improved solids control, resulting in enhanced mud handling capabilities during drilling operations.3. Unmatched Durability and Longevity:Durability is a key factor in the oil and gas industry, where equipment must withstand harsh operating conditions. The Duraflo D500 Flat Oil Shaker Screen excels in this aspect, offering exceptional resistance against abrasive materials and corrosive fluids encountered during drilling operations. The screen's materials are specifically chosen for their ruggedness and ability to withstand intense pressure, providing long-lasting performance and reducing the need for frequent replacements.4. Customization for Optimal Performance:Recognizing the diverse needs of the drilling industry, [], the manufacturer of the Duraflo D500 Flat Oil Shaker Screen, offers customization options to meet specific requirements. By tailoring the screen to match unique drilling conditions, customers can achieve optimal performance and maximize efficiency. With a wide range of sizes and configurations available, drillers can seamlessly integrate the screen into their operations, resulting in improved overall output.5. Environmental Benefits:In addition to its operational advantages, the Duraflo D500 Flat Oil Shaker Screen offers environmental benefits. Its efficient solids control capabilities aid in reducing the amount of waste generated during drilling operations. By effectively separating cuttings and solids from the drilling mud, this screen minimizes the environmental impact associated with disposal and promotes responsible waste management practices.6. Global Adoption and Recognition:The Duraflo D500 Flat Oil Shaker Screen has gained widespread recognition and global adoption within the drilling community. Its outstanding performance has led to increased productivity and cost savings for drilling companies worldwide. Collaborating with industry leaders and continuously improving their products, [], the manufacturer has successfully established themselves as a reliable provider of next-generation drilling solutions.Conclusion:As the oil and gas industry continues to evolve, the demand for effective equipment solutions has never been greater. The Duraflo D500 Flat Oil Shaker Screen has emerged as a revolutionary product, setting new standards for efficiency, durability, and environmental sustainability. With its advanced design, customized options, and recognized performance, this screen proves to be a vital asset for drillers seeking enhanced productivity and cost savings. As technology advances, the Duraflo D500 Flat Oil Shaker Screen showcases how innovation can revolutionize the drilling industry, paving the way for more efficient and sustainable practices.

High-Quality Shaker Screen for Efficient Separation of Solids and Liquids

Title: Innovative Shale Shaker Screen Revolutionizes Drilling IndustryIntroduction:In an era of technological advancements, the drilling industry constantly seeks innovative solutions to improve efficiency and reduce costs. As drilling operations become increasingly complex, ensuring reliable and efficient separation of solids from drilling fluid is crucial. Enter an industry-leading product that is making waves with its exceptional performance - the Venom Shaker Screen.Revolutionizing the way drilling companies approach solid control, the Venom Shaker Screen, developed by an innovative company, offers a cutting-edge solution that not only enhances efficiency but also reduces downtime and operational costs. This advanced shale shaker screen is poised to transform the drilling industry by leveraging its unique features and superior performance.Unveiling Advancements:The Venom Shaker Screen is designed to eliminate the common limitations of conventional shaker screens. Its groundbreaking technology effectively removes solids, ensuring better drilling fluid quality without compromising capacity. Developed using a combination of premium materials and advanced manufacturing techniques, this product offers unparalleled durability, reliable performance, and increased efficiency.Key Features:1. Enhanced Solid Control: The Venom Shaker Screen utilizes a state-of-the-art design that promotes efficient solid separation. The combination of precise mesh sizes and reinforced frame construction ensures optimal particle retention while efficiently allowing drilling fluid to pass through.2. Maximum Cuttings Recovery: With its unique layered design, the Venom Shaker Screen maximizes the recovery of valuable drill cuttings, promoting efficient disposal and reducing waste. This results in cost savings for drilling companies.3. Durable Construction: The screen is built to withstand the harsh conditions encountered during drilling operations. With a rugged frame and corrosion-resistant materials, it offers longevity and reduced maintenance requirements, minimizing downtime and associated costs.4. Versatile Application: The Venom Shaker Screen is compatible with various shale shakers, allowing drilling companies to seamlessly integrate it into their existing operations. Its universal design ensures easy installation and replacement, eliminating the need for costly equipment modifications.Industry Impact:The introduction of the Venom Shaker Screen marks a significant milestone in the drilling industry. By improving the efficiency of solid control and reducing waste, this innovative product enhances drilling operations on multiple levels:1. Increased Efficiency: The Venom Shaker Screen's superior solid separation capabilities result in improved drilling fluid quality, allowing for more efficient and effective drilling operations. This translates into reduced drilling time and increased productivity.2. Cost Reduction: The screen's ability to maximize cuttings recovery results in reduced waste disposal costs. Additionally, its durability minimizes maintenance and replacement expenses, optimizing overall operational costs for drilling companies.3. Environmental Benefits: By minimizing waste and promoting efficient disposal of drill cuttings, the Venom Shaker Screen contributes to environmentally responsible drilling practices. This advancement aligns with the industry's growing focus on sustainable operations.Partnerships and Future Developments:The development and success of the Venom Shaker Screen are a testament to the company's commitment to innovation. Collaborations with drilling companies worldwide have allowed for real-time feedback, resulting in continuous improvements.Furthermore, ongoing research and development efforts aim to enhance the screen's capabilities even further. These future developments will provide drilling companies with an even more efficient and reliable solution, ensuring continuous progress in the industry.Conclusion:The introduction of the Venom Shaker Screen signifies a game-changing advancement in the drilling industry. By addressing the limitations of traditional shaker screens and offering exceptional solid control capabilities, this innovative product has the potential to revolutionize drilling operations.With its enhanced efficiency, cost-saving features, and commitment to sustainability, the Venom Shaker Screen is poised to become an essential component in the arsenal of drilling companies worldwide. Embracing this groundbreaking technology will enable drilling operations to thrive in an increasingly competitive and dynamic industry.

