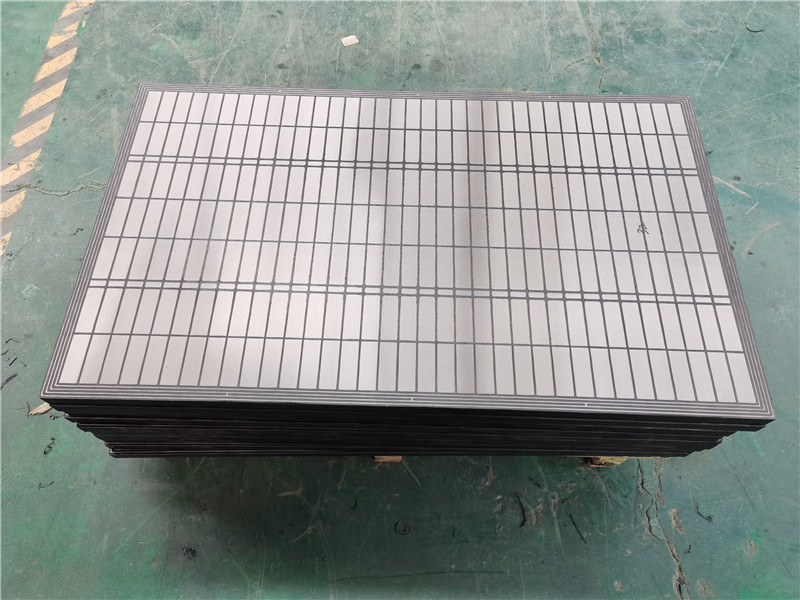

Multi-sizer Scapling Shaker Screen: Latest Innovations in Shale Shaker Technology

By:Admin

The VSM Multi-sizer Scalping Shaker Screen is designed to deliver high capacity with a small footprint, making it ideal for various drilling applications. With its advanced technology and durable construction, this shaker screen offers improved performance and extended longevity in comparison to traditional screens.

As the oil and gas industry continues to evolve, NOV remains at the forefront of innovation with their commitment to delivering cutting-edge solutions that address the evolving needs of their customers. The VSM Multi-sizer Scalping Shaker Screen is a prime example of NOV's dedication to setting new industry standards and exceeding customer expectations.

The Multi-sizer Scalping Shaker Screen boasts a robust design that ensures durability and longevity, even in the most challenging drilling environments. Its high-capacity performance significantly improves the efficiency of the drilling process, resulting in reduced downtime and lower overall operational costs for oil and gas companies.

In addition to its superior performance, the VSM Multi-sizer Scalping Shaker Screen is also designed for easy installation and maintenance, further enhancing its appeal to drilling operations. Its user-friendly design simplifies the replacement process, minimizing the time and effort required to keep operations running smoothly.

According to the product manager at NOV, "The VSM Multi-sizer Scalping Shaker Screen exemplifies our ongoing commitment to innovation and excellence in the oil and gas industry. We are proud to introduce a product that not only enhances operational efficiency but also contributes to cost savings for our customers."

NOV's dedication to providing high-quality products and services has solidified its reputation as a trusted leader in the oil and gas industry. With a focus on continuous improvement and technological advancement, NOV remains dedicated to meeting the evolving needs of their clients and driving progress within the industry.

The introduction of the VSM Multi-sizer Scalping Shaker Screen marks another significant milestone for NOV as they continue to push the boundaries of innovation and redefine industry standards. With a proven track record of delivering exceptional products and services, NOV is well-positioned to shape the future of the oil and gas industry.

In conclusion, NOV's introduction of the VSM Multi-sizer Scalping Shaker Screen represents a significant step forward in the world of oil and gas drilling technology. With its advanced design, enhanced performance, and cost-saving benefits, this innovative shaker screen is set to make a lasting impact on the industry. As NOV continues to lead the way in providing cutting-edge solutions, the VSM Multi-sizer Scalping Shaker Screen stands as a testament to their unwavering commitment to excellence and innovation.

