Steel Frame Shaker Screen: A Durable and Efficient Solution

By:Admin

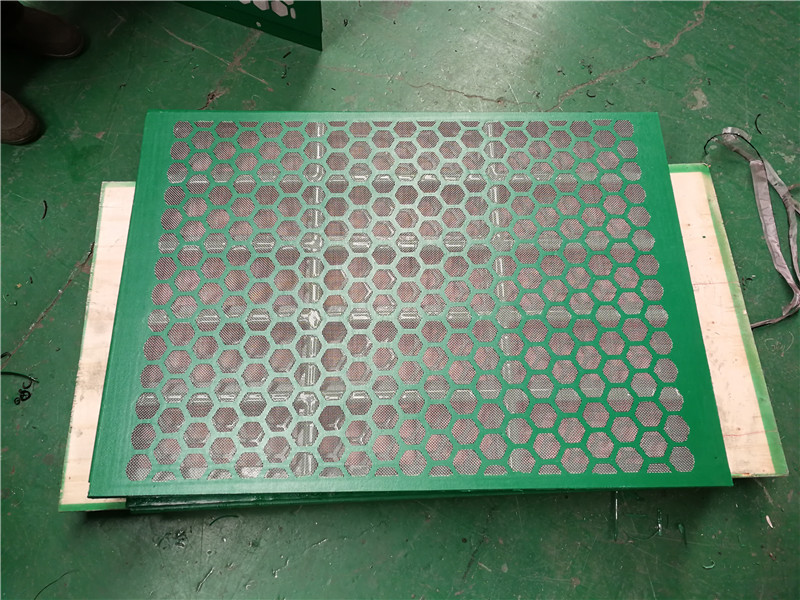

The DFTS Steel Frame Shaker Screen is designed to effectively separate solids and fluids in the drilling mud, ensuring that the drilling operation runs smoothly and efficiently. This new addition to the DFTS product line is built with a strong and durable steel frame, allowing it to withstand the harsh conditions of drilling operations without compromising its performance.

With a focus on providing top-notch quality products, DFTS has garnered a strong reputation in the industry for their high-performance shaker screens. The company takes pride in their commitment to innovation and excellence, which is reflected in the latest DFTS Steel Frame Shaker Screen. This product is the result of extensive research and development, aimed at meeting the evolving needs of the oil and gas industry.

DFTS has a long-standing history of delivering reliable and cost-effective solutions to their clients. The company understands the challenges faced by drilling operations and is dedicated to providing products that address these challenges. The DFTS Steel Frame Shaker Screen is a testament to their dedication to delivering exceptional products that enhance operational efficiency and productivity.

One of the key features of the DFTS Steel Frame Shaker Screen is its superior performance in separating solids from drilling mud. This is essential in maintaining the overall integrity of the drilling process, as it prevents the build-up of solids that can hinder the operation. The screen’s advanced design and construction ensure that it effectively filters out a wide range of solid particles, resulting in a cleaner and more efficient drilling mud.

Furthermore, the DFTS Steel Frame Shaker Screen is designed for easy installation and maintenance, reducing downtime and operational costs. The company has always placed a strong emphasis on user-friendly products, and this latest offering is no exception. With its simple and efficient design, this shaker screen is set to streamline the screening process, making it easier for drilling operators to maintain the equipment and keep it in optimal working condition.

In addition to its performance and user-friendly design, the DFTS Steel Frame Shaker Screen is also built for durability. The high-quality materials and construction ensure that the screen can withstand the toughest drilling conditions, providing long-term reliability and cost-efficiency. This is a critical factor in the oil and gas industry, where equipment reliability is paramount to the success of drilling operations.

The launch of the DFTS Steel Frame Shaker Screen is a significant milestone for DFTS, as it further solidifies their position as a leading provider of shaker screens for the oil and gas industry. The company’s commitment to quality, innovation, and customer satisfaction has been the driving force behind their success, and this latest product is a testament to their dedication to excellence.

