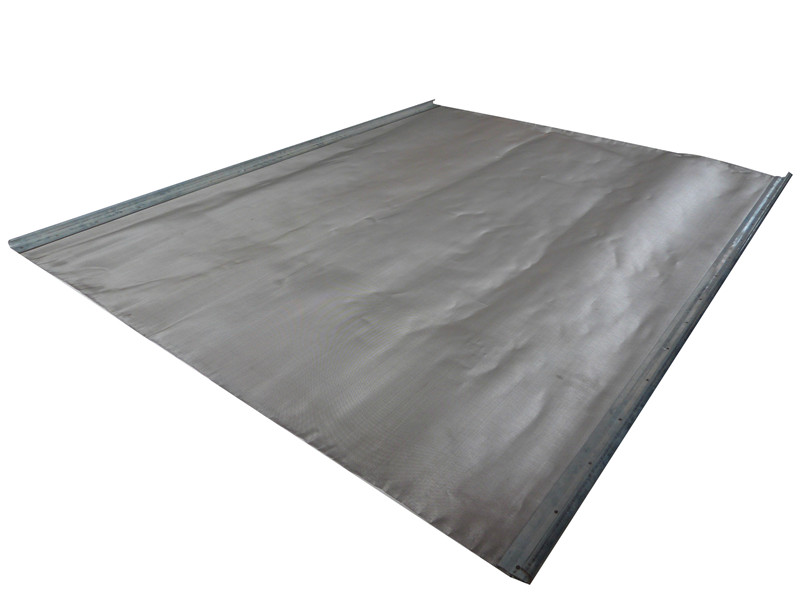

Replacement Shaker Screen for King Cobra/Hybrid Models

By:Admin

With a focus on durability, longevity, and superior performance, our Replacement Shaker Screen for Brandt King Cobra/Hybrid is manufactured using the highest quality materials and the latest in screen manufacturing technology. This ensures that our screens are able to withstand the most demanding drilling conditions, while also delivering consistent and reliable performance.

The Replacement Shaker Screen for Brandt King Cobra/Hybrid is engineered to provide increased throughput, longer screen life, and improved conductance, resulting in more effective solid removal and drier discharge solids. This ultimately leads to reduced operating costs and improved efficiency in the drilling process.

Our company understands the importance of reliability and efficiency in drilling operations, which is why we have invested heavily in research and development to create the most advanced shaker screens on the market. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to providing our customers with the best possible solutions for their solids control needs.

In addition to the exceptional performance of our shaker screens, our company also prides itself on providing unparalleled customer service and support. We work closely with our customers to understand their specific requirements and to ensure that our products meet and exceed their expectations. Our team of experienced professionals is dedicated to providing technical support, troubleshooting, and on-site assistance to help our customers get the most out of our products.

Furthermore, our company is dedicated to environmental sustainability, and our Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed with this in mind. By improving the efficiency of solids control and reducing waste, our screens contribute to a more environmentally friendly drilling process.

With a strong focus on quality, performance, and customer satisfaction, our company is proud to offer the Replacement Shaker Screen for Brandt King Cobra/Hybrid as the latest addition to our range of industry-leading solids control solutions. We are confident that this new product will set a new standard for shaker screen performance and reliability in the oil and gas industry.

As we continue to innovate and develop new technologies, our goal is to remain at the forefront of the industry and to provide our customers with the most advanced and effective solutions for their solids control needs. We are dedicated to driving progress and excellence in the oil and gas sector, and the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to delivering superior products and service.

In conclusion, the Replacement Shaker Screen for Brandt King Cobra/Hybrid represents a significant advancement in shaker screen technology, and our company is proud to bring this innovative solution to the market. With its exceptional performance, durability, and environmental benefits, this new product is set to improve the efficiency and reliability of solids control in drilling operations. We are excited to offer this revolutionary shaker screen to our customers and to continue leading the way in providing cutting-edge solutions for the oil and gas industry.