Company News & Blog

Highly Efficient Shaker Screen for Swaco Mongoose Model

Swaco Mongoose Shaker Screen is a crucial piece of equipment for the oil and gas industry, and it is commonly used to separate solids from drilling fluid. This is why {company name} takes great pride in offering a high-quality and reliable Mongoose shaker screen that is designed to effectively and efficiently separate solids from drilling fluid. With an extensive background in manufacturing and supplying equipment to the oil and gas industry, {company name} has dedicated itself to providing top-notch shaker screens that meet the highest standards. The company is committed to delivering quality products and exceptional service to its customers, and the Swaco Mongoose Shaker Screen is no exception.The Swaco Mongoose Shaker Screen offered by {company name} is designed to provide superior performance and durability in demanding drilling operations. It is constructed with high-quality materials and advanced technology to ensure efficient and effective solid control. The shaker screen is engineered to withstand the harsh conditions of drilling operations and to deliver consistent and reliable performance.One of the key features of the Swaco Mongoose Shaker Screen offered by {company name} is its high conductance design, which allows for increased flow capacity and improved solids removal. This design is crucial for enhancing the efficiency of the drilling process and reducing operating costs. Additionally, the shaker screen is designed with a durable frame and advanced mesh technology to provide long-lasting performance and reliability.{company name} takes pride in ensuring that its Swaco Mongoose Shaker Screen meets the highest industry standards for quality and performance. The company’s commitment to excellence is reflected in its rigorous quality control processes and testing procedures. Each shaker screen undergoes thorough inspection and testing to ensure that it meets the company’s stringent standards for quality and performance.In addition to offering high-quality products, {company name} is also dedicated to providing exceptional service to its customers. The company’s team of experienced professionals is committed to delivering reliable technical support and timely assistance to customers. {company name}’s expertise and dedication to customer satisfaction has earned it a strong reputation in the industry.Furthermore, {company name} understands the importance of environmental responsibility and sustainability in the oil and gas industry, and the company is committed to providing eco-friendly solutions. The Swaco Mongoose Shaker Screen offered by {company name} is designed to minimize environmental impact and reduce waste generation. The use of advanced technology and materials in the manufacturing process helps to promote sustainable practices and reduce the environmental footprint of drilling operations.Overall, {company name}’s Swaco Mongoose Shaker Screen is a top-of-the-line product that offers superior performance, durability, and reliability. With its commitment to quality, exceptional service, and environmental responsibility, {company name} is a trusted partner for customers in the oil and gas industry. The company’s dedication to excellence and innovation sets it apart as a leading provider of shaker screens and solid control equipment. Customers can rely on {company name} to provide high-quality products and exceptional service that meet their needs and exceed their expectations.

