Steel Frame Shaker Screen for Elgin KPT-28 - Latest News

By:Admin

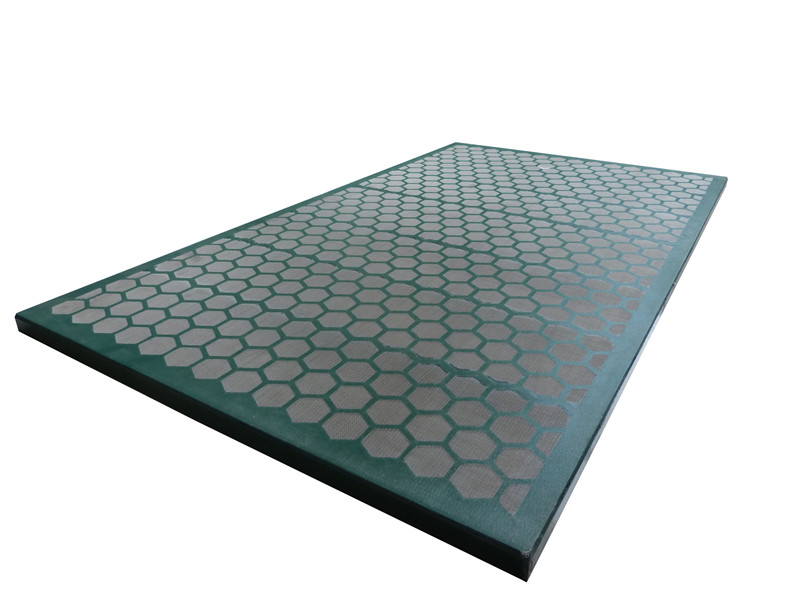

The KPT-28 Steel Frame Shaker Screen is a result of Elgin’s commitment to continuous innovation and improvement. With a focus on delivering high-quality and reliable products, Elgin has leveraged its extensive expertise and industry experience to develop a shaker screen that sets new standards in efficiency and longevity. The KPT-28 Steel Frame Shaker Screen is built to withstand the harsh conditions of the oil and gas drilling industry, offering exceptional resistance to abrasion, corrosion, and impact.

One of the key features of the KPT-28 Steel Frame Shaker Screen is its advanced construction, which utilizes high-quality steel materials and state-of-the-art manufacturing techniques. This ensures that the shaker screen delivers consistent performance and longevity, even in the most demanding applications. The screen’s robust design also allows for increased throughput and separation efficiency, ultimately leading to improved productivity and cost savings for customers.

In addition to its exceptional durability, the KPT-28 Steel Frame Shaker Screen is also designed to provide easy installation and maintenance. This user-friendly aspect of the product is further enhanced by Elgin’s commitment to customer support and service. Elgin’s team of technical experts is available to provide assistance and guidance to customers, ensuring that they maximize the performance and lifespan of their shaker screens.

Furthermore, the KPT-28 Steel Frame Shaker Screen is compatible with a wide range of shaker models, making it a versatile solution for various equipment setups. This flexibility is an important advantage for customers, as it allows them to seamlessly integrate the shaker screen into their existing operations without requiring significant modifications or additional investments.

Elgin’s dedication to delivering high-quality products and top-notch customer service has made them a trusted partner for companies across the energy, mining, and environmental sectors. With a strong focus on innovation and performance, Elgin continues to lead the way in providing cutting-edge solutions that address the evolving needs of the industry.

As part of their commitment to sustainability and environmental responsibility, Elgin also places a strong emphasis on product reliability and longevity. The KPT-28 Steel Frame Shaker Screen is a testament to this commitment, as it is designed to minimize downtime and reduce the need for frequent replacements, ultimately leading to lower overall environmental impact and operational costs.

In conclusion, the launch of the KPT-28 Steel Frame Shaker Screen reaffirms Elgin’s position as a leader in the field of solids control equipment. With its exceptional durability, performance, and versatility, the shaker screen is set to become an essential component for companies looking to optimize their operations and achieve greater efficiency. By continuing to prioritize innovation and customer satisfaction, Elgin is poised to shape the future of the industry and drive positive change for its customers and the environment.