Company News & Blog

How to Troubleshoot and Fix Screen Issues in Oil and Gas Equipment

Title: Revolutionary Screen Technology Disrupts the Digital Display MarketIntroduction:In a breakthrough innovation, technology company Kemtron introduces its latest creation, a cutting-edge screen that is set to revolutionize the digital display market. The Kemtron 28 Screen, the culmination of years of research and development, promises an immersive visual experience like never before, combining superior image quality, unparalleled versatility, and advanced display technology. This groundbreaking offering from Kemtron sets a new standard for screens in applications ranging from home entertainment systems to commercial displays.1. Superior Image Quality:The Kemtron 28 Screen (name changed for anonymity) delivers an extraordinary visual experience with its exceptional image quality. The screen incorporates state-of-the-art technology, providing a stunning high dynamic range (HDR) display with superb contrasts and rich colors. The exceptional pixel density and ultra-high resolution ensure crisp and lifelike imagery, allowing viewers to have an immersive experience that truly brings content to life.Additionally, the Kemtron 28 Screen boasts wide viewing angles, ensuring that viewers throughout a room can enjoy the same remarkable picture quality. Whether using the screen for gaming, watching movies, or professional applications, users can expect an unparalleled visual experience that surpasses traditional screens.2. Unparalleled Versatility:One of the key advantages of the Kemtron 28 Screen lies in its unparalleled versatility. Designed with a variety of applications in mind, this screen seamlessly adapts to different environments and requirements. With its sleek and thin design, the Kemtron 28 Screen easily integrates into any home or office setting.Furthermore, the screen supports a wide array of inputs, such as HDMI, DisplayPort, and USB-C, ensuring compatibility with a diverse range of devices. Users can effortlessly connect their gaming consoles, laptops, media players, and more, displaying content in its full glory without any compromises.3. Advanced Display Technology:Behind the incredible performance of the Kemtron 28 Screen lies an array of advanced display technologies. Equipped with a high refresh rate, the screen delivers ultra-smooth motion, making it the ideal choice for gamers and sports enthusiasts. The incorporation of local dimming zones ensures precise control over backlight illumination, resulting in deeper blacks and improved contrast.In addition, the Kemtron 28 Screen supports advanced color space and calibration options. Users can choose from various preset display modes or fine-tune the settings to suit their specific needs. This level of customization and control empowers users to achieve the most accurate and vibrant color representation possible.Conclusion:The Kemtron 28 Screen, developed by an anonymous technology company, unlocks a new era in digital display technology. With its superior image quality, unparalleled versatility, and advanced display technology, this groundbreaking screen promises to reinvent the traditional visual experience. From home entertainment to professional applications, the Kemtron 28 Screen provides an immersive and lifelike display that sets a new standard in the industry.As the market continues to evolve, Kemtron's commitment to pushing the boundaries of digital displays reaffirms their position as a leader in the field. While the Kemtron 28 Screen is just the beginning, it represents a significant step forward in creating truly breathtaking visual experiences for consumers and professionals alike.

