New and Efficient Mongoose Shaker Bringing Innovation to the Oil and Gas Industry

By:Admin

The oil and gas industry is a vital sector of the global economy, providing the fuel that powers the world. As such, it is essential for companies in this industry to employ the latest technologies and equipment to ensure efficient and safe operations. One such piece of equipment that has revolutionized solid control in the oil and gas industry is the Swaco Mongoose Shaker.

The Swaco Mongoose Shaker is a high-performance shale shaker that is designed to separate solid particles from drilling fluid. This is a critical process in the drilling operation, as it ensures that the drilling fluid is free from debris and can be reused, thus reducing waste and saving costs. The Swaco Mongoose Shaker is renowned for its efficiency and reliability, making it the go-to choice for many oil and gas companies around the world.

The Swaco Mongoose Shaker is manufactured by a leading company in the oilfield equipment industry. With years of experience and a commitment to innovation, this company is dedicated to providing top-quality products that meet the needs of its customers. The Swaco Mongoose Shaker is a prime example of this commitment, as it has set a new standard for solid control in the oil and gas industry.

One of the key features of the Swaco Mongoose Shaker is its dual-motion capability. This means that the shaker can operate in both linear and balanced elliptical motion, providing maximum performance in a variety of drilling conditions. This versatility is crucial in the ever-changing environment of the oil and gas industry, where different drilling operations may require different approaches to solid control.

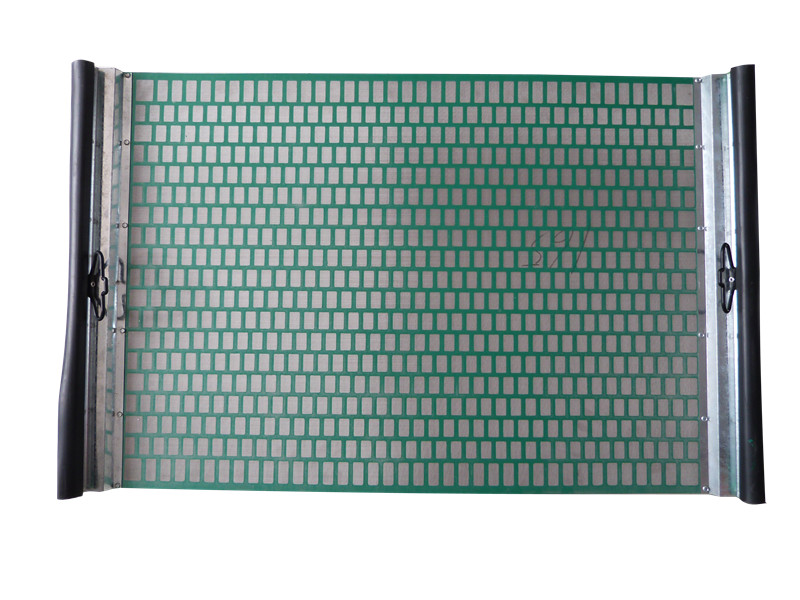

Another standout feature of the Swaco Mongoose Shaker is its advanced composite screens. These screens are designed to provide superior separation performance and longer lifespan, reducing the need for frequent replacements and saving costs for the oil and gas companies. Furthermore, the screens are quick and easy to install, minimizing downtime and maximizing productivity on the drilling site.

In addition to its technical features, the Swaco Mongoose Shaker is also designed with user-friendliness in mind. The shaker is equipped with an adjustable deck angle and a quick-disconnect feature, allowing for easy and quick adjustments and maintenance. This ensures that the shaker can be operated efficiently by the drilling crew, without the need for extensive training or specialized skills.

The Swaco Mongoose Shaker has made a significant impact on the oil and gas industry since its introduction. Its innovative design and high performance have enabled oil and gas companies to improve their solid control processes, leading to increased efficiency and cost savings. As a result, the Swaco Mongoose Shaker has become a preferred choice for many drilling operations around the world.

In conclusion, the Swaco Mongoose Shaker is a game-changer in solid control for the oil and gas industry. Its advanced features, user-friendly design, and superior performance have set a new standard for shale shakers, providing essential support for drilling operations worldwide. With a commitment to innovation and excellence, the company behind the Swaco Mongoose Shaker continues to lead the way in providing top-quality equipment for the oil and gas industry.