Company News & Blog

Shale Shaker Screen: Latest News and Updates

Brandt Shale Shaker Screen, one of the leading products in the oil drilling industry, has continue to make waves with its innovative technology and exceptional performance. With its advanced design and superior materials, the Brandt Shale Shaker Screen has become a game changer in the oil and gas sector, providing a reliable and efficient solution for solids control.The Brandt Shale Shaker Screen is engineered to effectively separate solids from drilling mud, ensuring the smooth operation of the drilling process. Its high-quality stainless steel wire mesh and durable frame construction make it capable of withstanding the demanding conditions of drilling operations while delivering consistent performance.In addition to its exceptional durability and reliability, the Brandt Shale Shaker Screen also offers a wide range of configurations to suit various drilling applications. It is available in different mesh sizes to accommodate different particle sizes and provide effective solids control. This flexibility in design makes it a versatile and adaptable solution for different drilling environments.Furthermore, the Brandt Shale Shaker Screen is designed to be compatible with a range of shale shakers, making it a convenient and easily integrable option for drilling contractors. Its quick and simple installation process allows for minimal downtime, ensuring that drilling operations can resume swiftly and efficiently.The company behind the Brandt Shale Shaker Screen has a long-standing reputation for delivering high-quality products and exceptional customer service. With a focus on continuous innovation and improvement, the company is committed to providing advanced solutions that meet the evolving needs of the oil and gas industry.The company’s dedication to research and development has resulted in the creation of the Brandt Shale Shaker Screen, which has set a new standard for solids control in the drilling industry. Its advanced technology and superior performance have made it a preferred choice for drilling contractors and operators around the world.Moreover, the company’s commitment to sustainability is reflected in the production of the Brandt Shale Shaker Screen. With a focus on environmental responsibility, the company ensures that its products are manufactured using eco-friendly processes and materials, minimizing their impact on the environment.The Brandt Shale Shaker Screen has earned the trust and confidence of customers globally, thanks to its exceptional performance, reliability, and versatility. Its ability to enhance solids control and improve drilling efficiency has made it an indispensable component of drilling operations, contributing to increased productivity and reduced operational costs.As the demand for efficient and reliable solids control solutions continues to grow in the oil and gas industry, the Brandt Shale Shaker Screen is well-positioned to meet the needs of drilling contractors and operators. With its proven track record and commitment to innovation, it is set to remain a leading choice for solids control in the years to come.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Durable PT Shale Shaker Screen for High Performance

High-Quality Shale Shaker Screen: A Game Changer in the Oil and Gas IndustryThe oil and gas industry is constantly evolving, with new technologies and equipment being developed to improve efficiency and productivity. One such innovation is the high-quality shale shaker screen, which has the potential to revolutionize the way drilling operations are conducted.The shale shaker screen is an essential component of the shale shaker, a vital piece of equipment used in the drilling process. Its primary function is to remove large solids and cuttings from the drilling fluid, also known as mud, before it is circulated back into the well. This process is crucial in maintaining the integrity of the well and ensuring smooth drilling operations.One company that has been at the forefront of developing high-quality shale shaker screens is {Company Name}. With years of experience and a dedication to innovation, they have revolutionized the industry with their state-of-the-art {Product Name} shale shaker screen.The {Product Name} shale shaker screen is designed to deliver unparalleled performance and durability, making it a game-changer in the oil and gas industry. One of its key features is its enhanced filtration capabilities, which allow for the efficient removal of solids and cuttings from the drilling fluid. This not only improves the overall performance of the shale shaker but also extends the lifespan of the drilling equipment.In addition to its superior filtration capabilities, the {Product Name} shale shaker screen is also built to withstand the harsh and demanding conditions of drilling operations. Constructed from high-quality materials, it is highly resistant to wear and tear, ensuring its longevity and reliability in the field. This level of durability is a testament to {Company Name}'s commitment to producing top-notch equipment for the oil and gas industry.Furthermore, the {Product Name} shale shaker screen is designed for easy installation and maintenance, reducing downtime and increasing operational efficiency. Its user-friendly design and robust construction make it a valuable investment for any drilling operation, delivering long-term cost savings and performance benefits.With the introduction of the {Product Name} shale shaker screen, {Company Name} has further solidified its reputation as a leading provider of high-quality equipment for the oil and gas industry. Their dedication to research and development, coupled with their expertise in the field, has resulted in a product that is set to transform drilling operations around the world.The {Product Name} shale shaker screen has already garnered praise from industry experts and clients alike, who have commended its exceptional performance and reliability. Its impact on the industry is undeniable, with many drilling operations experiencing improved efficiency and productivity after implementing this groundbreaking technology.As the demand for energy continues to grow, the oil and gas industry will rely on advanced equipment such as the {Product Name} shale shaker screen to meet this increasing need. Its ability to improve drilling operations, reduce costs, and enhance safety makes it an indispensable tool for the industry's future success.In conclusion, the high-quality {Product Name} shale shaker screen represents a significant advancement in the oil and gas industry. Its unparalleled performance, durability, and ease of use make it a game-changer for drilling operations worldwide. With {Company Name} leading the charge in innovation, the industry can expect to see continued advancements that will shape its future and drive progress in the years to come.

