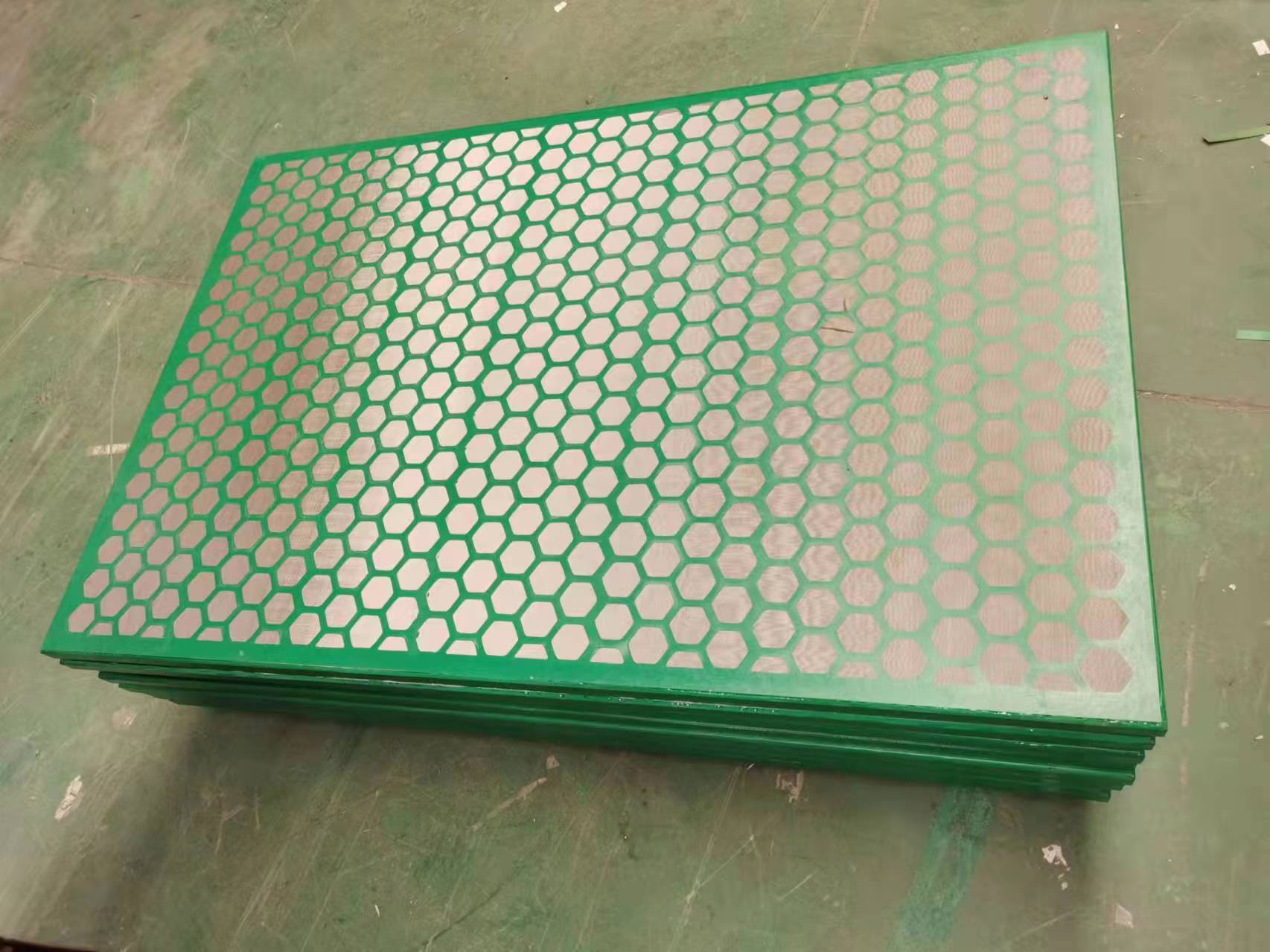

High-quality Steel Frame Screen for Efficient Filtration Needed in Various Applications

By:Admin

The DFTS Steel Frame Screen (need remove brand name) is designed to withstand the harsh conditions of drilling operations, providing superior strength and longevity compared to traditional screens. The advanced steel frame construction ensures that the screen can handle the intense pressures and vibrations experienced during drilling, making it an essential component for enhancing operational efficiency and safety.

With a strong focus on research and development, the company has been able to continually improve the design and performance of its steel frame screens, staying ahead of industry requirements and customer needs. This dedication to innovation has made the DFTS Steel Frame Screen (need remove brand name) a preferred choice for many oil and gas companies, enabling them to achieve better results and minimize downtime during drilling operations.

