High-Quality Shale Shaker Screen for Improved Efficiency and Performance

By:Admin

In the fast-paced world of oil and gas drilling, efficiency and productivity are crucial. Every second counts, and any delays can result in significant financial losses. That's why companies are constantly on the lookout for innovative technology that can help streamline their operations and minimize downtime.

One company that has been at the forefront of providing cutting-edge solutions for the oil and gas industry is {}. With a proven track record of delivering high-quality products and services, they have earned a reputation as a trusted partner for many drilling companies around the world.

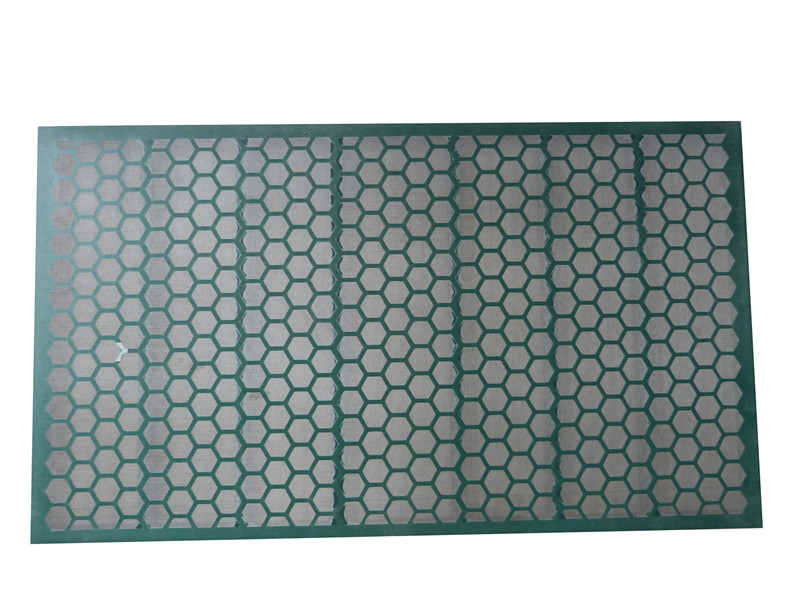

One of their flagship products, the (Kemtron) Shale Shaker Screen, has been making waves in the industry for its exceptional performance and reliability. This critical component plays a vital role in the drilling process, as it is responsible for separating drilling cuttings from the fluid, allowing for the recovery of valuable drilling fluid and minimizing waste.

The (Kemtron) Shale Shaker Screen is designed to withstand the harsh conditions of drilling operations, including high temperatures, high pressure, and abrasive materials. Its durable construction and high-quality materials ensure that it can effectively withstand the demands of the job, leading to longer service life and reduced maintenance costs.

In addition to its robust design, the (Kemtron) Shale Shaker Screen is also engineered for optimal performance. Its precise mesh size and efficient filtration capabilities allow for the effective removal of solid particles from the drilling fluid, resulting in cleaner fluid and improved drilling efficiency.

Furthermore, the (Kemtron) Shale Shaker Screen is easy to install and maintain, minimizing downtime and maximizing productivity for drilling operations. Its user-friendly design and simple, straightforward maintenance requirements make it a practical choice for companies looking to enhance their overall operational efficiency.

With the increasing demand for sustainable and environmentally friendly practices in the oil and gas industry, the (Kemtron) Shale Shaker Screen is also designed to contribute to these efforts. By effectively removing solid particles from the drilling fluid, it helps to reduce waste and minimize the environmental impact of drilling operations.

As a leading provider of innovative solutions for the oil and gas industry, {} is committed to delivering products that not only improve operational efficiency but also align with the industry's evolving sustainability goals. The (Kemtron) Shale Shaker Screen is a testament to this commitment, as it offers a practical and effective solution for companies seeking to optimize their drilling operations while minimizing their environmental footprint.

