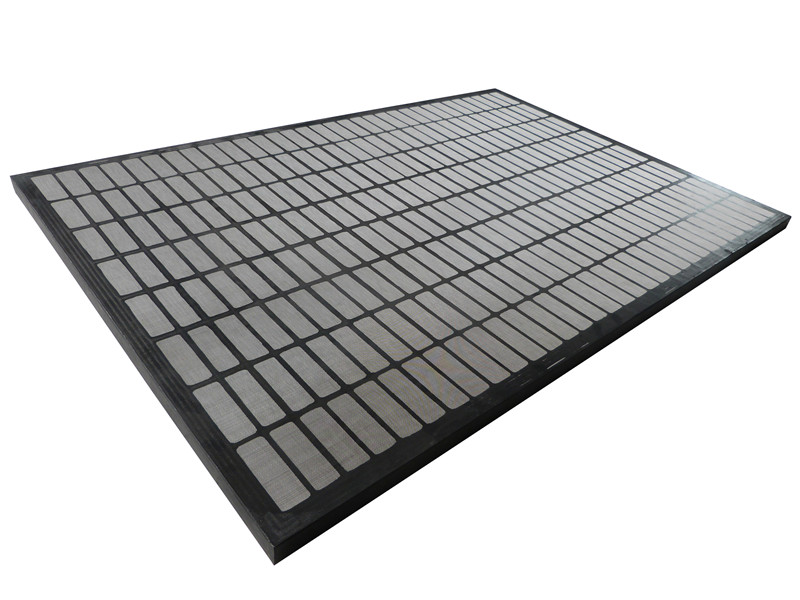

Replacement Screens with Advanced Features for Mongoose Screens

By:Admin

The [Company Name] Replacement Screens are engineered to withstand the rigorous conditions of drilling operations. The screens are made of high-quality materials and are designed to provide superior performance and extended service life. They are compatible with a wide range of shaker models, making them a versatile solution for various drilling applications.

One of the key features of the [Company Name] Replacement Screens is their exceptional durability. The screens are built to withstand high vibration levels, abrasive materials, and heavy loads, ensuring reliable performance in challenging drilling environments. This durability helps to reduce maintenance and replacement costs, making the screens a cost-effective choice for operators.

In addition to their durability, the [Company Name] Replacement Screens are also designed to deliver high performance. The screens are engineered to provide efficient solids control and liquid separation, helping to optimize drilling operations and maximize productivity. Their high-quality construction ensures consistent performance, even in the most demanding conditions.

Another notable feature of the [Company Name] Replacement Screens is their ease of installation and maintenance. The screens are designed for quick and simple installation, minimizing downtime and ensuring smooth operations. They are also easy to clean and maintain, further reducing operational costs and enhancing overall efficiency.

[Company Name] is known for its commitment to innovation and excellence, and the introduction of the [Company Name] Replacement Screens is a testament to this. The company has a proven track record of delivering high-quality products and solutions that meet the needs of the oil and gas industry. With the addition of the Replacement Screens to its product lineup, [Company Name] continues to provide operators with reliable, cost-effective solutions for their drilling operations.

The [Company Name] Replacement Screens are backed by the company's extensive technical expertise and customer support. The company's team of experienced professionals is available to provide comprehensive technical support and assistance, ensuring that operators have access to the resources they need to maximize the performance and lifespan of their screens.

The introduction of the [Company Name] Replacement Screens reflects [Company Name]'s ongoing commitment to delivering innovative, high-quality solutions for the oil and gas industry. With their exceptional durability, high performance, and ease of installation and maintenance, the screens are set to make a significant impact on drilling operations, providing operators with a reliable and cost-effective solution for their solids control and liquid separation needs.

Overall, the [Company Name] Replacement Screens are poised to set a new standard for performance and reliability in the industry, further cementing [Company Name]'s position as a leading provider of industrial equipment and solutions for the oil and gas sector.