Primary Shaker Screen for VSM300 - All You Need to Know

VSM300 Primary Shaker Screen: A Breakthrough Innovation in the Oil and Gas IndustryThe oil and gas industry has been a vital part of the global economy for many years, and as technology continues to advance, so does the need for more efficient and reliable equipment to meet the growing demand for energy resources. One such equipment that has been making waves in the industry is the VSM300 Primary Shaker Screen, a breakthrough innovation that has revolutionized the way drilling waste is managed.The VSM300 Primary Shaker Screen is a high-performance vibrating screen designed specifically for solids control in the oil and gas drilling industry. It is a critical component of the drilling fluids system and is used to separate and remove large drilling cuttings from the drilling fluid, allowing for the reuse of the fluid and the proper disposal of the cuttings. The VSM300 Primary Shaker Screen is known for its exceptional performance, durability, and reliability, making it a popular choice among drilling contractors and operators worldwide.The VSM300 Primary Shaker Screen is manufactured by a leading company in the oil and gas industry that specializes in providing high-quality solid control equipment and solutions to the global market. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of developing cutting-edge technologies that help enhance the efficiency and sustainability of drilling operations.The VSM300 Primary Shaker Screen is an excellent example of the company's commitment to innovation and quality. It is designed to withstand the harsh conditions of drilling operations, including high temperatures, extreme pressures, and abrasive drilling fluids. The screen is made from high-quality materials that are resistant to wear and corrosion, ensuring long-term performance and reliability in the field.One of the key features of the VSM300 Primary Shaker Screen is its unique design, which is optimized for maximum efficiency and productivity. The screen is equipped with a dual-deck design, which allows for increased capacity and better performance in separating solids from the drilling fluid. This design also helps reduce the amount of energy and resources required to process drilling waste, making it a more sustainable solution for managing drilling cuttings.In addition to its superior performance, the VSM300 Primary Shaker Screen is also designed for ease of use and maintenance. It is equipped with quick-release tensioning systems that make it easy to install and replace the screen panels, reducing downtime and increasing productivity on the rig. The screen is also compatible with a wide range of shaker models, making it a versatile solution for different drilling applications.As the demand for energy continues to grow, the oil and gas industry is under increasing pressure to find more sustainable and environmentally friendly solutions for drilling operations. The VSM300 Primary Shaker Screen is a perfect example of how innovation in equipment design can help address these challenges and contribute to the industry's efforts to reduce its environmental footprint.With its exceptional performance, durability, and sustainability, the VSM300 Primary Shaker Screen has become a preferred choice for drilling contractors and operators around the world. It has helped improve the efficiency and reliability of drilling operations, while also contributing to reducing the environmental impact of drilling waste.As the oil and gas industry continues to evolve, the VSM300 Primary Shaker Screen is expected to play a crucial role in helping meet the growing demand for energy resources while also promoting sustainability and environmental responsibility. With its advanced technology and innovative design, this breakthrough innovation is set to be a game-changer in the solid control equipment market for years to come.