In conclusion, the DFTS Steel Frame Shaker Screen is poised to make a significant impact on the oil and gas industry with its advanced technology, reliable performance, and durable construction. DFTS continues to set the standard for excellence in shaker screen solutions, and this latest addition to their product line is a testament to their ongoing commitment to meeting the evolving needs of the industry. With the launch of the DFTS Steel Frame Shaker Screen, DFTS reaffirms their position as a trusted partner for drilling operators seeking top-quality solutions for their operations.

Company News & Blog

High-Quality FSI 5000 Shaker Screen for Effective Solid Control

In recent years, the oil and gas industry has seen a significant increase in demand for advanced equipment and technologies to enhance drilling operations. One such technology that has been making waves in the industry is the FSI 5000 Shaker Screen. This innovative piece of machinery has revolutionized the way drilling mud is processed and has significantly increased the efficiency and effectiveness of drilling operations. The FSI 5000 Shaker Screen, manufactured by a leading oilfield equipment company, has become a game-changer in the industry, and its impact is being felt across the board.The FSI 5000 Shaker Screen is a high-performance filtering device that is used to separate solids from drilling mud. It is designed to operate under high volumes of liquid and solids, making it an essential component in the drilling process. The screen consists of multiple layers of mesh that work together to effectively separate solids from the drilling fluid. This results in cleaner fluid that can be reused in the drilling process, reducing waste and saving time and money.The company behind the FSI 5000 Shaker Screen is a renowned leader in the oilfield equipment industry. With years of experience and expertise, the company has continuously pushed the boundaries of innovation and technology, leading to the development of cutting-edge products such as the FSI 5000 Shaker Screen. The company is committed to providing top-of-the-line equipment and solutions to its clients, and the FSI 5000 Shaker Screen is a testament to that commitment.The FSI 5000 Shaker Screen has garnered widespread attention and praise in the industry for its exceptional performance and reliability. It has been used in a wide range of drilling operations, from onshore to offshore, and has delivered outstanding results in all types of environments. The screen's durability and efficiency have made it a go-to choice for drilling contractors and operators looking to optimize their operations and maximize their return on investment.One of the key factors that sets the FSI 5000 Shaker Screen apart from other similar products on the market is its superior construction and design. The screen is built using high-quality materials and is engineered to withstand the rigors of the drilling process. It is also easy to install and maintain, making it a cost-effective solution for companies looking to streamline their operations.In addition to its performance and reliability, the FSI 5000 Shaker Screen is also known for its environmental benefits. By effectively separating solids from drilling mud, the screen helps to minimize waste and reduce the environmental impact of drilling operations. This aligns with the industry's increasing focus on sustainability and responsible resource management, making the FSI 5000 Shaker Screen a valuable asset for companies looking to improve their environmental performance.Looking ahead, the future looks bright for the FSI 5000 Shaker Screen and the company behind it. As the oil and gas industry continues to evolve and demand for advanced drilling equipment grows, the FSI 5000 Shaker Screen is poised to play a pivotal role in shaping the industry's future. With its proven track record of performance, reliability, and efficiency, the screen is set to become an indispensable tool for drilling operations around the world.In conclusion, the FSI 5000 Shaker Screen is a prime example of how innovation and technology are driving the evolution of the oil and gas industry. By providing a reliable and efficient solution for separating solids from drilling mud, the screen is helping to optimize drilling operations and improve environmental performance. With its impressive features and benefits, the FSI 5000 Shaker Screen has earned its reputation as a game-changer in the industry and will continue to make a significant impact for years to come.