With its exceptional performance, durability, and environmental benefits, the (Kemtron) Shale Shaker Screen has quickly become a sought-after solution for many drilling companies. As the industry continues to evolve and demand more efficient and sustainable practices, it is clear that products like the (Kemtron) Shale Shaker Screen will play a crucial role in shaping the future of oil and gas drilling operations.

In conclusion, the (Kemtron) Shale Shaker Screen is a valuable addition to the portfolio of innovative solutions offered by {}. Its exceptional performance, durability, and environmental benefits make it a practical choice for drilling companies seeking to enhance their operational efficiency and minimize their environmental impact. As the industry continues to evolve, solutions like the (Kemtron) Shale Shaker Screen will undoubtedly continue to be a driving force in shaping the future of oil and gas drilling operations.

Company News & Blog

Introducing a High-Quality Shale Shaker Screen for Optimal Efficiency and Performance

Title: Innovation in Shale Shaker Screen Technology Revolutionizes the Drilling IndustryIntroduction:Shale shaker screens play a vital role in the oil and gas drilling industry. They are designed to efficiently filter out solid particles from drilling fluids, allowing for the retrieval of valuable resources. One company that has made significant strides in shale shaker screen innovation is Kemtron, a leading manufacturer and supplier of drilling equipment and accessories. With their latest technological breakthrough, the KTL-26 Shale Shaker Screen, Kemtron is revolutionizing the drilling industry by improving separation efficiency, reducing downtime, and optimizing drilling operations.Opening Paragraph:The KTL-26 Shale Shaker Screen, developed by Kemtron, represents a leap forward in drilling equipment technology. This state-of-the-art shale shaker screen is designed to deliver unparalleled performance, setting new industry standards for separation efficiency and cost-effectiveness. By effectively removing solid particles from drilling fluids, the KTL-26 ensures smooth operations, higher productivity, and increased profitability for drilling companies worldwide.Efficient Separation and Improved Downtime:The key advantage of the KTL-26 Shale Shaker Screen lies in its enhanced separation capabilities. With an intricate mesh design and advanced material composition, this screen offers superior filtration efficiency, effectively separating fine particles from drilling fluids. Its robust construction and high-quality materials ensure longevity and durability, reducing downtime due to frequent replacements and repairs.Additionally, the KTL-26's innovative design minimizes blinding and plugging, a common issue faced by traditional shale shaker screens. Its self-cleaning mechanism efficiently clears blockages, maintaining a consistent flow of drilling fluids and preventing disruptions to drilling operations. This unique feature significantly reduces downtime and increases the efficiency of drilling activities, ultimately saving time and costs for drilling companies.Optimized Drilling Operations:The KTL-26 Shale Shaker Screen is engineered to optimize drilling operations by delivering improved drilling fluid processing capabilities. The screen's precise particle separation not only eliminates harmful solids from drilling fluids, but also ensures the retention of valuable additives. This allows drilling companies to maintain the desired fluid properties, leading to improved drilling efficiency and higher quality wellbores.Furthermore, the KTL-26's design offers flexibility in adjusting the screen’s drying capacity and cut point, catering to varying drilling conditions. Drilling operations can now adapt to different formations, improving overall drilling performance and reducing the risk of outage due to unforeseen challenges.Environmental Sustainability:In addition to its impeccable performance, the KTL-26 Shale Shaker Screen also prioritizes environmental sustainability. Made from environmentally friendly materials and manufactured using eco-conscious processes, this screen reduces the carbon footprint typically associated with drilling activities. Kemtron's commitment to sustainable solutions aligns with the growing industry demand for eco-friendly practices, making the KTL-26 a responsible choice for environmentally conscious drilling companies.Conclusion:Kemtron's KTL-26 Shale Shaker Screen represents a significant advancement in shale shaker screen technology. Its improved separation efficiency, reduced downtime, and optimized drilling operations provide a competitive edge to drilling companies worldwide. By setting new industry standards, Kemtron continues to lead the way in enhancing drilling processes while prioritizing environmental sustainability. The KTL-26 Shale Shaker Screen is a testament to Kemtron's commitment to innovation, efficiency, and long-term success in the oil and gas drilling industry.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Efficient and Advanced Shaker: Improving Operations and Optimizing Results