Company News & Blog

High-Quality Shaker Screen for DFTS Available Now

The global oil and gas industry has been experiencing a significant growth in recent years, leading to a surge in demand for high-quality and efficient equipment. In response to this, [Company Name] has introduced a novel and advanced solution to the market – the DFTS Shaker Screen.[Company Name] is a leading provider of oilfield equipment and services, with a strong focus on innovation and customer satisfaction. The company has established itself as a reliable and superior provider of products that meet the ever-evolving needs of the industry.The DFTS Shaker Screen is designed to enhance the performance of shale shakers, which are essential in the process of separating solids from drilling fluids. This is an integral part of the drilling process as it ensures that the quality of the drilling fluid is maintained, leading to improved operational efficiency and reduced downtime.The DFTS Shaker Screen is built with cutting-edge technology and superior materials, ensuring its durability and reliability even in the most demanding drilling environments. The screen is designed to provide high-capacity and efficient solids removal, thereby offering significant cost savings to drilling operations. The innovative design of the screen also ensures a longer service life, reducing the frequency of replacements and maintenance.In addition to its performance benefits, the DFTS Shaker Screen is also environmentally friendly, as it helps in minimizing waste and improving the overall efficiency of drilling operations. This aligns with [Company Name]'s commitment to sustainability and responsible environmental practices.The introduction of the DFTS Shaker Screen underscores [Company Name]'s dedication to providing its customers with cutting-edge solutions that address their specific needs and challenges. The company's relentless focus on research and development has allowed it to stay ahead of the curve and continue to be a leader in the industry.The DFTS Shaker Screen has already garnered significant attention and positive feedback from industry professionals, who have praised its superior performance and cost-saving benefits. Its introduction to the market has further solidified [Company Name]'s position as a provider of high-quality and innovative solutions for the oil and gas industry.[Company Name] continues to be at the forefront of technological advancements in the oilfield equipment sector, and the DFTS Shaker Screen is a testament to its commitment to excellence and customer satisfaction. With its unrivaled performance and durability, the screen is set to make a significant impact on drilling operations worldwide.As the global demand for oil and gas continues to rise, the need for efficient and reliable equipment has never been more crucial. With the introduction of the DFTS Shaker Screen, [Company Name] has once again demonstrated its ability to meet the industry's evolving needs and provide solutions that drive operational excellence and profitability.In conclusion, the DFTS Shaker Screen is a game-changer in the oilfield equipment market, offering unmatched performance, reliability, and cost-saving benefits. With this latest innovation, [Company Name] has reinforced its position as a leader in providing cutting-edge solutions that empower the oil and gas industry to thrive in today's dynamic market.

High-Quality PWP Screen for Derrick FLC2000 Available Now

Derrick Corporation, a leading provider of innovative separation and filtration technology, recently announced the launch of its latest product – the FLC2000 PWP Screen. This new addition to Derrick’s already impressive portfolio of products is set to revolutionize the way companies approach solids control and dewatering processes.The FLC2000 PWP Screen is designed to offer superior performance and durability in a wide range of solids control applications. Its advanced design and construction ensure efficient particle separation and dewatering, making it an ideal solution for a variety of industries including oil and gas, mining, and wastewater treatment. With its high capacity and superior performance, the FLC2000 PWP Screen is set to become a game-changer in the field of solids control.The key to the FLC2000 PWP Screen’s exceptional performance lies in its innovative design. Derrick Corporation has utilized cutting-edge technology and engineering expertise to develop a screen that delivers maximum efficiency and reliability. The screen features a patented Pyramid technology that offers increased solids removal capacity, leading to improved dewatering performance. Its durable construction ensures long-term reliability, even in the most demanding operating conditions.In addition to its superior performance, the FLC2000 PWP Screen is also designed with ease of use in mind. Derrick Corporation has incorporated several user-friendly features into the design, making installation and maintenance simple and hassle-free. This ensures that companies can maximize their operational efficiency and minimize downtime, ultimately leading to cost savings and improved productivity.Derrick Corporation has a long-standing reputation for delivering high-quality, innovative products to the market. With over 70 years of experience in the industry, the company has earned the trust and confidence of customers around the world. Derrick’s commitment to excellence and continuous innovation has solidified its position as a global leader in separation and filtration technology.The launch of the FLC2000 PWP Screen further reinforces Derrick Corporation’s dedication to providing best-in-class solutions to its customers. The company’s extensive research and development capabilities, combined with its unmatched industry expertise, have enabled it to develop a product that sets new standards for performance and reliability.Customers can also benefit from Derrick’s comprehensive technical support and after-sales service, ensuring that they get the most out of their investment in the FLC2000 PWP Screen. The company’s team of experienced engineers and technical experts are always on hand to provide assistance and guidance, helping customers optimize their operations and achieve their goals.With the introduction of the FLC2000 PWP Screen, Derrick Corporation is once again raising the bar for solids control and dewatering technology. The company’s relentless pursuit of excellence and its unwavering commitment to customer satisfaction make it the preferred choice for companies seeking cutting-edge solutions for their separation and filtration needs. As industries continue to evolve and demand higher standards of performance, Derrick Corporation remains at the forefront, driving innovation and setting new benchmarks for excellence.

