High-Quality Shaker Screen for Fluid Systems in Demand

By:Admin

The [Need to remove brand name] Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced by industries in achieving effective solid-liquid separation. With a focus on improving efficiency and reducing operational costs, Fluid Systems Inc has successfully engineered a shaker screen that boasts superior performance and durability.

The key feature of the [Need to remove brand name] Shaker Screen lies in its advanced design and construction, which allows for increased throughput and better separation of solids from drilling fluids. This results in improved operational efficiency and reduced wastage of valuable resources. Additionally, the shaker screen is built to withstand the harshest operating conditions, ensuring long-term reliability and performance.

"We are proud to introduce the [Need to remove brand name] Shaker Screen to the market," said a spokesperson for Fluid Systems Inc. "This product represents a significant advancement in solid-liquid separation technology, and we believe it will greatly benefit our customers by improving their operational efficiency and reducing downtime."

In addition to its innovative design, the [Need to remove brand name] Shaker Screen is also available in a range of sizes and configurations to cater to the specific requirements of different industries. This ensures that customers can find a solution that best fits their needs, further enhancing the product's versatility and applicability.

Furthermore, Fluid Systems Inc has invested in rigorous testing and quality control measures to ensure that the [Need to remove brand name] Shaker Screen meets the highest standards of performance and reliability. By conducting extensive field trials and customer feedback sessions, the company has been able to fine-tune the product to deliver optimal results in real-world operating conditions.

Beyond the product itself, Fluid Systems Inc is also committed to providing exceptional customer support and service. The company's team of experienced engineers and technical experts are on hand to offer guidance and assistance to customers, ensuring that they are able to maximize the benefits of the [Need to remove brand name] Shaker Screen in their operations.

With its innovative design, superior performance, and commitment to customer satisfaction, the [Need to remove brand name] Shaker Screen is set to make a significant impact in the field of solid-liquid separation. As industries continue to seek more efficient and cost-effective solutions, Fluid Systems Inc is poised to lead the way with its cutting-edge product offerings.

As the global demand for reliable and efficient separation technologies continues to grow, Fluid Systems Inc remains dedicated to pushing the boundaries of innovation and delivering solutions that empower industries to thrive in a competitive marketplace. The [Need to remove brand name] Shaker Screen is a testament to the company's unwavering commitment to excellence and its ability to meet the evolving needs of its customers.

Company News & Blog

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

High-Quality Replacement Shaker Screens for Improved Performance

As the demand for oil and gas continues to rise, the need for effective drilling equipment has become increasingly important. One company that has been at the forefront of providing innovative solutions for the oil and gas industry is {[Company Name]}. With a focus on technology and environmental stewardship, {[Company Name]} has consistently delivered high-quality products and services to its customers.One of the key products offered by {[Company Name]} is its line of replacement shaker screens. Shaker screens are a vital component of the drilling process, as they are used to separate solids and liquids during the drilling operation. The efficiency and performance of these screens can have a significant impact on the overall success of a drilling project. This is where {[Company Name]}'s replacement shaker screens come into play.The {[Company Name]} replacement shaker screens are designed to provide optimal performance in various drilling conditions. These screens are made from high-quality materials and are engineered to withstand the demands of the oil and gas industry. With a focus on durability and efficiency, {[Company Name]}'s replacement shaker screens have become a preferred choice for many drilling operations around the world.One of the key features of {[Company Name]}'s replacement shaker screens is their innovative design. These screens are built to maximize the efficiency of the shaker unit, resulting in improved solids control and better overall performance. The screens are also designed to be easy to install and maintain, reducing downtime and optimizing the drilling process.In addition to their performance, {[Company Name]}'s replacement shaker screens are also designed with environmental considerations in mind. The company is committed to reducing its environmental impact and has developed screens that are more energy-efficient and produce less waste. This aligns with {[Company Name]}'s overall commitment to sustainability and responsible business practices.As a testament to the quality and performance of their replacement shaker screens, {[Company Name]} has built a strong reputation in the industry. Their screens have been used in some of the most challenging drilling environments and have consistently delivered superior results. This has led to a loyal customer base that continues to rely on {[Company Name]}'s products for their drilling operations.In addition to their replacement shaker screens, {[Company Name]} offers a wide range of other products and services to support the oil and gas industry. This includes drilling fluids, well construction equipment, and various technical services. With a focus on technological innovation and customer satisfaction, {[Company Name]} is well-positioned to continue leading the way in providing cutting-edge solutions for the oil and gas industry.Looking ahead, {[Company Name]} remains committed to driving innovation and sustainability in the oil and gas industry. The company is constantly investing in research and development to bring new and improved products to market. With a strong focus on environmental responsibility and technological advancement, {[Company Name]} is well-positioned to meet the evolving needs of the industry and continue to deliver value to its customers.In conclusion, {[Company Name]}'s replacement shaker screens are a testament to the company's commitment to excellence and innovation. With a focus on performance, durability, and environmental stewardship, these screens have become a trusted choice for drilling operations around the world. As the demand for oil and gas continues to grow, {[Company Name]} is well-positioned to continue providing the industry with the products and services it needs to thrive.