High-quality Oil Shaker Screen for FLC2000 Shakers

The oil and gas industry is a complex and demanding sector that requires cutting-edge technology and equipment to ensure smooth operations. One such essential piece of equipment is the FLC2000 Shaker screen, a vital component in the drilling process.The FLC2000 Shaker screen is a high-performance vibrating screen used to separate solids from liquids in the drilling mud. It is designed to efficiently remove solid particles from drilling fluids, which is a crucial step in the drilling process to ensure the integrity of the wellbore and protect downstream equipment.The FLC2000 Shaker screen, manufactured by a leading oilfield equipment company, is known for its durability, efficiency, and reliability. With a strong focus on quality and performance, the company has positioned itself as a trusted provider of drilling equipment and solutions to the oil and gas industry.The company behind the FLC2000 Shaker screen has a solid reputation for delivering innovative and high-quality products that meet the demanding requirements of the oil and gas sector. With a strong emphasis on research and development, the company has continuously improved and enhanced its product offerings to meet the evolving needs of the industry.In addition to the FLC2000 Shaker screen, the company also offers a comprehensive range of drilling equipment, including shale shakers, mud cleaners, centrifuges, and other solids control equipment. These products are designed to optimize drilling performance, reduce downtime, and minimize environmental impact, making them essential for efficient and sustainable drilling operations.The company's commitment to quality and customer satisfaction is evident in its rigorous testing and certification processes, ensuring that its products meet the highest industry standards. This dedication to excellence has earned the company the trust and confidence of leading oil and gas companies worldwide.Furthermore, the company's expertise in providing custom solutions and technical support sets it apart as a reliable partner for the oil and gas industry. Its team of experienced engineers and technicians are readily available to provide installation, maintenance, and troubleshooting services, ensuring that its customers' operations run smoothly and efficiently.With a global network of distribution and service centers, the company is well-positioned to provide timely support and reliable delivery of its products to customers around the world. This extensive network underscores the company's commitment to being a valuable and dependable partner to the oil and gas industry.In conclusion, the FLC2000 Shaker screen, combined with the company's extensive experience, technical expertise, and commitment to quality, exemplifies the essential role of advanced technology and equipment in the oil and gas industry. By consistently delivering reliable and innovative solutions, the company has established itself as a trusted provider of drilling equipment and solutions, contributing to the efficiency and sustainability of the oil and gas sector.

High-Quality D380 Shale Shaker Screen for Effective Shale Separation

The shale shaker screen is a critical component in the oil drilling process. It is responsible for separating the solid particles from the drilling fluid or mud, allowing for the efficient extraction of oil and gas. One company that has been making waves in the industry with their top-of-the-line shale shaker screens is Brandt D380.Brandt D380 has been a pioneer in the oil drilling industry since their inception. With a focus on innovation and quality, the company has quickly risen to become a leader in the market. Their commitment to developing cutting-edge technology and providing superior products has earned them a reputation as a trusted partner for oil drilling companies around the world.The Brandt D380 Shale Shaker Screen is a prime example of the company's dedication to excellence. This high-quality screen is designed to withstand the harsh conditions of oil drilling, delivering exceptional performance and reliability. Made from premium materials and utilizing advanced manufacturing techniques, the Brandt D380 Shale Shaker Screen sets a new standard for efficiency and durability.One of the key features of the Brandt D380 Shale Shaker Screen is its advanced particle separation capabilities. The screen is meticulously engineered to efficiently separate solid particles from the drilling fluid, ensuring that the extraction process runs smoothly and without interruption. This not only improves the overall efficiency of the drilling operation but also reduces the wear and tear on other equipment, leading to cost savings for the drilling company.In addition to its superior performance, the Brandt D380 Shale Shaker Screen is also designed for easy installation and maintenance. The user-friendly design allows for quick and hassle-free replacement, minimizing downtime and maximizing productivity. This makes it an ideal choice for drilling companies that prioritize efficiency and reliability.Furthermore, the company's commitment to customer satisfaction is evident in their comprehensive support services. Brandt D380 offers expert technical assistance and advice to help their clients optimize the performance of their shale shaker screens. Their team of professionals is dedicated to providing personalized solutions that meet the specific needs of each client, ensuring the success of every drilling operation.The success of the Brandt D380 Shale Shaker Screen can be attributed to the company's unwavering commitment to quality and innovation. With a strong focus on research and development, Brandt D380 continues to push the boundaries of technology, constantly seeking new ways to improve the efficiency and performance of their products. This dedication to excellence has cemented their position as a leading provider of shale shaker screens in the oil drilling industry.As the demand for oil and gas continues to grow, the need for reliable and efficient drilling equipment becomes increasingly important. With the Brandt D380 Shale Shaker Screen, drilling companies can count on superior performance, durability, and support, ensuring a smooth and successful drilling operation. It is clear that Brandt D380 is dedicated to helping their clients achieve their goals, making them a valuable partner for oil drilling companies worldwide.