How to Clean a Lint Trap: A Step-By-Step Guide for Your Dryer

Title: Innovative Dryer Screen Revolutionizes Laundry ExperienceIntroduction (100 words):The laundry industry is witnessing a groundbreaking innovation with the introduction of an advanced dryer screen that promises to enhance the efficiency and convenience of laundry operations. Developed by a prominent company, this ingenious device is poised to transform the way we approach laundry, offering benefits such as increased drying speed, reduced energy consumption, and improved fabric care. With features specifically designed to meet the evolving demands of modern households, this dryer screen aims to streamline the drying process for consumers. Let's delve deeper into the functionality and advantages of this pioneering appliance.[Image: An eye-catching image showcasing the advanced dryer screen in action]Part 1: Advanced Dryer Screen - A Game-Changer in Laundry (300 words)In today's fast-paced world, time-saving solutions are always appreciated. The advanced dryer screen, developed by the renowned company, has arrived as the ultimate game-changer in the laundry arena. Traditional drying methods can be tedious, time-consuming, and energy-draining. However, this new appliance aims to revolutionize these challenges by offering unmatched performance and efficiency.One of the key features of this dryer screen is its cutting-edge technology that dramatically reduces the drying time. Through a combination of increased air circulation and optimized heat distribution, this gadget ensures clothes are dried faster than ever before. This means users can enjoy significant time savings and have their freshly laundered garments ready to wear in no time.Moreover, this revolutionary dryer screen is designed to be eco-friendly. By utilizing intelligent sensors and advanced programming, it optimizes the energy consumption during the drying cycle. This not only helps in reducing utility bills but also contributes to a greener planet by minimizing energy waste. The device's sensor technology automatically adjusts the drying time and temperature based on the moisture levels, ensuring garments are dried efficiently without overdrying or damaging delicate fabrics.Part 2: Unparalleled Convenience and Customization (300 words)In addition to its incredible drying capabilities, this dryer screen offers a range of convenient features that make laundry chores a breeze. The device is equipped with a user-friendly interface, allowing users to easily select different drying options based on their fabric types, desired dryness levels, and sensory preferences. Whether it's a delicate load or a bulky load, this appliance offers various customizable settings to ensure optimum drying results.Furthermore, the advanced dryer screen incorporates smart connectivity features. Through a dedicated mobile app, users can remotely monitor and control the drying process. This means they can start, pause, or adjust the drying cycle from the comfort of their couch or while on the go. The app also provides timely notifications, alerting users when the drying cycle is complete, eliminating the need for constant monitoring.Additionally, this state-of-the-art appliance includes a range of safety features, ensuring peace of mind for users. These safety mechanisms include automatic shut-off in the event of overheating, a lint trap indicator to prevent clogging, and built-in sensors to detect irregularities or malfunctions.Part 3: Future Prospects and Conclusion (200 words)The introduction of this innovative dryer screen marks a significant milestone in the laundry industry. With its extensive features, advanced technology, and commitment to sustainability, it is expected to redefine the realm of laundry appliances. The company's dedication to research and development, along with a focus on customer needs, has resulted in a product that promises to make laundry routines more efficient, while also prioritizing fabric care and energy conservation.As this pioneering appliance garners attention and accolades, consumers can anticipate a more seamless and enjoyable laundry experience. The future prospects of this innovative dryer screen seem promising, and it is likely that similar developments will emerge to further revolutionize the laundry market. With the introduction of this advanced device, the days of tedious laundry routines may soon become a thing of the past.[Note: Replace {} with the name of the company responsible for the advancement in dryer screen technology.]