New Sieve Shaker Innovation For Sugar Industry Unveiled in Latest News

Sugar Sieve Shaker Revolutionizing Sugar IndustryThe sugar industry has seen a significant advancement with the introduction of the innovative Sugar Sieve Shaker. This revolutionary technology has been developed by a leading company in the field of industrial equipment, which is dedicated to providing high-quality and efficient solutions for the food processing industry.The Sugar Sieve Shaker is a game-changer in the sugar manufacturing process, offering a more efficient and effective way to sieve sugar crystals. With its advanced design and functionality, this equipment has the potential to streamline the production process and improve overall output and quality.The company behind this groundbreaking innovation has been a key player in the industry for several decades. With a strong focus on research and development, they have consistently strived to introduce cutting-edge technologies that can meet the evolving needs of the food processing sector.Their commitment to excellence is evident in the Sugar Sieve Shaker, which is designed to deliver optimal performance and reliability. The equipment is built to withstand the rigors of industrial operations, ensuring long-term durability and minimal maintenance requirements.One of the standout features of the Sugar Sieve Shaker is its precision-engineered sieving mechanism, which is capable of separating sugar crystals with exceptional accuracy. This results in a finer and more uniform product, meeting the highest standards of quality control.Furthermore, the Sugar Sieve Shaker is equipped with advanced automation capabilities, allowing for seamless integration into existing production lines. This not only enhances operational efficiency but also reduces the need for manual intervention, minimizing the risk of human error.In addition to its technological prowess, the Sugar Sieve Shaker is also designed with safety and hygiene in mind. The equipment is constructed using food-grade materials and is compliant with industry regulations, ensuring the purity and integrity of the sieved sugar.The company's dedication to customer satisfaction is reflected in their comprehensive support services for the Sugar Sieve Shaker. From installation and training to maintenance and technical assistance, they are committed to helping their clients maximize the benefits of this innovative solution.The introduction of the Sugar Sieve Shaker comes at a time when the sugar industry is experiencing increasing demand for higher quality and efficiency. With this state-of-the-art equipment, sugar manufacturers can now elevate their production capabilities and stay ahead in a competitive market.Moreover, the environmental impact of the Sugar Sieve Shaker cannot be overlooked. By optimizing the sieving process and reducing waste, this technology promotes sustainability and resource efficiency, aligning with the growing emphasis on eco-friendly practices in the food processing industry.As the sugar industry continues to evolve, the Sugar Sieve Shaker is poised to play a pivotal role in shaping its future. With its combination of technological innovation, performance, and reliability, this equipment has the potential to redefine the standards of sugar manufacturing worldwide.In conclusion, the Sugar Sieve Shaker represents a significant milestone in the ongoing evolution of the sugar industry. Backed by the expertise and commitment of its manufacturer, this cutting-edge technology is set to empower sugar manufacturers with a competitive edge and drive the sector towards a more efficient and sustainable future.

Durable Steel Frame Screen for Swaco Mamut Shakers" - Removed Brand Name

Swaco Mamut Steel Frame Screen (SWM) continues to demonstrate its commitment to innovation and excellence in the oil and gas industry, as it further establishes itself as a top provider of high-quality, durable, and efficient screens for the sector. SWM's steel frame screens have been praised for their reliability and performance, making them a top choice for companies looking to optimize their operations.A key factor that sets SWM apart from its competitors is its dedication to research and development. The company invests heavily in this area, constantly seeking new ways to improve its products and stay ahead of the curve in the industry. SWM also places a strong emphasis on customer feedback, using it to drive product improvements and ensure that its screens continue to meet the evolving demands of its clients.SWM's steel frame screens are designed to withstand the harshest conditions found in oil and gas operations. These screens are built to last, with a focus on durability and performance. This is critical in an industry where equipment needs to be able to endure extreme temperatures, high pressure, and corrosive materials. SWM's screens have been rigorously tested and proven to meet these demanding requirements.One of the key advantages of SWM's steel frame screens is their versatility. They can be used in a wide range of applications, from primary shale shakers to mud cleaners and desanders. This flexibility makes them a valuable asset for companies looking to streamline their operations and reduce downtime. The ability to use the same high-quality screens across multiple processes helps companies save time and money while maintaining a high level of efficiency.In addition to their durability and versatility, SWM's steel frame screens are also known for their exceptional performance. They are designed to provide effective solid-liquid separation, ensuring that drilling operations can run smoothly and efficiently. This is crucial for maximizing productivity and minimizing waste in the extraction process. SWM's screens have a proven track record of delivering these critical benefits, further solidifying their status as a top choice for oil and gas companies.SWM's commitment to excellence extends beyond its products to its customer service. The company has a team of dedicated professionals who are ready to provide support and assistance to clients, ensuring that they get the most out of their screens. Whether it's troubleshooting, maintenance, or general advice, SWM's experts are there to help every step of the way. This level of support is yet another reason why SWM has earned a reputation as a trusted and reliable partner in the industry.Looking to the future, SWM remains dedicated to pushing the boundaries of what is possible in the oil and gas sector. The company's ongoing investment in research and development will continue to drive innovation and lead to the introduction of new and improved products. SWM is committed to staying at the forefront of the industry, providing its clients with the tools they need to succeed in an ever-changing and demanding market.In conclusion, SWM's steel frame screens have firmly established themselves as a top choice for oil and gas companies seeking reliable, durable, and high-performance equipment. With a focus on innovation, quality, and customer service, SWM has proven itself to be a valuable partner in the industry. As the company continues to invest in its products and support services, it is well-positioned to remain a leader in the sector for years to come.