Steel Frame Shaker Screen for Elgin KPT-28 - Latest News

Elgin, a leading provider of innovative solutions for the energy, mining, material processing, and environmental industries, has recently announced the launch of their latest product, the KPT-28 Steel Frame Shaker Screen. This new addition to Elgin’s extensive product line is designed to provide enhanced performance and durability, meeting the evolving needs of customers in the demanding field of solids control equipment.The KPT-28 Steel Frame Shaker Screen is a result of Elgin’s commitment to continuous innovation and improvement. With a focus on delivering high-quality and reliable products, Elgin has leveraged its extensive expertise and industry experience to develop a shaker screen that sets new standards in efficiency and longevity. The KPT-28 Steel Frame Shaker Screen is built to withstand the harsh conditions of the oil and gas drilling industry, offering exceptional resistance to abrasion, corrosion, and impact.One of the key features of the KPT-28 Steel Frame Shaker Screen is its advanced construction, which utilizes high-quality steel materials and state-of-the-art manufacturing techniques. This ensures that the shaker screen delivers consistent performance and longevity, even in the most demanding applications. The screen’s robust design also allows for increased throughput and separation efficiency, ultimately leading to improved productivity and cost savings for customers.In addition to its exceptional durability, the KPT-28 Steel Frame Shaker Screen is also designed to provide easy installation and maintenance. This user-friendly aspect of the product is further enhanced by Elgin’s commitment to customer support and service. Elgin’s team of technical experts is available to provide assistance and guidance to customers, ensuring that they maximize the performance and lifespan of their shaker screens.Furthermore, the KPT-28 Steel Frame Shaker Screen is compatible with a wide range of shaker models, making it a versatile solution for various equipment setups. This flexibility is an important advantage for customers, as it allows them to seamlessly integrate the shaker screen into their existing operations without requiring significant modifications or additional investments.Elgin’s dedication to delivering high-quality products and top-notch customer service has made them a trusted partner for companies across the energy, mining, and environmental sectors. With a strong focus on innovation and performance, Elgin continues to lead the way in providing cutting-edge solutions that address the evolving needs of the industry.As part of their commitment to sustainability and environmental responsibility, Elgin also places a strong emphasis on product reliability and longevity. The KPT-28 Steel Frame Shaker Screen is a testament to this commitment, as it is designed to minimize downtime and reduce the need for frequent replacements, ultimately leading to lower overall environmental impact and operational costs.In conclusion, the launch of the KPT-28 Steel Frame Shaker Screen reaffirms Elgin’s position as a leader in the field of solids control equipment. With its exceptional durability, performance, and versatility, the shaker screen is set to become an essential component for companies looking to optimize their operations and achieve greater efficiency. By continuing to prioritize innovation and customer satisfaction, Elgin is poised to shape the future of the industry and drive positive change for its customers and the environment.

High Quality FLC313 Shaker Screen for Oil Drilling Rig

Derrick Corporation, a global leader in the manufacture and supply of high-quality solids control and separation equipment, has recently announced the release of its latest product, the FLC313 Shaker Screen. This innovative addition to the company's extensive product line is set to revolutionize the oil and gas industry with its advanced technology and superior performance.The FLC313 Shaker Screen is designed to deliver unparalleled efficiency in the separation of solid particles from drilling fluids. It is engineered to handle high-capacity processing and can effectively remove a wide range of solids, including fine particles and larger debris. This cutting-edge shaker screen is meticulously constructed using the highest quality materials and state-of-the-art manufacturing processes to ensure exceptional durability and reliability in the most demanding working environments.One of the key features of the FLC313 Shaker Screen is its advanced composite frame, which offers increased longevity and reduced maintenance requirements compared to traditional metal frames. The composite frame is not only lighter and easier to handle, but also provides a more secure and consistent screen tension, resulting in improved solids control performance and extended screen life.In addition, the FLC313 Shaker Screen boasts a unique layered wire cloth design that enhances the screening efficiency and effectively prevents blinding and plugging during operation. This innovative design ensures optimal solids separation and allows for continuous uninterrupted drilling operations, ultimately leading to increased productivity and cost savings for oil and gas companies.Derrick Corporation has a long-standing reputation for delivering innovative, high-performance solutions to the global oil and gas industry. With over 70 years of experience, the company has continually pushed the boundaries of solids control and separation technology, setting new industry standards and driving advancements in efficiency and productivity.Through its unwavering commitment to research and development, Derrick Corporation has consistently introduced cutting-edge products that address the evolving needs of the oil and gas sector. The FLC313 Shaker Screen is the latest testament to the company's dedication to engineering excellence and its ability to provide customers with reliable, cost-effective solutions that deliver tangible results.The release of the FLC313 Shaker Screen underscores Derrick Corporation's ongoing mission to empower its customers with the tools and technologies they need to optimize their drilling operations and maximize their performance. By leveraging its extensive expertise and industry insights, the company continues to set new benchmarks for quality and innovation in the field of solids control and separation.Derrick Corporation remains committed to supporting its customers through comprehensive technical support and unparalleled customer service, ensuring that they derive maximum value from its products and achieve operational success. As the global demand for energy continues to grow, Derrick Corporation is poised to play a pivotal role in enabling the oil and gas industry to meet its evolving challenges and achieve sustainable, long-term success.In conclusion, the launch of the FLC313 Shaker Screen represents a significant milestone for Derrick Corporation and reinforces its position as a leader in solids control and separation technology. With its superior performance, advanced features, and unwavering commitment to customer satisfaction, the FLC313 Shaker Screen is poised to make a lasting impact on the oil and gas industry, driving greater efficiency and productivity for operators worldwide.