High-quality Replacement Wave Screens for Hyperpool Shakers

The demand for efficient and high-quality solid control equipment in the oil and gas industry has led to the development of advanced technology to enhance the performance of drilling operations. One such innovation is the Replacement Wave Screens for Derrock Hyperpool Shakers, which is set to revolutionize the way solid control equipment is used in drilling operations.This new technology promises to deliver improved efficiency and cost-effectiveness for oil and gas companies, as it can significantly enhance the performance of drilling operations. These screens are designed to fit seamlessly into Derrock Hyperpool Shakers, which are widely used in the industry for solid control during drilling operations.The Replacement Wave Screens are manufactured using state-of-the-art technology and high-quality materials, ensuring a longer lifespan and superior performance compared to traditional screens. The unique wave design of the screens allows for increased capacity and efficiency, resulting in better solid control and reduced maintenance costs.In addition to the innovative design, these replacement screens are also easy to install and maintain, making them an ideal choice for drilling operations. The company behind this advanced technology has a strong track record in providing reliable and cutting-edge solutions for the oil and gas industry.With a team of experienced engineers and industry experts, the company is committed to delivering top-notch products and services that meet the evolving needs of the oil and gas sector. The Replacement Wave Screens for Derrock Hyperpool Shakers are a testament to this commitment, as they are designed to improve the overall performance and cost-effectiveness of drilling operations.Furthermore, the company's dedication to quality and customer satisfaction sets them apart in the industry. They prioritize customer feedback and constantly strive to innovate and improve their products to meet the changing demands of the market. This customer-centric approach has earned them a solid reputation as a leading provider of solid control equipment and services.In addition to offering innovative products, the company also provides comprehensive support and services to ensure that their clients get the most out of their equipment. From installation and training to maintenance and troubleshooting, the company's team of experts is dedicated to assisting their clients every step of the way.The Replacement Wave Screens for Derrock Hyperpool Shakers are just one example of the company's commitment to driving excellence and innovation in the oil and gas industry. As the demand for efficient and reliable solid control equipment continues to grow, this new technology is expected to play a pivotal role in enhancing drilling operations around the world.The company's dedication to delivering high-quality products and exceptional customer service makes them a trusted partner for oil and gas companies seeking advanced solutions for their drilling operations. With the Replacement Wave Screens for Derrock Hyperpool Shakers, the company is set to raise the bar for solid control equipment in the industry and set new standards for efficiency and performance.In conclusion, the Replacement Wave Screens for Derrock Hyperpool Shakers represent a significant advancement in solid control technology for the oil and gas industry. Backed by a company with a strong reputation for excellence and innovation, these screens are poised to revolutionize the way drilling operations are conducted, delivering improved efficiency, cost-effectiveness, and overall performance for oil and gas companies around the world.