Company News & Blog

Top performance PMD Shaker screen for Derrick Hyperpool

Derrick Corporation, a global leader in the manufacture of high-performance screening and separation equipment, has recently introduced its latest innovation - the Hyperpool PMD Shaker screen. This advanced technology promises to revolutionize the oil and gas drilling industry by offering unprecedented efficiency and performance in solids control.The Hyperpool PMD Shaker screen is designed to provide exceptional solids removal and fluid handling capabilities, making it the ideal solution for challenging drilling operations. With its unique, patented design, the screen is able to effectively separate solids from drilling fluids, leading to improved drilling efficiency and reduced operating costs.The key to the Hyperpool PMD Shaker screen's exceptional performance lies in its advanced composite frame and ultra-fine mesh, which are engineered to maximize screen life and provide superior particle separation. This not only results in cleaner drilling fluids, but also minimizes the environmental impact of drilling operations by reducing waste and enhancing recycling efforts.Derrick Corporation has a long-standing reputation for delivering innovative and reliable solutions to the oil and gas industry. With over 70 years of experience, the company has become a trusted partner for major oil and gas companies around the world, providing them with state-of-the-art equipment and exceptional customer service.The Hyperpool PMD Shaker screen is just one example of Derrick Corporation's commitment to advancing the oil and gas industry through technological innovation. The company continuously invests in research and development to create products that address the evolving needs of the industry and contribute to improved operational efficiency and environmental sustainability.In addition to its cutting-edge technology, Derrick Corporation is also known for its customer-focused approach. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique challenges. This collaborative approach has made Derrick Corporation a preferred partner for many leading oil and gas companies, enabling them to achieve their production goals and optimize their drilling operations.The introduction of the Hyperpool PMD Shaker screen is set to further strengthen Derrick Corporation's position as a market leader in the solids control and waste management sector. The screen's exceptional performance, coupled with the company's reputation for reliability and innovation, is expected to drive its adoption across the oil and gas industry, leading to improved operational efficiencies and cost savings for drilling operators.As the global demand for oil and gas continues to grow, the need for efficient and sustainable drilling practices has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen represents a significant step forward in advancing the industry's capabilities, and is poised to make a positive impact on drilling operations around the world.In conclusion, Derrick Corporation's introduction of the Hyperpool PMD Shaker screen is a testament to the company's ongoing commitment to innovation and excellence in the oil and gas industry. With its cutting-edge technology and customer-driven approach, Derrick Corporation is well-positioned to continue leading the way in providing advanced solutions for solids control and fluid management in drilling operations.

Replacement Shaker Screen for King Cobra/Hybrid Models

Due to the increasing demand for efficient and reliable equipment in the oil and gas industry, our company is proud to introduce the latest innovation in shaker screen technology - the Replacement Shaker Screen for Brandt King Cobra/Hybrid. This new product is designed to revolutionize the solids control process and improve the overall performance of shakers in drilling operations.With a focus on durability, longevity, and superior performance, our Replacement Shaker Screen for Brandt King Cobra/Hybrid is manufactured using the highest quality materials and the latest in screen manufacturing technology. This ensures that our screens are able to withstand the most demanding drilling conditions, while also delivering consistent and reliable performance.The Replacement Shaker Screen for Brandt King Cobra/Hybrid is engineered to provide increased throughput, longer screen life, and improved conductance, resulting in more effective solid removal and drier discharge solids. This ultimately leads to reduced operating costs and improved efficiency in the drilling process.Our company understands the importance of reliability and efficiency in drilling operations, which is why we have invested heavily in research and development to create the most advanced shaker screens on the market. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to providing our customers with the best possible solutions for their solids control needs.In addition to the exceptional performance of our shaker screens, our company also prides itself on providing unparalleled customer service and support. We work closely with our customers to understand their specific requirements and to ensure that our products meet and exceed their expectations. Our team of experienced professionals is dedicated to providing technical support, troubleshooting, and on-site assistance to help our customers get the most out of our products.Furthermore, our company is dedicated to environmental sustainability, and our Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed with this in mind. By improving the efficiency of solids control and reducing waste, our screens contribute to a more environmentally friendly drilling process.With a strong focus on quality, performance, and customer satisfaction, our company is proud to offer the Replacement Shaker Screen for Brandt King Cobra/Hybrid as the latest addition to our range of industry-leading solids control solutions. We are confident that this new product will set a new standard for shaker screen performance and reliability in the oil and gas industry.As we continue to innovate and develop new technologies, our goal is to remain at the forefront of the industry and to provide our customers with the most advanced and effective solutions for their solids control needs. We are dedicated to driving progress and excellence in the oil and gas sector, and the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to delivering superior products and service.In conclusion, the Replacement Shaker Screen for Brandt King Cobra/Hybrid represents a significant advancement in shaker screen technology, and our company is proud to bring this innovative solution to the market. With its exceptional performance, durability, and environmental benefits, this new product is set to improve the efficiency and reliability of solids control in drilling operations. We are excited to offer this revolutionary shaker screen to our customers and to continue leading the way in providing cutting-edge solutions for the oil and gas industry.