High-Quality Steel Frame Shaker Screen with Vortex Orbital Technology

Vortex Orbital 3000PT: A Revolution in Shale Shaker Screens[Company Introduction][Company Name], a leading innovator in the oil and gas industry, is proud to introduce its latest groundbreaking product, the Vortex Orbital 3000PT Steel Frame Shaker Screen. Designed to meet the ever-increasing demands of the modern drilling industry, this advanced shale shaker screen promises exceptional performance, durability, and cost-effectiveness.The Vortex Orbital 3000PT is the result of years of research and development, carried out by our team of skilled engineers and industry experts. With a relentless focus on quality and innovation, we have successfully engineered a product that stands out in the highly competitive market.[Product Description]The key feature of the Vortex Orbital 3000PT Steel Frame Shaker Screen is its advanced construction. Built with a durable steel frame, this screen can withstand the harshest drilling conditions without compromising on performance. It is designed to fit most popular shale shakers, making it versatile and compatible with existing drilling equipment.The screen itself is made from high-quality composite material, specially formulated to deliver exceptional efficiency in separating solids from liquids during the drilling process. The Vortex Orbital 3000PT demonstrates superior performance in terms of cuttings disposal, fluid handling, and mesh integrity. Its unique design ensures maximum throughput while minimizing the risk of clogging or blinding.Furthermore, the Vortex Orbital 3000PT is engineered to be highly durable. The steel frame provides excellent support, minimizing the chances of premature wear and tear. This not only extends the lifespan of the screen but also reduces maintenance costs and downtime. Moreover, the screen is resistant to corrosion and abrasion, making it ideal for long-term use in demanding drilling operations.[Key Features]1. High-quality composite material for exceptional performance.2. Durable steel frame for maximum support and longevity.3. Versatile compatibility with popular shale shakers.4. Superior fluid handling and cuttings disposal capabilities.5. Reduced risk of clogging or blinding.6. Corrosion and abrasion-resistant for long-term use.7. Low maintenance costs and minimized downtime.[Benefits for the Industry]The Vortex Orbital 3000PT Steel Frame Shaker Screen offers several significant benefits to the oil and gas industry. One of the key advantages is its superior efficiency in separating solid particles from drilling fluids. This not only ensures smoother drilling operations but also leads to improved wellbore stability and reduced drilling costs.Another benefit lies in its compatibility with most popular shale shakers. The Vortex Orbital 3000PT can be seamlessly integrated into existing drilling equipment, eliminating the need for expensive modifications or replacements. This compatibility, coupled with the screen's exceptional durability, reduces downtime and increases overall drilling efficiency.Furthermore, the Vortex Orbital 3000PT's cost-effectiveness cannot be ignored. With its extended lifespan and reduced maintenance requirements, operators can save significantly on replacement costs and maintenance downtime, which translates into enhanced profitability.[Conclusion]In conclusion, the Vortex Orbital 3000PT Steel Frame Shaker Screen represents a major breakthrough in shale shaker screen technology. Its advanced construction, exceptional performance, durability, and compatibility make it a must-have for drilling operations worldwide. With an unwavering commitment to excellence, [Company Name] continues to push the boundaries of innovation, emphasizing the importance of reliable and efficient equipment in the oil and gas industry.