Discover the Importance of Vibrating Screen Frequency for Optimal Efficiency

Vibrating Screen Frequency Advancements Revolutionize the Screening ProcessInnovative Technology Sets New Standards for Efficiency and Productivity[City], [Country] - The global industrial equipment market has witnessed tremendous growth over the years, driven by advancements in technology and increasing demand for efficient and sustainable solutions. One company at the forefront of this revolution is [Company Name], a leader in the development and manufacturing of vibrating screens. Their latest breakthrough, the new Vibrating Screen Frequency, is set to revolutionize the screening process.The traditional vibrating screens have been widely used in various industries such as mining, construction, and recycling. However, these screens often encounter challenges in terms of efficiency and productivity, hampering the overall effectiveness of the screening process. Recognizing these limitations, [Company Name] invested heavily in research and development to create the Vibrating Screen Frequency – a cutting-edge technology that promises to address these issues head-on.What sets the Vibrating Screen Frequency apart from its predecessors is its superior operating frequency. By increasing the frequency at which the screen vibrates, the screening efficiency is significantly improved. This means that more material can be processed in a shorter amount of time, leading to higher productivity and reduced operational costs. Additionally, the increased frequency allows for better separation of particles, resulting in higher quality end products.The Vibrating Screen Frequency also boasts enhanced versatility. It can be easily adjusted to accommodate different materials and particle sizes, making it suitable for a wide range of applications. Whether it is separating aggregates in the mining industry, classifying plastics in recycling processes, or grading sand in the construction field, the Vibrating Screen Frequency delivers accurate and precise results every time.Furthermore, the new technology offers advanced customization options. [Company Name] understands that different industries have specific screening requirements, and the Vibrating Screen Frequency can be tailored to meet these needs. With adjustable parameters such as amplitude and vibration direction, operators can optimize the screen's performance for their specific applications, maximizing efficiency and throughput.Another key advantage of the Vibrating Screen Frequency is its durability and reliability. Manufactured using high-quality materials and state-of-the-art engineering techniques, this innovative product is built to withstand the toughest operating conditions. It boasts a longer lifespan compared to conventional screens, reducing maintenance costs and downtime, ensuring uninterrupted production.In addition to its impressive technical features, [Company Name] is renowned for its commitment to sustainability. The Vibrating Screen Frequency aligns with their philosophy of providing eco-friendly solutions to the industry. By optimizing screening efficiency, this technology enables companies to reduce energy consumption and minimize their environmental footprint.[Company Name] has already received positive feedback from early adopters of the Vibrating Screen Frequency. Several companies have reported significant improvements in their screening processes, with increased productivity and higher-quality output. In fact, one mining company claims that the Vibrating Screen Frequency has helped them achieve a 20% increase in overall efficiency, translating into substantial cost savings and improved profitability.As global industries continue to prioritize efficiency and sustainability, groundbreaking technologies like the Vibrating Screen Frequency will play a crucial role in boosting productivity and reducing environmental impact. With its exceptional performance, versatility, and reliability, the Vibrating Screen Frequency is set to reshape the future of the screening process across various sectors.About [Company Name]:[Company Name] is a globally recognized leader in the development, manufacturing, and supply of industrial equipment. With a strong focus on innovation, they continuously strive to deliver cutting-edge solutions that enhance efficiency, productivity, and sustainability. Through their superior products and unwavering commitment to customer satisfaction, [Company Name] has established itself as a trusted partner for businesses worldwide.For more information about [Company Name] and their revolutionary Vibrating Screen Frequency, please visit their official website or contact their customer service department.Media Contact:[Contact Name][Company Name][Phone Number][Email Address]

