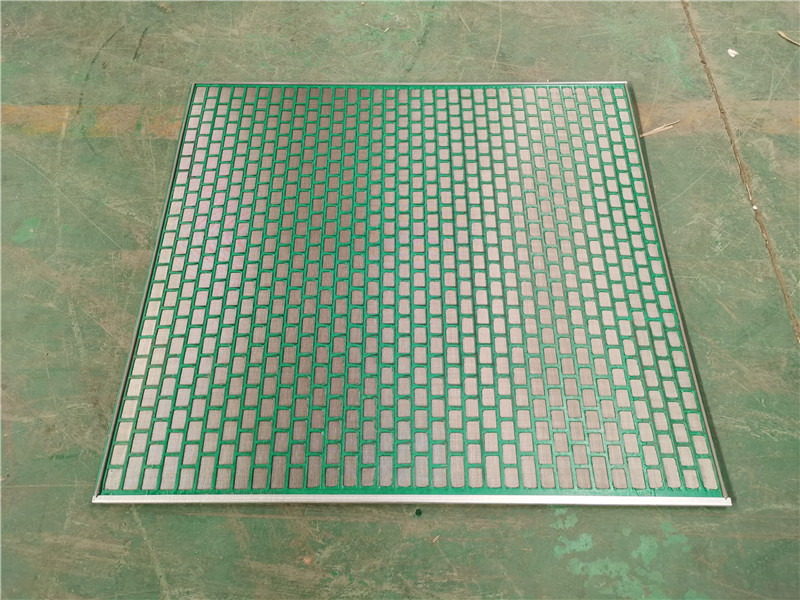

Highly Efficient Shaker Screen for Swaco Mongoose Model

By:Admin

With an extensive background in manufacturing and supplying equipment to the oil and gas industry, {company name} has dedicated itself to providing top-notch shaker screens that meet the highest standards. The company is committed to delivering quality products and exceptional service to its customers, and the Swaco Mongoose Shaker Screen is no exception.

The Swaco Mongoose Shaker Screen offered by {company name} is designed to provide superior performance and durability in demanding drilling operations. It is constructed with high-quality materials and advanced technology to ensure efficient and effective solid control. The shaker screen is engineered to withstand the harsh conditions of drilling operations and to deliver consistent and reliable performance.

One of the key features of the Swaco Mongoose Shaker Screen offered by {company name} is its high conductance design, which allows for increased flow capacity and improved solids removal. This design is crucial for enhancing the efficiency of the drilling process and reducing operating costs. Additionally, the shaker screen is designed with a durable frame and advanced mesh technology to provide long-lasting performance and reliability.

{company name} takes pride in ensuring that its Swaco Mongoose Shaker Screen meets the highest industry standards for quality and performance. The company’s commitment to excellence is reflected in its rigorous quality control processes and testing procedures. Each shaker screen undergoes thorough inspection and testing to ensure that it meets the company’s stringent standards for quality and performance.

In addition to offering high-quality products, {company name} is also dedicated to providing exceptional service to its customers. The company’s team of experienced professionals is committed to delivering reliable technical support and timely assistance to customers. {company name}’s expertise and dedication to customer satisfaction has earned it a strong reputation in the industry.

Furthermore, {company name} understands the importance of environmental responsibility and sustainability in the oil and gas industry, and the company is committed to providing eco-friendly solutions. The Swaco Mongoose Shaker Screen offered by {company name} is designed to minimize environmental impact and reduce waste generation. The use of advanced technology and materials in the manufacturing process helps to promote sustainable practices and reduce the environmental footprint of drilling operations.

Overall, {company name}’s Swaco Mongoose Shaker Screen is a top-of-the-line product that offers superior performance, durability, and reliability. With its commitment to quality, exceptional service, and environmental responsibility, {company name} is a trusted partner for customers in the oil and gas industry. The company’s dedication to excellence and innovation sets it apart as a leading provider of shaker screens and solid control equipment. Customers can rely on {company name} to provide high-quality products and exceptional service that meet their needs and exceed their expectations.