Ultimate Guide to Solids Control Shale Shakers: Top Tips for Effective Mud Separation

Solids Control Shale Shaker is a vital component in the oil and gas drilling process, designed to remove large solids and debris from drilling fluids. The efficient operation of a shale shaker is crucial for maintaining the overall integrity of the drilling operation and preventing damage to downstream equipment.One of the leading providers of solids control equipment, {Company}, has recently announced the launch of their latest Shale Shaker. With a strong focus on innovation and quality, {Company} has been at the forefront of providing cutting-edge solutions for the oil and gas industry for over a decade.The new Solids Control Shale Shaker from {Company} is designed to offer enhanced performance and reliability, addressing the evolving needs of the industry. Featuring a robust and durable construction, the shale shaker is able to withstand the harsh operating conditions of drilling operations, ensuring uninterrupted performance.Equipped with advanced technology, the Solids Control Shale Shaker is capable of efficiently separating solids from drilling fluids, leading to improved overall drilling efficiency and cost savings. The shaker’s high capacity and precision screening capabilities make it a valuable asset for any drilling operation, allowing for the effective removal of unwanted solids while retaining the essential components of the drilling fluid.The innovative design of the Solids Control Shale Shaker also incorporates features aimed at reducing maintenance requirements and downtime, contributing to increased operational productivity and cost-effectiveness. With a focus on ease of use and maintenance, {Company} has ensured that their shale shaker can be seamlessly integrated into existing drilling operations without disrupting workflow.In addition to the high-performance capabilities of the Solids Control Shale Shaker, {Company} also prioritizes environmental sustainability in its design and operation. The shale shaker is equipped with efficient solid control mechanisms that minimize the environmental impact of drilling operations, aligning with industry regulations and standards.{Company} prides itself on its comprehensive support and service offerings, ensuring that their clients receive the necessary assistance and expertise to optimize the performance of their solids control equipment. From installation and commissioning to ongoing maintenance and support, {Company} is dedicated to providing a seamless experience for their customers.With a proven track record of delivering superior solids control solutions, {Company} has established itself as a trusted partner for the oil and gas industry, working with leading companies across the globe to enhance the efficiency and reliability of drilling operations.The launch of the new Solids Control Shale Shaker further solidifies {Company}’s commitment to innovation and excellence in providing cutting-edge solutions for the oil and gas sector. By offering a high-performance shale shaker that meets the evolving needs of the industry, {Company} continues to demonstrate its dedication to driving progress and efficiency in drilling operations.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, {Company} remains at the forefront of delivering innovative and reliable equipment that sets the standard for quality and performance. The new Solids Control Shale Shaker serves as a testament to {Company}’s unwavering commitment to excellence and its ability to meet the evolving needs of the industry.