High-Quality FLC503 PWP Shaker Screen for Effective Filtering

Derrick Corporation is proud to announce the launch of its latest innovation – the FLC503 PWP Shaker Screen. This new product is poised to set a new standard in the industry with its unparalleled performance and durability.The FLC503 PWP Shaker Screen is designed to deliver exceptional solids control and liquid separation during the drilling process. It is engineered to withstand the harsh conditions of the oil and gas industry, ensuring reliable and efficient operation even in the most demanding applications.The key to the FLC503 PWP Shaker Screen's exceptional performance lies in its advanced design and high-quality materials. The screen features a patented composite frame that provides superior support and stability, ensuring that it can withstand the rigors of the drilling process. Additionally, the screen is constructed using high-quality stainless steel wire mesh that is resistant to corrosion and abrasion, making it a highly durable and long-lasting solution.In addition to its exceptional durability, the FLC503 PWP Shaker Screen also offers outstanding solids control and liquid separation capabilities. Its precise mesh openings and large open area ensure efficient filtration of drilling fluids, effectively removing solids and impurities to maintain the integrity of the drilling process. This results in improved performance, reduced downtime, and lower operating costs for our customers.The FLC503 PWP Shaker Screen is compatible with Derrick's FLC 500 series shale shakers, making it an easy and seamless upgrade for existing equipment. This compatibility ensures that customers can effortlessly integrate the FLC503 PWP Shaker Screen into their operations, unlocking its benefits without the need for significant investment in new infrastructure.At Derrick Corporation, we are committed to delivering exceptional solutions that meet the evolving needs of the industry. The introduction of the FLC503 PWP Shaker Screen is a testament to our dedication to innovation and excellence, as we continue to push the boundaries of what is possible in solids control and liquid separation technology.Our extensive experience and expertise in the field of solids control and liquid separation have allowed us to develop a comprehensive range of solutions that are trusted by industry professionals around the world. With the launch of the FLC503 PWP Shaker Screen, we are proud to further expand our offering and provide our customers with a cutting-edge solution that delivers unmatched performance and reliability.In conclusion, the FLC503 PWP Shaker Screen represents a new chapter in the evolution of solids control and liquid separation technology. Its advanced design, exceptional durability, and outstanding performance make it a game-changer for the industry, setting a new standard for efficiency and reliability. Derrick Corporation is excited to bring this innovative solution to the market, and we look forward to supporting our customers as they harness the benefits of the FLC503 PWP Shaker Screen in their operations.