Top Shale Shaker for Derrick Shale Operations: Key Features and Benefits

Derrick Corporation, a global leader in the manufacture of high-performance equipment for the oil and gas industry, has recently introduced a revolutionary new product to its line-up – the Derrick Shale Shaker. This cutting-edge technology represents a significant advancement in solids control and fine particle removal, offering unprecedented efficiency and performance in oil drilling operations.The Derrick Shale Shaker is designed to address the challenges of separating solids and drilling fluid in the most demanding drilling environments. Its innovative design and advanced technology enable it to deliver exceptional performance, making it an indispensable tool for oil and gas exploration and production companies.The key feature of the Derrick Shale Shaker is its high G-force linear motion, which ensures effective separation of solids from the drilling fluid. This high G-force capability allows for greater throughput and improved solids removal, resulting in enhanced drilling efficiency and reduced operating costs. In addition, the shaker’s adjustable deck angle and variable frequency controls provide operators with the flexibility to optimize performance for specific drilling conditions.The Derrick Shale Shaker is also equipped with an advanced screening technology that enables it to effectively handle a wide range of drilling fluids and solids, including those with high viscosity and fine particles. This flexibility allows operators to achieve superior performance in diverse drilling environments, from conventional to challenging applications such as deepwater and extended-reach drilling.Furthermore, the Derrick Shale Shaker boasts a robust and durable design, ensuring reliable operation in harsh and demanding drilling conditions. Its rugged construction and high-quality components make it capable of withstanding the rigors of the oilfield, while requiring minimal maintenance and downtime.In addition to its exceptional performance, the Derrick Shale Shaker also offers a user-friendly interface and advanced monitoring capabilities. Operators can easily adjust and monitor the shaker’s performance parameters, enabling real-time optimization for maximum efficiency and productivity. This sophisticated control system also provides valuable data and diagnostics, facilitating proactive maintenance and troubleshooting to minimize downtime and maximize uptime.The introduction of the Derrick Shale Shaker represents a significant milestone for Derrick Corporation, further solidifying its position as a leading provider of innovative solutions for the oil and gas industry. With its unparalleled performance, durability, and advanced features, the shaker is set to revolutionize solids control and fine particle removal, setting new standards for efficiency and productivity in drilling operations.At its core, the Derrick Shale Shaker embodies Derrick Corporation’s commitment to excellence and innovation, driven by a deep understanding of the evolving needs and challenges of the oil and gas industry. With a legacy of over 70 years in the business, Derrick Corporation continues to deliver cutting-edge technologies that empower its customers to achieve optimal performance and cost-effectiveness in their operations.In conclusion, the introduction of the Derrick Shale Shaker marks a significant advancement in solids control and fine particle removal for the oil and gas industry. Its exceptional performance, durability, and advanced features position it as a game-changing solution for drilling operations, delivering unparalleled efficiency and productivity. As Derrick Corporation continues to drive innovation and excellence, the future of solids control in the oil and gas industry looks brighter than ever.