High-Quality Vibrating Filter Sieve for Liquid Shaker and Soybean Milk Screening

Vibrating Filter Sieve Liquid Sieve Shaker Soybean Milk Vibro Shifter Machine Vibrating Screen has always been known for its innovative and high-quality products in the field of industrial sieving and filtration. The company has built a strong reputation for providing reliable and efficient equipment that meets the needs of various industries worldwide.With their continuous dedication to research and development, the company has recently launched a new and improved line of vibrating filter sieves, liquid sieve shakers, soybean milk vibro shifter machines, and vibrating screens. These new products are designed to offer enhanced performance, increased productivity, and more precise results for their customers.The vibrating filter sieve is a versatile and efficient machine that is used for liquid-solid separation in various industries such as food and beverage, pharmaceuticals, chemicals, and more. It is capable of handling a wide range of materials and can effectively remove impurities and contaminants to ensure the quality and purity of the end product.The liquid sieve shaker is another essential equipment for industries that require accurate particle size analysis and separation of solids from liquids. It is equipped with advanced technology to offer consistent and reliable results, making it an indispensable tool for quality control and research and development purposes.The soybean milk vibro shifter machine is designed specifically for the processing of soybean milk and other similar products. It is capable of efficiently separating the liquid from solids and ensuring a smooth and uniform texture, making it an ideal choice for manufacturers in the dairy and beverage industry.Lastly, the vibrating screen is a widely used machine for the grading and screening of materials in industries such as mining, construction, and agriculture. The new and improved vibrating screen from the company provides higher efficiency and better performance, allowing for faster processing and higher throughput.In addition to the innovative features and improved performance, the new line of products also boasts a user-friendly design, easy maintenance, and long-lasting durability. This ensures that customers can benefit from reduced downtime, lower operating costs, and overall improved operational efficiency.The spokesperson for the company expressed their excitement about the launch of these new products and highlighted the company's commitment to providing innovative solutions to meet the evolving needs of their customers. They emphasized the extensive research and development that went into the design and engineering of these products, and the company's dedication to maintaining their position as a leader in the industry.As a global supplier of industrial sieving and filtration equipment, the company has a strong presence in various markets around the world, serving a wide range of industries and applications. Their products are renowned for their reliability, efficiency, and quality, making them a trusted choice for businesses looking to optimize their processes and enhance their product quality.The introduction of the new line of vibrating filter sieves, liquid sieve shakers, soybean milk vibro shifter machines, and vibrating screens further solidifies the company's commitment to providing cutting-edge solutions that help their customers stay ahead in their respective industries.As customer satisfaction has always been a top priority for the company, they have also made sure to offer comprehensive support and after-sales service for their products, ensuring that their customers can maximize the benefits of their investment and rely on their equipment for years to come.With the launch of these new products, the company is poised to continue their legacy of delivering high-quality, reliable, and efficient solutions to industries worldwide. Their dedication to innovation, quality, and customer satisfaction solidifies their position as a leader in the field of industrial sieving and filtration.