Efficient Shaker Screen for Optimal Solids Separation

Title: Groundbreaking S250 Shaker Screen Sets New Standards in Oil and Gas IndustryIntroduction:In a world reliant on energy extraction, the oil and gas industry remains a vital player, constantly seeking innovative technologies to optimize drilling and production processes. Step forward the revolutionary S250 Shaker Screen, a cutting-edge solution developed by industry-leading experts, poised to reshape the landscape of oilfield equipment. This groundbreaking equipment promises improved performance, increased durability, and enhanced efficiency, cementing its position as a game-changer in the global market.Section 1: Evolution of Shaker Screens in the Oil and Gas IndustryThe oil and gas industry is known for its relentless pursuit of efficiency and cost-effectiveness. Over the years, there has been an evolution in shaker screens, which play a crucial role in filtering drilling fluids during extraction operations. The S250 Shaker Screen encompasses the latest innovations in material science and design, surpassing its predecessors in terms of longevity and performance.Section 2: Unparalleled Design and Superior PerformanceThe development team behind the S250 Shaker Screen focused on improving the efficiency of the screening process. By enhancing the screen's capacity to retain solids while allowing drilling fluid to pass through, the S250 ensures uninterrupted operation and reduces downtime. Its state-of-the-art design maximizes solids removal, leading to cleaner drilling fluids and increased productivity on-site.Section 3: Enhanced Durability and Cost-EffectivenessIn the oilfield, durability is of paramount importance. The S250 Shaker Screen guarantees exceptional longevity, enabling operators to optimize equipment performance while reducing overall maintenance costs. Manufactured using high-quality materials and employing advanced engineering techniques, this screen withstands the harshest operating conditions, making it an indispensable asset for drilling companies worldwide.Section 4: Eco-Friendly and Sustainable SolutionCorporate social responsibility has become a crucial aspect of the oil and gas industry. Recognizing this, the S250 Shaker Screen is designed with sustainability in mind. By ensuring optimal solids removal and minimizing waste, it significantly reduces environmental impact. Additionally, its extended lifespan and reduced maintenance contribute to minimizing the carbon footprint associated with equipment replacement.Section 5: Market Impact and Industry AdoptionThe launch of the S250 Shaker Screen has generated substantial excitement within the oil and gas industry. Major drilling companies are already adopting this cutting-edge technology, recognizing its potential to revolutionize their operations. With demand rising, manufacturers are increasing production capacity to meet global market needs and capitalize on the expanding customer base.Section 6: Testing and ValidationBefore its launch, the S250 Shaker Screen underwent rigorous testing to ensure it met the industry's stringent quality standards. Evaluation criteria included efficiency, durability, and compatibility with various drilling fluids. The results were overwhelmingly positive, confirming that this novel solution is ready to transform the industry.Conclusion:The S250 Shaker Screen stands as a testament to the relentless pursuit of innovation within the oil and gas industry. Its revolutionary design, exceptional performance, and unmatched durability set a new benchmark for shaker screens. With the global market embracing this game-changing technology, the stage is set for a more efficient and sustainable future in oil and gas extraction.