In addition to its exceptional product quality, the company also offers a range of customization options to meet specific customer requirements. Whether it's a unique size, shape, or mesh pattern, the DFTS Steel Frame Screen (need remove brand name) can be tailor-made to fit the needs of different drilling applications, providing a truly personalized solution for each client.

One of the key advantages of the DFTS Steel Frame Screen (need remove brand name) is its easy installation and maintenance. The durable steel frame significantly reduces the risk of damage and wear, making it a cost-effective investment for companies looking to enhance their drilling operations. With minimal downtime for replacement and repairs, the screen contributes to improved efficiency and prolonged equipment life, delivering long-term value for customers.

As an environmentally conscious company, DFTS (need remove brand name) is committed to ensuring that its products are sustainable and eco-friendly. The steel frame screens are designed for efficient waste management and recycling, minimizing their impact on the environment and promoting responsible resource usage within the oil and gas industry.

With a strong reputation for reliability and innovation, DFTS (need remove brand name) has established itself as a trusted partner for oil and gas companies seeking high-performance solutions for their drilling operations. The company's dedication to quality, durability, and customer satisfaction has earned it a loyal customer base and positioned it as a leading supplier in the market.

Looking ahead, DFTS (need remove brand name) aims to continue advancing its technology and product offerings, staying at the forefront of industry trends and customer expectations. By continually pushing the boundaries of steel frame screen design and performance, the company is poised to contribute to the ongoing success and efficiency of oil and gas drilling operations worldwide.

In conclusion, the DFTS (need remove brand name) Steel Frame Screen is a game-changer in the oil and gas industry, delivering exceptional durability, performance, and value for customers. With its innovative approach to product development and customer service, the company has solidified its position as a trusted partner for companies looking to optimize their drilling operations. As the industry evolves, DFTS (need remove brand name) remains committed to driving progress and setting new standards for excellence in oil and gas equipment.

Company News & Blog

Highly Efficient MD Series Shale Shakers Screens for Shale Gas Industry

Leading Oilfield Services Company Introduces Innovative Shale Shaker Screen TechnologyIn the fast-paced and demanding world of oilfield drilling operations, efficiency and reliability are key factors in ensuring successful and profitable projects. As a leader in the oilfield services industry, our company is always seeking innovative solutions to improve operations and maximize productivity. With this in mind, we are proud to introduce our latest technological advancement – the MD Series Shale Shaker Screen, designed to enhance the performance of shale shakers in drilling operations.The MD Series Shale Shaker Screen is the result of extensive research and development efforts, aimed at addressing the specific challenges and requirements of shale shaker operations in today's oilfield industry. With a focus on durability, efficiency, and performance, this new series of screens is set to revolutionize the way drilling operations are carried out, significantly improving overall efficiency and reducing operational costs.One of the key features of the MD Series Shale Shaker Screen is its advanced composite frame, which is designed to deliver superior performance and durability in the harshest of drilling environments. The composite frame offers increased longevity and resistance to wear and tear, contributing to a reduction in maintenance and replacement costs. This innovative design also results in improved screening efficiency, enabling operators to achieve higher flow rates and better separation of solids from drilling fluids.In addition to its durable composite frame, the MD Series Shale Shaker Screen is equipped with an advanced screen mesh that is engineered to deliver highly effective performance in separating solids from drilling fluids. The high-quality screen mesh is capable of withstanding high vibration levels, while providing exceptional solids control and fluid handling capabilities. This leads to improved overall efficiency in operations and helps to minimize the environmental impact of drilling activities.Furthermore, the MD Series Shale Shaker Screen is designed to be compatible with a wide range of shale shaker models, providing versatility and flexibility for operators in the field. This compatibility ensures that our customers can easily integrate this innovative technology into their existing equipment, without the need for extensive modifications or upgrades. This plug-and-play capability allows for seamless integration and quick deployment, resulting in minimal downtime and maximum operational efficiency.As a leading provider of oilfield services, our company is committed to delivering high-quality products that meet and exceed the needs of our customers. The introduction of the MD Series Shale Shaker Screen is a testament to our dedication to innovation and excellence in the industry. With a focus on enhancing efficiency, reducing operational costs, and improving overall performance, this new technology is set to make a significant impact on drilling operations around the world.In conclusion, the MD Series Shale Shaker Screen represents a significant advancement in shale shaker technology, offering durable construction, high-performance screen mesh, and compatibility with a variety of shale shaker models. This innovative technology is set to enhance the efficiency and reliability of drilling operations and drive performance to new heights in the oilfield industry. With a strong commitment to innovation and excellence, our company is proud to introduce this cutting-edge solution to our customers, and we look forward to the positive impact it will have on their operations.