Title: Efficient Solution for Oil and Gas Drilling: Revolutionary Shaker System Enhances Efficiency and SustainabilitySubtitle: Groundbreaking Shaker System Introduces New Possibilities in Oil and Gas Drilling OperationsIntroduction:In the rapidly evolving landscape of oil and gas drilling, innovation is the key to unlocking greater efficiency and sustainability. One technological breakthrough that promises to revolutionize the industry is the advanced shaker system developed by a leading solutions provider. Combining cutting-edge technology with a commitment to sustainability, this revolutionary shaker system presents a game-changing solution for oil and gas drilling operations worldwide.Key Features and Benefits:The revolutionary shaker system offers a plethora of features and benefits that set it apart from traditional conventional systems. Firstly, it significantly enhances the efficiency of the drilling process by efficiently separating solids from drilling fluid, enabling quicker recycling and reuse. By removing solid particles, the system ensures that the fluid remains at the optimum consistency for drilling, resulting in improved performance and reduced downtime.Moreover, the shaker system is equipped with state-of-the-art technology that dramatically minimizes waste generation. The introduction of advanced filtration mechanisms enables the removal of hazardous materials, ensuring compliance with environmental regulations. This technology also reduces the frequency of waste disposal, contributing to a cleaner and more sustainable drilling operation.Furthermore, the shaker system operates with an automatic self-cleaning mechanism, eliminating the need for manual maintenance and reducing labor costs. This allows drilling operations to run smoothly and efficiently, minimizing downtime and maximizing productivity.Sustainability and Environmental Impact:The importance of sustainability in the oil and gas industry cannot be understated. Recognizing this, the groundbreaking shaker system demonstrates a strong commitment to environmental preservation. By reducing waste generation, recycling drilling fluid, and minimizing disposal frequency, the system significantly lessens the environmental impact of drilling operations, ensuring a greener and more sustainable future.The company's dedication to sustainability goes beyond just the shaker system itself. Emphasizing responsible resource management, the company has implemented stringent ethical and eco-friendly guidelines for its manufacturing processes. This commitment to sustainable production extends to the selection of materials, ensuring that the shaker system is built to last while minimizing waste in the production chain.Global Applications:The revolutionary shaker system has already garnered significant attention and recognition across the global oil and gas drilling industry. Its advanced technology and efficiency-enhancing features make it an attractive choice for drilling operations worldwide.From offshore rigs to onshore drilling sites, the shaker system is versatile enough to adapt to various environments, making it suitable for a range of applications. Whether dealing with challenging drilling conditions or stringent regulatory restrictions, this adaptable system ensures optimal performance and compliance.Looking forward, the shaker system holds significant potential for revolutionizing drilling operations in emerging markets. As these markets continue to grow and evolve, the need for efficient and sustainable drilling solutions becomes increasingly evident. By providing a cost-effective, efficient, and environmentally friendly option, the shaker system empowers these markets to overcome operational challenges and embrace industry best practices.Conclusion:The revolutionary shaker system presents a breakthrough solution that redefines the oil and gas drilling landscape. Combining cutting-edge technology, efficiency-enhancing features, and a strong commitment to sustainability, this system charts a new course for the industry. By optimizing drilling operations, reducing waste generation, and minimizing environmental impact, the shaker system ensures a more efficient, sustainable, and prosperous future in oil and gas exploration and production.