High-Quality BEM-650 Shaker Screen for OEM Equipment

Shaker screens are a crucial component in the oil and gas industry, used in the process of separating solids from drilling fluid. This allows for the efficient and cost-effective removal of solid particles from the fluid, which is essential for maintaining the quality and performance of the drilling operation. One company that has been at the forefront of developing high-quality shaker screens for the oil and gas industry is {company}.{Company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has a strong reputation for delivering innovative and reliable products that meet the needs of its customers. With a focus on quality and performance, {company} has become a trusted partner for many drilling operations around the world.One of the flagship products from {company} is the BEM-650 shaker screen. This shaker screen is designed to provide superior performance in the separation of solids from drilling fluid. The BEM-650 is known for its durability and efficiency, making it a popular choice among drilling operators.The BEM-650 shaker screen is designed to fit OEM Swaco shakers, making it a versatile and compatible option for many drilling operations. The screen features a high-quality mesh that is capable of effectively separating a wide range of solid particles from the drilling fluid. This is essential for maintaining the integrity of the fluid and ensuring that the drilling operation runs smoothly and efficiently.In addition to its superior performance, the BEM-650 shaker screen is also known for its durability. The screen is built to withstand the harsh conditions of the drilling environment, ensuring that it remains effective and reliable even in challenging circumstances. This level of reliability is crucial for drilling operators, who rely on their equipment to perform consistently in order to maintain the quality and efficiency of their operations.{Company} is committed to delivering high-quality products and exceptional customer service. The company works closely with its customers to understand their needs and develop solutions that meet their specific requirements. This customer-focused approach has helped {company} build strong and lasting relationships with its clients, who trust the company to deliver reliable and effective equipment for their drilling operations.With a track record of innovation and excellence, {company} continues to lead the way in the development of shaker screens and other equipment for the oil and gas industry. The company's dedication to quality, performance, and customer satisfaction has made it a trusted partner for drilling operators around the world.As the demand for reliable and efficient equipment in the oil and gas industry continues to grow, {company} is well-positioned to meet the needs of its customers. With its high-quality products and commitment to excellence, the company is poised to remain a leader in the development of shaker screens and other equipment for the drilling industry.In conclusion, {company} is a top manufacturer of shaker screens and other equipment for the oil and gas industry. The company's commitment to quality and performance is evident in its flagship product, the BEM-650 shaker screen. With its superior performance and durability, the BEM-650 is a popular choice among drilling operators. Combined with {company}'s dedication to customer service and innovation, the company is well-positioned to remain a leader in the development of equipment for the oil and gas industry.

New Shale Shaker Screen: A Brief Overview

The shale shaker screen is an essential tool in the oil and gas industry, used to separate drilling cuttings from the drilling fluid. A high-quality shale shaker screen is crucial for efficient and effective drilling operations, and the GNZS-752 Shale Shaker Screen is making waves in the industry for its exceptional performance and reliability.The GNZS-752 Shale Shaker Screen is manufactured by a leading company in the oil and gas equipment industry. With a strong focus on innovation and quality, the company has become a trusted name in providing equipment and solutions for oil and gas drilling operations worldwide.The GNZS-752 Shale Shaker Screen is designed with the latest technology and high-quality materials to deliver superior performance in separating drilling cuttings from the drilling fluid. It is specifically engineered to withstand the demanding conditions of drilling operations, making it a reliable and durable option for oil and gas companies.One of the key features of the GNZS-752 Shale Shaker Screen is its high capacity and efficiency in removing solids from the drilling fluid. This helps to improve the overall performance of the drilling operation and ensures a clean and efficient drilling fluid for further processing.The design of the GNZS-752 Shale Shaker Screen also allows for easy installation and maintenance, saving time and resources for oil and gas companies. Its durable construction and long lifespan make it a cost-effective investment for any drilling operation.In addition, the GNZS-752 Shale Shaker Screen is designed to be compatible with a wide range of shale shakers, making it a versatile and convenient option for oil and gas companies with varying equipment requirements.The company behind the GNZS-752 Shale Shaker Screen has a strong commitment to customer satisfaction and support. They provide comprehensive technical support and after-sales service, ensuring that their customers can rely on the performance and durability of their equipment.With a focus on continuous improvement and innovation, the company is dedicated to providing cutting-edge solutions for the oil and gas industry. The GNZS-752 Shale Shaker Screen is a testament to their dedication to quality and performance, and it has quickly become a popular choice for oil and gas companies looking for reliable and efficient shale shaker screens.In conclusion, the GNZS-752 Shale Shaker Screen is a top-of-the-line solution for oil and gas companies in need of a high-performance shale shaker screen. With its exceptional capacity, efficiency, and durability, it is a valuable investment for any drilling operation. Combined with the company's commitment to quality and customer satisfaction, the GNZS-752 Shale Shaker Screen is set to continue making a significant impact in the oil and gas industry.