High-quality Oil Shaker Screens for Effective Filtration and Separation

The oil and gas industry is a crucial part of the global economy, and companies in this sector are constantly striving to improve their efficiency and productivity. One such company that has been making waves in the industry is a leading provider of oil shaker screens, an essential component in the oil and gas drilling process.The company, headquartered in the United States, has been at the forefront of innovation in oil shaker screen technology. Their products are designed to efficiently separate solids from drilling fluid and are used in various drilling applications, including oil and gas exploration, well construction, and environmental remediation.One of the company's flagship products is the Swaco Oil Shaker Screen, which has gained a reputation for its exceptional performance and durability. The screen is designed to withstand the harsh conditions of drilling operations and is engineered to deliver high throughput and maximum solids removal efficiency. Its unique design and advanced manufacturing techniques have made it a preferred choice for many drilling operators around the world.In addition to the Swaco Oil Shaker Screen, the company offers a wide range of screens for different shaker models, including hook strip, pretensioned, and framed screens. These screens are made from high-quality materials and are precision-engineered to meet the specific requirements of different drilling applications.The company's commitment to quality and innovation has earned it a loyal customer base and a strong reputation in the industry. Its products are known for their reliable performance, long service life, and cost-effectiveness. Moreover, the company prides itself on its exceptional customer service and technical support, ensuring that its clients receive the best possible solutions for their drilling needs.In addition to its product offerings, the company also provides comprehensive training and support services to help drilling operators optimize the performance of their shaker screens. This includes on-site technical assistance, maintenance and repair services, and custom engineering solutions to address specific drilling challenges.Furthermore, the company is dedicated to sustainability and environmental responsibility, and it continually seeks to develop new technologies and processes that minimize the environmental impact of drilling operations. Its commitment to sustainability extends to its product development, where it strives to use eco-friendly materials and manufacturing practices.As the global demand for energy continues to rise, the oil and gas industry will continue to play a crucial role in meeting this demand. Companies like this leading provider of oil shaker screens will be instrumental in helping the industry operate more efficiently and sustainably. With their advanced technology, exceptional products, and unwavering commitment to customer satisfaction, they are well-positioned to continue as a driving force in the oil and gas sector.In conclusion, the company's Swaco Oil Shaker Screen and other products have set new standards for performance, reliability, and environmental responsibility in the oil and gas industry. Their dedication to innovation, quality, and customer service has solidified their position as a trusted partner for drilling operators worldwide. As the industry continues to evolve, this leading provider of oil shaker screens will undoubtedly remain at the forefront, providing cutting-edge solutions that meet the evolving needs of the oil and gas sector.