How to Clean a Lint Trap: A Step-By-Step Guide for Your Dryer

Title: Innovative Dryer Screen Revolutionizes Laundry ExperienceIntroduction (100 words):The laundry industry is witnessing a groundbreaking innovation with the introduction of an advanced dryer screen that promises to enhance the efficiency and convenience of laundry operations. Developed by a prominent company, this ingenious device is poised to transform the way we approach laundry, offering benefits such as increased drying speed, reduced energy consumption, and improved fabric care. With features specifically designed to meet the evolving demands of modern households, this dryer screen aims to streamline the drying process for consumers. Let's delve deeper into the functionality and advantages of this pioneering appliance.[Image: An eye-catching image showcasing the advanced dryer screen in action]Part 1: Advanced Dryer Screen - A Game-Changer in Laundry (300 words)In today's fast-paced world, time-saving solutions are always appreciated. The advanced dryer screen, developed by the renowned company, has arrived as the ultimate game-changer in the laundry arena. Traditional drying methods can be tedious, time-consuming, and energy-draining. However, this new appliance aims to revolutionize these challenges by offering unmatched performance and efficiency.One of the key features of this dryer screen is its cutting-edge technology that dramatically reduces the drying time. Through a combination of increased air circulation and optimized heat distribution, this gadget ensures clothes are dried faster than ever before. This means users can enjoy significant time savings and have their freshly laundered garments ready to wear in no time.Moreover, this revolutionary dryer screen is designed to be eco-friendly. By utilizing intelligent sensors and advanced programming, it optimizes the energy consumption during the drying cycle. This not only helps in reducing utility bills but also contributes to a greener planet by minimizing energy waste. The device's sensor technology automatically adjusts the drying time and temperature based on the moisture levels, ensuring garments are dried efficiently without overdrying or damaging delicate fabrics.Part 2: Unparalleled Convenience and Customization (300 words)In addition to its incredible drying capabilities, this dryer screen offers a range of convenient features that make laundry chores a breeze. The device is equipped with a user-friendly interface, allowing users to easily select different drying options based on their fabric types, desired dryness levels, and sensory preferences. Whether it's a delicate load or a bulky load, this appliance offers various customizable settings to ensure optimum drying results.Furthermore, the advanced dryer screen incorporates smart connectivity features. Through a dedicated mobile app, users can remotely monitor and control the drying process. This means they can start, pause, or adjust the drying cycle from the comfort of their couch or while on the go. The app also provides timely notifications, alerting users when the drying cycle is complete, eliminating the need for constant monitoring.Additionally, this state-of-the-art appliance includes a range of safety features, ensuring peace of mind for users. These safety mechanisms include automatic shut-off in the event of overheating, a lint trap indicator to prevent clogging, and built-in sensors to detect irregularities or malfunctions.Part 3: Future Prospects and Conclusion (200 words)The introduction of this innovative dryer screen marks a significant milestone in the laundry industry. With its extensive features, advanced technology, and commitment to sustainability, it is expected to redefine the realm of laundry appliances. The company's dedication to research and development, along with a focus on customer needs, has resulted in a product that promises to make laundry routines more efficient, while also prioritizing fabric care and energy conservation.As this pioneering appliance garners attention and accolades, consumers can anticipate a more seamless and enjoyable laundry experience. The future prospects of this innovative dryer screen seem promising, and it is likely that similar developments will emerge to further revolutionize the laundry market. With the introduction of this advanced device, the days of tedious laundry routines may soon become a thing of the past.[Note: Replace {} with the name of the company responsible for the advancement in dryer screen technology.]