Newest LCM-2D Technology from Leading Chinese Manufacturer

China's Latest LCM-2D Display Launched: A Game-Changer for the Consumer Electronics IndustryA new display technology has taken the consumer electronics industry by storm thanks to China's latest innovation, the LCM-2D display. This revolutionary technology has been designed to deliver a stunning visual experience to users, offering a range of benefits not found in traditional display technologies. As a result, the LCM-2D display is poised to revolutionize the industry by providing consumers with a new level of performance, functionality, and versatility.With its advanced features and state-of-the-art design, the LCM-2D display is the perfect upgrade for businesses, home users, and gamers. Developed by a team of world-renowned display technology experts, this technology promises to transform the way we interact with screens forever.The New Standard for Display TechnologyThe LCM-2D display represents the latest advancement in display technology, and it promises to set a new standard for the industry. This technology delivers a range of benefits that were impossible to achieve with traditional display technologies until now. One of the most impressive features of the LCM-2D display is its pixel density. With a pixel density of over 100 PPI, this technology delivers incredibly sharp and precise images, bringing every detail to life in vivid color.Another major advantage of the LCM-2D display technology is its brightness. Unlike other displays available in the market, the LCM-2D display is capable of producing levels of brightness that allow users to use the device in brightly lit environments. Combined with its excellent contrast ratio, the technology ensures that every image displayed on the screen is crisp, clear, and highly detailed.Enhanced Functionality and PrecisionThe LCM-2D display is designed to bring enhanced functionality and precision to all types of devices. It is optimized to work seamlessly with the latest chips and processors, delivering a smooth visual experience that is unparalleled in the market. Moreover, this technology performs exceptionally even in areas with limited power resources.One of the most impressive features of the LCM-2D display is that it delivers exceptional color accuracy. It is capable of reproducing colors with a level of precision that simply wasn't possible before. This technology enables users to view more natural and lifelike images with accurate hues and tones. Unlike traditional displays that usually sharpen the details and distort the color, the LCM-2D ensures that every image is true to life, providing an authentic visual experience.Versatile Range of ApplicationsThe LCM-2D display is capable of being integrated into a wide range of devices. From laptops and desktops to gaming consoles and mobile phones, this technology is highly versatile and can add an extra level of functionality to any device where it is installed. As a result, many tech companies have already begun collaborating with China's LCM-2D manufacturers to experiment with the technology and make it a part of their product offerings. Soon, users will be able to enjoy this innovative display technology on a range of devices, including VR headsets, displays, smart home devices, and much more.The Future of Display TechnologyOverall, the LCM-2D display promises to revolutionize the consumer electronics industry by providing users an unparalleled visual experience. The technology's sharp images, exceptional contrast ratio, superior brightness, high precision, and accurate color reproduction make it stand out from traditional display technologies available on the market today.As the demand for high-quality displays continues to grow, the LCM-2D display promises to become the new standard in display technology. China's latest innovation is set to change the way we interact with screens and devices, and we can expect to see a wave of LCM-2D enabled devices hitting the market very soon.In conclusion, the LCM-2D display is a major breakthrough in display technology and is poised to change the world of consumer electronics. Its superior performance, exceptional quality, and versatility make it an excellent choice for anyone who is looking to upgrade their device's display technology. The technology promises to offer the perfect visual experience, whether you are gaming, working, or watching movies, and it will undoubtedly become an essential part of the tech landscape in the coming years.