Industry News: Upgraded Shale Shaker Screens for Efficient Solids Control on S250 Shakers

Shale Shaker Screen for S250: The New Breakthrough in Oil and Gas Drilling IndustryThe oil and gas drilling industry has been facing increasing pressure to improve its operational efficiency as the oil prices continue to fluctuate. With the need to maximize production and minimize costs, operators are consistently seeking new technology to improve the drilling process. One of the biggest challenges in the drilling industry is the proper handling of drilled cuttings and mud away from the borehole. This is where the shale shaker screen comes in.A shale shaker screen is an essential component of drilling equipment that is used to screen the drilling fluid and cuttings from the borehole. The shale shaker screen is designed to handle a high capacity of solids to ensure that the drilling fluid is well controlled and to extend the life of the drilling equipment through efficient solids removal. A new technology, the shale shaker screen for S250, has been developed to solve the problem of inefficient solids control during drilling operations.The S250 shale shaker screen is a breakthrough technology in the oil and gas industry. It is designed to replace the conventional screens and improve the shale shaker's performance with its advanced capabilities. The shale shaker screen for S250 is manufactured using advanced techniques to ensure its durability and longevity. It is made from high-quality stainless steel mesh, ensuring its resistance to wear and tear, and it has been tested under the harshest drilling conditions to ensure its efficiency in dealing with high-speed cuttings.The shale shaker screen for S250 provides significant operational and financial benefits. With its high-capacity performance, it reduces the overall cost of drilling operations by reducing the number of screens required for the operation. The shale shaker screen for S250 is also easy to install and replace, reducing the downtime of the drilling operation, which results in higher efficiency and faster drilling times.The company behind the development of the S250 shale shaker screen has a reputation for excellence. The company has been providing cutting-edge technology solutions for drilling, exploration, and production operations for more than a decade. Its mission is to provide customized solutions that optimize operational efficiency in the oil and gas industry. The S250 shale shaker screen is a testament to the company's commitment to providing innovative solutions that meet the needs of the industry.In conclusion, the shale shaker screen for S250 is a game-changer in the drilling industry. It is designed to improve the efficiency of the drilling operation by providing a high-capacity, durable and efficient solution for solids removal. Its advanced capabilities result in reduced screen usage and faster drilling times, leading to significant operational and financial benefits. The company behind the development of the S250 shale shaker screen is dedicated to delivering innovative technology solutions that help the drilling industry achieve peak performance. The future of the drilling industry is bright with advancements like the shale shaker screen for S250, and the industry can expect even more breakthroughs in the years to come as we continue to push the limits of innovation.

High Quality Oil Shale Shaker Screen for Vortex Prima Shakers" --> "High Quality Oil Shale Shaker Screen for Shakers

Vortex Prima Oil Shale Shaker Screen has recently made waves in the oil and gas industry with its advanced technology and high-performance capabilities. The shaker screen is designed to improve the efficiency of solids control equipment, providing greater accuracy in particle separation and better overall performance in drilling operations.The Vortex Prima Oil Shale Shaker Screen is specifically engineered to address the challenges faced in the extraction of oil and gas from shale formations. It is built with a robust frame and high-quality wire mesh that can withstand the high-frequency vibrations and intense pressure encountered during the drilling process. The screen is also designed to minimize the risk of plugging and blinding, which can significantly impact the effectiveness of solids control equipment.With its advanced technology, the Vortex Prima Oil Shale Shaker Screen offers several key advantages for operators in the oil and gas industry. These include improved efficiency in particle separation, reduced downtime for maintenance, and lower overall operating costs. The screen is also designed to enhance the overall performance of the solids control equipment, leading to greater productivity and profitability for drilling operations.In addition to its technical capabilities, the Vortex Prima Oil Shale Shaker Screen is backed by a reputable and experienced company. The manufacturer has a strong track record in providing high-quality products and solutions for the oil and gas industry. The company's commitment to innovation and customer satisfaction has earned it a solid reputation as a trusted provider of solids control equipment and related technologies.Furthermore, the manufacturer of Vortex Prima Oil Shale Shaker Screen offers comprehensive support and service to its customers. This includes technical assistance, training, and ongoing maintenance to ensure that the equipment performs at its best. The company's dedication to customer support reflects its commitment to delivering value and reliability to operators in the oil and gas sector.The introduction of the Vortex Prima Oil Shale Shaker Screen has generated significant interest and excitement in the oil and gas industry. Operators are eager to leverage the benefits of this advanced technology to enhance the efficiency and effectiveness of their drilling operations. The screen is poised to make a meaningful impact on the industry by improving solids control and increasing overall productivity in shale formations.In conclusion, the Vortex Prima Oil Shale Shaker Screen represents a significant advancement in solids control technology for the oil and gas industry. Its cutting-edge design and high-performance capabilities offer operators a valuable tool for improving efficiency and productivity in drilling operations. With the backing of a reputable manufacturer and a strong commitment to customer support, the Vortex Prima Oil Shale Shaker Screen is set to become a go-to solution for operators seeking to maximize their performance in shale formations.

