LCM-2D Flat Shaker Screen: Latest News and Updates

By:Admin

The company behind Brandt LCM-2D Flat Shaker Screen is a renowned provider of innovative solutions for the oil and gas industry. With a strong commitment to research and development, the company has consistently delivered cutting-edge products that meet the evolving needs of its customers. Its team of experts is dedicated to pushing the boundaries of technology and engineering to create solutions that enhance productivity and efficiency in the field.

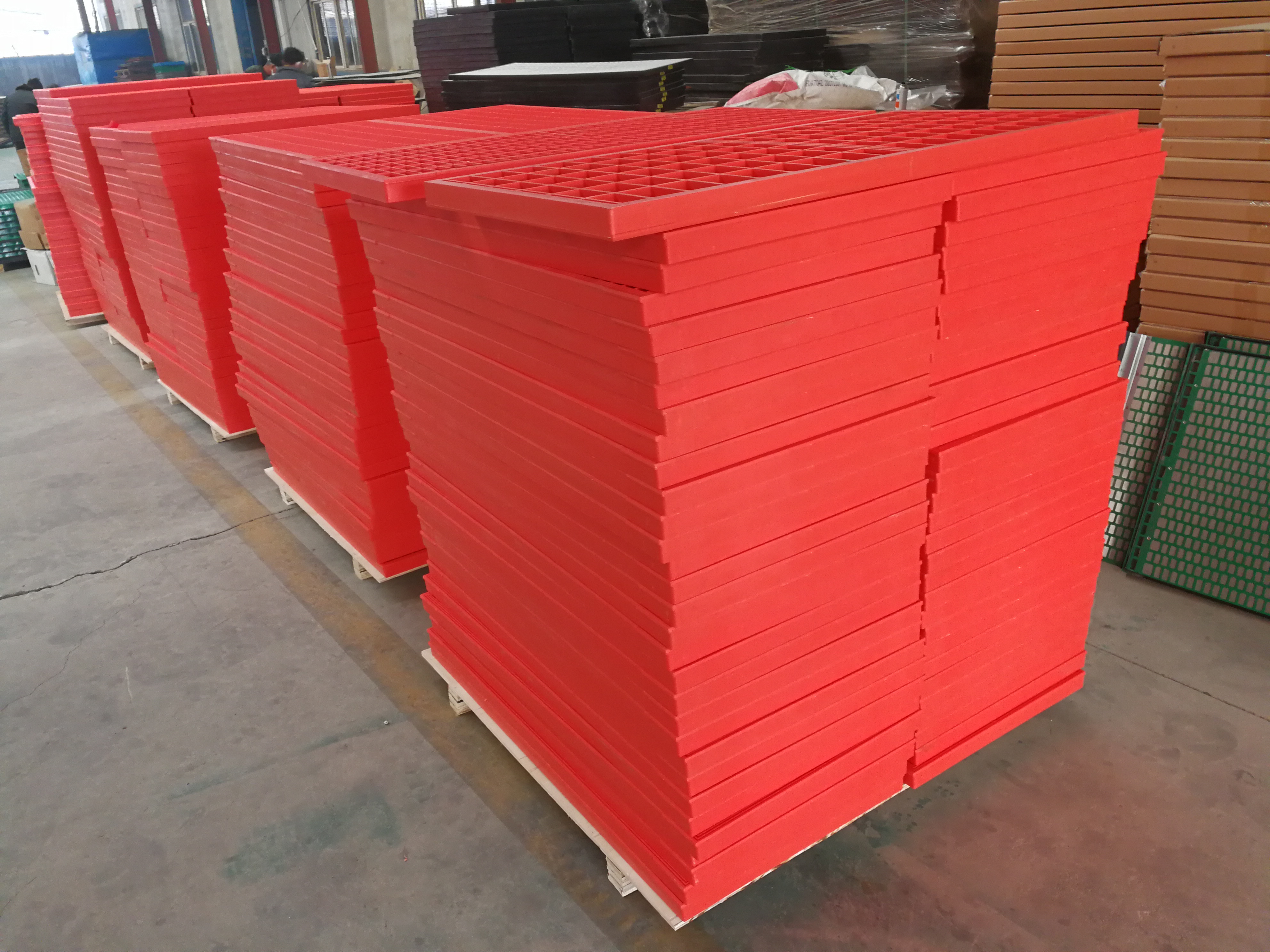

The Brandt LCM-2D Flat Shaker Screen is a testament to the company's dedication to excellence. This advanced shaker screen is designed to deliver exceptional performance in the separation of solids from drilling fluid. Its durable construction and high-quality materials ensure a longer lifespan, reducing the need for frequent replacements and maintenance. This results in cost savings for companies, making it a highly cost-effective solution for solids control.