Latest Updates on High-Quality Stainless Steel Shaker Screens

Stainless Steel Shaker Screen Plays a Crucial Role in Oil and Gas DrillingThe importance of high-quality shaker screens in the oil and gas drilling industry is undeniable. They are vital in the separation of drilling fluids and solids during the drilling process. Therefore, it is imperative to have reliable, durable shaker screens that can withstand the rigorous demands of the industry.{The company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has established itself as a trusted brand in the industry, providing innovative solutions that meet the needs of customers.The {company} stainless steel shaker screen is one of the most popular products in its lineup. The screen is known for its high efficiency and durability, making it a top choice for drilling operations. It is made of high-quality stainless steel wire mesh and features a unique frame design that ensures maximum screen life and performance.One of the key features of the stainless steel shaker screen is its ability to withstand high temperatures and corrosive materials. This is crucial in the drilling process because the drilling fluids contain various chemicals, which can be highly corrosive and can damage the screen quickly. The {company} shaker screen can handle these harsh conditions without compromising its performance.Another advantage of the {company} stainless steel shaker screen is its superior filtration capabilities. The screen's unique design allows for maximum fluid handling capacity, ensuring that the drilling fluids and solids are separated efficiently. This not only improves the performance of the drilling process but also helps to reduce costs associated with replacing shaker screens frequently.In addition to its technical features, the {company} stainless steel shaker screen is also designed with ease of use in mind. The screen can be easily installed and removed from the shaker, reducing downtime and increasing efficiency.The {company} stainless steel shaker screen is available in a range of sizes and configurations to meet the diverse needs of customers. Whether it is a small-scale drilling operation or a large-scale project, the {company} shaker screen can provide the necessary performance and reliability needed to get the job done.The success of any drilling operation relies on the quality and performance of the equipment used, and the {company} stainless steel shaker screen is an excellent example of equipment that can make a significant difference. With its durable design, superior filtration capabilities, and ease of use, the {company} shaker screen has become a popular choice for drilling companies around the world.In conclusion, the importance of high-quality shaker screens in the oil and gas drilling industry cannot be overstated. The {company} stainless steel shaker screen is an outstanding example of equipment that can make a significant difference in the success of drilling operations. Its durability, filtration capabilities, and ease of use are just a few of the reasons why it has become a trusted choice for drilling companies worldwide.