Company News & Blog

Oil Shale Shaker Screen BEM-650 for MI Swaco - All You Need to Know

MI Swaco BEM-650 Oil Shale Shaker Screen is a newly developed product that has been making waves in the oil and gas industry. This advanced shaker screen is designed to effectively remove solids from drilling fluids while also delivering higher flow rates and longer screen life. As a result, it has quickly gained popularity among companies in the oil and gas sector.The BEM-650 Oil Shale Shaker Screen is manufactured by a well-established company that has been at the forefront of providing innovative solutions for the oil and gas industry. With years of experience and a strong focus on research and development, the company has been able to create products that are not only efficient but also cost-effective. The BEM-650 Shaker Screen is yet another example of the company's commitment to delivering high-quality solutions to its customers.One of the key features of the BEM-650 Oil Shale Shaker Screen is its superior performance in removing solids from drilling fluids. This is crucial in the oil and gas industry, as the presence of solids in drilling fluids can cause a range of issues, including reduced efficiency and equipment damage. By effectively removing these solids, the BEM-650 Shaker Screen helps companies to maintain the quality of their drilling fluids and ensure smooth operations.In addition to its solid removal capabilities, the BEM-650 Oil Shale Shaker Screen also offers higher flow rates compared to traditional shaker screens. This means that companies can process larger volumes of drilling fluids in a shorter amount of time, resulting in increased productivity and reduced downtime. Furthermore, the screen is designed to have a longer life, which helps companies save on replacement costs and maintenance expenses.The development of the BEM-650 Oil Shale Shaker Screen is a testament to the company's ongoing efforts to innovate and improve its product offerings. By leveraging cutting-edge technologies and manufacturing processes, the company has been able to create a product that meets the evolving needs of the oil and gas industry. Moreover, the company has a strong commitment to quality and reliability, ensuring that its products perform consistently in the harshest operating environments.As the oil and gas industry continues to face challenges in drilling operations, the demand for efficient and reliable equipment has never been greater. The BEM-650 Oil Shale Shaker Screen addresses this demand by providing a solution that not only improves operational efficiency but also reduces costs. With a focus on performance, durability, and cost-effectiveness, the BEM-650 Shaker Screen is poised to become a staple in drilling operations worldwide.In conclusion, the introduction of the BEM-650 Oil Shale Shaker Screen represents a significant advancement in the oil and gas industry. With its superior solid removal capabilities, higher flow rates, and longer screen life, the BEM-650 Shaker Screen is a game-changer for companies looking to optimize their drilling operations. As the company behind this innovative product continues to push the boundaries of technology and engineering, it is clear that the future of the oil and gas industry is brighter than ever.