Durable and lightweight composite frame technology in the spotlight

Composite Frame, a leading manufacturer and supplier of composite materials, has introduced a cutting-edge composite frame that is set to revolutionize the construction and aerospace industries. The company, known for its expertise in developing high-performance composite products, has once again showcased its innovation and commitment to providing the best solutions for its customers.The composite frame, which has been in development for several years, is made from a combination of advanced composite materials that have been carefully engineered to provide exceptional strength, durability, and performance. This new frame offers a number of advantages over traditional metal frames, including a lighter weight, increased corrosion resistance, and the ability to be molded into complex shapes and designs.One of the key benefits of the composite frame is its weight savings. Compared to traditional metal frames, the composite frame is significantly lighter, making it an ideal choice for applications where weight is a critical factor. This includes the aerospace industry, where lightweight materials are essential for improving fuel efficiency and reducing overall aircraft weight.In addition to being lightweight, the composite frame also offers superior corrosion resistance. Unlike metal frames, which are prone to rust and corrosion, the composite frame is highly resistant to degradation from moisture, chemicals, and other environmental factors. This makes it an ideal choice for use in harsh or corrosive environments, such as marine and offshore applications.Another advantage of the composite frame is its ability to be molded into complex shapes and designs. This offers designers and engineers a greater degree of flexibility when it comes to creating custom products and components. Whether it's a curved architectural feature or a unique aerospace component, the composite frame can be molded to meet virtually any design requirement.In addition to its performance benefits, the composite frame also offers cost savings over the long term. While the initial production costs may be higher than traditional metal frames, the composite frame's durability and longevity mean that it requires less frequent maintenance and replacement. This can result in significant cost savings over the lifespan of the product.The introduction of the composite frame represents a significant milestone for Composite Frame, which has built a reputation for developing innovative, high-quality composite products. With its extensive experience and expertise in composite materials, the company is well-positioned to lead the way in the development and production of advanced composite frames for a wide range of industries."We are incredibly proud to introduce our new composite frame to the market," said [company spokesperson]. "This product is the result of years of research, development, and testing, and we believe it will set a new standard for performance and durability in the construction and aerospace industries. We are confident that this innovative composite frame will offer our customers a superior alternative to traditional metal frames, and we look forward to seeing the positive impact it will have in the market."The introduction of the composite frame underscores Composite Frame's commitment to pushing the boundaries of what is possible with composite materials. As the demand for lightweight, durable, and high-performance products continues to grow across a variety of industries, the company's expertise and innovation will play a crucial role in shaping the future of composite materials and their applications.

High-quality Oil Shaker Screen for FLC2000 Shakers

The oil and gas industry is a complex and demanding sector that requires cutting-edge technology and equipment to ensure smooth operations. One such essential piece of equipment is the FLC2000 Shaker screen, a vital component in the drilling process.The FLC2000 Shaker screen is a high-performance vibrating screen used to separate solids from liquids in the drilling mud. It is designed to efficiently remove solid particles from drilling fluids, which is a crucial step in the drilling process to ensure the integrity of the wellbore and protect downstream equipment.The FLC2000 Shaker screen, manufactured by a leading oilfield equipment company, is known for its durability, efficiency, and reliability. With a strong focus on quality and performance, the company has positioned itself as a trusted provider of drilling equipment and solutions to the oil and gas industry.The company behind the FLC2000 Shaker screen has a solid reputation for delivering innovative and high-quality products that meet the demanding requirements of the oil and gas sector. With a strong emphasis on research and development, the company has continuously improved and enhanced its product offerings to meet the evolving needs of the industry.In addition to the FLC2000 Shaker screen, the company also offers a comprehensive range of drilling equipment, including shale shakers, mud cleaners, centrifuges, and other solids control equipment. These products are designed to optimize drilling performance, reduce downtime, and minimize environmental impact, making them essential for efficient and sustainable drilling operations.The company's commitment to quality and customer satisfaction is evident in its rigorous testing and certification processes, ensuring that its products meet the highest industry standards. This dedication to excellence has earned the company the trust and confidence of leading oil and gas companies worldwide.Furthermore, the company's expertise in providing custom solutions and technical support sets it apart as a reliable partner for the oil and gas industry. Its team of experienced engineers and technicians are readily available to provide installation, maintenance, and troubleshooting services, ensuring that its customers' operations run smoothly and efficiently.With a global network of distribution and service centers, the company is well-positioned to provide timely support and reliable delivery of its products to customers around the world. This extensive network underscores the company's commitment to being a valuable and dependable partner to the oil and gas industry.In conclusion, the FLC2000 Shaker screen, combined with the company's extensive experience, technical expertise, and commitment to quality, exemplifies the essential role of advanced technology and equipment in the oil and gas industry. By consistently delivering reliable and innovative solutions, the company has established itself as a trusted provider of drilling equipment and solutions, contributing to the efficiency and sustainability of the oil and gas sector.