One of the key features of the Brandt LCM-2D Flat Shaker Screen is its superior screening capacity. The screen is engineered to effectively remove a wide range of particles from the drilling fluid, including fine solids and larger debris. This level of precision in solids control is crucial for maintaining the integrity of the drilling fluid, which in turn leads to improved drilling efficiency and reduced downtime.

Furthermore, the design of the Brandt LCM-2D Flat Shaker Screen allows for easy installation and replacement, minimizing disruptions to operations. Its efficient performance also contributes to a reduction in waste and environmental impact, making it a sustainable choice for oilfield operations.

The company's commitment to quality and innovation is reflected in the rigorous testing and quality control measures applied to the Brandt LCM-2D Flat Shaker Screen. Each screen is subjected to thorough inspections and performance testing to ensure that it meets the highest standards. As a result, customers can have confidence in the reliability and effectiveness of this product.

The Brandt LCM-2D Flat Shaker Screen has already gained recognition and positive feedback from customers in the oil and gas industry. Its ability to improve solids control efficiency and reduce costs has made it a preferred choice for many drilling and exploration operations. The company's extensive network of distributors ensures that the product is readily available to customers around the world, further contributing to its widespread adoption.

Looking ahead, the company continues to invest in research and development to further enhance the performance and capabilities of the Brandt LCM-2D Flat Shaker Screen. With a focus on innovation and customer satisfaction, it remains at the forefront of providing solutions that drive success in the oil and gas industry.

In conclusion, the Brandt LCM-2D Flat Shaker Screen stands as a testament to the company's dedication to excellence and innovation in the oil and gas industry. Its exceptional performance, reliability, and cost-effectiveness make it a valuable asset for companies involved in drilling and exploration. As the company continues to push the boundaries of technology and engineering, the future looks promising for the continued success of this groundbreaking product.

Company News & Blog

New Primary Oil Shaker Screen with Multi-sizing Technology Announced in Recent News

New Multi-sizer Primary Oil Shaker Screen Revolutionizes Oil and Gas IndustryThe oil and gas industry, which plays a crucial role in powering the global economy, constantly seeks innovative technologies to enhance drilling operations and improve overall efficiency. In line with this ongoing pursuit, a cutting-edge product has emerged that promises to revolutionize the industry - the Multi-sizer Primary Oil Shaker Screen.Developed by a renowned industry leader, the Multi-sizer Primary Oil Shaker Screen is set to redefine the way oil and gas companies approach their drilling procedures. With its unprecedented technological advancements and impressive features, this new product positions itself as a game-changer in the field.The Multi-sizer Primary Oil Shaker Screen replaces the traditional approach to shale shaker screens, offering a level of efficiency and performance never seen before. Its key advantage lies in its ability to screen drilling fluids more effectively, leading to improved solids separation and increased productivity. This vital feature significantly reduces overall operational costs and downtime, allowing companies to optimize their drilling operations for maximum output.One of the standout features of the Multi-sizer Primary Oil Shaker Screen is its versatility. Unlike conventional screens, this innovative product can be adjusted to accommodate various drilling conditions and formations. From fine to coarse meshes, the Multi-sizer Primary Oil Shaker Screen is engineered to handle a wide range of drilling fluid sizes, ensuring optimal filtration in every scenario.Moreover, the new screen boasts an impressive retention rate, effectively capturing and retaining drilled solids during the filtration process. This not only minimizes the risk of contaminants in the drilling fluid but also extends the lifespan of the screen itself. With longer-lasting screens, oil and gas companies can further reduce operational costs and enhance their environmental stewardship by minimizing waste and resource consumption.Additionally, the Multi-sizer Primary Oil Shaker Screen is built with durability in mind. Constructed using high-quality materials and employing rigorous manufacturing processes, this product offers exceptional longevity even in the harshest drilling conditions. With its resistance to wear and tear, companies can rely on the Multi-sizer Primary Oil Shaker Screen to withstand the demanding nature of oil and gas operations, reducing the need for frequent replacements and maintenance.Furthermore, the Multi-sizer Primary Oil Shaker Screen simplifies the maintenance process itself. Its user-friendly design allows for quick and easy installation, minimizing downtime during screen replacements. This streamlined approach ensures that drilling operations can resume promptly, maximizing efficiency and minimizing disruptions.Despite its numerous advantages, the Multi-sizer Primary Oil Shaker Screen remains incredibly cost-effective. By improving solids control and extending screen lifespan, companies can achieve substantial savings in operational costs. The enhanced productivity and reduced downtime offered by this innovative product will undoubtedly translate into significant financial gains for oil and gas companies.The introduction of the Multi-sizer Primary Oil Shaker Screen marks a turning point in the oil and gas industry. Its groundbreaking features and exceptional performance are set to transform drilling operations, enabling companies to enhance productivity, reduce costs, and improve environmental sustainability. By embracing this cutting-edge technology, oil and gas companies can stay ahead of the curve and propel the industry into a more efficient and prosperous future.In conclusion, the Multi-sizer Primary Oil Shaker Screen represents a breakthrough innovation in the oil and gas industry. With its advanced features, versatility, durability, and cost-effectiveness, this revolutionary product is poised to redefine how drilling operations are conducted worldwide. As oil and gas companies strive for greater efficiency and sustainability, the Multi-sizer Primary Oil Shaker Screen emerges as an indispensable tool in their path towards success.