High-Quality BEM-650 Shaker Screen for OEM Equipment

Shaker screens are a crucial component in the oil and gas industry, used in the process of separating solids from drilling fluid. This allows for the efficient and cost-effective removal of solid particles from the fluid, which is essential for maintaining the quality and performance of the drilling operation. One company that has been at the forefront of developing high-quality shaker screens for the oil and gas industry is {company}.{Company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has a strong reputation for delivering innovative and reliable products that meet the needs of its customers. With a focus on quality and performance, {company} has become a trusted partner for many drilling operations around the world.One of the flagship products from {company} is the BEM-650 shaker screen. This shaker screen is designed to provide superior performance in the separation of solids from drilling fluid. The BEM-650 is known for its durability and efficiency, making it a popular choice among drilling operators.The BEM-650 shaker screen is designed to fit OEM Swaco shakers, making it a versatile and compatible option for many drilling operations. The screen features a high-quality mesh that is capable of effectively separating a wide range of solid particles from the drilling fluid. This is essential for maintaining the integrity of the fluid and ensuring that the drilling operation runs smoothly and efficiently.In addition to its superior performance, the BEM-650 shaker screen is also known for its durability. The screen is built to withstand the harsh conditions of the drilling environment, ensuring that it remains effective and reliable even in challenging circumstances. This level of reliability is crucial for drilling operators, who rely on their equipment to perform consistently in order to maintain the quality and efficiency of their operations.{Company} is committed to delivering high-quality products and exceptional customer service. The company works closely with its customers to understand their needs and develop solutions that meet their specific requirements. This customer-focused approach has helped {company} build strong and lasting relationships with its clients, who trust the company to deliver reliable and effective equipment for their drilling operations.With a track record of innovation and excellence, {company} continues to lead the way in the development of shaker screens and other equipment for the oil and gas industry. The company's dedication to quality, performance, and customer satisfaction has made it a trusted partner for drilling operators around the world.As the demand for reliable and efficient equipment in the oil and gas industry continues to grow, {company} is well-positioned to meet the needs of its customers. With its high-quality products and commitment to excellence, the company is poised to remain a leader in the development of shaker screens and other equipment for the drilling industry.In conclusion, {company} is a top manufacturer of shaker screens and other equipment for the oil and gas industry. The company's commitment to quality and performance is evident in its flagship product, the BEM-650 shaker screen. With its superior performance and durability, the BEM-650 is a popular choice among drilling operators. Combined with {company}'s dedication to customer service and innovation, the company is well-positioned to remain a leader in the development of equipment for the oil and gas industry.

Discover Affordable and High-Quality Shaker Screens Available for Purchase

Shaker Screens for Sale: Enhanced Performance and Efficiency in Industrial ProcessesIn the rapidly evolving landscape of industrial processes, the demand for efficient and reliable machinery has never been higher. Among the various components used in industries such as oil and gas, mining, and wastewater management, shaker screens play a vital role in ensuring smooth operations and improved productivity. With a commitment to delivering high-quality equipment, {Company Name} has emerged as a trusted provider of shaker screens for sale, revolutionizing the way industries function.In an era where extracting resources from the earth has become increasingly complex, shaker screens have proven to be indispensable tools. These screens are primarily used in the drilling industry to extract valuable materials such as oil and gas from beneath the earth's surface. Shaker screens are installed on shale shakers, which vibrate at high frequencies to separate solids from drilling fluids or mud. By removing unwanted solids, shaker screens prevent clogging of drilling equipment, boost efficiency, and help maintain the integrity of drilling fluids.Recognizing the crucial role shaker screens play, {Company Name} has invested significant resources in research and development to create cutting-edge products that cater to the diverse needs of industries worldwide. Tapping into the expertise of a dedicated team of engineers and technicians, they have developed a range of shaker screens that offer enhanced performance and durability.One of the key innovations from {Company Name} is the use of advanced mesh technology in their shaker screens. These screens are constructed with precision-woven mesh, ensuring a uniform distribution of openings throughout the surface. This design feature allows for efficient filtration and separation of different particle sizes, leading to improved solids control. Additionally, the advanced mesh technology enhances screen life, reducing the frequency of replacements and thereby minimizing downtime.Moreover, {Company Name} understands the importance of customization in meeting the unique requirements of various industries. They offer an extensive range of shaker screens in different sizes and configurations, allowing customers to select the most suitable option for their specific applications. Whether it is a small-scale mining operation or a large-scale oil drilling project, {Company Name} has the capability to provide tailor-made solutions, ensuring optimal performance and cost-effectiveness.Furthermore, environmental sustainability has become a critical consideration for industries across the globe. Recognizing this, {Company Name} has incorporated eco-friendly practices into their manufacturing processes. They have implemented measures to reduce energy consumption and minimize waste generation. By using recyclable materials and adhering to stringent quality standards, {Company Name} ensures that their shaker screens not only enhance efficiency but also contribute to a greener future.In addition to providing industry-leading products, {Company Name} places great emphasis on customer satisfaction and after-sales support. Their team of technical experts is readily available to provide guidance and assistance, ensuring seamless integration of shaker screens into existing equipment. Furthermore, {Company Name} offers prompt delivery services and robust warranty programs to instill trust and confidence in their customers.As industries continue to evolve, shaker screens will remain essential components of various processes. With its commitment to innovation, customization, and sustainability, {Company Name} has emerged as a reputable and reliable provider of shaker screens for sale. By continually pushing the boundaries of technology, they empower industries to achieve higher levels of productivity, efficiency, and environmental responsibility.In conclusion, shaker screens have become indispensable for industries that rely on efficient solids control. {Company Name} has positioned itself as a leader in this sector by offering high-quality shaker screens that deliver improved performance, durability, and environmental sustainability. With their commitment to customer satisfaction and cutting-edge technology, {Company Name} continues to redefine the standards for shaker screens, driving progress in industrial processes worldwide.