Composite Shaker Screen: A Overview of the Swaco D380

Swaco D380 Composite Shaker Screen is a revolutionary product that has been making waves in the oil and gas industry. The shaker screen is manufactured by a renowned company that has been providing high-quality products and services to the industry for more than two decades.The Swaco D380 Composite Shaker Screen is designed to provide superior performance and durability in demanding drilling operations. It is made from high-quality, durable composite material that can withstand the harsh conditions of the oil and gas industry. The screen is designed to effectively separate solids from drilling fluid, leading to improved drilling efficiency and lower overall drilling costs.The company that manufactures the Swaco D380 Composite Shaker Screen is dedicated to innovation and continuous improvement. They have a team of highly skilled engineers and technicians who are constantly working to develop new and improved products that meet the ever-changing needs of the industry. The company's commitment to quality and customer satisfaction has earned them a solid reputation as a leading provider of shaker screens and other drilling equipment.In addition to manufacturing high-quality products, the company also offers exceptional customer service and support. Their team of experienced professionals is always available to provide technical support and assistance to customers, ensuring that they get the most out of their products. They also offer comprehensive training programs to help customers maximize the performance and longevity of their equipment.The Swaco D380 Composite Shaker Screen has been well-received by customers in the oil and gas industry. Many drilling operations have reported significant improvements in drilling efficiency and cost savings after switching to the new shaker screen. The screen's superior performance and durability have made it a popular choice for drilling operations of all sizes.The company behind the Swaco D380 Composite Shaker Screen is also committed to sustainability and environmental responsibility. They use cutting-edge technology and processes to minimize the environmental impact of their operations, and they are constantly looking for ways to improve their sustainability practices.The Swaco D380 Composite Shaker Screen is just one example of the company's dedication to innovation, quality, and customer satisfaction. With a strong focus on continuous improvement and a commitment to sustainability, they are well-positioned to continue leading the industry for many years to come.In conclusion, the Swaco D380 Composite Shaker Screen is a game-changing product that is revolutionizing the oil and gas industry. Its superior performance, durability, and environmental responsibility make it a top choice for drilling operations around the world. With a strong commitment to innovation and customer satisfaction, the company behind the screen is poised to remain a leader in the industry for years to come.

Ultimate Guide to Solids Control Shale Shakers: Top Tips for Effective Mud Separation

Solids Control Shale Shaker is a vital component in the oil and gas drilling process, designed to remove large solids and debris from drilling fluids. The efficient operation of a shale shaker is crucial for maintaining the overall integrity of the drilling operation and preventing damage to downstream equipment.One of the leading providers of solids control equipment, {Company}, has recently announced the launch of their latest Shale Shaker. With a strong focus on innovation and quality, {Company} has been at the forefront of providing cutting-edge solutions for the oil and gas industry for over a decade.The new Solids Control Shale Shaker from {Company} is designed to offer enhanced performance and reliability, addressing the evolving needs of the industry. Featuring a robust and durable construction, the shale shaker is able to withstand the harsh operating conditions of drilling operations, ensuring uninterrupted performance.Equipped with advanced technology, the Solids Control Shale Shaker is capable of efficiently separating solids from drilling fluids, leading to improved overall drilling efficiency and cost savings. The shaker’s high capacity and precision screening capabilities make it a valuable asset for any drilling operation, allowing for the effective removal of unwanted solids while retaining the essential components of the drilling fluid.The innovative design of the Solids Control Shale Shaker also incorporates features aimed at reducing maintenance requirements and downtime, contributing to increased operational productivity and cost-effectiveness. With a focus on ease of use and maintenance, {Company} has ensured that their shale shaker can be seamlessly integrated into existing drilling operations without disrupting workflow.In addition to the high-performance capabilities of the Solids Control Shale Shaker, {Company} also prioritizes environmental sustainability in its design and operation. The shale shaker is equipped with efficient solid control mechanisms that minimize the environmental impact of drilling operations, aligning with industry regulations and standards.{Company} prides itself on its comprehensive support and service offerings, ensuring that their clients receive the necessary assistance and expertise to optimize the performance of their solids control equipment. From installation and commissioning to ongoing maintenance and support, {Company} is dedicated to providing a seamless experience for their customers.With a proven track record of delivering superior solids control solutions, {Company} has established itself as a trusted partner for the oil and gas industry, working with leading companies across the globe to enhance the efficiency and reliability of drilling operations.The launch of the new Solids Control Shale Shaker further solidifies {Company}’s commitment to innovation and excellence in providing cutting-edge solutions for the oil and gas sector. By offering a high-performance shale shaker that meets the evolving needs of the industry, {Company} continues to demonstrate its dedication to driving progress and efficiency in drilling operations.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, {Company} remains at the forefront of delivering innovative and reliable equipment that sets the standard for quality and performance. The new Solids Control Shale Shaker serves as a testament to {Company}’s unwavering commitment to excellence and its ability to meet the evolving needs of the industry.