Top Primary Screens for NOV VSM 300 Shale Shakers

Leading provider of oilfield equipment and technology, NOV, introduces a new high-quality primary screen that promises to revolutionize the oil and gas industry. The NOV VSM 300 Primary Screen offers exceptional performance and efficiency, making it a game-changer for oilfield operations.The primary screen is a critical component of the shale shaker, which is an essential tool used in the drilling process to separate drilling fluid and solids. With its advanced design and construction, the NOV VSM 300 Primary Screen delivers superior performance in separating solids from drilling fluid, ultimately improving overall drilling efficiency and reducing waste.The key features of the NOV VSM 300 Primary Screen include a patented composite frame that is lighter, more durable, and more reliable than traditional metal frames. This innovative design also minimizes the risk of screen failure and extends the screen's lifespan, resulting in cost savings for oilfield operators.In addition to its durable frame, the NOV VSM 300 Primary Screen utilizes an advanced screening technology that enhances fluid handling capacity and achieves better solids separation. This leads to improved drilling efficiency and reduced downtime, ultimately increasing productivity on the rig.The NOV VSM 300 Primary Screen also features an easy-to-install and quick-change design, which allows for rapid screen replacement and maintenance, further reducing downtime and optimizing operational efficiency.This new primary screen is the latest addition to NOV's comprehensive portfolio of oilfield equipment and technology, which includes a wide range of solutions for drilling, completion, production, and intervention operations.With a global presence and a strong commitment to innovation and excellence, NOV is a trusted partner for oil and gas companies seeking to enhance their operational performance and achieve sustainable growth."We are thrilled to introduce the NOV VSM 300 Primary Screen to the market," said a spokesperson for NOV. "This new addition to our product lineup reflects our ongoing dedication to providing cutting-edge solutions that address the evolving needs of the oil and gas industry. We believe that this primary screen will deliver significant value to our customers by improving drilling efficiency and reducing operational costs."The NOV VSM 300 Primary Screen is now available for purchase and is poised to make a significant impact on oilfield operations worldwide. With its advanced technology, durable construction, and user-friendly design, this primary screen is set to become the industry standard for efficient and reliable solids control.As the oil and gas industry continues to evolve and adapt to new challenges, NOV remains at the forefront, leading the way with innovative solutions that drive success and sustainability for its customers.NOV's commitment to excellence and its unwavering dedication to providing best-in-class products and services position the company as a trusted partner for oilfield operators looking to optimize their operations and maximize their profitability.With the introduction of the NOV VSM 300 Primary Screen, NOV is once again demonstrating its leadership in delivering groundbreaking technology that sets new standards for performance, reliability, and efficiency in the oil and gas industry. This primary screen is set to redefine the way solids control is handled in drilling operations, setting a new benchmark for operational excellence and success.