New and Innovative 26-Inch Screen Released in Latest Tech News

Kemtron 26 Screen, a leading provider of advanced display solutions, has recently unveiled their latest cutting-edge technology in the form of a high-performance screen that is set to revolutionize the display industry. With a focus on delivering exceptional image quality and ultimate user experience, the new Kemtron 26 Screen represents a significant leap forward in display technology.The Kemtron 26 Screen features a stunning 26-inch display with a resolution of 3840 x 2160 pixels, delivering crystal-clear images with vivid colors and incredible detail. This level of resolution is unprecedented in a screen of this size, making it ideal for a wide range of applications including professional use in design, editing, and content creation, as well as for immersive entertainment experiences.One of the key features of the Kemtron 26 Screen is its advanced HDR (High Dynamic Range) technology, which enables it to deliver a wider range of colors and greater contrast, resulting in a more lifelike and immersive viewing experience. This makes the screen ideal for content creators and consumers who demand the utmost in visual quality.The Kemtron 26 Screen also boasts a refresh rate of 120Hz, ensuring smooth and fluid motion, making it perfect for gaming and other fast-paced applications. Additionally, the screen features a low input lag, minimizing the delay between input from the user and the corresponding action on the screen, further enhancing the overall responsiveness and performance of the display.In terms of design, the Kemtron 26 Screen has been meticulously crafted to be sleek and modern, with a slim profile and minimal bezels, making it an attractive addition to any professional or home setup. The screen is also equipped with a range of connectivity options including multiple HDMI and DisplayPort inputs, as well as built-in speakers and a headphone jack for a complete audio-visual experience.Speaking about the launch of the new Kemtron 26 Screen, the company's CEO stated, "We are thrilled to introduce our latest display technology that sets new standards for image quality and performance. The Kemtron 26 Screen represents the culmination of years of research and development, and we are confident that it will exceed the expectations of even the most discerning users."The CEO further added, "At Kemtron, we are committed to pushing the boundaries of display technology and delivering innovative solutions that empower our customers to unleash their creativity and fully immerse themselves in their work and entertainment. With the Kemtron 26 Screen, we are proud to offer a display that truly redefines what is possible."The Kemtron 26 Screen is set to be available for purchase in the coming months, and it is expected to attract attention from professionals in creative industries, as well as enthusiasts who seek the best in display technology. With its exceptional image quality, advanced features, and elegant design, the Kemtron 26 Screen is poised to make a significant impact in the display market and cement Kemtron's position as a leader in the industry.