High-Quality Venom Shakers Screen for Effective Particle Separation

Shakers Screen: A Game-Changer in the Oil and Gas IndustryThe oil and gas industry continues to evolve and adapt with the advancement of technology. One such innovation that is making waves in the industry is the Shakers Screen, a key component in the process of separating solids and fluids during the drilling process. Among the leading brands in this space, the (remove brand name) Shakers Screen has gained widespread recognition for its efficiency and effectiveness in improving the overall operation of oil and gas drilling.The (remove brand name) Shakers Screen is a vital tool used in the drilling process to separate drilling fluid from the solids that are brought to the surface during the drilling of oil and gas wells. This separation process is essential to ensure the integrity of the well and to maintain proper drilling fluid properties. The Shakers Screen is designed to remove the solid particles from the drilling fluid, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner.The (remove brand name) Shakers Screen stands out from the competition due to its advanced design and high-quality materials. With a commitment to innovation and quality, the company has developed a range of screens that are durable, efficient, and cost-effective. The screens are designed to withstand the harsh conditions of drilling operations while providing reliable performance throughout the drilling process.The company prides itself on its dedication to research and development, continuously working to improve the design and functionality of the Shakers Screen. By listening to the needs of their customers, the company has been able to create screens that meet and exceed industry standards, providing a reliable solution for the challenges faced in the drilling process.In addition to its exceptional performance, the (remove brand name) Shakers Screen is also known for its ease of use and maintenance. The screens are designed for quick and simple installation, allowing for minimal downtime during the drilling process. Furthermore, the company provides comprehensive support and training for the maintenance and replacement of the screens, ensuring that they continue to operate at optimal efficiency.The impact of the Shakers Screen on the oil and gas industry cannot be overstated. By improving the efficiency of the drilling process, the screens help to reduce costs and increase overall productivity. This, in turn, has a positive impact on the bottom line for oil and gas companies, making the Shakers Screen a valuable investment for those in the industry.Furthermore, the screens play a crucial role in environmental sustainability. By allowing for the reuse of drilling fluid and the proper disposal of solids, the Shakers Screen helps to minimize the environmental impact of drilling operations. This aligns with the increasing emphasis on sustainable practices within the oil and gas industry, making the Shakers Screen a valuable tool for addressing environmental concerns.Looking ahead, the (remove brand name) Shakers Screen is poised to continue its upward trajectory in the oil and gas industry. With ongoing advancements in technology and a commitment to quality, the company is well-positioned to meet the evolving needs of the industry and provide innovative solutions for the challenges of drilling operations.In conclusion, the (remove brand name) Shakers Screen has emerged as a game-changer in the oil and gas industry, providing a reliable and efficient solution for the separation of solids and fluids during the drilling process. With its advanced design, high-quality materials, and commitment to innovation, the screens have significantly improved the operation of drilling operations, making them a valuable asset for oil and gas companies. As the industry continues to evolve, the Shakers Screen will undoubtedly play a vital role in driving efficiency, productivity, and sustainability in oil and gas drilling.

High-efficiency vibrating screen for industrial applications

[Company Introduction][The Company] is a leading manufacturing company specializing in the production of industrial equipment for various applications including mining, construction, and recycling. With a commitment to delivering high-quality and efficient solutions, the company has a strong track record of providing innovative products that meet the evolving needs of its customers.[The Company] offers a wide range of equipment including crushers, screens, feeders, and conveyors, designed to enhance productivity and efficiency in diverse industrial settings. The company's dedication to research and development, as well as its focus on customer satisfaction, has earned it a solid reputation in the industry.[Shaker Vibrating Screen]The [Shaker Vibrating Screen] is one of the flagship products offered by [The Company]. This state-of-the-art screening equipment is designed to efficiently separate and sort various materials, making it an essential tool for countless industrial applications. Whether it's separating aggregates in mining operations, classifying sand and gravel in construction projects, or sorting recyclable materials, the [Shaker Vibrating Screen] is engineered to deliver optimal performance and reliability.The [Shaker Vibrating Screen] features a robust construction and a high-capacity design, making it capable of handling large volumes of material while maintaining accuracy in sorting and separating particles of different sizes. With adjustable settings and customizable configurations, this versatile screening equipment can be tailored to specific needs, providing a tailored solution for diverse industrial requirements.Furthermore, the [Shaker Vibrating Screen] is equipped with advanced technology to ensure smooth operation and minimal downtime. Its efficient design reduces energy consumption and maintenance requirements, contributing to cost-effective and sustainable operations for customers.[News Content][The Company] is pleased to announce the launch of its latest innovation, the upgraded [Model Name] Shaker Vibrating Screen, which sets a new benchmark for efficiency and performance in the screening equipment market. Building upon the success of its predecessors, the new [Model Name] incorporates cutting-edge features and engineering advancements to deliver unparalleled results for customers across various industries.The [Model Name] Shaker Vibrating Screen is designed to address the evolving demands of modern industrial applications, offering increased capacity, improved accuracy, and enhanced durability. Its advanced vibratory mechanism ensures a smooth and efficient screening process, allowing for the effective separation of materials with different particle sizes.One of the key highlights of the [Model Name] is its versatility, as it can be configured to accommodate various screening requirements. Whether it's classifying aggregates, sorting recyclable materials, or screening bulk solids, this adaptable equipment can be tailored to meet specific operational needs, providing a customized solution for every application.Furthermore, the [Model Name] is engineered with a focus on ease of maintenance and serviceability, minimizing downtime and maximizing productivity for end users. Its user-friendly interface and intuitive controls make it simple to operate, while its robust construction ensures reliability even in the most demanding environments.In addition to its technological advancements, the [Model Name] Shaker Vibrating Screen also prioritizes sustainability and efficiency. By optimizing energy usage and minimizing waste, [The Company] remains committed to eco-friendly practices and responsible manufacturing, aligning with the global push for environmental stewardship."We are excited to introduce the new [Model Name] Shaker Vibrating Screen to our customers," said [Spokesperson], [Position] at [The Company]. "This latest addition to our product lineup represents our dedication to innovation and our commitment to delivering top-of-the-line solutions to the industries we serve. The [Model Name] sets a new standard for performance, reliability, and sustainability in screening equipment, and we are confident that it will exceed the expectations of our customers."With its cutting-edge features and unmatched capabilities, the [Model Name] Shaker Vibrating Screen reinforces [The Company]'s position as a leading provider of industrial equipment, setting a new industry benchmark for efficiency and productivity. As the global market continues to evolve, [The Company] remains at the forefront of innovation, driving progress and delivering value to its customers through best-in-class solutions.