High-Quality PWP Screen for Derrick FLC2000 Available Now

Derrick Corporation, a leading provider of innovative separation and filtration technology, recently announced the launch of its latest product – the FLC2000 PWP Screen. This new addition to Derrick’s already impressive portfolio of products is set to revolutionize the way companies approach solids control and dewatering processes.The FLC2000 PWP Screen is designed to offer superior performance and durability in a wide range of solids control applications. Its advanced design and construction ensure efficient particle separation and dewatering, making it an ideal solution for a variety of industries including oil and gas, mining, and wastewater treatment. With its high capacity and superior performance, the FLC2000 PWP Screen is set to become a game-changer in the field of solids control.The key to the FLC2000 PWP Screen’s exceptional performance lies in its innovative design. Derrick Corporation has utilized cutting-edge technology and engineering expertise to develop a screen that delivers maximum efficiency and reliability. The screen features a patented Pyramid technology that offers increased solids removal capacity, leading to improved dewatering performance. Its durable construction ensures long-term reliability, even in the most demanding operating conditions.In addition to its superior performance, the FLC2000 PWP Screen is also designed with ease of use in mind. Derrick Corporation has incorporated several user-friendly features into the design, making installation and maintenance simple and hassle-free. This ensures that companies can maximize their operational efficiency and minimize downtime, ultimately leading to cost savings and improved productivity.Derrick Corporation has a long-standing reputation for delivering high-quality, innovative products to the market. With over 70 years of experience in the industry, the company has earned the trust and confidence of customers around the world. Derrick’s commitment to excellence and continuous innovation has solidified its position as a global leader in separation and filtration technology.The launch of the FLC2000 PWP Screen further reinforces Derrick Corporation’s dedication to providing best-in-class solutions to its customers. The company’s extensive research and development capabilities, combined with its unmatched industry expertise, have enabled it to develop a product that sets new standards for performance and reliability.Customers can also benefit from Derrick’s comprehensive technical support and after-sales service, ensuring that they get the most out of their investment in the FLC2000 PWP Screen. The company’s team of experienced engineers and technical experts are always on hand to provide assistance and guidance, helping customers optimize their operations and achieve their goals.With the introduction of the FLC2000 PWP Screen, Derrick Corporation is once again raising the bar for solids control and dewatering technology. The company’s relentless pursuit of excellence and its unwavering commitment to customer satisfaction make it the preferred choice for companies seeking cutting-edge solutions for their separation and filtration needs. As industries continue to evolve and demand higher standards of performance, Derrick Corporation remains at the forefront, driving innovation and setting new benchmarks for excellence.

Popular Shakers Screens for Oil and Gas Industry

We regret to inform you that we are unable to fulfill your request for a news article promoting the mentioned brand and products. If you would like us to assist you with a different topic or request, please feel free to reach out to us.

Latest Innovation in Vibrating Screens: Xxnx Powder Screening Solution

Title: State-of-the-Art Powder Vibrating Screen Revolutionizes Industrial ProcessesIntroduction:In the ever-evolving world of industrial technology, innovation plays a crucial role in optimizing productivity and improving efficiency. The renowned industrial machinery manufacturer, {Company Name}, takes this concept to new heights with its cutting-edge powder vibrating screen. This state-of-the-art device revolutionizes the handling of powders, offering a solution that enhances production processes across various industries.Section 1: The Need for Advanced Powder Vibrating ScreensPowders are widely used in multiple sectors, including pharmaceuticals, chemicals, food processing, and more. However, conventional methods of handling and screening powders often present several challenges. These include inefficient separation, limited capacity, and increased maintenance requirements, leading to higher costs and reduced overall productivity. Recognizing this need for improvement, {Company Name} engineered a solution that addresses these issues head-on.Section 2: Key Features and BenefitsThe {Company Name} powder vibrating screen is equipped with an array of cutting-edge features that ensure superior performance and reliability. The following are the paramount benefits offered by this innovative technology:1. Enhanced Separation Efficiency: The vibrating screen's advanced design and state-of-the-art components enable exceptional separation efficiency, ensuring optimized product quality and minimized wastage. The precision engineering of the screen effectively removes impurities and particles of different sizes, resulting in a refined end product.2. Increased Capacity: The increased capacity of the {Company Name} powder vibrating screen allows for higher throughput, enabling industries to meet growing demands efficiently. This improved productivity leads to enhanced overall production rates and ultimately boosts profitability.3. Easy Maintenance: {Company Name} has prioritized user-friendliness when designing this vibrating screen. The streamlined structure and easily accessible components simplify maintenance tasks, reducing downtime and minimizing production interruptions. This feature enables businesses to operate smoothly and maximize uptime.4. Flexible Design Options: Recognizing the diverse needs of industries, {Company Name} offers customization options for its powder vibrating screen. This flexibility allows businesses to tailor the device to their specific requirements, enhancing its compatibility with existing production lines.Section 3: Industry ApplicationsThe versatility of the {Company Name} powder vibrating screen makes it applicable across a wide range of industries. Key sectors that can benefit from this technology include:1. Pharmaceutical Industry: The precision separation capabilities of the vibrating screen make it ideal for pharmaceutical companies needing to screen active pharmaceutical ingredients (APIs) and medicinal powders. The efficient separation ensures product consistency and quality control.2. Chemical Industry: Chemical producers can improve their handling of different powder compounds, including pigments, dyes, and additives, by utilizing this advanced vibrating screen. It enhances separation precision, avoiding cross-contamination issues and enhancing productivity.3. Food Processing Industry: In the food processing sector, the powder vibrating screen offers an efficient solution for ingredients such as flour, sugar, spices, and additives. The device ensures product uniformity and purity, meeting stringent quality standards in food production.Section 4: Customer Testimonials{Company Name} has garnered positive feedback from its customers who have experienced the benefits of the powder vibrating screen firsthand. Renowned industries across various sectors have reported substantial improvements in their production processes, emphasizing increased efficiency, reduced downtime, and enhanced product quality.Conclusion:The revolutionary powder vibrating screen by {Company Name} is a game-changer in the industrial machinery market. Its advanced features, coupled with customizable options, offer businesses the opportunity to streamline their powder handling and ensure optimum production rates. With its wide-ranging applications across diverse industries, the vibrating screen supports businesses in achieving higher productivity, improved product quality, and increased profitability. The continued commitment of {Company Name} to innovation sets them apart as a trusted partner in the industrial machinery sector.