Highly Efficient FLC500 Series Screen for Industries - A Must-Have Equipment

Modern drilling operations require cutting-edge equipment to ensure efficiency and effectiveness. One such important equipment is the Derrick FLC500 Series Screen, which plays a crucial role in the solid control system of drilling rigs. At {} (company name), we are proud to offer this top-of-the-line product to our clients in the oil and gas industry.The Derrick FLC500 Series Screen is designed to effectively remove large solids from the drilling fluid, commonly known as mud, during the drilling process. This is a critical function as it ensures that the drilling fluid remains in top condition for optimal performance. The solid control system, of which the screen is a key component, also helps to minimize waste and reduce environmental impact by recycling the drilling fluid.At {}, we understand the importance of reliable and efficient equipment in the oil and gas industry. That's why we have partnered with leading manufacturers, including Derrick, to provide our clients with the best products on the market. The Derrick FLC500 Series Screen is a testament to our commitment to offering high-quality solutions that meet the evolving needs of the industry.One of the standout features of the Derrick FLC500 Series Screen is its innovative design, which allows for easy installation and maintenance. This is a crucial aspect for our clients, as it minimizes downtime and ensures that their operations run smoothly. Additionally, the screen is highly durable, able to withstand the harsh conditions typically found on drilling rigs.In addition to its practical features, the Derrick FLC500 Series Screen also offers impressive performance. Its high-capacity design allows for efficient solid removal, while its precise cut point ensures that the drilling fluid is properly conditioned for the drilling process. This translates to improved overall efficiency and cost savings for our clients.At {}, we take pride in not only offering top-quality products, but also providing excellent customer service. Our team of experts is dedicated to supporting our clients every step of the way, from product selection to installation and ongoing maintenance. We understand the unique challenges of the oil and gas industry, and we are committed to helping our clients overcome them.Furthermore, as a company that values sustainability, we recognize the importance of responsible waste management in drilling operations. The solid control system, with the Derrick FLC500 Series Screen at its core, plays a crucial role in reducing environmental impact by effectively managing drilling waste. This aligns with our commitment to offering solutions that are both efficient and environmentally friendly.In conclusion, the Derrick FLC500 Series Screen is a crucial component of the solid control system in modern drilling operations. Its innovative design, impressive performance, and durability make it a standout product in the industry. At {}, we are proud to offer this top-of-the-line solution to our clients, backed by our commitment to excellence and customer satisfaction. With the Derrick FLC500 Series Screen, our clients can expect improved efficiency, cost savings, and environmental responsibility in their drilling operations.

Highly Durable Shaker Screen: A Key Component for Efficient Solid Control

The FSI 5000 Shaker Screen has been making waves in the oil and gas industry due to its exceptional performance and reliability. This innovative product has been designed to meet the demanding requirements of drilling operations, providing effective solids control and outstanding efficiency.The FSI 5000 Shaker Screen boasts a unique design that allows for efficient fluid processing and excellent cuttings removal. With its advanced technology and durable construction, this shaker screen has become a go-to solution for companies looking to improve their drilling processes and maximize productivity.The key to the exceptional performance of the FSI 5000 Shaker Screen lies in its high-quality materials and precision engineering. This product is designed to withstand the harshest drilling conditions, ensuring reliable and consistent operation in any environment. Its robust construction and innovative features make it a top choice for companies seeking a shaker screen that can deliver exceptional results while minimizing downtime and maintenance costs.With its superior performance and durability, the FSI 5000 Shaker Screen has quickly become the preferred choice for drilling operations around the world. Companies rely on this product to improve their solids control processes, enhance cuttings removal, and ultimately increase drilling efficiency. The FSI 5000 Shaker Screen has proven to be a valuable asset for companies looking to optimize their operations and achieve greater success in the field.In addition to its outstanding performance, the FSI 5000 Shaker Screen is also backed by a company with a strong track record of delivering reliable and innovative solutions for the oil and gas industry. This company has a long history of providing high-quality products and exceptional customer service, earning a reputation as a trusted partner for drilling operations of all sizes. With its commitment to excellence and dedication to meeting the needs of its customers, this company has built a solid foundation for success and continues to be a leader in the industry.The FSI 5000 Shaker Screen is just one example of the company's commitment to innovation and customer satisfaction. By combining cutting-edge technology with a focus on quality and reliability, this company continues to set the standard for excellence in the oil and gas industry. Its dedication to providing superior products and exceptional service has earned it the trust and loyalty of its customers, positioning it as a top choice for companies seeking reliable solutions for their drilling operations.As the oil and gas industry continues to evolve, companies are under increasing pressure to improve efficiency, reduce costs, and optimize their operations. The FSI 5000 Shaker Screen, along with the support of its dependable and reputable company, offers a solution that meets these challenges head-on. With its exceptional performance, durability, and strong track record, this product has become a key asset for companies looking to stay ahead in today's competitive market.In conclusion, the FSI 5000 Shaker Screen, combined with its reputable and reliable company, represents a powerful and effective solution for the oil and gas industry. With its exceptional performance, innovative design, and commitment to customer satisfaction, this product has quickly become a go-to choice for companies seeking to maximize their drilling operations. As companies continue to face increasing demands and competition, the FSI 5000 Shaker Screen offers a solution that delivers superior results and sets a new standard for excellence in the field.