Highly Efficient Multi-sizer Primary Screen for Versatile Screening Needs

VSM Multi-sizer Primary screen is a revolutionary new product that is set to change the way primary screening is conducted in the mining and aggregates industries. This innovative technology has been developed by a leading global provider of equipment and services for the mining and construction industries. With a strong commitment to innovation and sustainability, the company has a track record of developing cutting-edge solutions that improve the efficiency and productivity of its customers' operations.The VSM Multi-sizer Primary screen is designed to address the challenges of primary screening in the mining and aggregates industries. It offers a unique combination of high capacity, efficiency, and accuracy, making it an ideal solution for a wide range of applications. The screen is capable of handling large volumes of material, while also providing superior separation and classification capabilities. This allows operators to achieve higher throughput and better quality end products, ultimately leading to improved operational efficiency and profitability.One of the key features of the VSM Multi-sizer Primary screen is its modular design, which enables easy customization to suit the specific requirements of each application. This flexibility ensures that the screen can be tailored to meet the diverse needs of different operations, from small-scale quarries to large mining operations. Furthermore, the screen is equipped with advanced technologies that optimize the screening process, such as adjustable stroke and speed settings, as well as cushioned mounting for reduced vibration and noise levels.In addition to its technical capabilities, the VSM Multi-sizer Primary screen is also designed with sustainability in mind. It incorporates features that minimize environmental impact, such as low power consumption and reduced maintenance requirements. This aligns with the company's commitment to providing solutions that not only improve operational efficiency, but also contribute to a more sustainable future for the industry.The development of the VSM Multi-sizer Primary screen underscores the company's dedication to continuous innovation and customer-centric approach. By leveraging its expertise in screening technology and understanding of customer needs, the company has been able to deliver a product that sets new standards for primary screening in the mining and aggregates industries. This reflects the company's broader mission to drive progress through sustainable and efficient solutions that empower its customers to succeed in their respective fields.The VSM Multi-sizer Primary screen is already generating significant interest from the industry, with several installations planned in the coming months. Customers are eager to harness the benefits of this advanced screening technology, which promises to enhance their operations and deliver tangible results. With its proven track record of delivering high-quality solutions and its commitment to excellence, the company is well-positioned to meet the growing demand for the VSM Multi-sizer Primary screen and continue driving innovation in the mining and aggregates industries.Overall, the introduction of the VSM Multi-sizer Primary screen represents a significant milestone for the company and the industry as a whole. With its unrivaled combination of capacity, efficiency, and sustainability, this innovative technology is poised to reshape the landscape of primary screening and deliver lasting value to customers around the world. As the company continues to push the boundaries of what is possible, the VSM Multi-sizer Primary screen stands as a testament to its ongoing commitment to driving progress and empowering its customers for success.