High-Quality D380 Shaker Screen for Efficient Solid Control Operations

Shale shakers are essential tools used in the oil and gas industry for separating solids from drilling fluid. They play a crucial role in the drilling process by removing large solids from the drilling fluid, allowing the fluid to be recycled and reused. Therefore, the quality and efficiency of shale shaker screens are of utmost importance in ensuring smooth and productive drilling operations.In this regard, the Swaco D380 shaker screen has gained widespread recognition for its exceptional performance and durability. Manufactured by a leading company in the industry, this shaker screen is designed to withstand the most demanding drilling conditions while delivering consistent and reliable performance.The Swaco D380 shaker screen features a high-quality stainless steel wire mesh that is tightly woven to ensure maximum filtration efficiency. The screen is further reinforced with multiple layers of support mesh and a durable frame to withstand the high levels of vibration and impact encountered during drilling operations. This robust construction not only enhances the longevity of the screen but also ensures consistent performance in separating solids from the drilling fluid.One of the key advantages of the Swaco D380 shaker screen is its ability to provide a larger effective screening area, allowing for increased throughput and improved solids removal. This is particularly beneficial in high-volume drilling operations where the efficient removal of solids is critical to maintaining the integrity of the drilling fluid and the overall success of the operation.Additionally, the Swaco D380 shaker screen is designed for compatibility with a wide range of shale shaker models, making it a versatile and cost-effective solution for drilling contractors and operators. This compatibility ensures that the screen can be easily integrated into existing equipment, minimizing downtime and optimizing operational efficiency.Furthermore, the company behind the Swaco D380 shaker screen is committed to upholding the highest quality standards in its manufacturing processes. With state-of-the-art facilities and a team of experienced engineers and technicians, the company ensures that each screen meets strict quality control measures, resulting in a product that consistently meets and exceeds industry requirements.In line with its commitment to quality, the company also provides comprehensive technical support and assistance to its customers, ensuring that the Swaco D380 shaker screen is installed and maintained correctly for optimal performance. This level of support is indicative of the company's dedication to customer satisfaction and its understanding of the critical role that the shaker screen plays in the overall drilling process.As the oil and gas industry continues to evolve and demand grows for more efficient and reliable drilling technologies, the Swaco D380 shaker screen remains a trusted solution for operators seeking to enhance their drilling operations. Its superior performance, durability, and compatibility make it an indispensable tool for achieving maximum solids control and fluid management.In conclusion, the Swaco D380 shaker screen, manufactured by a leading company in the industry, stands as a testament to the commitment to quality, innovation, and customer satisfaction. With its exceptional performance and reliability, this shaker screen continues to set the standard for excellence in the field of solids control, contributing to the success of drilling operations worldwide.

High-quality Shaker Screen for Kemtron 48 - A Comprehensive Review

Kemtron 48 Shaker Screen: The Ultimate Solution for Solid Control in the Oil and Gas IndustryIn the fast-paced world of oil and gas exploration, every second counts. From drilling to extraction, each step of the process requires precision and efficiency. A key aspect of this process is the management of solid control, which is essential for ensuring the smooth functioning of drilling operations. This is where the Kemtron 48 Shaker Screen comes in. The Kemtron 48 Shaker Screen is a revolutionary product that has been designed to effectively manage solid control in the oil and gas industry. It is a vital component of the Kemtron 48 Shale Shaker, which is known for its high-performance and reliability. The shaker screen is made of high-quality stainless steel wire mesh and is designed to effectively separate solid particles from drilling fluid. This not only ensures the smooth functioning of drilling operations but also protects downstream equipment and reduces waste disposal costs.One of the key features of the Kemtron 48 Shaker Screen is its superior durability. Made of high-quality materials, it is designed to withstand the harsh conditions of the oil and gas industry. It is also easy to install and maintain, making it a cost-effective solution for solid control. In addition, the screen has a large screening area, which allows for high capacity and efficiency. This means that operators can achieve optimal performance and productivity with the Kemtron 48 Shaker Screen.The Kemtron 48 Shaker Screen is also designed with versatility in mind. It can be used with a wide range of drilling fluids and is compatible with various types of shakers. This means that it can be seamlessly integrated into existing operations, minimizing downtime and disruption. This is crucial in the oil and gas industry, where every minute of downtime can result in significant financial losses.In addition to its technical capabilities, the Kemtron 48 Shaker Screen is also backed by exceptional customer support. The company behind the product is known for its commitment to customer satisfaction and has a team of experts who are dedicated to providing support and assistance to clients. This means that operators can rely on the company not only for top-of-the-line products but also for reliable service and support.The Kemtron 48 Shaker Screen has already made a significant impact in the oil and gas industry. Its innovative design and superior performance have helped operators around the world achieve greater efficiency and productivity in their drilling operations. From onshore to offshore projects, the Kemtron 48 Shaker Screen has proven to be an indispensable tool for solid control.Looking to the future, the company is committed to further enhancing the capabilities of the Kemtron 48 Shaker Screen. With ongoing research and development, the company aims to continually improve the product and adapt to the evolving needs of the industry. This includes exploring new materials, technologies, and designs to ensure that the Kemtron 48 Shaker Screen remains at the forefront of solid control solutions.In conclusion, the Kemtron 48 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, superior durability, and exceptional performance make it the ultimate solution for solid control. Backed by a commitment to customer satisfaction and continuous innovation, the company behind the product has established itself as a leader in the industry. As the demand for efficient solid control solutions continues to grow, the Kemtron 48 Shaker Screen is poised to play a crucial role in shaping the future of the oil and gas industry.