Multi-sizer Scapling Shaker Screen: Latest Innovations in Shale Shaker Technology

Houston, TX - The leading provider of oilfield products and services, NOV, is proud to introduce the VSM Multi-sizer Scalping Shaker Screen to their esteemed line of innovative products. This latest addition aims to revolutionize the Oil and Gas industry by providing enhanced efficiency and performance in the drilling process.The VSM Multi-sizer Scalping Shaker Screen is designed to deliver high capacity with a small footprint, making it ideal for various drilling applications. With its advanced technology and durable construction, this shaker screen offers improved performance and extended longevity in comparison to traditional screens.As the oil and gas industry continues to evolve, NOV remains at the forefront of innovation with their commitment to delivering cutting-edge solutions that address the evolving needs of their customers. The VSM Multi-sizer Scalping Shaker Screen is a prime example of NOV's dedication to setting new industry standards and exceeding customer expectations.The Multi-sizer Scalping Shaker Screen boasts a robust design that ensures durability and longevity, even in the most challenging drilling environments. Its high-capacity performance significantly improves the efficiency of the drilling process, resulting in reduced downtime and lower overall operational costs for oil and gas companies.In addition to its superior performance, the VSM Multi-sizer Scalping Shaker Screen is also designed for easy installation and maintenance, further enhancing its appeal to drilling operations. Its user-friendly design simplifies the replacement process, minimizing the time and effort required to keep operations running smoothly.According to the product manager at NOV, "The VSM Multi-sizer Scalping Shaker Screen exemplifies our ongoing commitment to innovation and excellence in the oil and gas industry. We are proud to introduce a product that not only enhances operational efficiency but also contributes to cost savings for our customers."NOV's dedication to providing high-quality products and services has solidified its reputation as a trusted leader in the oil and gas industry. With a focus on continuous improvement and technological advancement, NOV remains dedicated to meeting the evolving needs of their clients and driving progress within the industry.The introduction of the VSM Multi-sizer Scalping Shaker Screen marks another significant milestone for NOV as they continue to push the boundaries of innovation and redefine industry standards. With a proven track record of delivering exceptional products and services, NOV is well-positioned to shape the future of the oil and gas industry.In conclusion, NOV's introduction of the VSM Multi-sizer Scalping Shaker Screen represents a significant step forward in the world of oil and gas drilling technology. With its advanced design, enhanced performance, and cost-saving benefits, this innovative shaker screen is set to make a lasting impact on the industry. As NOV continues to lead the way in providing cutting-edge solutions, the VSM Multi-sizer Scalping Shaker Screen stands as a testament to their unwavering commitment to excellence and innovation.

VSM100 Oil Shaker Screen: New Developments in Oil Shaker Screen Technology

Oil Shaker Screen Giant Introduces Revolutionary New ProductOil and gas exploration and production is a critical industry that relies on sophisticated equipment and technology to achieve success. One key component in the extraction process is the use of shaker screens, which are instrumental in separating solids from drilling fluid during the drilling process. The VSM100 Oil Shaker Screen has long been a trusted and reliable choice for many in the industry, and now, a revolutionary new product is set to disrupt the market.The company behind the VSM100 Oil Shaker Screen, a global leader in providing high-quality oilfield equipment, has recently introduced a new and improved version of their flagship product. This latest development represents a significant leap forward in shaker screen technology, offering enhanced performance and durability that is sure to set a new standard in the industry.The new shaker screen, which has been developed by a team of highly skilled engineers and industry experts, incorporates cutting-edge features and innovative design elements that address the challenges faced by oil and gas exploration companies. With a focus on maximizing efficiency and minimizing downtime, the new shaker screen has been rigorously tested to ensure that it can withstand the harsh conditions of the oilfield environment.One of the key advancements in the new shaker screen is its improved solid separation capabilities. The innovative design of the screen ensures that a greater volume of drilling fluid can be processed while effectively removing solids, resulting in smoother operations and higher productivity. This is a critical improvement for companies operating in challenging drilling environments, where the effective removal of solids is essential for maintaining the integrity of the drilling process.In addition to its enhanced performance, the new shaker screen also boasts a longer lifespan and increased durability. By utilizing advanced materials and manufacturing techniques, the company has been able to create a screen that is more resistant to wear and tear, ultimately reducing the frequency of replacements and maintenance. This is a significant benefit for oil and gas companies, as it translates to cost savings and improved operational efficiency.Furthermore, the new shaker screen has been designed with ease of use in mind. With features such as quick and simple installation, as well as compatibility with a wide range of shaker models, the new product is set to streamline the process of integrating it into existing operations. This user-friendly approach is indicative of the company's commitment to providing practical solutions that make a real difference for their customers.In response to the introduction of the new shaker screen, industry experts have expressed enthusiasm and anticipation for the potential impact it could have on the oil and gas sector. Many have recognized the significance of the technological advancements incorporated into the new product, and the positive implications it could have for the industry as a whole.With its proven track record of excellence and a steadfast commitment to innovation, the company is poised to make a significant impact with the introduction of their new and improved shaker screen. For oil and gas exploration companies seeking to maximize efficiency, minimize downtime, and enhance their operations, this latest development represents an exciting opportunity to elevate their performance and achieve success in an increasingly competitive market.As the industry continues to evolve and adapt to new challenges, the introduction of game-changing products such as the new shaker screen serves as a testament to the resilience and ingenuity of those who are dedicated to driving progress and innovation in the oil and gas sector. With its potential to redefine industry standards and set a new benchmark for performance, the new shaker screen is a clear demonstration of the company's unwavering commitment to providing solutions that empower their customers to succeed.