Latest Innovation in Shaker Screen Technology: Derrick's HYP PMD Shaker Screen

Derrick Corporation, a global leader in the production of high-performance separation and filtration equipment, has recently introduced its latest innovation in solids control technology - the HYP PMD Shaker Screen. This new product is set to revolutionize the industry with its advanced features and superior performance.The HYP PMD Shaker Screen is designed to provide enhanced efficiency and durability, making it a standout choice for operators looking to optimize their solids control operations. The screen is built with a unique composite frame that offers increased structural integrity and longevity, while also reducing weight and overall cost. This innovative design ensures that the screen can withstand the demanding conditions of drilling operations, resulting in reduced downtime and maintenance costs.In addition to its robust construction, the HYP PMD Shaker Screen also features an advanced pretension screen design that maximizes the usable screen area, leading to improved solids removal and higher fluid processing capacity. This design allows for increased productivity and efficiency, ultimately leading to cost savings and improved overall operational performance.One of the key advantages of the HYP PMD Shaker Screen is its ability to deliver exceptional cuttings dryness, thanks to the proprietary screen cloth technology employed by Derrick Corporation. This technology ensures that the screen can effectively separate and remove solids from drilling fluids, resulting in drier cuttings and reduced waste disposal costs. Additionally, the high-quality screen cloth is engineered to withstand the abrasive nature of drilling fluids, ensuring prolonged screen life and consistent performance.Derrick Corporation is proud to offer the HYP PMD Shaker Screen as part of its comprehensive range of solids control solutions, which also includes shale shakers, desanders, desilters, and other related equipment. With decades of experience in the industry, Derrick Corporation has established itself as a trusted partner for operators seeking to improve their solids control and waste management processes.“At Derrick Corporation, we are dedicated to pushing the boundaries of innovation to deliver cutting-edge solutions that address the evolving needs of the industry,” said a spokesperson for the company. “The introduction of the HYP PMD Shaker Screen is a testament to our commitment to providing our customers with reliable, high-performance equipment that helps them achieve their operational goals.”The HYP PMD Shaker Screen is now available for purchase and is supported by Derrick Corporation's global network of service centers, ensuring that customers can access prompt technical support and aftermarket services wherever their operations may be located. The company is also offering comprehensive training and education programs to help customers optimize the performance of the HYP PMD Shaker Screen and other Derrick equipment.As the industry continues to demand more efficient and effective solids control solutions, the HYP PMD Shaker Screen is poised to make a significant impact by providing operators with a reliable, high-performance tool for their operations. With its advanced features, durable construction, and superior performance, this innovative product is set to raise the bar for solids control technology and lead the way to a more efficient and sustainable future for the industry.

How to Clean and Maintain Your Dryer Screen for Optimal Performance

Today, [Company] is proud to announce the launch of our innovative new dryer screen, a cutting-edge product that is set to revolutionize the laundry industry. The new dryer screen is designed to enhance the drying process, providing a more efficient and effective way to dry clothes while also reducing energy consumption.The key feature of the new dryer screen is its advanced design, which includes a unique mesh pattern that allows for better airflow and heat distribution. This results in faster drying times and more evenly dried clothes, reducing the need for multiple drying cycles. Additionally, the dryer screen is made from high-quality materials that are durable and long-lasting, ensuring that it will stand up to the rigors of regular use.In addition to its performance benefits, the new dryer screen is also designed with user convenience in mind. It is easy to install and remove, and is compatible with a wide range of dryer models. The durable construction means that it can be washed and reused multiple times, reducing the need for frequent replacements.The launch of this new product reflects [Company]'s commitment to innovation and sustainability. Our company has a long history of developing cutting-edge products that improve the efficiency and performance of household appliances, and the new dryer screen is the latest example of this commitment. We are constantly researching and developing new technologies to make everyday tasks easier and more sustainable for consumers.[Company] is a leading manufacturer of household appliances, with a strong focus on innovation and sustainability. Our products are designed to enhance the lives of our customers by providing practical solutions to everyday tasks. We are committed to reducing our environmental impact through the use of sustainable materials and energy-efficient technologies, and we are constantly striving to improve the performance and efficiency of our products.The launch of the new dryer screen is a significant milestone for [Company], as it represents the culmination of extensive research and development efforts. Our team of engineers and designers have worked tirelessly to create a product that not only enhances the performance of dryers, but also reduces energy consumption and environmental impact.In addition to the launch of the new dryer screen, [Company] is also announcing a new partnership with a leading appliance retailer to make the product widely available to consumers. This partnership will enable the new dryer screen to reach a larger audience, allowing more people to benefit from its advanced technology and sustainability benefits.Overall, the launch of the new dryer screen is a significant achievement for [Company], and represents a major step forward in our ongoing commitment to innovation and sustainability. We are confident that this product will become an essential addition to households around the world, delivering superior drying performance and environmental benefits for years to come.