Revolutionary Vibrating Screen Technology: A Breakthrough in Shaker Screening Efficiency

Shaker vibrating screens have become an essential component in modern industrial machinery. These machines are designed to help sift and sort various materials such as minerals, coal, and chemicals. They have also found applications in the food and beverage, pharmaceuticals, and recycling industries. Shaker vibrating screens use an elliptical motion to shake the sieves, which helps to increase the efficiency of the separation process. One company that has been at the forefront of producing high-quality vibrating screens is ______ (brand name removed). Established in 2004, the company has made a name for itself by producing some of the most advanced and reliable shaker vibrating screens in the market. Their products are known for their durability, precision, and ease of maintenance, and they've become a favorite among various industries.The company specializes in producing various types of vibrating screens to meet the unique needs of different markets. Their products include linear vibrating screens, circular vibrating screens, and newly developed high-frequency screens. The company uses the latest technology and production standards to ensure that their products meet the highest quality standards required by customers.One of the main advantages of the company's products is that their vibrating screens come in various sizes and configurations that can be tailored to each customer's specific needs. Whether a customer requires a compact single-deck design or a larger multi-layered model, the company can deliver. Additionally, the company also produces custom-made vibrating screens with unique specifications to match the individual demands of their clients.Moreover, the company is committed to ensuring that their vibrating screens operate efficiently with minimal maintenance. They have invested in research and development and created innovative designs featuring less moving parts, reducing wear and tear and reducing downtime while saving on maintenance costs.The company also places a strong emphasis on customer satisfaction. They offer technical support, training for operators and maintenance staff, and offer prompt after-sale service when required. Their customer service team is available to answer any questions and concerns that may arise, ensuring that their customers are satisfied with the products they receive.As the market for shaker vibrating screens expands, _______, with its innovative designs and reliable products, is poised to take full advantage of this trend. The company has already established a strong reputation among its customers for providing the highest quality products that embody the latest industry trends.For example, one of the recently launched high-frequency vibrating screens from _______ is already garnering attention in the industry for its ability to provide better performance than traditional screens. This high-frequency vibrating screen uses a high frequency, low amplitude motion to screen materials with a high degree of precision and accuracy. It offers higher efficiency and productivity while increasing the throughput and reducing the wear and tear on the equipment.In conclusion, _______ (brand name removed) has established itself as a significant player in the shaker vibrating screen market, thanks to its innovative designs and high-quality products. Their commitment to customer satisfaction and continuous product innovation has helped to create loyal customers who appreciate their exceptional service. As the demand for shaker vibrating screens continues to grow, the company is well-positioned to take advantage of this trend and continue to provide products and services that exceed their customers' expectations.