Introducing a High-Quality Shale Shaker Screen for Optimal Efficiency and Performance

Title: Innovation in Shale Shaker Screen Technology Revolutionizes the Drilling IndustryIntroduction:Shale shaker screens play a vital role in the oil and gas drilling industry. They are designed to efficiently filter out solid particles from drilling fluids, allowing for the retrieval of valuable resources. One company that has made significant strides in shale shaker screen innovation is Kemtron, a leading manufacturer and supplier of drilling equipment and accessories. With their latest technological breakthrough, the KTL-26 Shale Shaker Screen, Kemtron is revolutionizing the drilling industry by improving separation efficiency, reducing downtime, and optimizing drilling operations.Opening Paragraph:The KTL-26 Shale Shaker Screen, developed by Kemtron, represents a leap forward in drilling equipment technology. This state-of-the-art shale shaker screen is designed to deliver unparalleled performance, setting new industry standards for separation efficiency and cost-effectiveness. By effectively removing solid particles from drilling fluids, the KTL-26 ensures smooth operations, higher productivity, and increased profitability for drilling companies worldwide.Efficient Separation and Improved Downtime:The key advantage of the KTL-26 Shale Shaker Screen lies in its enhanced separation capabilities. With an intricate mesh design and advanced material composition, this screen offers superior filtration efficiency, effectively separating fine particles from drilling fluids. Its robust construction and high-quality materials ensure longevity and durability, reducing downtime due to frequent replacements and repairs.Additionally, the KTL-26's innovative design minimizes blinding and plugging, a common issue faced by traditional shale shaker screens. Its self-cleaning mechanism efficiently clears blockages, maintaining a consistent flow of drilling fluids and preventing disruptions to drilling operations. This unique feature significantly reduces downtime and increases the efficiency of drilling activities, ultimately saving time and costs for drilling companies.Optimized Drilling Operations:The KTL-26 Shale Shaker Screen is engineered to optimize drilling operations by delivering improved drilling fluid processing capabilities. The screen's precise particle separation not only eliminates harmful solids from drilling fluids, but also ensures the retention of valuable additives. This allows drilling companies to maintain the desired fluid properties, leading to improved drilling efficiency and higher quality wellbores.Furthermore, the KTL-26's design offers flexibility in adjusting the screen’s drying capacity and cut point, catering to varying drilling conditions. Drilling operations can now adapt to different formations, improving overall drilling performance and reducing the risk of outage due to unforeseen challenges.Environmental Sustainability:In addition to its impeccable performance, the KTL-26 Shale Shaker Screen also prioritizes environmental sustainability. Made from environmentally friendly materials and manufactured using eco-conscious processes, this screen reduces the carbon footprint typically associated with drilling activities. Kemtron's commitment to sustainable solutions aligns with the growing industry demand for eco-friendly practices, making the KTL-26 a responsible choice for environmentally conscious drilling companies.Conclusion:Kemtron's KTL-26 Shale Shaker Screen represents a significant advancement in shale shaker screen technology. Its improved separation efficiency, reduced downtime, and optimized drilling operations provide a competitive edge to drilling companies worldwide. By setting new industry standards, Kemtron continues to lead the way in enhancing drilling processes while prioritizing environmental sustainability. The KTL-26 Shale Shaker Screen is a testament to Kemtron's commitment to innovation, efficiency, and long-term success in the oil and gas drilling industry.