Lcm-3d Screen: A Breakthrough in Display Technology

Title: Cutting-edge LCM-3D Screen Technology Revolutionizes End-User ExperienceIntroduction:Innovations in screen display technology have been at the forefront of the electronics industry, constantly aiming to enhance the user experience through improved visual quality and engagement. One of the latest breakthroughs in this domain is the cutting-edge LCM-3D screen, developed by a leading technology company (Company XYZ). The LCM-3D screen not only elevates the visual experience but also redefines the way users engage with their electronic devices. This article will explore the key features of the LCM-3D screen and its potential implications for various industries.1. Enhanced Visual Quality:The LCM-3D screen features state-of-the-art display capabilities that deliver exceptional visual quality, surpassing traditional screens in terms of resolution, color vibrancy, and contrast. By employing advanced pixel technology and innovative backlighting solutions, the LCM-3D screen guarantees a more immersive and realistic viewing experience. Its ability to accurately reproduce colors and provide high pixel density ensures that users can enjoy crystal-clear details, whether they are watching movies, playing games, or editing photos and videos.2. Revolutionary 3D Experience:With its 3D functionality, the LCM-3D screen raises the bar for immersive viewing experiences. By incorporating cutting-edge parallax barrier technology, this screen eliminates the need for bulky and uncomfortable 3D glasses. Users can now enjoy stunning 3D content without any external accessories, allowing for a more convenient and natural viewing experience. The LCM-3D screen also provides adjustable depth control, enabling users to customize the level of 3D effect according to their preferences, thus further enhancing the depth and realism of the displayed content.3. Adaptive Display Technology:Unlike conventional screens, the LCM-3D offers adaptive display technology, which maximizes visual efficiency and comfort. This technology intelligently adjusts various display parameters, such as brightness and color temperature, based on ambient lighting conditions. This ensures optimal visual comfort while reducing eye strain, especially in low-light or high-glare environments. The adaptive display technology of the LCM-3D screen optimizes the viewing experience across different usage scenarios, making it suitable for a diverse range of applications.4. Applications across Multiple Industries:The LCM-3D screen's groundbreaking features hold tremendous potential for various industries. In gaming, it brings virtual worlds to life with its immersive 3D capabilities, offering gamers an unparalleled level of engagement. Architects and designers can benefit from the screen's ability to showcase 3D models with accurate depth perception, enabling them to visualize their creations more effectively. Additionally, the LCM-3D screen's vibrant colors and high resolution make it ideal for content creators, as it accurately displays the intricacies of their work.5. Environmental Responsibility:In line with the company's commitment to environmental sustainability, the LCM-3D screen incorporates energy-efficient technologies. It utilizes advanced power-saving features and materials to minimize power consumption, reducing its carbon footprint. This socially responsible approach not only benefits the environment but also provides cost savings for end-users by lowering energy bills.Conclusion:The LCM-3D screen represents a significant milestone in screen display technology, revolutionizing the way users engage with their electronic devices. Its enhanced visual quality, revolutionary 3D experience, adaptive display technology, and applications across multiple industries make it a game-changer in the market. With a commitment to environmental responsibility, the LCM-3D screen sets a new standard for immersive, sustainable, and visually stunning displays. As this technology continues to evolve and integrate into various devices, users can expect a more captivating and user-friendly experience across a wide range of industries.