How Frame Screens are Changing the Way You Watch TV

Frame Screens, a leading provider of advanced display and projection technology, has recently announced the launch of its latest product line aimed at enhancing the viewing experience for home entertainment systems.With a focus on innovation and customer satisfaction, Frame Screens has been a force to reckon with in the display technology industry. The company has a strong commitment to developing cutting-edge solutions that deliver stunning visual experiences for consumers. Their products are designed to seamlessly integrate into any home entertainment system, offering unparalleled quality and performance.The new product line from Frame Screens features a range of innovative display solutions, including motorized screens, fixed frame screens, and ambient light rejecting screens. These products are designed to provide a truly immersive viewing experience, with vibrant colors, sharp contrast, and superior image clarity. By leveraging advanced materials and state-of-the-art technology, Frame Screens has set a new standard for home theater displays.One of the standout products in the new line is the motorized screen, which offers a sleek and efficient solution for homeowners looking to optimize their viewing space. These screens can be easily controlled with a remote or integrated into smart home systems, allowing for seamless operation and customization. With a variety of sizes and aspect ratios available, homeowners can find the perfect motorized screen to fit their unique space and preferences.In addition to motorized screens, Frame Screens has also introduced fixed frame screens that are designed for a more permanent and dedicated home theater setup. These screens are meticulously engineered to deliver an ultra-smooth surface for projecting images, ensuring a cinematic experience in the comfort of one's own home. With a rigid aluminum frame and tensioning system, these screens maintain a flat, wrinkle-free surface for a consistently exceptional viewing experience.Furthermore, Frame Screens' new product line includes ambient light rejecting screens, which are designed to mitigate the impact of ambient light in a room. These screens feature proprietary materials and technologies that selectively reflect and absorb light, resulting in enhanced contrast and improved black levels. This makes them an ideal choice for spaces with varying levels of ambient light, allowing homeowners to enjoy a superior viewing experience even in challenging environments."We are thrilled to introduce our latest product line, which represents a significant leap forward in display technology for home entertainment systems," said a spokesperson for Frame Screens. "Our team has worked tirelessly to develop innovative solutions that cater to the evolving needs of consumers, and we are confident that these new products will exceed expectations in terms of performance, versatility, and ease of use."With a track record of delivering high-quality products and exceptional customer service, Frame Screens has quickly become a trusted name in the display technology industry. The company's commitment to innovation and excellence has earned them a loyal customer base and industry recognition.As demand for premium home entertainment experiences continues to grow, Frame Screens remains at the forefront of the industry, offering a diverse range of display solutions designed to elevate the viewing experience for consumers. With the launch of their latest product line, the company is set to further solidify its position as a leader in the display technology market.

Upgrade Your Shakers with New Generation Replacement Wave Screens for Enhanced Performance

Title: High-Quality Replacement Screens for Hyperpool Shakers Now AvailableIntroduction:In the ever-evolving world of oil and gas drilling, the search for advanced technologies and equipment that enhance efficiency and performance never ceases. The demand for reliable and durable shaker screens to optimize drilling operations has led to the development of cutting-edge replacement screens. One such offering is the recently launched Replacement Wave Screens, engineered specifically for Derrock Hyperpool Shakers, distributed by a leading industry player.Company Introduction:XYZ Drilling Solutions is a renowned company committed to providing innovative solutions to the oil and gas industry. With years of expertise and a strong track record of excellence, XYZ Drilling Solutions has established itself as a trusted partner for enhancing drilling efficiency and productivity.With a team of highly skilled professionals and a state-of-the-art manufacturing facility, XYZ Drilling Solutions strives to meet the ever-increasing demands of the global drilling market. Their commitment to quality and continuous improvement has earned them a reputation for delivering reliable and superior products.Replacement Wave Screens for Derrock Hyperpool Shakers:XYZ Drilling Solutions has recently unveiled their latest offering – Replacement Wave Screens for Derrock Hyperpool Shakers. These screens are designed to maximize the performance and efficiency of drilling operations, addressing the challenges faced by drilling professionals worldwide.The key features of the Replacement Wave Screens include:1. Superior Performance: The Replacement Wave Screens are engineered using advanced technology to provide exceptional solids control efficiency. The innovative design allows for better separation and increased throughput, resulting in improved drilling fluid recovery and reduced waste.2. Enhanced Durability: Made from top-quality materials that ensure longevity, the Replacement Wave Screens are built to withstand the harsh conditions encountered during drilling operations. Their robust construction minimizes the chance of premature failure, reducing downtime and maintenance costs.3. Optimized Conductance: The optimized design of the Wave Screens provides enhanced fluid conductance, allowing for efficient fluid flow while effectively retaining solids. This feature improves solids control, extends screen life, and reduces overall operating costs.4. Quick and Easy Installation: The Replacement Wave Screens are designed for hassle-free installation, ensuring minimal downtime during screen changeouts. The screens can seamlessly fit onto Derrock Hyperpool Shakers, making them a convenient and reliable choice for drilling professionals.5. Compatibility: XYZ Drilling Solutions' Replacement Wave Screens are exclusively engineered to fit Derrock Hyperpool Shakers. This compatibility ensures a perfect fit, maintaining the integrity of the shaker and optimizing the overall performance."XYZ Drilling Solutions is proud to introduce our Replacement Wave Screens for Derrock Hyperpool Shakers," said John Doe, CEO of XYZ Drilling Solutions. "We have relished the opportunity to work closely with drilling professionals to develop a high-quality screen that addresses their specific needs. Our team has invested significant time and expertise to ensure that our screens maximize drilling efficiency and reduce overall operational costs."With a commitment to providing exceptional customer service, XYZ Drilling Solutions offers comprehensive technical support and guidance to assist clients in selecting the right Replacement Wave Screens for their operations. The company's extensive network of distribution centers ensures prompt and reliable delivery to customers worldwide.Conclusion:With the introduction of XYZ Drilling Solutions' Replacement Wave Screens exclusively designed for Derrock Hyperpool Shakers, the industry can embrace a new level of drilling efficiency and performance. The advanced technology employed in these screens ensures superior performance, enhanced durability, and easy installation. XYZ Drilling Solutions continues to set industry standards and reaffirms its dedication to providing innovative solutions to the global oil and gas drilling industry.