- High-Quality Vibration Screen Mesh for Shale Shaker Screens

Vibration Screen Mesh Shale Shaker Screen to Improve Drilling EfficiencyThe global oil and gas industry is constantly evolving, and with it, the technology and equipment used in drilling operations. One such advancement is the development of high-quality vibration screen mesh shale shaker screens, designed to improve the efficiency and effectiveness of drilling processes.These innovative screens, also known as vibrating screens, are a crucial component of shale shakers, which are an integral part of the drilling fluid system. They are used to separate drilling cuttings from the drilling fluid, also known as mud, so that it can be recycled and reused in the drilling process. This not only reduces waste but also saves time and money for drilling companies.The key to the effectiveness of vibration screen mesh shale shaker screens lies in their design and construction. These screens are made up of multiple layers of mesh, with each layer serving a specific purpose. The first layer is responsible for catching larger particles, while the subsequent layers capture smaller and smaller particles. This ensures that the drilling fluid is thoroughly cleaned before being reused, leading to improved drilling efficiency and performance.In addition to their innovative design, these screens are also known for their durability and reliability. They are made from high-quality materials that can withstand the harsh conditions of drilling operations, including high temperatures, high pressure, and abrasive materials. This means that they can perform consistently and effectively, even in the most challenging drilling environments.One company that has been at the forefront of developing and manufacturing vibration screen mesh shale shaker screens is {Company}. With years of experience in the oil and gas industry, {Company} has established itself as a trusted supplier of high-quality drilling equipment and accessories. Their dedication to research and development has led to the creation of a range of innovative products that are designed to meet the evolving needs of the industry.{Company} prides itself on its commitment to quality and customer satisfaction. They have stringent quality control measures in place to ensure that all their products meet the highest standards of performance and reliability. This has earned them a reputation for excellence in the industry, and they have become a preferred supplier for many drilling companies around the world.In addition to their superior products, {Company} also offers exceptional customer service and support. Their team of experts is always on hand to provide technical advice, assistance with installation and maintenance, and troubleshooting for any issues that may arise. This level of support gives their customers peace of mind, knowing that they can rely on {Company} for all their drilling equipment needs.As the oil and gas industry continues to evolve, the demand for high-quality drilling equipment, such as vibration screen mesh shale shaker screens, will only continue to grow. Companies like {Company} are well-positioned to meet this demand, thanks to their dedication to innovation, quality, and customer satisfaction. With their cutting-edge products and exceptional service, {Company} is set to play a key role in improving drilling efficiency and performance for years to come.

MD Series Shakers Screen: A Breakthrough in Solids Control Technology

M-I SWACO MD Series Shakers Screen Sets New Standard for Solids Control in Oil and Gas IndustryThe oil and gas industry is constantly innovating to improve efficiency, reduce costs, and ensure environmental safety in operations. One of the key components in the drilling process is solids control equipment, which helps separate drilling cuttings from drilling fluid to maintain the quality and performance of the fluid. M-I SWACO, a leading provider of drilling fluid systems, has recently introduced the MD Series Shakers Screen, a game-changing product that is set to revolutionize solids control in the oil and gas industry.The MD Series Shakers Screen is designed to provide unmatched performance and reliability in the separation of solids from drilling fluid. It features advanced technology and innovative design to deliver higher throughput, longer screen life, and reduced maintenance, resulting in significant cost savings for drilling operations. The screen is engineered to deliver consistent and reliable performance in a wide range of drilling conditions, making it a versatile and cost-effective solution for operators.One of the key features of the MD Series Shakers Screen is its advanced composite frame, which is designed to be more durable and reliable than traditional steel frames. This innovative design helps extend the screen life, reduce maintenance costs, and minimize downtime during drilling operations. In addition, the screen’s high-quality mesh and tensioning system ensure consistent and efficient solids control, leading to improved drilling fluid quality and overall operational efficiency.The MD Series Shakers Screen also offers enhanced performance in terms of fluid handling capacity. Its larger open area and improved conductance allow for higher throughput, which means more efficient solids control and processing. This is particularly beneficial in high-volume drilling operations, where maintaining optimal drilling fluid quality is critical to the success of the operation.M-I SWACO, the company behind the MD Series Shakers Screen, is a global leader in drilling fluid systems and solutions. With a wealth of experience and expertise in the industry, the company is committed to delivering cutting-edge products and technologies that meet the evolving needs of oil and gas operators. The introduction of the MD Series Shakers Screen is a testament to M-I SWACO’s dedication to innovation and excellence in solids control and drilling fluid management.In addition to the MD Series Shakers Screen, M-I SWACO offers a comprehensive range of products and services to support drilling operations. From drilling fluid systems and filtration technologies to waste management solutions, the company provides a complete suite of offerings to help operators optimize their drilling processes and achieve superior performance and results.With a strong focus on research and development, M-I SWACO continues to drive innovation in the oil and gas industry, developing cutting-edge technologies and solutions to address the industry’s most pressing challenges. The introduction of the MD Series Shakers Screen is a testament to the company’s commitment to pushing the boundaries of solids control and delivering game-changing solutions to the market.As the oil and gas industry continues to evolve, with more demanding drilling conditions and stricter environmental regulations, the need for advanced and reliable solids control solutions has never been greater. The MD Series Shakers Screen from M-I SWACO is set to raise the bar in solids control, providing operators with a cost-effective, efficient, and durable solution to optimize their drilling fluid performance and achieve superior results.In conclusion, the introduction of the MD Series Shakers Screen by M-I SWACO marks a significant milestone in the evolution of solids control in the oil and gas industry. With its advanced technology, innovative design, and unmatched performance, the MD Series Shakers Screen is poised to set a new standard for solids control, delivering superior results and cost savings for operators. M-I SWACO’s commitment to excellence and innovation in drilling fluid management positions the company as a trusted partner for operators looking to optimize their drilling operations and achieve success in today’s competitive oil and gas industry.