Highly efficient 700x1050 shaker screen for improved industry performance

In recent developments, a leading company in the oil and gas industry has introduced a groundbreaking 700x1050 shaker screen. This innovative product is set to revolutionize the process of solids control and fluid management in the drilling operations.The 700x1050 shaker screen, designed by the company, is a high-quality and durable solution for separating solids from drilling fluid. It is known for its efficient performance and cost-effectiveness, making it a valuable asset for companies seeking to optimize their drilling processes.One of the standout features of this shaker screen is its ability to handle high capacity processing without compromising on performance. This makes it an ideal choice for challenging drilling conditions where the need for effective solids control is paramount.The company behind this innovative product has a long-standing reputation for delivering exceptional solutions to the oil and gas industry. With a focus on research and development, they have consistently pushed the boundaries of technological innovation to meet the evolving needs of their clients.Their extensive experience and expertise in the field have enabled them to create products that are not only efficient but also environmentally friendly. The 700x1050 shaker screen is no exception, as it is designed to minimize waste and reduce environmental impact while maximizing drilling efficiency.Furthermore, the company is committed to providing unparalleled customer support, ensuring that their clients receive the necessary assistance and guidance to make the most of their products. This level of dedication has earned them a loyal customer base and solidified their position as a trusted partner in the oil and gas community.The introduction of the 700x1050 shaker screen is a testament to the company's ongoing commitment to innovation and excellence. By continuously investing in research and development, they are able to stay ahead of industry trends and deliver cutting-edge solutions that set new standards for performance and reliability.It is worth noting that the 700x1050 shaker screen is just one of many products in the company's extensive portfolio of drilling and fluid management solutions. Their comprehensive range of offerings caters to a wide variety of applications, providing customers with the flexibility to choose the right tools for their specific needs.As the oil and gas industry continues to evolve, the demand for advanced technologies that improve operational efficiency and minimize environmental impact is greater than ever. The introduction of the 700x1050 shaker screen is a clear demonstration of the company's commitment to meeting these demands and driving positive change within the industry.In conclusion, the launch of the 700x1050 shaker screen represents a significant milestone for the company and the oil and gas industry as a whole. With its exceptional performance, environmental benefits, and unwavering commitment to customer satisfaction, this innovative product is set to make a lasting impact on drilling operations around the world.