Innovative FLC313M PWP Screen Offers Enhanced Performance and Durability

Derrick Corporation, a global leader in the production of industrial separation machines, has recently unveiled its new FLC313M PWP Screen. This latest addition to the company’s extensive line of high-quality equipment is designed to provide superior performance and reliability in a variety of industrial applications.The FLC313M PWP Screen features a state-of-the-art design that incorporates advanced technology and innovative engineering to deliver exceptional results. The screen is built to withstand the rigors of demanding operating conditions, making it an ideal choice for use in a wide range of industries, including oil and gas, mining, and environmental remediation.One of the key features of the FLC313M PWP Screen is its durable construction, which is designed to ensure long-lasting performance in even the harshest environments. The screen is made from high-strength materials that are resistant to corrosion, erosion, and other forms of wear and tear, giving customers the peace of mind that their equipment will continue to perform reliably for years to come.In addition to its robust construction, the FLC313M PWP Screen also offers a number of performance-enhancing features. The screen is designed to provide efficient and effective separation of solids and liquids, making it an invaluable tool for processing and recycling operations. Its advanced design also allows for easy installation and maintenance, helping to minimize downtime and maximize productivity.Derrick Corporation is known for its commitment to quality and innovation, and the launch of the FLC313M PWP Screen is a testament to the company’s dedication to providing cutting-edge solutions to its customers. With a long history of success in the industrial separation industry, Derrick Corporation has established itself as a trusted partner for businesses around the world, providing them with the tools and expertise they need to succeed.The introduction of the FLC313M PWP Screen further solidifies Derrick Corporation’s position as a leader in the field, and customers can be confident that they are investing in a product that is backed by a company with a proven track record of excellence. Whether used in the oil and gas industry to separate drilling mud and other waste materials, or in mining operations to process ore and tailings, the FLC313M PWP Screen is poised to make a significant impact on a wide range of industrial processes.In conclusion, the unveiling of the FLC313M PWP Screen represents a significant milestone for Derrick Corporation, and a major advancement for the industrial separation industry as a whole. With its cutting-edge design, durable construction, and unmatched performance, this new addition to the company’s product line is sure to set a new standard for excellence in the field. Derrick Corporation continues to raise the bar for industrial separation equipment, and the FLC313M PWP Screen is a prime example of the company’s unwavering commitment to innovation and customer satisfaction.

How to Clean and Maintain Your Dryer Screen for Optimal Performance

Today, [Company] is proud to announce the launch of our innovative new dryer screen, a cutting-edge product that is set to revolutionize the laundry industry. The new dryer screen is designed to enhance the drying process, providing a more efficient and effective way to dry clothes while also reducing energy consumption.The key feature of the new dryer screen is its advanced design, which includes a unique mesh pattern that allows for better airflow and heat distribution. This results in faster drying times and more evenly dried clothes, reducing the need for multiple drying cycles. Additionally, the dryer screen is made from high-quality materials that are durable and long-lasting, ensuring that it will stand up to the rigors of regular use.In addition to its performance benefits, the new dryer screen is also designed with user convenience in mind. It is easy to install and remove, and is compatible with a wide range of dryer models. The durable construction means that it can be washed and reused multiple times, reducing the need for frequent replacements.The launch of this new product reflects [Company]'s commitment to innovation and sustainability. Our company has a long history of developing cutting-edge products that improve the efficiency and performance of household appliances, and the new dryer screen is the latest example of this commitment. We are constantly researching and developing new technologies to make everyday tasks easier and more sustainable for consumers.[Company] is a leading manufacturer of household appliances, with a strong focus on innovation and sustainability. Our products are designed to enhance the lives of our customers by providing practical solutions to everyday tasks. We are committed to reducing our environmental impact through the use of sustainable materials and energy-efficient technologies, and we are constantly striving to improve the performance and efficiency of our products.The launch of the new dryer screen is a significant milestone for [Company], as it represents the culmination of extensive research and development efforts. Our team of engineers and designers have worked tirelessly to create a product that not only enhances the performance of dryers, but also reduces energy consumption and environmental impact.In addition to the launch of the new dryer screen, [Company] is also announcing a new partnership with a leading appliance retailer to make the product widely available to consumers. This partnership will enable the new dryer screen to reach a larger audience, allowing more people to benefit from its advanced technology and sustainability benefits.Overall, the launch of the new dryer screen is a significant achievement for [Company], and represents a major step forward in our ongoing commitment to innovation and sustainability. We are confident that this product will become an essential addition to households around the world, delivering superior drying performance and environmental benefits for years to come.