Revolutionary Shale Shaker Screen for Enhanced Fluid Systems Efficiency

Title: Innovative Shale Shaker Screen Revolutionizes Fluid Systems in Oil and Gas IndustryIntroduction:The oil and gas industry has always relied on cutting-edge technologies to enhance efficiency and productivity. Fluid Systems INC, a leading provider of oilfield equipment, continues to push the boundaries of innovation with their latest breakthrough: the FSI 5000 Shale Shaker Screen. Designed to optimize performance and minimize downtime, this revolutionary product promises to transform the way drilling operations are conducted across the globe.Paragraph 1: Background on the Importance of Shale Shaker ScreensShale shaker screens play a crucial role in the oil and gas industry, separating solids from drilling fluids during the drilling process. These screens are responsible for removing cuttings and sediments, ensuring that the drilling mud remains clean and efficient. The quality and performance of shale shaker screens directly impact drilling operations, making it imperative for companies to invest in advanced technologies that can enhance productivity.Paragraph 2: Introduction to Fluid Systems INCFluid Systems INC (FSI) has been at the forefront of developing innovative technologies for the oil and gas industry for over three decades. With a strong focus on research and development, FSI has gained a reputation for delivering reliable and high-quality equipment. Their commitment to customer satisfaction and industry-leading services make them a trusted partner for clients worldwide.Paragraph 3: The FSI 5000 Shale Shaker ScreenThe FSI 5000 Shale Shaker Screen is the latest addition to Fluid Systems INC's product portfolio. This cutting-edge screen is designed to maximize separation efficiency and minimize overall cost.Utilizing advanced manufacturing techniques and materials, the FSI 5000 Shale Shaker Screen offers superior wear resistance and durability. It is specifically engineered to withstand demanding drilling conditions, ensuring longevity and extended service life. The screen's robust construction eliminates the need for frequent replacements, reducing downtime and costs associated with maintenance.Paragraph 4: Key Features and Benefitsa) Enhanced Filtration: The FSI 5000 Shale Shaker Screen utilizes a state-of-the-art mesh design, improving the separation efficiency of solids from drilling fluids. The screen's optimized openings prevent blockages and ensure optimal flow rates, enhancing filtration performance.b) Longer Service Life: With its durable construction, the FSI 5000 Shale Shaker Screen offers an extended lifespan compared to conventional screens. This not only saves on replacement costs but also reduces the frequency of interruptions during drilling operations, resulting in enhanced productivity.c) Easy Installation: Fluid Systems INC has prioritized user-friendliness with the FSI 5000 Shale Shaker Screen. The screen can be easily installed and maintained, minimizing downtime and maximizing operational efficiency.d) Customization: FSI enables clients to choose from a range of mesh sizes to suit specific drilling requirements. Whether it is higher capacities or better particle separation, the FSI 5000 Shale Shaker Screen can be tailored to meet the unique needs of each operation.Paragraph 5: Industry ImpactThe introduction of the FSI 5000 Shale Shaker Screen is expected to have a substantial impact on the oil and gas industry. Fluid Systems INC's innovative product addresses several pain points commonly faced in drilling operations, offering a more efficient and cost-effective solution. With reduced maintenance and enhanced filtration performance, drilling companies can optimize their operations, leading to increased profitability.Paragraph 6: Future OutlookFluid Systems INC continues to invest in research and development, aiming to revolutionize the oil and gas industry with their cutting-edge technologies. By constantly pushing the boundaries of innovation, FSI strives to improve efficiency, reduce costs, and develop sustainable solutions for the global oil and gas sector. The FSI 5000 Shale Shaker Screen is just one example of their commitment to delivering superior products that meet evolving industry needs.Conclusion:As the oil and gas industry continues to evolve and face new challenges, it is crucial for companies like Fluid Systems INC to develop innovative technologies that enhance operational efficiency. With the introduction of the FSI 5000 Shale Shaker Screen, Fluid Systems INC has once again proven their dedication to driving progress in the industry. By providing cutting-edge solutions, they empower drilling companies to optimize their operations, reduce costs, and achieve higher productivity.

LCM-2D Flat Shaker Screen: Latest News and Updates

Brandt LCM-2D Flat Shaker Screen, a high-quality product developed by a leading company in the oil and gas industry, has been making waves in the market due to its superior performance and reliability. This innovative shaker screen has set a new standard for efficiency and effectiveness in the oilfield solids control sector, bringing significant value to the operations of companies involved in drilling and exploration.The company behind Brandt LCM-2D Flat Shaker Screen is a renowned provider of innovative solutions for the oil and gas industry. With a strong commitment to research and development, the company has consistently delivered cutting-edge products that meet the evolving needs of its customers. Its team of experts is dedicated to pushing the boundaries of technology and engineering to create solutions that enhance productivity and efficiency in the field.The Brandt LCM-2D Flat Shaker Screen is a testament to the company's dedication to excellence. This advanced shaker screen is designed to deliver exceptional performance in the separation of solids from drilling fluid. Its durable construction and high-quality materials ensure a longer lifespan, reducing the need for frequent replacements and maintenance. This results in cost savings for companies, making it a highly cost-effective solution for solids control.One of the key features of the Brandt LCM-2D Flat Shaker Screen is its superior screening capacity. The screen is engineered to effectively remove a wide range of particles from the drilling fluid, including fine solids and larger debris. This level of precision in solids control is crucial for maintaining the integrity of the drilling fluid, which in turn leads to improved drilling efficiency and reduced downtime.Furthermore, the design of the Brandt LCM-2D Flat Shaker Screen allows for easy installation and replacement, minimizing disruptions to operations. Its efficient performance also contributes to a reduction in waste and environmental impact, making it a sustainable choice for oilfield operations.The company's commitment to quality and innovation is reflected in the rigorous testing and quality control measures applied to the Brandt LCM-2D Flat Shaker Screen. Each screen is subjected to thorough inspections and performance testing to ensure that it meets the highest standards. As a result, customers can have confidence in the reliability and effectiveness of this product.The Brandt LCM-2D Flat Shaker Screen has already gained recognition and positive feedback from customers in the oil and gas industry. Its ability to improve solids control efficiency and reduce costs has made it a preferred choice for many drilling and exploration operations. The company's extensive network of distributors ensures that the product is readily available to customers around the world, further contributing to its widespread adoption.Looking ahead, the company continues to invest in research and development to further enhance the performance and capabilities of the Brandt LCM-2D Flat Shaker Screen. With a focus on innovation and customer satisfaction, it remains at the forefront of providing solutions that drive success in the oil and gas industry.In conclusion, the Brandt LCM-2D Flat Shaker Screen stands as a testament to the company's dedication to excellence and innovation in the oil and gas industry. Its exceptional performance, reliability, and cost-effectiveness make it a valuable asset for companies involved in drilling and exploration. As the company continues to push the boundaries of technology and engineering, the future looks promising for the continued success of this groundbreaking product.