Derrick Hyperpool Shaker Screen for PMD - What You Need to Know

Derrick Corporation, a global leader in the supply of high-performance separation and filtration equipment, has introduced its latest innovation in solids control technology - the Hyperpool PMD Shaker screen. This cutting-edge product offers superior performance and durability to enhance drilling operations in the oil and gas industry.The Hyperpool PMD Shaker screen is designed to efficiently remove solid particles from drilling fluid, also known as drilling mud, during the drilling process. This is a crucial step in the extraction of oil and gas, as the presence of solid particles can hinder the performance of drilling equipment and ultimately affect the overall efficiency of the operation.One of the key features of the Hyperpool PMD Shaker screen is its advanced design, which allows for increased throughput capacity and improved solids removal efficiency. This results in higher productivity and cost savings for drilling operations, as the need for frequent screen changes and maintenance is significantly reduced.In addition, the Hyperpool PMD Shaker screen is built to withstand the challenging and harsh conditions encountered in oil and gas drilling operations. Its durable construction and long-lasting performance make it a reliable and cost-effective solution for operators looking to optimize their solids control processes.Furthermore, Derrick Corporation has a proven track record of delivering high-quality products and services to the oil and gas industry. With over 70 years of experience, the company has established itself as a trusted partner for operators seeking innovative and reliable solutions for their separation and filtration needs.The introduction of the Hyperpool PMD Shaker screen further solidifies Derrick Corporation's commitment to providing industry-leading technology that meets the evolving demands of the oil and gas sector. By continuously investing in research and development, the company strives to remain at the forefront of innovation and deliver solutions that drive operational efficiency and performance.In response to the introduction of the Hyperpool PMD Shaker screen, Derrick Corporation's CEO commented, "We are excited to bring this advanced technology to the market, as we believe it will greatly benefit our customers and help them achieve their operational objectives. The Hyperpool PMD Shaker screen is a testament to our ongoing dedication to delivering innovative and high-performance solutions that address the challenges faced by the oil and gas industry."As the global demand for oil and gas continues to rise, the need for efficient and reliable solids control equipment has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen is poised to make a significant impact on drilling operations worldwide, offering enhanced performance, durability, and cost savings.With its proven expertise and commitment to innovation, Derrick Corporation is well-positioned to continue driving advancements in solids control technology and empowering operators to achieve greater success in their drilling operations. The introduction of the Hyperpool PMD Shaker screen is a testament to the company's unwavering dedication to excellence and its ability to deliver solutions that meet the evolving needs of the oil and gas industry.

Durable Steel Frame Screen for Swaco Mamut Shakers" - Removed Brand Name

Swaco Mamut Steel Frame Screen (SWM) continues to demonstrate its commitment to innovation and excellence in the oil and gas industry, as it further establishes itself as a top provider of high-quality, durable, and efficient screens for the sector. SWM's steel frame screens have been praised for their reliability and performance, making them a top choice for companies looking to optimize their operations.A key factor that sets SWM apart from its competitors is its dedication to research and development. The company invests heavily in this area, constantly seeking new ways to improve its products and stay ahead of the curve in the industry. SWM also places a strong emphasis on customer feedback, using it to drive product improvements and ensure that its screens continue to meet the evolving demands of its clients.SWM's steel frame screens are designed to withstand the harshest conditions found in oil and gas operations. These screens are built to last, with a focus on durability and performance. This is critical in an industry where equipment needs to be able to endure extreme temperatures, high pressure, and corrosive materials. SWM's screens have been rigorously tested and proven to meet these demanding requirements.One of the key advantages of SWM's steel frame screens is their versatility. They can be used in a wide range of applications, from primary shale shakers to mud cleaners and desanders. This flexibility makes them a valuable asset for companies looking to streamline their operations and reduce downtime. The ability to use the same high-quality screens across multiple processes helps companies save time and money while maintaining a high level of efficiency.In addition to their durability and versatility, SWM's steel frame screens are also known for their exceptional performance. They are designed to provide effective solid-liquid separation, ensuring that drilling operations can run smoothly and efficiently. This is crucial for maximizing productivity and minimizing waste in the extraction process. SWM's screens have a proven track record of delivering these critical benefits, further solidifying their status as a top choice for oil and gas companies.SWM's commitment to excellence extends beyond its products to its customer service. The company has a team of dedicated professionals who are ready to provide support and assistance to clients, ensuring that they get the most out of their screens. Whether it's troubleshooting, maintenance, or general advice, SWM's experts are there to help every step of the way. This level of support is yet another reason why SWM has earned a reputation as a trusted and reliable partner in the industry.Looking to the future, SWM remains dedicated to pushing the boundaries of what is possible in the oil and gas sector. The company's ongoing investment in research and development will continue to drive innovation and lead to the introduction of new and improved products. SWM is committed to staying at the forefront of the industry, providing its clients with the tools they need to succeed in an ever-changing and demanding market.In conclusion, SWM's steel frame screens have firmly established themselves as a top choice for oil and gas companies seeking reliable, durable, and high-performance equipment. With a focus on innovation, quality, and customer service, SWM has proven itself to be a valuable partner in the industry. As the company continues to invest in its products and support services, it is well-positioned to remain a leader in the sector for years to come.