Upgrading Your Shaker Screens: Tips for Replacing and Choosing the Right Screens

Replacement Shaker Screens Transforming the Oil and Gas IndustryIn the ever-evolving oil and gas industry, technological advancements play a crucial role in optimizing efficiency and productivity. And one company at the forefront of this transformation is a leading innovator in the field of replacement shaker screens. By combining cutting-edge technology with a deep understanding of industry needs, this company is revolutionizing the way drilling fluids are filtered and processed.With global demand for oil and gas continuing to rise, drilling operations have become more complex and challenging. The extraction process involves drilling deep into the earth's crust, often in harsh and remote locations. Consequently, drilling contractors face numerous challenges in order to maintain profitable operations. Ensuring efficient solid control systems is a critical aspect of successful drilling, as it directly impacts the overall performance and longevity of drilling equipment.Replacement shaker screens are an integral component of a drilling rig's solid control system. They are used to filter out unwanted solids from drilling fluids, a process known as shale shaker. Shaker screens play a vital role in maintaining the quality and integrity of the drilling fluids, as well as protecting downstream equipment such as centrifuges and pumps. Hence, the durability, effectiveness, and efficiency of these screens are of utmost importance.The innovator in question has a long-standing reputation for producing high-quality replacement shaker screens that surpass industry standards. Their commitment to continuous research and development has led to breakthrough technologies that address the industry's most pressing challenges. By leveraging advanced engineering techniques, this company has created screens that excel in terms of durability, efficiency, and performance.One of the key features that sets these replacement shaker screens apart is the utilization of composite materials. By combining carefully selected grades of stainless steel with engineered polymer frames, these screens exhibit enhanced resistance to wear and corrosion. This ensures a longer lifespan, resulting in reduced maintenance costs and increased overall productivity.Moreover, the company's innovative screen design maximizes the usable screen area, significantly improving fluid handling capacity. This not only facilitates faster drilling operations but also minimizes the chance of screen blinding, a common issue faced by drilling contractors. With decreased screen blinding, operators are able to maintain optimal fluid flow rates, enhancing the overall efficiency of the drilling process.Furthermore, these replacement screens are meticulously engineered to deliver accurate particle separation. They employ advanced mesh technology that enables precise cut points, ensuring that only the desired solids are filtered out. This level of finesse in separation allows drilling contractors to better manage the drilling fluids' composition, thereby delivering superior drilling performance.The company's commitment to customer satisfaction extends beyond the quality of their products. They provide comprehensive technical support and responsive customer service, ensuring that their clients' specific needs are met. In an industry where downtime can have costly repercussions, this level of support is invaluable.To further enhance their service offering, the company actively collaborates with drilling contractors to develop customized solutions. By understanding the unique challenges faced by each client, they are able to tailor their screens to specific drilling conditions, thereby optimizing performance and efficiency. This collaborative approach has earned the company a loyal customer base and cemented their position as a trusted partner in the oil and gas industry.With replacement shaker screens playing such a vital role in the oil and gas sector, the technological advancements offered by this innovative company are poised to transform the industry. By improving durability, maximizing fluid handling capacity, enhancing particle separation accuracy, and providing exceptional customer support, they are revolutionizing the solid control process. As drilling operations continue to evolve, these replacement shaker screens serve as a testament to the power of innovation in shaping the future of the oil and gas industry.