Top performance PMD Shaker screen for Derrick Hyperpool

Derrick Corporation, a global leader in the manufacture of high-performance screening and separation equipment, has recently introduced its latest innovation - the Hyperpool PMD Shaker screen. This advanced technology promises to revolutionize the oil and gas drilling industry by offering unprecedented efficiency and performance in solids control.The Hyperpool PMD Shaker screen is designed to provide exceptional solids removal and fluid handling capabilities, making it the ideal solution for challenging drilling operations. With its unique, patented design, the screen is able to effectively separate solids from drilling fluids, leading to improved drilling efficiency and reduced operating costs.The key to the Hyperpool PMD Shaker screen's exceptional performance lies in its advanced composite frame and ultra-fine mesh, which are engineered to maximize screen life and provide superior particle separation. This not only results in cleaner drilling fluids, but also minimizes the environmental impact of drilling operations by reducing waste and enhancing recycling efforts.Derrick Corporation has a long-standing reputation for delivering innovative and reliable solutions to the oil and gas industry. With over 70 years of experience, the company has become a trusted partner for major oil and gas companies around the world, providing them with state-of-the-art equipment and exceptional customer service.The Hyperpool PMD Shaker screen is just one example of Derrick Corporation's commitment to advancing the oil and gas industry through technological innovation. The company continuously invests in research and development to create products that address the evolving needs of the industry and contribute to improved operational efficiency and environmental sustainability.In addition to its cutting-edge technology, Derrick Corporation is also known for its customer-focused approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique challenges. This collaborative approach has made Derrick Corporation a preferred partner for many leading oil and gas companies, enabling them to achieve their production goals and optimize their drilling operations.The introduction of the Hyperpool PMD Shaker screen is set to further strengthen Derrick Corporation's position as a market leader in the solids control and waste management sector. The screen's exceptional performance, coupled with the company's reputation for reliability and innovation, is expected to drive its adoption across the oil and gas industry, leading to improved operational efficiencies and cost savings for drilling operators.As the global demand for oil and gas continues to grow, the need for efficient and sustainable drilling practices has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen represents a significant step forward in advancing the industry's capabilities, and is poised to make a positive impact on drilling operations around the world.In conclusion, Derrick Corporation's introduction of the Hyperpool PMD Shaker screen is a testament to the company's ongoing commitment to innovation and excellence in the oil and gas industry. With its cutting-edge technology and customer-driven approach, Derrick Corporation is well-positioned to continue leading the way in providing advanced solutions for solids control and fluid management in drilling operations.

High-quality Shaker Screen for Oil and Gas Industry Applications

Derrick Corporation, a global leader in separation technology, has recently unveiled its latest innovation in shale shaker screen technology, the HYP PWP Shaker Screen. This new product is designed to provide unparalleled efficiency and durability in the oil and gas industry, setting a new standard for oilfield solids control equipment.The HYP PWP Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced in shale shaker operations. This new generation of shaker screens offers a significant improvement in performance, with enhanced solids removal and increased fluid handling capacity. The innovative design of the HYP PWP Shaker Screen ensures a longer lifespan and reduced maintenance, resulting in cost savings for oil and gas operators.Derrick Corporation has long been recognized for its commitment to advancing separation technology, and the introduction of the HYP PWP Shaker Screen further solidifies its position as a leader in the industry. The company's dedication to quality and innovation is evident in the design and engineering of this new product, which is set to revolutionize shale shaker performance.With a global footprint and a strong presence in major oil and gas producing regions, Derrick Corporation is well-positioned to meet the growing demands of the industry. The company's extensive experience and expertise in solids control equipment make it a trusted partner for oilfield operators seeking reliable and efficient solutions. The HYP PWP Shaker Screen is yet another example of Derrick Corporation's commitment to delivering superior products that meet the evolving needs of the oil and gas sector.In addition to its innovative products, Derrick Corporation also offers comprehensive aftermarket support and service to ensure the optimal performance of its equipment. The company's team of experts provides technical assistance, training, and maintenance services to help customers maximize the value of their investment in Derrick products. This commitment to customer satisfaction further underscores Derrick Corporation's reputation as a reliable and trusted partner in the oil and gas industry.The launch of the HYP PWP Shaker Screen marks a significant milestone for Derrick Corporation, as it continues to lead the way in advancing separation technology for the oil and gas sector. This new product is set to deliver tangible benefits for oilfield operators, including improved efficiency, reduced maintenance costs, and enhanced drilling fluid performance. With its proven track record of innovation and excellence, Derrick Corporation is well-positioned to shape the future of solids control equipment and make a lasting impact on the oil and gas industry.