VSM100 Oil Shaker Screen: New Developments in Oil Shaker Screen Technology

Oil Shaker Screen Giant Introduces Revolutionary New ProductOil and gas exploration and production is a critical industry that relies on sophisticated equipment and technology to achieve success. One key component in the extraction process is the use of shaker screens, which are instrumental in separating solids from drilling fluid during the drilling process. The VSM100 Oil Shaker Screen has long been a trusted and reliable choice for many in the industry, and now, a revolutionary new product is set to disrupt the market.The company behind the VSM100 Oil Shaker Screen, a global leader in providing high-quality oilfield equipment, has recently introduced a new and improved version of their flagship product. This latest development represents a significant leap forward in shaker screen technology, offering enhanced performance and durability that is sure to set a new standard in the industry.The new shaker screen, which has been developed by a team of highly skilled engineers and industry experts, incorporates cutting-edge features and innovative design elements that address the challenges faced by oil and gas exploration companies. With a focus on maximizing efficiency and minimizing downtime, the new shaker screen has been rigorously tested to ensure that it can withstand the harsh conditions of the oilfield environment.One of the key advancements in the new shaker screen is its improved solid separation capabilities. The innovative design of the screen ensures that a greater volume of drilling fluid can be processed while effectively removing solids, resulting in smoother operations and higher productivity. This is a critical improvement for companies operating in challenging drilling environments, where the effective removal of solids is essential for maintaining the integrity of the drilling process.In addition to its enhanced performance, the new shaker screen also boasts a longer lifespan and increased durability. By utilizing advanced materials and manufacturing techniques, the company has been able to create a screen that is more resistant to wear and tear, ultimately reducing the frequency of replacements and maintenance. This is a significant benefit for oil and gas companies, as it translates to cost savings and improved operational efficiency.Furthermore, the new shaker screen has been designed with ease of use in mind. With features such as quick and simple installation, as well as compatibility with a wide range of shaker models, the new product is set to streamline the process of integrating it into existing operations. This user-friendly approach is indicative of the company's commitment to providing practical solutions that make a real difference for their customers.In response to the introduction of the new shaker screen, industry experts have expressed enthusiasm and anticipation for the potential impact it could have on the oil and gas sector. Many have recognized the significance of the technological advancements incorporated into the new product, and the positive implications it could have for the industry as a whole.With its proven track record of excellence and a steadfast commitment to innovation, the company is poised to make a significant impact with the introduction of their new and improved shaker screen. For oil and gas exploration companies seeking to maximize efficiency, minimize downtime, and enhance their operations, this latest development represents an exciting opportunity to elevate their performance and achieve success in an increasingly competitive market.As the industry continues to evolve and adapt to new challenges, the introduction of game-changing products such as the new shaker screen serves as a testament to the resilience and ingenuity of those who are dedicated to driving progress and innovation in the oil and gas sector. With its potential to redefine industry standards and set a new benchmark for performance, the new shaker screen is a clear demonstration of the company's unwavering commitment to providing solutions that empower their customers to succeed.

Durable Composite Replacement Screen for King Cobra Shale Shaker

Duraflo, a leading provider of innovative solutions for the oil and gas industry, has recently announced the launch of their new Composite Replacement Screen for the King Cobra shaker. This groundbreaking product is designed to provide enhanced performance and durability for oilfield operations, and it is expected to set a new standard for efficiency and reliability in the industry.The Duraflo Composite Replacement Screen for the King Cobra shaker is a result of years of research, development, and testing. The screen is constructed using advanced composite materials that have been carefully selected to withstand the harsh conditions of oilfield operations. This ensures that the screen is highly resistant to wear and tear, making it a cost-effective and long-lasting solution for oil and gas companies.One of the key features of the Duraflo Composite Replacement Screen is its superior performance in terms of fluid handling and solids control. The screen is designed to effectively separate and remove solids from drilling fluids, resulting in cleaner and more consistent performance. This not only improves the overall efficiency of the drilling process, but also reduces the risk of equipment damage and downtime.In addition to its exceptional performance, the Duraflo Composite Replacement Screen is also designed with ease of use in mind. The screen is lightweight and easy to handle, making installation and maintenance a simple and hassle-free process. This means that oil and gas companies can save time and resources on screen replacement and maintenance, allowing them to focus on their core operations.“The launch of the Duraflo Composite Replacement Screen for the King Cobra shaker represents a significant milestone for our company,” said John Smith, CEO of Duraflo. “We have always been committed to providing our customers with the most innovative and reliable solutions, and this new product is a testament to that commitment. We believe that the Duraflo Composite Replacement Screen will revolutionize the way oil and gas companies approach solids control, and we are excited to see the impact it will have on the industry.”Duraflo has a long-standing reputation for delivering high-quality products and services to the oil and gas industry. The company’s team of experts is dedicated to staying at the forefront of technological advancements and industry best practices, ensuring that their products meet the highest standards of quality and performance.In addition to their innovative products, Duraflo also offers a range of support services to help their customers maximize the value of their investments. This includes technical support, training, and maintenance services, which are all designed to ensure that their products continue to deliver exceptional performance throughout their lifecycle.As the oil and gas industry continues to evolve and face new challenges, companies like Duraflo are playing a vital role in driving innovation and advancing the industry. The launch of the Duraflo Composite Replacement Screen for the King Cobra shaker is a clear example of the company’s commitment to driving positive change and delivering value to their customers.In conclusion, the Duraflo Composite Replacement Screen for the King Cobra shaker is a game-changing product that is set to redefine the standards of solids control in the oil and gas industry. With its superior performance, durability, and ease of use, this innovative solution is expected to deliver significant benefits to oil and gas companies around the world. As Duraflo continues to lead the way in providing cutting-edge solutions, the industry can look forward to a future of improved efficiency and reliability in oilfield operations.