High-performance 48-30 PMD Screen for Derrick FLC2000

The Derrick FLC2000 48-30 PMD Screen has recently made waves in the oil and gas drilling industry. The screen, designed and manufactured by a leading company in the industry, is proving to be a game-changer with its innovative features and superior performance.The company behind the Derrick FLC2000 48-30 PMD Screen is a renowned name in the oil and gas equipment manufacturing sector. With decades of experience and expertise in designing and producing high-quality equipment, the company has built a solid reputation for delivering reliable and efficient solutions to its clients. The company's commitment to innovation and excellence has made it a trusted partner for many businesses operating in the oil and gas industry.The Derrick FLC2000 48-30 PMD Screen is a testament to the company's dedication to staying ahead of the curve. The screen boasts a range of advanced features that set it apart from traditional screens used in drilling operations. Its high-quality construction and durable materials ensure that it can withstand the harshest operating conditions, making it a reliable and long-lasting solution for companies in the oil and gas sector.One of the key features of the Derrick FLC2000 48-30 PMD Screen is its superior performance in separating solids from drilling fluid. The screen's unique design and efficient filtration capabilities make it an essential component for ensuring the smooth operation of drilling equipment. It effectively removes unwanted solids, allowing the drilling fluid to be recycled and reused, thereby reducing waste and lowering operating costs for businesses.In addition to its exceptional performance, the Derrick FLC2000 48-30 PMD Screen is also designed with ease of use in mind. Its user-friendly interface and maintenance-friendly design make it simple for operators to install and maintain, saving time and effort in the field. This added convenience is a significant advantage for businesses looking to streamline their operations and improve overall efficiency.Furthermore, the company's dedication to customer satisfaction is evident in the support and services it provides to clients using the Derrick FLC2000 48-30 PMD Screen. The company offers comprehensive training and technical assistance to ensure that clients can maximize the performance and lifespan of the screen. This level of commitment to customer success sets the company apart as a reliable and trustworthy partner.The Derrick FLC2000 48-30 PMD Screen is quickly becoming the go-to choice for businesses in the oil and gas drilling industry. Its superior performance, innovative features, and the backing of a reputable company have positioned it as a must-have solution for companies looking to optimize their drilling operations.As the demand for efficient and reliable equipment continues to grow in the oil and gas sector, the Derrick FLC2000 48-30 PMD Screen has emerged as a top contender. Its proven track record and the strong reputation of the company behind it make it a compelling choice for businesses seeking to enhance their drilling operations.In conclusion, the Derrick FLC2000 48-30 PMD Screen, combined with the expertise and support of a leading company in the oil and gas equipment manufacturing sector, is setting new standards for performance and reliability in the industry. Its advanced features, user-friendly design, and commitment to customer satisfaction make it a standout solution for businesses seeking to improve their drilling operations. With the Derrick FLC2000 48-30 PMD Screen, companies can expect to achieve greater efficiency, lower operating costs, and ultimately, a more successful and sustainable business.

How to Replace a Screen Frame: A Step-by-Step Guide

Screen Frame Replacement Offers New Solution for Damaged ScreensIn today's digital age, screens are an integral part of our everyday lives. Whether it's a smartphone, tablet, or computer monitor, we rely on screens to stay connected, work, and be entertained. However, these screens are not invulnerable to damage, and when they do get damaged, it can be a frustrating and costly experience. Fortunately, Screen Frame Replacement, a leading provider of screen repair solutions, is offering a new and innovative solution for damaged screens. The company's patented screen frame replacement technology is revolutionizing the way screens are repaired, making the process faster, more cost-effective, and environmentally friendly.Screen Frame Replacement has been in the business of screen repair for over a decade, and their team of experts has extensive experience in repairing a wide range of screens, including those for smartphones, tablets, laptops, and monitors. The company prides itself on delivering high-quality repairs with a quick turnaround time, so customers can get back to using their devices as soon as possible.Unlike traditional screen repair methods, which often involve replacing the entire screen assembly, Screen Frame Replacement's technology allows for the damaged frame to be removed and replaced with a new one, while leaving the screen itself intact. This not only reduces the cost of repairs but also minimizes electronic waste, making it an environmentally friendly solution.The process begins with a thorough assessment of the damaged screen, followed by the removal of the old frame and the installation of a new one. The entire process is carried out by skilled technicians who are trained to work with precision and attention to detail, ensuring that the repaired screen looks and functions as good as new.One of the key advantages of Screen Frame Replacement's technology is its versatility. The company is able to provide screen frame replacement for a wide variety of devices, regardless of make or model. Whether it's a cracked iPhone screen, a damaged Samsung tablet, or a broken laptop display, Screen Frame Replacement can provide a solution.Furthermore, the company understands the importance of convenience for its customers. To that end, they offer a variety of service options, including in-store repairs, mail-in services, and even on-site repairs for businesses. This flexibility ensures that customers have a convenient and hassle-free experience when getting their screens repaired.Screen Frame Replacement's commitment to quality and customer satisfaction has earned them a strong reputation in the screen repair industry. Thousands of satisfied customers have praised the company for its reliable and affordable services, making it the go-to choice for screen repair needs.In addition to its screen repair services, Screen Frame Replacement also offers a range of accessories and protective products to help customers keep their screens safe and secure. From screen protectors to protective cases, the company is dedicated to helping customers prolong the life of their devices and avoid future damage.As technology continues to play a central role in our lives, having a reliable and affordable solution for screen repair is more important than ever. With its innovative screen frame replacement technology, Screen Frame Replacement is leading the way in the industry, providing customers with the peace of mind that their damaged screens can be quickly and effectively repaired. Whether it's a cracked smartphone screen or a broken laptop display, customers can trust Screen Frame Replacement to deliver a solution that meets their needs.