How to Replace a Screen Frame: A Step-by-Step Guide

Screen Frame Replacement Offers New Solution for Damaged ScreensIn today's digital age, screens are an integral part of our everyday lives. Whether it's a smartphone, tablet, or computer monitor, we rely on screens to stay connected, work, and be entertained. However, these screens are not invulnerable to damage, and when they do get damaged, it can be a frustrating and costly experience. Fortunately, Screen Frame Replacement, a leading provider of screen repair solutions, is offering a new and innovative solution for damaged screens. The company's patented screen frame replacement technology is revolutionizing the way screens are repaired, making the process faster, more cost-effective, and environmentally friendly.Screen Frame Replacement has been in the business of screen repair for over a decade, and their team of experts has extensive experience in repairing a wide range of screens, including those for smartphones, tablets, laptops, and monitors. The company prides itself on delivering high-quality repairs with a quick turnaround time, so customers can get back to using their devices as soon as possible.Unlike traditional screen repair methods, which often involve replacing the entire screen assembly, Screen Frame Replacement's technology allows for the damaged frame to be removed and replaced with a new one, while leaving the screen itself intact. This not only reduces the cost of repairs but also minimizes electronic waste, making it an environmentally friendly solution.The process begins with a thorough assessment of the damaged screen, followed by the removal of the old frame and the installation of a new one. The entire process is carried out by skilled technicians who are trained to work with precision and attention to detail, ensuring that the repaired screen looks and functions as good as new.One of the key advantages of Screen Frame Replacement's technology is its versatility. The company is able to provide screen frame replacement for a wide variety of devices, regardless of make or model. Whether it's a cracked iPhone screen, a damaged Samsung tablet, or a broken laptop display, Screen Frame Replacement can provide a solution.Furthermore, the company understands the importance of convenience for its customers. To that end, they offer a variety of service options, including in-store repairs, mail-in services, and even on-site repairs for businesses. This flexibility ensures that customers have a convenient and hassle-free experience when getting their screens repaired.Screen Frame Replacement's commitment to quality and customer satisfaction has earned them a strong reputation in the screen repair industry. Thousands of satisfied customers have praised the company for its reliable and affordable services, making it the go-to choice for screen repair needs.In addition to its screen repair services, Screen Frame Replacement also offers a range of accessories and protective products to help customers keep their screens safe and secure. From screen protectors to protective cases, the company is dedicated to helping customers prolong the life of their devices and avoid future damage.As technology continues to play a central role in our lives, having a reliable and affordable solution for screen repair is more important than ever. With its innovative screen frame replacement technology, Screen Frame Replacement is leading the way in the industry, providing customers with the peace of mind that their damaged screens can be quickly and effectively repaired. Whether it's a cracked smartphone screen or a broken laptop display, customers can trust Screen Frame Replacement to deliver a solution that meets their needs.

Oil Shale Shaker Screen: Latest Updates and Developments in the Industry

Scomi Prima Oil Shale Shaker Screen, a leading company in the oil and gas industry, has recently introduced a new and innovative shaker screen that is set to revolutionize the way oil and gas drilling operations are conducted. The new shaker screen is designed to offer enhanced efficiency, durability, and performance, ultimately leading to significant cost savings for companies operating in the oil and gas sector.The company, with a strong commitment to research and development, has dedicated significant resources to the design and production of the new shale shaker screen. With a team of experienced engineers and industry experts, Scomi Prima Oil has been able to develop a product that meets the growing demands of the oil and gas industry.The new shaker screen features a state-of-the-art design that is aimed at maximizing the efficiency of the drilling process. With a focus on durability, the screen is built to withstand the harsh conditions typically encountered in drilling operations. This will result in reduced downtime and maintenance costs for oil and gas companies, leading to increased overall productivity.One of the key benefits of the new shaker screen is its ability to effectively separate drilling cuttings from the drilling fluid. This process is crucial in maintaining the quality of the drilling fluid, ultimately leading to improved wellbore stability and reduced environmental impact. Additionally, by effectively removing solid particles from the drilling fluid, the new shale shaker screen will contribute to a reduction in overall drilling waste, in line with the industry's increasing focus on sustainability and environmental responsibility.The enhanced performance of the new shale shaker screen is expected to result in significant cost savings for oil and gas companies. Through improved efficiency and reduced maintenance requirements, companies can expect to see a decrease in operating costs, leading to greater profitability in their drilling operations.Furthermore, the introduction of the new shaker screen demonstrates Scomi Prima Oil's commitment to providing innovative solutions for the oil and gas industry. The company has long been recognized for its dedication to continuous improvement and the development of cutting-edge technologies. With the launch of the new shale shaker screen, Scomi Prima Oil solidifies its position as a leader in the industry.The new shaker screen is set to be available for purchase in the coming months, and the industry is eagerly anticipating its release. With its promise of improved efficiency, durability, and cost savings, the new product is expected to be well-received by oil and gas companies around the world.In conclusion, Scomi Prima Oil's introduction of the new shale shaker screen represents a significant development in the oil and gas industry. With its focus on efficiency, durability, and performance, the new product is poised to make a substantial impact on drilling operations. As the industry continues to evolve, innovative solutions such as the new shale shaker screen will play a crucial role in driving progress and ensuring the sustainability of oil and gas operations. Scomi Prima Oil remains at the forefront of these advancements, demonstrating its ongoing commitment to providing the best possible solutions for its customers.