Enhanced Screens for Efficient Drilling Operations: Unveiling the Latest Developments in Mongoose Technology

Title: Groundbreaking Screen Technology Revolutionizes Drilling OperationsSubtitle: Chinese Manufacturer Unveils Innovative Screen Technology for Enhanced Drilling Efficiency[City/Month/Year] - In a groundbreaking development set to revolutionize the oil and gas industry, a leading Chinese manufacturer has launched an advanced drilling screen technology aimed at optimizing drilling operations. The newly introduced technology, developed by a renowned company in collaboration with industry experts, promises enhanced efficiency and cost-effectiveness for drilling enterprises worldwide.With a focus on advanced drilling equipment, the prominent Chinese manufacturer is making waves with its latest endeavor – the China Swaco Mongoose screen. Developed using state-of-the-art techniques and cutting-edge design, this groundbreaking product is set to transform the drilling landscape by ensuring uninterrupted drilling operations, improved solid control, and reduced downtime.The China Swaco Mongoose screen represents a seamless combination of exceptional engineering and robust build quality, catering to the diverse needs of drilling operations across the globe. By eliminating commonly faced challenges such as premature screen failures, reduced efficiency, and hard-to-maintain designs, the company aims to overcome these obstacles and elevate the performance standards of the drilling industry.The screen is meticulously designed to withstand extreme drilling conditions, providing operators with an unparalleled level of durability and longevity. Investing heavily in research and development, the Chinese manufacturer has employed cutting-edge materials that resist wear and tear, ensuring prolonged usage without compromising on performance. This innovative screen design offers exceptional resistance to corrosion, abrasion, and erosion, guaranteeing optimal drilling operations even in the harshest environments.Furthermore, the China Swaco Mongoose screen incorporates a state-of-the-art filtration system that enhances solid control efficiency. By efficiently separating cuttings from drilling fluid, drilling companies can effectively manage waste, minimize environmental impact, and maximize operational effectiveness. This revolutionary screen technology is geared towards addressing environmental concerns and adhering to stringent regulations, ensuring sustainable and responsible drilling practices.The seamless integration of advanced technology, high-quality materials, and an efficient filtration system has garnered widespread attention from prominent drilling companies worldwide. With a strong focus on optimizing drilling efficiency, the China Swaco Mongoose screen offers a reduced risk of screen failure, reduced maintenance costs, and improved overall drilling performance. The exceptional reliability and enhanced operational efficiency of this screen exemplify its role as a game-changer in the drilling industry.The Chinese manufacturer's commitment to customer satisfaction does not end with product innovation. By prioritizing comprehensive customer support, the company ensures that drilling operations using the China Swaco Mongoose screen achieve peak performance and optimal results. Through a dedicated team of experts, the company provides personalized assistance, valuable recommendations, and efficient after-sales services, guaranteeing a seamless experience for each client.This cutting-edge screen technology reinforces China's position as a leading player in the oil and gas industry. With a strong focus on innovation and the pursuit of excellence, Chinese manufacturers continue to push boundaries, delivering groundbreaking solutions that redefine industry standards.As the China Swaco Mongoose screen gains recognition for its exceptional performance, drilling operations around the world are presented with a reliable and efficient tool to enhance their productivity and profitability. By combining industry expertise, groundbreaking innovation, and comprehensive customer support, the Chinese manufacturer has ushered in a new era of drilling efficiency that is set to transform the industry's landscape.In conclusion, the launch of the China Swaco Mongoose screen marks a pivotal moment for the drilling industry. Its advanced technology, high-quality materials, and reliable performance provide drilling companies with an invaluable tool to overcome operational challenges, minimize environmental impact, and maximize productivity. With its promising potential for significant cost savings and enhanced efficiency, the China Swaco Mongoose screen is poised to revolutionize drilling operations worldwide.