How to Choose the Right Screen for Your Industrial Separation Needs

HanZhi Tech Unveils Cutting-Edge GNZS-833 Screen to Revolutionize Visual Display IndustryIn a remarkable breakthrough, HanZhi Tech, a leading innovator in the field of visual display solutions, has introduced the highly anticipated GNZS-833 Screen. This revolutionary display technology is set to redefine the way we perceive visual content, offering unmatched clarity, depth, and realism.HanZhi Tech, renowned for its commitment to pushing technological boundaries, has an impressive track record of delivering exceptional visual experiences to its customers. With the launch of the GNZS-833 Screen, the company has yet again raised the bar by offering a truly immersive and captivating visual display that is bound to leave audiences spellbound.This state-of-the-art screen boasts an array of advanced features that set it apart from its competitors. The GNZS-833 offers an astonishingly high resolution, creating images that are incredibly lifelike and vibrant. With a pixel density that surpasses anything seen before, every minute detail of the content displayed is brought to life with remarkable clarity.One of the key highlights of the GNZS-833 Screen is its exceptional color accuracy and reproduction capabilities. Leveraging the latest in display technology, HanZhi Tech has managed to achieve an unparalleled color gamut, allowing for true-to-life representation of colors. From deep blacks to vivid reds and blues, the GNZS-833 delivers visuals that are both captivating and true to the original intent of the content creator.Furthermore, the GNZS-833 Screen presents an impressive range of viewing angles, ensuring that everyone in the room can enjoy an optimal visual experience. A common limitation in traditional display technology is the loss of image quality when viewed from an angle, resulting in reduced enjoyment for those not directly in front of the screen. However, HanZhi Tech has overcome this obstacle by integrating advanced panel technology into the GNZS-833, enabling consistent picture quality regardless of the viewer's position.Additionally, the GNZS-833 boasts an impressively high refresh rate and response time, making it ideal for applications that require rapid image transitions and low latency. Whether for gaming, sports broadcasting, or fast-paced action sequences in movies, the GNZS-833 ensures a fluid and seamless viewing experience, immersing the audience in every frame with breathtaking clarity and smoothness.HanZhi Tech has not only focused on the technical aspects of the GNZS-833, but also on the user experience. The screen comes equipped with an intuitive user interface, allowing users to effortlessly navigate through settings and customize their viewing preferences. With the inclusion of smart features, such as voice control and compatibility with popular streaming platforms, HanZhi Tech aims to cater to the evolving needs of modern consumers.As HanZhi Tech continues to break new ground, the company remains committed to sustainability. The GNZS-833 Screen is designed with eco-friendly materials and adheres to stringent energy efficiency standards. By reducing power consumption and minimizing the environmental impact, HanZhi Tech has reaffirmed its dedication to a greener future.The GNZS-833 Screen by HanZhi Tech is a testament to the company's unwavering pursuit of excellence in the visual display industry. With its cutting-edge features, impeccable visual fidelity, and commitment to sustainability, the GNZS-833 is poised to transform the way we consume and appreciate visual content. Whether for entertainment, professional applications, or educational purposes, this groundbreaking display technology is set to elevate the viewing experience to unprecedented heights.