Ultimate Guide to Shale Shaker Screen – Exploring Flc2000 Technology

Title: Cutting-Edge Shale Shaker Screen Revolutionizes Oil and Gas IndustryIntroduction:In today's rapidly evolving oil and gas industry, advancements in technology play a crucial role in optimizing drilling processes and ensuring the efficient extraction of valuable resources. One such breakthrough innovation is the Flc2000 Shale Shaker Screen, a cutting-edge solution that has revolutionized shale shaker performance. Developed by a leading industry player (company name), this state-of-the-art screen offers unparalleled efficiency and reliability, transforming drilling operations globally.Paragraph 1:The Flc2000 Shale Shaker Screen, designed and manufactured by (company name), has garnered significant attention due to its exceptional performance and cost-saving features. This innovative solution boasts advanced features such as enhanced solids separation, superior screen life, and increased operating efficiency. The Flc2000 screen's design incorporates meticulous engineering coupled with high-quality materials to ensure reliability and longevity.Paragraph 2:Compared to conventional shale shaker screens, the Flc2000 screen offers greatly improved solids separation capabilities. With its unique design, this screen effectively separates drilling cuttings from the drilling fluid, resulting in cleaner and drier solids. This not only maximizes drilling efficiency but also reduces the environmental impact of drilling operations by minimizing waste generation.Paragraph 3:Another key advantage of the Flc2000 Shale Shaker Screen is its extended screen life. Traditional screens often suffer from premature failure or excessive wear due to the harsh drilling conditions encountered in the industry. However, the implementation of advanced manufacturing techniques and durable materials ensures that the Flc2000 screen maintains optimal performance for extended periods, significantly reducing downtime and replacement costs.Paragraph 4:Efficiency is a top priority in the oil and gas industry, and the Flc2000 Shale Shaker Screen has raised the bar in this regard. Incorporating cutting-edge technology, the screen enhances the overall operational efficiency of shale shakers. Its unique design minimizes the number of required screen changes, meaning less downtime during drilling operations. This increased uptime translates into substantial cost savings and improved productivity for drilling companies.Paragraph 5:The Flc2000 Shale Shaker Screen has been widely adopted by industry leaders worldwide, rendering positive results in diverse drilling environments. Its adaptability spans across various drilling applications, including oil and gas exploration, geothermal drilling, and directional drilling. The screen's compatibility with different shale shaker models further adds to its versatility, making it a versatile choice for drilling operations of all scales.Paragraph 6:Furthermore, the Flc2000 Shale Shaker Screen offers a user-friendly experience. Its installation and maintenance procedures are straightforward and can be implemented easily by field personnel. The screen's robust construction ensures resistance to common issues such as blinding and plugging, enabling continuous operation even in challenging conditions.Conclusion:In conclusion, the Flc2000 Shale Shaker Screen stands as a game-changing solution in the oil and gas industry. By combining advanced technology, superior design, and exceptional performance, this screen has transformed drilling operations worldwide. The Flc2000's ability to enhance solids separation, extend screen life, and optimize operational efficiency has made it an invaluable asset for drilling companies seeking to maximize their productivity, reduce costs, and minimize environmental impact. The Flc2000 Shale Shaker Screen continues to set new standards for excellence, ultimately propelling the oil and gas industry toward a more efficient and sustainable future.