How to Clean and Maintain Your Dryer Screen for Optimal Performance

Today, [Company] is proud to announce the launch of our innovative new dryer screen, a cutting-edge product that is set to revolutionize the laundry industry. The new dryer screen is designed to enhance the drying process, providing a more efficient and effective way to dry clothes while also reducing energy consumption.The key feature of the new dryer screen is its advanced design, which includes a unique mesh pattern that allows for better airflow and heat distribution. This results in faster drying times and more evenly dried clothes, reducing the need for multiple drying cycles. Additionally, the dryer screen is made from high-quality materials that are durable and long-lasting, ensuring that it will stand up to the rigors of regular use.In addition to its performance benefits, the new dryer screen is also designed with user convenience in mind. It is easy to install and remove, and is compatible with a wide range of dryer models. The durable construction means that it can be washed and reused multiple times, reducing the need for frequent replacements.The launch of this new product reflects [Company]'s commitment to innovation and sustainability. Our company has a long history of developing cutting-edge products that improve the efficiency and performance of household appliances, and the new dryer screen is the latest example of this commitment. We are constantly researching and developing new technologies to make everyday tasks easier and more sustainable for consumers.[Company] is a leading manufacturer of household appliances, with a strong focus on innovation and sustainability. Our products are designed to enhance the lives of our customers by providing practical solutions to everyday tasks. We are committed to reducing our environmental impact through the use of sustainable materials and energy-efficient technologies, and we are constantly striving to improve the performance and efficiency of our products.The launch of the new dryer screen is a significant milestone for [Company], as it represents the culmination of extensive research and development efforts. Our team of engineers and designers have worked tirelessly to create a product that not only enhances the performance of dryers, but also reduces energy consumption and environmental impact.In addition to the launch of the new dryer screen, [Company] is also announcing a new partnership with a leading appliance retailer to make the product widely available to consumers. This partnership will enable the new dryer screen to reach a larger audience, allowing more people to benefit from its advanced technology and sustainability benefits.Overall, the launch of the new dryer screen is a significant achievement for [Company], and represents a major step forward in our ongoing commitment to innovation and sustainability. We are confident that this product will become an essential addition to households around the world, delivering superior drying performance and environmental benefits for years to come.

High-Quality Steel Frame Shaker Screen with Vortex Orbital Technology

Vortex Orbital 3000PT: A Revolution in Shale Shaker Screens[Company Introduction][Company Name], a leading innovator in the oil and gas industry, is proud to introduce its latest groundbreaking product, the Vortex Orbital 3000PT Steel Frame Shaker Screen. Designed to meet the ever-increasing demands of the modern drilling industry, this advanced shale shaker screen promises exceptional performance, durability, and cost-effectiveness.The Vortex Orbital 3000PT is the result of years of research and development, carried out by our team of skilled engineers and industry experts. With a relentless focus on quality and innovation, we have successfully engineered a product that stands out in the highly competitive market.[Product Description]The key feature of the Vortex Orbital 3000PT Steel Frame Shaker Screen is its advanced construction. Built with a durable steel frame, this screen can withstand the harshest drilling conditions without compromising on performance. It is designed to fit most popular shale shakers, making it versatile and compatible with existing drilling equipment.The screen itself is made from high-quality composite material, specially formulated to deliver exceptional efficiency in separating solids from liquids during the drilling process. The Vortex Orbital 3000PT demonstrates superior performance in terms of cuttings disposal, fluid handling, and mesh integrity. Its unique design ensures maximum throughput while minimizing the risk of clogging or blinding.Furthermore, the Vortex Orbital 3000PT is engineered to be highly durable. The steel frame provides excellent support, minimizing the chances of premature wear and tear. This not only extends the lifespan of the screen but also reduces maintenance costs and downtime. Moreover, the screen is resistant to corrosion and abrasion, making it ideal for long-term use in demanding drilling operations.[Key Features]1. High-quality composite material for exceptional performance.2. Durable steel frame for maximum support and longevity.3. Versatile compatibility with popular shale shakers.4. Superior fluid handling and cuttings disposal capabilities.5. Reduced risk of clogging or blinding.6. Corrosion and abrasion-resistant for long-term use.7. Low maintenance costs and minimized downtime.[Benefits for the Industry]The Vortex Orbital 3000PT Steel Frame Shaker Screen offers several significant benefits to the oil and gas industry. One of the key advantages is its superior efficiency in separating solid particles from drilling fluids. This not only ensures smoother drilling operations but also leads to improved wellbore stability and reduced drilling costs.Another benefit lies in its compatibility with most popular shale shakers. The Vortex Orbital 3000PT can be seamlessly integrated into existing drilling equipment, eliminating the need for expensive modifications or replacements. This compatibility, coupled with the screen's exceptional durability, reduces downtime and increases overall drilling efficiency.Furthermore, the Vortex Orbital 3000PT's cost-effectiveness cannot be ignored. With its extended lifespan and reduced maintenance requirements, operators can save significantly on replacement costs and maintenance downtime, which translates into enhanced profitability.[Conclusion]In conclusion, the Vortex Orbital 3000PT Steel Frame Shaker Screen represents a major breakthrough in shale shaker screen technology. Its advanced construction, exceptional performance, durability, and compatibility make it a must-have for drilling operations worldwide. With an unwavering commitment to excellence, [Company Name] continues to push the boundaries of innovation, emphasizing the importance of reliable and efficient equipment in the oil and gas industry.