High-Quality FSI 5000 Shaker Screen for Effective Solid Control

In recent years, the oil and gas industry has seen a significant increase in demand for advanced equipment and technologies to enhance drilling operations. One such technology that has been making waves in the industry is the FSI 5000 Shaker Screen. This innovative piece of machinery has revolutionized the way drilling mud is processed and has significantly increased the efficiency and effectiveness of drilling operations. The FSI 5000 Shaker Screen, manufactured by a leading oilfield equipment company, has become a game-changer in the industry, and its impact is being felt across the board.The FSI 5000 Shaker Screen is a high-performance filtering device that is used to separate solids from drilling mud. It is designed to operate under high volumes of liquid and solids, making it an essential component in the drilling process. The screen consists of multiple layers of mesh that work together to effectively separate solids from the drilling fluid. This results in cleaner fluid that can be reused in the drilling process, reducing waste and saving time and money.The company behind the FSI 5000 Shaker Screen is a renowned leader in the oilfield equipment industry. With years of experience and expertise, the company has continuously pushed the boundaries of innovation and technology, leading to the development of cutting-edge products such as the FSI 5000 Shaker Screen. The company is committed to providing top-of-the-line equipment and solutions to its clients, and the FSI 5000 Shaker Screen is a testament to that commitment.The FSI 5000 Shaker Screen has garnered widespread attention and praise in the industry for its exceptional performance and reliability. It has been used in a wide range of drilling operations, from onshore to offshore, and has delivered outstanding results in all types of environments. The screen's durability and efficiency have made it a go-to choice for drilling contractors and operators looking to optimize their operations and maximize their return on investment.One of the key factors that sets the FSI 5000 Shaker Screen apart from other similar products on the market is its superior construction and design. The screen is built using high-quality materials and is engineered to withstand the rigors of the drilling process. It is also easy to install and maintain, making it a cost-effective solution for companies looking to streamline their operations.In addition to its performance and reliability, the FSI 5000 Shaker Screen is also known for its environmental benefits. By effectively separating solids from drilling mud, the screen helps to minimize waste and reduce the environmental impact of drilling operations. This aligns with the industry's increasing focus on sustainability and responsible resource management, making the FSI 5000 Shaker Screen a valuable asset for companies looking to improve their environmental performance.Looking ahead, the future looks bright for the FSI 5000 Shaker Screen and the company behind it. As the oil and gas industry continues to evolve and demand for advanced drilling equipment grows, the FSI 5000 Shaker Screen is poised to play a pivotal role in shaping the industry's future. With its proven track record of performance, reliability, and efficiency, the screen is set to become an indispensable tool for drilling operations around the world.In conclusion, the FSI 5000 Shaker Screen is a prime example of how innovation and technology are driving the evolution of the oil and gas industry. By providing a reliable and efficient solution for separating solids from drilling mud, the screen is helping to optimize drilling operations and improve environmental performance. With its impressive features and benefits, the FSI 5000 Shaker Screen has earned its reputation as a game-changer in the industry and will continue to make a significant impact for years to come.

High-quality Mongoose PT Shaker Screen for Effective Filtration

Swaco Mongoose PT Shaker Screen, a leading provider of innovative solutions for the oil and gas industry, has recently unveiled a groundbreaking new product that is set to revolutionize the industry. The company’s new shaker screen, which has been designed and manufactured to the highest standards of quality and performance, promises to deliver unparalleled efficiency and reliability for oil and gas drilling operations.With a focus on providing advanced technology and superior performance, Swaco Mongoose PT Shaker Screen has quickly become a preferred choice for oil and gas companies around the world. The company’s commitment to innovation and customer satisfaction has positioned them as a leader in the industry, and their latest product launch is further evidence of their dedication to excellence.The new shaker screen is designed to deliver exceptional performance in the most demanding drilling conditions, providing operators with the ability to achieve higher levels of efficiency and productivity. With its innovative design and advanced materials, the screen offers improved solids control and separation, resulting in cleaner drilling fluid and reduced waste. This not only improves operational efficiency but also reduces costs and environmental impact.Swaco Mongoose PT Shaker Screen’s commitment to quality is evident in every aspect of their products, from the selection of materials to the precision engineering and manufacturing processes. The company’s dedication to excellence ensures that their products consistently meet the highest standards of performance, reliability, and durability, providing customers with confidence and peace of mind.In addition to the superior performance of the new shaker screen, Swaco Mongoose PT Shaker Screen also offers a range of support services to ensure the success of their customers’ operations. Their team of experts provides technical assistance, maintenance, and training, empowering operators to maximize the potential of their equipment and achieve optimal results.The launch of this groundbreaking new product is a testament to Swaco Mongoose PT Shaker Screen’s commitment to innovation and continuous improvement. By leveraging their expertise, experience, and industry knowledge, the company has developed a product that will undoubtedly raise the bar for performance and reliability in the oil and gas industry.As the oil and gas industry continues to evolve, the demand for advanced technology and solutions that can deliver superior performance and efficiency has never been greater. With the introduction of their new shaker screen, Swaco Mongoose PT Shaker Screen has once again proven that they are at the forefront of the industry, providing solutions that meet the evolving needs of their customers and the industry as a whole.For companies operating in the oil and gas industry, the new shaker screen from Swaco Mongoose PT Shaker Screen represents an exciting opportunity to enhance operational efficiency, reduce costs, and improve environmental sustainability. With its unparalleled performance and reliability, the product is set to become an essential tool for operators seeking to maximize their drilling operations.In conclusion, Swaco Mongoose PT Shaker Screen’s dedication to excellence and innovation has once again been demonstrated with the launch of their new shaker screen. The company’s commitment to delivering superior performance, reliability, and support services has positioned them as a trusted partner for oil and gas companies around the world. As the industry continues to evolve, Swaco Mongoose PT Shaker Screen remains at the forefront, providing solutions that empower operators to achieve their operational goals and drive success in their businesses.