High-quality Shaker Screen for Kemtron 48 - A Comprehensive Review

Kemtron 48 Shaker Screen: The Ultimate Solution for Solid Control in the Oil and Gas IndustryIn the fast-paced world of oil and gas exploration, every second counts. From drilling to extraction, each step of the process requires precision and efficiency. A key aspect of this process is the management of solid control, which is essential for ensuring the smooth functioning of drilling operations. This is where the Kemtron 48 Shaker Screen comes in. The Kemtron 48 Shaker Screen is a revolutionary product that has been designed to effectively manage solid control in the oil and gas industry. It is a vital component of the Kemtron 48 Shale Shaker, which is known for its high-performance and reliability. The shaker screen is made of high-quality stainless steel wire mesh and is designed to effectively separate solid particles from drilling fluid. This not only ensures the smooth functioning of drilling operations but also protects downstream equipment and reduces waste disposal costs.One of the key features of the Kemtron 48 Shaker Screen is its superior durability. Made of high-quality materials, it is designed to withstand the harsh conditions of the oil and gas industry. It is also easy to install and maintain, making it a cost-effective solution for solid control. In addition, the screen has a large screening area, which allows for high capacity and efficiency. This means that operators can achieve optimal performance and productivity with the Kemtron 48 Shaker Screen.The Kemtron 48 Shaker Screen is also designed with versatility in mind. It can be used with a wide range of drilling fluids and is compatible with various types of shakers. This means that it can be seamlessly integrated into existing operations, minimizing downtime and disruption. This is crucial in the oil and gas industry, where every minute of downtime can result in significant financial losses.In addition to its technical capabilities, the Kemtron 48 Shaker Screen is also backed by exceptional customer support. The company behind the product is known for its commitment to customer satisfaction and has a team of experts who are dedicated to providing support and assistance to clients. This means that operators can rely on the company not only for top-of-the-line products but also for reliable service and support.The Kemtron 48 Shaker Screen has already made a significant impact in the oil and gas industry. Its innovative design and superior performance have helped operators around the world achieve greater efficiency and productivity in their drilling operations. From onshore to offshore projects, the Kemtron 48 Shaker Screen has proven to be an indispensable tool for solid control.Looking to the future, the company is committed to further enhancing the capabilities of the Kemtron 48 Shaker Screen. With ongoing research and development, the company aims to continually improve the product and adapt to the evolving needs of the industry. This includes exploring new materials, technologies, and designs to ensure that the Kemtron 48 Shaker Screen remains at the forefront of solid control solutions.In conclusion, the Kemtron 48 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, superior durability, and exceptional performance make it the ultimate solution for solid control. Backed by a commitment to customer satisfaction and continuous innovation, the company behind the product has established itself as a leader in the industry. As the demand for efficient solid control solutions continues to grow, the Kemtron 48 Shaker Screen is poised to play a crucial role in shaping the future of the oil and gas industry.