High-Quality KPT 28 Shaker Screen for China's Oil and Gas Industry

China-based company KPT 28 Shaker Screen is making waves in the oil and gas industry with its state-of-the-art shaker screens. The company has been gaining recognition for its high-quality products and innovative solutions for the oil and gas drilling industry.Founded in 2008, KPT 28 Shaker Screen has quickly established itself as a leading manufacturer and supplier of shaker screens for various types of shakers used in the oil and gas drilling process. The company's commitment to quality, performance, and customer satisfaction has earned it a stellar reputation among its clients.KPT 28 Shaker Screen's products are designed to withstand the harsh conditions of drilling operations, providing reliable and efficient performance, reducing downtime and increasing productivity. The company's shaker screens are engineered to effectively separate solids from drilling fluid, ensuring smooth and efficient drilling operations.The company offers a wide range of shaker screens to meet the diverse needs of its clients, including hook strip, pretention, and flat panel screens. KPT 28 Shaker Screen's products are compatible with most major brands of shale shakers, making them a versatile and reliable choice for drilling operations.In addition to its high-quality products, KPT 28 Shaker Screen is also known for its exceptional customer service. The company's team of experts are dedicated to providing personalized support and guidance to help clients select the best shaker screens for their specific needs. KPT 28 Shaker Screen's commitment to customer satisfaction has helped it build strong and long-lasting relationships with its clients.With a focus on innovation and continuous improvement, KPT 28 Shaker Screen invests in research and development to enhance its product offerings and stay ahead of industry trends. The company leverages the latest technologies and manufacturing processes to produce shaker screens that meet the highest standards of quality and performance.KPT 28 Shaker Screen's dedication to excellence has not gone unnoticed, as the company has received numerous accolades and certifications for its products and services. Its shaker screens have been widely used in oil and gas drilling operations in the Middle East, North America, and other regions, earning recognition for their reliability and durability.As the demand for energy continues to grow, the oil and gas industry is expected to expand, driving the need for efficient and reliable drilling equipment. KPT 28 Shaker Screen is well-positioned to meet this demand with its cutting-edge shaker screens and unwavering commitment to customer satisfaction.Looking ahead, KPT 28 Shaker Screen is poised to further expand its presence in the global oil and gas market and continue its tradition of delivering top-quality products and stellar service to its clients.In conclusion, KPT 28 Shaker Screen is a trusted and reputable provider of shaker screens for the oil and gas industry. With a steadfast focus on quality, performance, and customer satisfaction, the company has made a name for itself as a leader in the field. As the industry continues to evolve, KPT 28 Shaker Screen is well-equipped to meet the changing needs of its clients and maintain its position as a top supplier of shaker screens.