Analyzing the Latest Advancements in Atl 1000 Shaker Screen Technology

In the world of drilling and oil production, the utilization of efficient and high-quality equipment has been a major factor in ensuring the success of operations. Among these pieces of equipment is the shaker screen, which plays a vital role in optimizing the drilling process. A shaker screen is essentially a sieve, which separates the drilling fluids from the solids, thereby decreasing the waste generation and allowing the recyclability of drilling mud. As such, the quality and performance of shaker screens are of utmost importance to companies in the oil and gas industry.One of the top-rated shaker screens in the industry is the Brandt Atl 1000 (brand name removed) shaker screen. This shaker screen boasts of a variety of features that make it stand out from the rest. Its technology and design are based on the latest advancements in the industry, optimizing its performance to meet the demands of drilling operations.The Brandt Atl 1000 shaker screen has been engineered to enhance the separation process of drilling fluids and solids. The screen has a large effective screen area, which translates to a better-solid removal efficiency. In addition, the screen is designed to prevent the clogging of particles, thereby increasing its overall performance.Another feature that makes the Brandt Atl 1000 shaker screen popular among drilling companies is its durability. The screen has been constructed from high-quality materials that ensure it can withstand the harsh conditions that exist in the oil and gas industry. Furthermore, the mesh layers of the screen have been treated with a specialized chemical that protects them from wear and tear, increasing its lifespan.The design of the screen has also been tailored to provide ease of use for the operator. The screen uses a hook-strip feature, which enables its installation or removal to be done in a shorter time period. This feature is crucial as it significantly reduces the downtime, which would have a negative effect on the overall operation.Moreover, the Brandt Atl 1000 shaker screen has a unique labeling system that allows for optimal identification and tracking of the screen’s maintenance and repair history. This feature is important as it ensures that the screen is well-maintained, guaranteeing optimal performance during its lifespan.The Brandt Atl 1000 shaker screen has been embraced by drilling companies worldwide, with positive feedback being received on its performance and durability. In addition, it has been tested and validated to meet the industry standards, with a false-positive rate of less than 5%. This low rate of false positives is essential in ensuring that drilling companies can accurately identify and separate solids from drilling mud.Therefore, the Brandt Atl 1000 shaker screen has become a go-to for drilling companies worldwide, with its high-quality performance, durability, and ease of use being among the top reasons for this. The screen’s design and technology have been optimized to meet the needs of the industry, ensuring that drilling companies can operate efficiently, with minimal waste generation, and maximum yield. While the market for shaker screens is competitive, the Brandt Atl 1000 shaker screen has managed to stand out, with its features enabling it to meet and exceed the expectations of the oil and gas industry.

Mongoose PRO Shaker Meerkat PT Dual-Motion Screen: The Latest in Shaker Technology

Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen, a product of a leading global oilfield service company, has been making waves in the oil and gas industry due to its innovative design and advanced capabilities.The shaker screen is a vital component in the process of separating solids and fluids during the drilling of oil and gas wells. It is crucial for the efficiency and effectiveness of the drilling operation, as it helps to ensure that the drilling fluid remains free of solids, which in turn helps to prevent equipment damage and maintain the integrity of the wellbore.The Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen is a cutting-edge solution that has been designed to address the evolving needs of the industry. It features a dual-motion mechanism that offers both linear and balanced elliptical motion, providing operators with the flexibility to tackle a wide range of drilling conditions. This allows for better control of the fluid handling capacity and the ability to handle a higher throughput of material, leading to improved efficiency and reduced costs.The Meerkat PT screen also incorporates advanced technology that enhances its performance and longevity. It is constructed with high-quality composite material that improves resistance to corrosion, abrasion, and impact, resulting in a longer lifespan and reduced maintenance requirements. Additionally, the screen is designed with an innovative sealing system that minimizes the risk of leaks and improves the overall reliability of the equipment.In addition to its technical capabilities, the Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen is backed by a comprehensive support system provided by the company. The company has a global network of service centers and experienced technicians who are dedicated to ensuring that their customers receive the assistance they need to maximize the performance of their equipment. This includes installation support, maintenance services, and training programs to help operators optimize the use of their screens.Furthermore, the company is committed to sustainability and environmental responsibility. The Meerkat PT screen is designed with efficiency in mind, reducing energy consumption and waste generation during operation. It also complies with industry standards and regulations for environmental protection, ensuring that it meets the highest level of performance while minimizing its impact on the environment.The introduction of the Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen has been met with positive feedback from industry professionals. Its advanced features and reliable performance have been recognized as a significant advancement in drilling technology, enabling operators to improve their operations and achieve better results.As the oil and gas industry continues to evolve, the demand for innovative and reliable equipment will remain high. The Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen is a testament to the dedication of the company to provide cutting-edge solutions that meet the needs of its customers and contribute to the advancement of the industry.In conclusion, the Swaco Mongoose PRO Shaker Meerkat PT Dual-Motion Screen is a game-changing product that offers unmatched performance, reliability, and support. With its advanced technology and commitment to sustainability, it is set to become a preferred choice for operators looking to optimize their drilling operations. As the oil and gas industry continues to face new challenges and demands, the company is well-positioned to continue leading the way with innovative solutions like the Meerkat PT screen.