Ultimate Guide to Solids Control Shale Shakers: Top Tips for Effective Mud Separation

Solids Control Shale Shaker is a vital component in the oil and gas drilling process, designed to remove large solids and debris from drilling fluids. The efficient operation of a shale shaker is crucial for maintaining the overall integrity of the drilling operation and preventing damage to downstream equipment.One of the leading providers of solids control equipment, {Company}, has recently announced the launch of their latest Shale Shaker. With a strong focus on innovation and quality, {Company} has been at the forefront of providing cutting-edge solutions for the oil and gas industry for over a decade.The new Solids Control Shale Shaker from {Company} is designed to offer enhanced performance and reliability, addressing the evolving needs of the industry. Featuring a robust and durable construction, the shale shaker is able to withstand the harsh operating conditions of drilling operations, ensuring uninterrupted performance.Equipped with advanced technology, the Solids Control Shale Shaker is capable of efficiently separating solids from drilling fluids, leading to improved overall drilling efficiency and cost savings. The shaker’s high capacity and precision screening capabilities make it a valuable asset for any drilling operation, allowing for the effective removal of unwanted solids while retaining the essential components of the drilling fluid.The innovative design of the Solids Control Shale Shaker also incorporates features aimed at reducing maintenance requirements and downtime, contributing to increased operational productivity and cost-effectiveness. With a focus on ease of use and maintenance, {Company} has ensured that their shale shaker can be seamlessly integrated into existing drilling operations without disrupting workflow.In addition to the high-performance capabilities of the Solids Control Shale Shaker, {Company} also prioritizes environmental sustainability in its design and operation. The shale shaker is equipped with efficient solid control mechanisms that minimize the environmental impact of drilling operations, aligning with industry regulations and standards.{Company} prides itself on its comprehensive support and service offerings, ensuring that their clients receive the necessary assistance and expertise to optimize the performance of their solids control equipment. From installation and commissioning to ongoing maintenance and support, {Company} is dedicated to providing a seamless experience for their customers.With a proven track record of delivering superior solids control solutions, {Company} has established itself as a trusted partner for the oil and gas industry, working with leading companies across the globe to enhance the efficiency and reliability of drilling operations.The launch of the new Solids Control Shale Shaker further solidifies {Company}’s commitment to innovation and excellence in providing cutting-edge solutions for the oil and gas sector. By offering a high-performance shale shaker that meets the evolving needs of the industry, {Company} continues to demonstrate its dedication to driving progress and efficiency in drilling operations.As the demand for efficient solids control solutions continues to grow in the oil and gas industry, {Company} remains at the forefront of delivering innovative and reliable equipment that sets the standard for quality and performance. The new Solids Control Shale Shaker serves as a testament to {Company}’s unwavering commitment to excellence and its ability to meet the evolving needs of the industry.