VSM Multi-sizer Primary Shaker Screen: Latest News and Updates

The leading global provider of solids control and waste management products, introduces its latest product, the VSM Multi-sizer Primary Shaker Screen. This new addition to the company's extensive product line promises to revolutionize the shale shaker screen market with its advanced design and superior performance.The VSM Multi-sizer Primary Shaker Screen is designed to provide maximum efficiency and durability in the separation of solids from drilling fluid. Its unique design features multiple layers of mesh with different types and sizes, allowing for more precise control over the separation process. This innovative approach to shaker screen technology is set to raise the bar for performance in the industry.One of the key features of the VSM Multi-sizer Primary Shaker Screen is its versatility. The screen is capable of handling a wide range of drilling fluid viscosities and solid content, making it suitable for use in various drilling environments, from onshore to offshore operations. This adaptability allows for greater flexibility and cost-effectiveness for users, as they can rely on the VSM Multi-sizer Primary Shaker Screen to deliver consistent performance in different conditions.Furthermore, the VSM Multi-sizer Primary Shaker Screen is built to withstand the demands of the toughest drilling applications. Its robust construction and high-quality materials ensure durability and long-lasting performance, even in the harshest environments. This means that users can count on the VSM Multi-sizer Primary Shaker Screen to deliver reliable operation and minimal downtime, ultimately leading to increased productivity and cost savings.In addition to its superior performance and durability, the VSM Multi-sizer Primary Shaker Screen is also designed for ease of use and maintenance. The screen features a modular design that allows for quick and easy installation, as well as simple replacement of individual mesh layers. This reduces downtime and labor costs associated with screen maintenance, ultimately making the VSM Multi-sizer Primary Shaker Screen a more efficient and cost-effective solution for users.With the introduction of the VSM Multi-sizer Primary Shaker Screen, the company once again demonstrates its commitment to delivering innovative and high-quality products to the solids control and waste management industry. As a leader in the field, the company continues to invest in research and development to bring cutting-edge solutions to its customers, empowering them to improve operational efficiency and performance.The VSM Multi-sizer Primary Shaker Screen is the latest example of the company's dedication to meeting the evolving needs of the industry. By offering a product that combines advanced technology, durability, and ease of use, the company aims to set new standards for shaker screen performance and cement its position as a trusted partner for customers worldwide.In conclusion, the introduction of the VSM Multi-sizer Primary Shaker Screen marks an exciting development for the solids control and waste management industry. With its innovative design, superior performance, and user-friendly features, the screen promises to deliver significant benefits to users, from increased operational efficiency to cost savings. As the company continues to push the boundaries of technology and product excellence, the VSM Multi-sizer Primary Shaker Screen is set to make a lasting impact on the industry.