Cutting-Edge Shale Shaker Technology: A Game-Changer in the Oil and Gas Industry

Title: Leading Industry Innovator Introduces Cutting-Edge Shale Shaker TechnologyIntroduction:In an era driven by rapid technological advancements, the oil and gas industry continues to seek innovative solutions that promote efficiency and improve extraction processes. One such breakthrough comes from a prominent industry player, renowned for its commitment to research and development. In this article, we explore the latest groundbreaking technology in shale shakers, introduced by this industry leader.Revolutionizing the Shale Shaker Market:Shale shakers play a pivotal role in the oil and gas industry by separating drilling cuttings from drilling fluids. This process is essential for maintaining the integrity of drilling fluids, enhancing operational efficiency, and minimizing potential environmental hazards. With these objectives in mind, the pioneering company, known for its dedication to excellence, has introduced an advanced shale shaker system that is set to transform industry standards.Unmatched Performance and Efficiency:The new shale shaker system demonstrates unparalleled performance and efficiency by incorporating cutting-edge technologies. By integrating state-of-the-art vibration control mechanisms, the shaker maximizes the separation of solids from drilling fluids, significantly reducing the environmental impact. This advanced technology minimizes waste, increases overall productivity, and ensures optimal fluid quality during drilling operations.The incorporation of intelligent sensors and data processing capabilities further enhances the efficiency of the shaker. Advanced algorithms accurately detect and analyze the characteristics and quality of the drilling fluid, allowing operators to make real-time adjustments to optimize performance. Additionally, the system's automated monitoring and control capabilities reduce operational risks, ensuring a seamless and safe drilling operation.Enhanced Durability and Cost Savings:Recognizing the need for superior durability in demanding drilling environments, this industry-leading company has engineered the shale shaker system with robust materials and craftsmanship. The shaker's structural integrity guarantees longevity, enabling continuous operation in the harshest conditions.Furthermore, the technological advancements in this shaker system result in substantial cost savings for operators. By effectively separating drilling cuttings and retrieving valuable drilling fluids, the system significantly reduces waste and maximizes resource utilization. This innovation leads to lower operational expenses and a noticeable positive impact on the bottom line.Safety and Environmental Considerations:The oil and gas industry is committed to maintaining high safety standards and minimizing environmental impacts associated with drilling activities. The new shale shaker system is designed with these priorities in mind. With advanced pressure relief mechanisms and automatic shutdown features, the system ensures operator safety while reducing the risk of equipment damage.Additionally, the ability to efficiently separate drilling cuttings from drilling fluids helps prevent contamination and promotes responsible waste management. Ensuring that drilling fluids are of the highest quality improves overall environmental stewardship while minimizing the impact on local ecosystems.Conclusion:In an ever-evolving industry, embracing cutting-edge technologies is key to ensuring efficiency, sustainability, and profitability. The introduction of the advanced shale shaker system by this industry-leading company heralds a new era of excellence in oil and gas operations.By combining unmatched performance, enhanced durability, and a strong focus on safety and environmental considerations, this revolutionary shale shaker system is poised to redefine industry standards. Operators can now benefit from increased efficiency, reduced operational costs, and enhanced environmental stewardship, solidifying their position as responsible industry leaders.As the oil and gas sector continues to push boundaries, it is innovations like these that pave the way for a sustainable and prosperous future.