D285P Composite Oil Shaker Screen for Effective Solids Control

Introduction:The global oil and gas industry has been witnessing a significant transformation in recent years, and technological advancements have played a crucial role in boosting the efficiency and productivity of operations. One such innovation that has gained traction in the industry is the Brandt D285P Composite Oil Shaker Screen, a cutting-edge solution offered by a leading oilfield equipment company.Company Background:Established over two decades ago, our company has remained committed to providing high-quality, innovative, and reliable products to the oil and gas sector. With a strong focus on research and development, we have continuously strived to address the evolving needs of our clients and the industry as a whole. Over the years, we have built an impeccable reputation for our dedication to excellence and our ability to deliver superior solutions that enhance operational performance and cost-efficiency.The Brandt D285P Composite Oil Shaker Screen:The Brandt D285P Composite Oil Shaker Screen is a superior offering designed to enhance the efficiency and cost-effectiveness of oil and gas drilling operations. Featuring advanced composite materials and cutting-edge manufacturing techniques, this innovative shaker screen offers unparalleled performance and durability in demanding drilling environments.The key highlights of the Brandt D285P Composite Oil Shaker Screen include:1. Superior Solid Control: The shaker screen is engineered to effectively separate solids and liquids, thereby improving the overall performance of drilling fluid systems. Its advanced design and construction ensure reliable and efficient solid control, leading to improved drilling efficiency and reduced downtime.2. Enhanced Durability: The use of high-quality composite materials ensures exceptional durability, making the shaker screen resistant to wear, tear, and corrosion. This extended lifespan translates to lower maintenance costs and reduced replacement frequency, further contributing to cost savings for operators.3. Improved Particle Control: The Brandt D285P Composite Oil Shaker Screen is designed to efficiently control the size and distribution of particles in drilling fluids, thereby contributing to better wellbore stability and overall drilling performance. This feature is particularly valuable in challenging drilling conditions, where precise particle control is critical.4. Compatibility and Versatility: The shaker screen is compatible with a wide range of shaker models, providing operators with flexibility and ease of integration into their existing drilling equipment. Its versatile design enables seamless installation and operation across various drilling applications, contributing to operational efficiency and adaptability.Industry Impact:The introduction of the Brandt D285P Composite Oil Shaker Screen has garnered significant attention within the oil and gas industry, with operators recognizing its potential to enhance drilling operations and deliver cost savings. The innovative features and performance capabilities of the shaker screen align with the industry's increasing demand for advanced solutions that optimize operational efficiency and minimize environmental impact.The use of advanced composite materials in the construction of the shaker screen represents a notable shift towards sustainable and eco-friendly practices in the oil and gas sector. By improving the longevity and performance of drilling equipment, the Brandt D285P Composite Oil Shaker Screen contributes to reducing overall resource consumption and waste generation, aligning with the industry's sustainability goals.Furthermore, the enhanced solid control and particle management capabilities of the shaker screen are expected to positively impact wellbore stability, drilling fluid quality, and overall drilling efficiency. This, in turn, can lead to improved well productivity, reduced drilling costs, and minimized environmental footprint, positioning the shaker screen as a valuable asset for operators seeking to achieve operational excellence.In conclusion, the Brandt D285P Composite Oil Shaker Screen represents a significant advancement in the field of oil and gas drilling equipment, offering operators a reliable and cost-effective solution to optimize their operations. With its superior performance, durability, and compatibility, the shaker screen is poised to make a lasting impact on the industry, contributing to enhanced efficiency, sustainability, and overall operational success. As the industry continues to evolve, innovative solutions like the Brandt D285P Composite Oil Shaker Screen will play a pivotal role in driving its progress and competitiveness.