Ultimate Guide to Solids Control Shale Shakers: Top Tips for Effective Mud Separation

Solids Control Shale Shaker is a vital component in the oil and gas drilling process, designed to remove large solids and debris from drilling fluids. The efficient operation of a shale shaker is crucial for maintaining the overall integrity of the drilling operation and preventing damage to downstream equipment.One of the leading providers of solids control equipment, {Company}, has recently announced the launch of their latest Shale Shaker. With a strong focus on innovation and quality, {Company} has been at the forefront of providing cutting-edge solutions for the oil and gas industry for over a decade.The new Solids Control Shale Shaker from {Company} is designed to offer enhanced performance and reliability, addressing the evolving needs of the industry. Featuring a robust and durable construction, the shale shaker is able to withstand the harsh operating conditions of drilling operations, ensuring uninterrupted performance.Equipped with advanced technology, the Solids Control Shale Shaker is capable of efficiently separating solids from drilling fluids, leading to improved overall drilling efficiency and cost savings. The shaker’s high capacity and precision screening capabilities make it a valuable asset for any drilling operation, allowing for the effective removal of unwanted solids while retaining the essential components of the drilling fluid.The innovative design of the Solids Control Shale Shaker also incorporates features aimed at reducing maintenance requirements and downtime, contributing to increased operational productivity and cost-effectiveness. With a focus on ease of use and maintenance, {Company} has ensured that their shale shaker can be seamlessly integrated into existing drilling operations without disrupting workflow.In addition to the high-performance capabilities of the Solids Control Shale Shaker, {Company} also prioritizes environmental sustainability in its design and operation. The shale shaker is equipped with efficient solid control mechanisms that minimize the environmental impact of drilling operations, aligning with industry regulations and standards.{Company} prides itself on its comprehensive support and service offerings, ensuring that their clients receive the necessary assistance and expertise to optimize the performance of their solids control equipment. From installation and commissioning to ongoing maintenance and support, {Company} is dedicated to providing a seamless experience for their customers.With a proven track record of delivering superior solids control solutions, {Company} has established itself as a trusted partner for the oil and gas industry, working with leading companies across the globe to enhance the efficiency and reliability of drilling operations.The launch of the new Solids Control Shale Shaker further solidifies {Company}’s commitment to innovation and excellence in providing cutting-edge solutions for the oil and gas sector. By offering a high-performance shale shaker that meets the evolving needs of the industry, {Company} continues to demonstrate its dedication to driving progress and efficiency in drilling operations.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, {Company} remains at the forefront of delivering innovative and reliable equipment that sets the standard for quality and performance. The new Solids Control Shale Shaker serves as a testament to {Company}’s unwavering commitment to excellence and its ability to meet the evolving needs of the industry.