Tandem Shaker Screen: Latest News and Updates

Tandem Shaker Screen, a revolutionary new product in the field of oil and gas drilling, has been making waves in the industry due to its innovative design and superior performance. Developed by {Company}, a leading provider of drilling solutions and equipment, this cutting-edge technology is set to revolutionize the way drilling operations are conducted.The Tandem Shaker Screen is a key component in the process of separating solids and fluids during the drilling process. It is designed to handle high-capacity drilling fluids and provide exceptional performance in a variety of drilling conditions. What sets the Tandem Shaker Screen apart from traditional shaker screens is its unique tandem design, which allows for increased efficiency and improved results.One of the key features of the Tandem Shaker Screen is its high-capacity design, which enables it to handle large volumes of drilling fluids without compromising performance. This is particularly important in the oil and gas industry, where drilling operations often involve high-pressure and high-volume drilling fluids. The Tandem Shaker Screen's ability to handle these challenging conditions sets it apart as a game-changing technology in the field.Additionally, the Tandem Shaker Screen is designed to be highly durable and long-lasting, making it a cost-effective solution for drilling operations. The screen is constructed using high-quality materials and advanced manufacturing techniques, ensuring that it can withstand the rigors of drilling operations without compromising on performance. This reliability is a key factor in the Tandem Shaker Screen's appeal to drilling companies looking to improve their operations.In addition to its exceptional performance and durability, the Tandem Shaker Screen also offers a number of operational benefits for drilling companies. Its innovative tandem design allows for easier installation and maintenance, reducing downtime and increasing overall efficiency. This, combined with its high-capacity design, makes the Tandem Shaker Screen a highly practical and efficient solution for drilling operations.{Company} has a long history of providing innovative and reliable drilling solutions to the oil and gas industry. The company has built a strong reputation for excellence, and its products are trusted by drilling companies around the world. With the introduction of the Tandem Shaker Screen, {Company} is once again demonstrating its commitment to pushing the boundaries of what is possible in the field of drilling technology.The Tandem Shaker Screen is the result of extensive research and development by {Company}'s team of engineers and experts in the field of drilling technology. The company's dedication to innovation and continuous improvement is evident in the design and performance of the Tandem Shaker Screen, and it is expected to have a significant impact on the industry.In conclusion, the introduction of the Tandem Shaker Screen by {Company} represents a significant advancement in the field of drilling technology. With its innovative tandem design, high-capacity performance, and exceptional durability, the Tandem Shaker Screen is set to become a game-changing technology in the oil and gas industry. {Company} has once again proven itself as a leader in the field, and its commitment to innovation and excellence is evident in the development of this revolutionary new product.