High-efficient Rotary Vibrating Screen Shaker for Screening Applications

Rotary Vibrating Screen Shaker (name removed for privacy reasons) is a highly efficient and innovative screening solution that has revolutionized the way companies in various industries process materials. With its advanced design and state-of-the-art technology, this shaker has become a preferred choice for many businesses looking to improve their screening processes.The (name removed) Rotary Vibrating Screen Shaker is designed to efficiently separate and remove oversized particles from materials such as chemicals, minerals, plastics, and more. Its unique rotary motion and high-frequency vibration allow for a more precise and effective screening process, resulting in higher product quality and reduced downtime.The key features of the (name removed) Rotary Vibrating Screen Shaker include its compact design, easy operation, and low maintenance requirements. This makes it an ideal solution for companies looking to streamline their screening operations without compromising on performance.In addition to its technical capabilities, (name removed) is also committed to providing excellent customer service and support. The company's team of experienced professionals is dedicated to helping customers find the right screening solution for their specific needs, and its extensive network of distributors ensures that customers have access to reliable and responsive support wherever they are located.Furthermore, (name removed) takes pride in its commitment to environmental sustainability. The Rotary Vibrating Screen Shaker is designed with energy efficiency in mind, helping companies reduce their carbon footprint while improving their overall screening processes. This aligns with (name removed)'s mission to provide eco-friendly solutions that benefit both businesses and the environment.The (name removed) Rotary Vibrating Screen Shaker has already been adopted by a wide range of industries, including pharmaceuticals, food and beverage, ceramics, and more. Its versatility and adaptability make it a valuable asset for companies looking to enhance their material processing capabilities.Customer testimonials speak to the effectiveness and reliability of the (name removed) Rotary Vibrating Screen Shaker. Many companies have reported significant improvements in their screening processes after implementing this innovative solution, leading to increased productivity and cost savings.Looking ahead, (name removed) is continuously exploring ways to enhance the performance and capabilities of the Rotary Vibrating Screen Shaker. The company is committed to staying at the forefront of technological advancements in the screening industry, ensuring that its customers always have access to the most efficient and reliable solutions.In conclusion, the (name removed) Rotary Vibrating Screen Shaker has set a new standard for screening technology in various industries. Its advanced design, efficiency, and commitment to customer satisfaction have made it a preferred choice for companies worldwide. With a focus on innovation and sustainability, (name removed) continues to lead the way in providing cutting-edge solutions for material processing and screening needs.

High-Quality FLC313M Screen: What You Need to Know

Derrick Corporation, a leading global provider of high-quality separation and filtration equipment, has recently launched its latest innovation – the FLC313M screen. This new addition to the company’s extensive product line promises to revolutionize the way the oil and gas industry approaches solids control and dewatering.The FLC313M screen is designed to deliver superior performance and efficiency in separating solids from drilling fluid. Its advanced design features a unique combination of high-quality materials and innovative engineering, resulting in increased throughput and reduced operating costs for customers. With a focus on durability and reliability, this screen is built to withstand the demands of the most challenging drilling environments.One of the standout features of the FLC313M screen is its versatility. Suitable for both onshore and offshore applications, this screen excels in a wide range of operating conditions, including high temperature and high-pressure environments. Its ability to consistently deliver exceptional performance in such diverse settings sets it apart from other products currently available on the market.Furthermore, Derrick Corporation is committed to providing best-in-class customer service and support. The launch of the FLC313M screen is part of the company’s ongoing effort to meet the evolving needs of its global customer base. By offering innovative solutions that enhance efficiency and productivity, Derrick Corporation continues to solidify its position as a trusted partner to the oil and gas industry.In addition to the FLC313M screen, Derrick Corporation offers a comprehensive range of separation and filtration equipment, including shakers, hydrocyclones, and centrifuges. With a proven track record of delivering high-performance solutions, the company has established itself as a leader in the field of solids control and dewatering.The development and launch of the FLC313M screen underscore Derrick Corporation’s dedication to innovation and excellence. By staying at the forefront of technological advancements, the company remains well-positioned to address the evolving needs of the oil and gas industry. As the industry continues to seek more efficient and cost-effective solutions, Derrick Corporation is poised to provide the cutting-edge equipment required to meet these demands.In conclusion, the introduction of the FLC313M screen represents a significant milestone for Derrick Corporation. With its unmatched performance, durability, and versatility, this new addition to the company’s product line is set to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to push the boundaries of innovation, customers can expect to benefit from the superior quality and reliability that have become synonymous with the company’s brand.About Derrick Corporation:Derrick Corporation is a global provider of high-quality separation and filtration equipment for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner to its global customer base. Derrick Corporation is committed to delivering best-in-class equipment and solutions that enhance efficiency and productivity in solids control and dewatering applications.