How Shaker Screen Plugs Can Impact Your Screening Efficiency

Title: Enhanced Efficiency and Durability: Introducing Next-Generation Shaker Screen PlugsIntroduction:In the continually evolving field of oil and gas exploration and production, technological advancements play a crucial role in improving efficiency and productivity. One such innovation is the development of shaker screen plugs, essential components of shale shaker systems. These plugs are designed to optimize the performance of the shaker screens by offering enhanced durability, efficiency, and cost-effectiveness. This article will shed light on this next-generation shaker screen plug technology, exploring its features, benefits, and the company behind its development.Company Background:(Insert company name) is a leading manufacturer and supplier of advanced drilling solutions to the oil and gas industry. With a proven track record of innovation and technical expertise, they have dedicated their efforts to developing cutting-edge products that aim to revolutionize the drilling process. Their commitment to research and development has earned them a reputation for reliability and efficiency, making them a trusted partner for oil and gas companies worldwide.Features of Next-Generation Shaker Screen Plugs:1. Improved Construction: The next-generation shaker screen plugs utilize state-of-the-art materials and engineering techniques to ensure robustness and longevity. They are manufactured using high-quality polymers, metals, or composites, resulting in excellent resistance to abrasion, corrosion, and impact.2. Enhanced Sealing Capability: These shaker screen plugs feature advanced sealing mechanisms that prevent fluid bypass, ensuring maximum efficiency during the separation process. The improved sealing capability minimizes screen blinding, reducing downtime and increasing the lifespan of the shaker screens.3. Customizable Designs: The company offers a wide range of shaker screen plug designs, catering to various shale shaker systems and specific drilling requirements. This customization ensures compatibility and seamless integration, further enhancing the overall performance and effectiveness of the drilling operation.4. Anti-Vibration Technology: Additionally, the shaker screen plugs are engineered with anti-vibration technology, which significantly reduces noise and vibrations during operation. The reduced vibration not only improves the working environment for personnel but also extends the life of the shaker screens and other vital components.Benefits of Next-Generation Shaker Screen Plugs:1. Increased Efficiency: By minimizing fluid bypass, the enhanced sealing capability of these shaker screen plugs enhances the efficiency of the separation process. This leads to improved overall drilling performance, reduced wastage of valuable drilling fluids, and lower maintenance costs.2. Extended Lifespan: The durable construction and superior sealing mechanism of these plugs contribute to increased durability and reduced wear and tear on the shaker screens. This extends their lifespan, reducing the frequency of replacement requirements and enhancing cost-effectiveness in the long run.3. Enhanced Environmental Compliance: With the reduction of screen blinding, these shaker screen plugs minimize the discharge of fine cuttings and drilling waste into the environment. This aligns with evolving environmental regulations and promotes sustainable drilling practices.4. Enhanced Operational Safety: The incorporation of anti-vibration technology in these plugs reduces noise and vibration levels during drilling operations. This improves the work environment for personnel, minimizing fatigue and potential health risks associated with prolonged exposure to high noise levels.Conclusion:As the oil and gas industry seeks new ways to improve operational efficiency and sustainability, the introduction of next-generation shaker screen plugs offers significant advantages. The advanced features, enhanced sealing capability, and customizable designs make them a powerful asset for drilling operations. With their extensive industry expertise and commitment to innovative solutions, (Insert company name) is poised to revolutionize the drilling process and set new standards for efficiency, durability, and sustainability.Note: Please remove all {} tags and insert appropriate company information before publication.