Latest Innovation in Shaker Screen Technology: Derrick's HYP PMD Shaker Screen

Derrick Corporation, a global leader in the production of high-performance separation and filtration equipment, has recently introduced its latest innovation in solids control technology - the HYP PMD Shaker Screen. This new product is set to revolutionize the industry with its advanced features and superior performance.The HYP PMD Shaker Screen is designed to provide enhanced efficiency and durability, making it a standout choice for operators looking to optimize their solids control operations. The screen is built with a unique composite frame that offers increased structural integrity and longevity, while also reducing weight and overall cost. This innovative design ensures that the screen can withstand the demanding conditions of drilling operations, resulting in reduced downtime and maintenance costs.In addition to its robust construction, the HYP PMD Shaker Screen also features an advanced pretension screen design that maximizes the usable screen area, leading to improved solids removal and higher fluid processing capacity. This design allows for increased productivity and efficiency, ultimately leading to cost savings and improved overall operational performance.One of the key advantages of the HYP PMD Shaker Screen is its ability to deliver exceptional cuttings dryness, thanks to the proprietary screen cloth technology employed by Derrick Corporation. This technology ensures that the screen can effectively separate and remove solids from drilling fluids, resulting in drier cuttings and reduced waste disposal costs. Additionally, the high-quality screen cloth is engineered to withstand the abrasive nature of drilling fluids, ensuring prolonged screen life and consistent performance.Derrick Corporation is proud to offer the HYP PMD Shaker Screen as part of its comprehensive range of solids control solutions, which also includes shale shakers, desanders, desilters, and other related equipment. With decades of experience in the industry, Derrick Corporation has established itself as a trusted partner for operators seeking to improve their solids control and waste management processes.“At Derrick Corporation, we are dedicated to pushing the boundaries of innovation to deliver cutting-edge solutions that address the evolving needs of the industry,” said a spokesperson for the company. “The introduction of the HYP PMD Shaker Screen is a testament to our commitment to providing our customers with reliable, high-performance equipment that helps them achieve their operational goals.”The HYP PMD Shaker Screen is now available for purchase and is supported by Derrick Corporation's global network of service centers, ensuring that customers can access prompt technical support and aftermarket services wherever their operations may be located. The company is also offering comprehensive training and education programs to help customers optimize the performance of the HYP PMD Shaker Screen and other Derrick equipment.As the industry continues to demand more efficient and effective solids control solutions, the HYP PMD Shaker Screen is poised to make a significant impact by providing operators with a reliable, high-performance tool for their operations. With its advanced features, durable construction, and superior performance, this innovative product is set to raise the bar for solids control technology and lead the way to a more efficient and sustainable future for the industry.

Highly Efficient Primary Screen for Industrial Applications Now Available

Vibrating screens are a crucial part of many industrial processes, particularly in the mining and aggregate industries. These screens are used to separate and sort materials based on size, making them essential in the production of various materials such as gravel, sand, and minerals. One company at the forefront of producing high-quality vibrating screens is {Company Name}, which has recently introduced their latest innovation, the VSM100 Primary Screen.The VSM100 Primary Screen is designed to meet the demanding requirements of the mining and aggregate industries. It is built with a focus on durability, efficiency, and ease of maintenance, making it a reliable and cost-effective solution for processing operations. This new addition to {Company Name}'s product line is set to provide customers with a highly efficient screening solution that can handle the toughest of materials.One of the key features of the VSM100 Primary Screen is its robust construction. It is built to withstand the harsh working conditions typically found in mining and aggregate operations. The screen is made from high-quality materials and is engineered to last, reducing downtime and maintenance costs for the end user.In addition to its durability, the VSM100 Primary Screen is designed for high efficiency. Its innovative design allows for a larger screening area, resulting in higher throughput and improved product quality. This means that customers can expect increased productivity and reduced operational costs when using this new vibrating screen.Another standout feature of the VSM100 Primary Screen is its ease of maintenance. The design of the screen allows for quick and simple access to critical components, making routine maintenance tasks much more straightforward. This not only minimizes downtime but also ensures that the screen operates at peak performance for longer periods between maintenance intervals.{Company Name} has a long-standing reputation for producing high-quality vibrating screens, and the VSM100 Primary Screen is no exception. The company has invested heavily in research and development to ensure that their products are at the cutting edge of technology and performance. The introduction of the VSM100 Primary Screen further solidifies {Company Name}'s position as a leader in the industry and demonstrates their commitment to providing innovative solutions to their customers.Customers can also benefit from {Company Name}'s extensive support network, which ensures that the VSM100 Primary Screen is backed by a team of experts who can provide technical assistance, spare parts, and service support as needed. This comprehensive support offering gives customers peace of mind and helps to maximize the uptime of their equipment.The introduction of the VSM100 Primary Screen is a significant milestone for {Company Name} and further establishes their position as a leading supplier of vibrating screens for the mining and aggregate industries. With its focus on durability, efficiency, and ease of maintenance, this new addition to their product line is set to make a positive impact on processing operations around the world.In conclusion, the VSM100 Primary Screen from {Company Name} is a testament to the company's dedication to developing high-quality solutions for the mining and aggregate industries. With its robust construction, high efficiency, and ease of maintenance, this new vibrating screen is poised to set a new standard for screening equipment. Customers can expect improved productivity, reduced operating costs, and reliable performance from the VSM100 Primary Screen, making it a valuable addition to any processing operation.