Highly Efficient Vibratory Shaker Screen for Separating Materials

In a world where efficiency and productivity are key, businesses are constantly on the lookout for advanced technologies that can enhance their operations. One such technology, the vibratory shaker screen, has been gaining attention for its ability to improve the screening and sorting processes in various industries.A vibratory shaker screen is a piece of equipment that uses vibration to separate materials based on their particle size. It is commonly used in industries such as mining, construction, agriculture, and recycling, where the need to separate and classify materials is paramount. The vibratory shaker screen works by applying an intense vibration to the screen deck, causing the particles to move and separate based on size, ensuring efficient and accurate screening.One of the leading providers of vibratory shaker screens is {}. With over two decades of experience in the industry, {} has established itself as a pioneer in the field of screening and separation technology. The company’s vibratory shaker screens are designed to deliver high-performance screening solutions, offering reliability, durability, and versatility to meet the diverse needs of its customers.The vibratory shaker screens offered by {} are known for their innovative design and advanced features. The company’s screens are equipped with high-quality vibratory motors that provide the necessary vibration force for efficient material separation. Additionally, the screens are designed to be easily adjustable, allowing for precise control over the screening process. This level of flexibility ensures that the screens can be tailored to the specific requirements of each application, resulting in optimal performance and productivity.In addition to the premium quality of its products, {} prides itself on providing exceptional customer service and support. The company works closely with its clients to understand their unique screening needs and offers customized solutions to address them. Furthermore, {}’s team of experienced engineers and technicians are readily available to provide technical assistance, maintenance, and repairs, ensuring that the vibratory shaker screens continue to operate at peak performance.The vibratory shaker screens from {} have been widely adopted across various industries, earning a reputation for their efficiency, reliability, and durability. These screens have been instrumental in improving the screening and sorting processes for a wide range of materials, including aggregates, minerals, chemicals, and even food products. The ability of {}’s vibratory shaker screens to handle diverse materials with precision and speed has made them a valuable asset for businesses aiming to optimize their operations.As industries continue to evolve and demand more advanced screening technologies, the vibratory shaker screens from {} are set to play a pivotal role in meeting these requirements. The company’s commitment to innovation and excellence ensures that its products will continue to be at the forefront of the industry, offering cutting-edge solutions for material separation and classification.In conclusion, the vibratory shaker screen has emerged as a game-changer in the field of material screening and separation. With {}’s extensive experience and expertise, its vibratory shaker screens are poised to revolutionize the way industries handle their screening needs, offering enhanced efficiency, productivity, and reliability. As businesses strive to stay ahead in a competitive market, the vibratory shaker screens from {} are undoubtedly a valuable investment for achieving optimal screening performance.

Highly Efficient Primary Screen for Industrial Applications Now Available

Vibrating screens are a crucial part of many industrial processes, particularly in the mining and aggregate industries. These screens are used to separate and sort materials based on size, making them essential in the production of various materials such as gravel, sand, and minerals. One company at the forefront of producing high-quality vibrating screens is {Company Name}, which has recently introduced their latest innovation, the VSM100 Primary Screen.The VSM100 Primary Screen is designed to meet the demanding requirements of the mining and aggregate industries. It is built with a focus on durability, efficiency, and ease of maintenance, making it a reliable and cost-effective solution for processing operations. This new addition to {Company Name}'s product line is set to provide customers with a highly efficient screening solution that can handle the toughest of materials.One of the key features of the VSM100 Primary Screen is its robust construction. It is built to withstand the harsh working conditions typically found in mining and aggregate operations. The screen is made from high-quality materials and is engineered to last, reducing downtime and maintenance costs for the end user.In addition to its durability, the VSM100 Primary Screen is designed for high efficiency. Its innovative design allows for a larger screening area, resulting in higher throughput and improved product quality. This means that customers can expect increased productivity and reduced operational costs when using this new vibrating screen.Another standout feature of the VSM100 Primary Screen is its ease of maintenance. The design of the screen allows for quick and simple access to critical components, making routine maintenance tasks much more straightforward. This not only minimizes downtime but also ensures that the screen operates at peak performance for longer periods between maintenance intervals.{Company Name} has a long-standing reputation for producing high-quality vibrating screens, and the VSM100 Primary Screen is no exception. The company has invested heavily in research and development to ensure that their products are at the cutting edge of technology and performance. The introduction of the VSM100 Primary Screen further solidifies {Company Name}'s position as a leader in the industry and demonstrates their commitment to providing innovative solutions to their customers.Customers can also benefit from {Company Name}'s extensive support network, which ensures that the VSM100 Primary Screen is backed by a team of experts who can provide technical assistance, spare parts, and service support as needed. This comprehensive support offering gives customers peace of mind and helps to maximize the uptime of their equipment.The introduction of the VSM100 Primary Screen is a significant milestone for {Company Name} and further establishes their position as a leading supplier of vibrating screens for the mining and aggregate industries. With its focus on durability, efficiency, and ease of maintenance, this new addition to their product line is set to make a positive impact on processing operations around the world.In conclusion, the VSM100 Primary Screen from {Company Name} is a testament to the company's dedication to developing high-quality solutions for the mining and aggregate industries. With its robust construction, high efficiency, and ease of maintenance, this new vibrating screen is poised to set a new standard for screening equipment. Customers can expect improved productivity, reduced operating costs, and reliable performance from the VSM100 Primary Screen, making it a valuable addition to any processing operation.