Highly Efficient Vibratory Shaker Screen for Separating Materials

In a world where efficiency and productivity are key, businesses are constantly on the lookout for advanced technologies that can enhance their operations. One such technology, the vibratory shaker screen, has been gaining attention for its ability to improve the screening and sorting processes in various industries.A vibratory shaker screen is a piece of equipment that uses vibration to separate materials based on their particle size. It is commonly used in industries such as mining, construction, agriculture, and recycling, where the need to separate and classify materials is paramount. The vibratory shaker screen works by applying an intense vibration to the screen deck, causing the particles to move and separate based on size, ensuring efficient and accurate screening.One of the leading providers of vibratory shaker screens is {}. With over two decades of experience in the industry, {} has established itself as a pioneer in the field of screening and separation technology. The company’s vibratory shaker screens are designed to deliver high-performance screening solutions, offering reliability, durability, and versatility to meet the diverse needs of its customers.The vibratory shaker screens offered by {} are known for their innovative design and advanced features. The company’s screens are equipped with high-quality vibratory motors that provide the necessary vibration force for efficient material separation. Additionally, the screens are designed to be easily adjustable, allowing for precise control over the screening process. This level of flexibility ensures that the screens can be tailored to the specific requirements of each application, resulting in optimal performance and productivity.In addition to the premium quality of its products, {} prides itself on providing exceptional customer service and support. The company works closely with its clients to understand their unique screening needs and offers customized solutions to address them. Furthermore, {}’s team of experienced engineers and technicians are readily available to provide technical assistance, maintenance, and repairs, ensuring that the vibratory shaker screens continue to operate at peak performance.The vibratory shaker screens from {} have been widely adopted across various industries, earning a reputation for their efficiency, reliability, and durability. These screens have been instrumental in improving the screening and sorting processes for a wide range of materials, including aggregates, minerals, chemicals, and even food products. The ability of {}’s vibratory shaker screens to handle diverse materials with precision and speed has made them a valuable asset for businesses aiming to optimize their operations.As industries continue to evolve and demand more advanced screening technologies, the vibratory shaker screens from {} are set to play a pivotal role in meeting these requirements. The company’s commitment to innovation and excellence ensures that its products will continue to be at the forefront of the industry, offering cutting-edge solutions for material separation and classification.In conclusion, the vibratory shaker screen has emerged as a game-changer in the field of material screening and separation. With {}’s extensive experience and expertise, its vibratory shaker screens are poised to revolutionize the way industries handle their screening needs, offering enhanced efficiency, productivity, and reliability. As businesses strive to stay ahead in a competitive market, the vibratory shaker screens from {} are undoubtedly a valuable investment for achieving optimal screening performance.