Sugar Sieve Shaker Offers Efficient Filtering: Discover its Benefits Today!

Introducing: A Revolutionary Sugar Sieve Shaker Enhancing Efficiency and Precision in Sugar ProcessingSugar processing, a crucial step in the food and beverage industry, has now received a notable upgrade with the introduction of an innovative sugar sieve shaker. This groundbreaking technology has been developed by a leading company in the field of food manufacturing equipment, whose dedication to enhancing efficiency and precision has revolutionized sugar processing.With an unwavering commitment to quality and continuous improvement, this esteemed company has become a key player in the industry. Their expertise lies in designing and manufacturing cutting-edge equipment that meets the ever-evolving needs of food producers worldwide.The new sugar sieve shaker has been meticulously designed and engineered to optimize the sugar processing workflow. By leveraging state-of-the-art technology, this device offers unparalleled efficiency and precision in separating sugar crystals of different sizes. The shaker's unique design allows for a controlled and uniform sieving process, ensuring that only the desired particle sizes make their way through.One of the standout features of this sugar sieve shaker is its ability to handle a high throughput, significantly boosting overall productivity. Equipped with a powerful motor, it can handle large quantities of sugar with ease, avoiding downtime and delays that can occur with traditional methods. Additionally, this advanced shaker operates with minimal noise, creating a more pleasant working environment for operators.To further enhance efficiency and precision, the company has integrated advanced automation capabilities into the sugar sieve shaker. By implementing precise controls and monitoring systems, the device can automatically adjust sieve settings based on predefined parameters. This automation reduces the risk of operator error and ensures a consistently high-quality end product.Another crucial aspect of the sugar sieve shaker is its versatility. Designed to cater to the diverse requirements of the sugar processing industry, this device can be customized to fit a range of needs. Whether it's adapting to different sugar crystal sizes or accommodating unique sieving processes, the shaker can be fine-tuned to meet specific demands.Furthermore, the company's relentless focus on sustainability shines through in the development of this state-of-the-art sugar sieve shaker. By optimizing energy consumption and maximizing efficiency, this device has made significant strides in reducing the environmental impact of sugar processing operations.The company's commitment to customer satisfaction is evident not only in the performance of their equipment but also in their exceptional customer service. Their dedicated team of experts works closely with clients to understand their needs and provide tailored solutions that meet and exceed expectations. From initial consultations to ongoing technical support, this company stands as a reliable partner throughout the entire process.In conclusion, the introduction of this revolutionary sugar sieve shaker marks a new era in sugar processing. With its unrivaled efficiency, precision, and adaptability, this breakthrough technology has the potential to transform the industry. Backed by a company renowned for its expertise and commitment to customer satisfaction, this sugar sieve shaker is set to redefine sugar processing standards worldwide.

High-Quality Food Grade Vibrating Shaker for Your Kitchen

Food Grade Vibrating Shaker Ensures Quality and Safety in Food ProcessingIn today's rapidly evolving food industry, ensuring the quality and safety of food products is of utmost importance. With the increasing demand for high-quality food products, food processing companies are constantly seeking innovative solutions to streamline their production processes while maintaining the highest standards of quality and safety. One such company, {}, has emerged as a leader in providing cutting-edge equipment for food processing, including the Food Grade Vibrating Shaker.The Food Grade Vibrating Shaker from {} is a state-of-the-art solution designed to meet the unique needs of food processing companies. It is specifically engineered to ensure the quality and safety of food products by effectively removing any impurities or contaminants during the processing and packaging stages. This innovative equipment plays a critical role in the overall quality control and safety measures implemented by food processing companies, helping them to adhere to stringent industry regulations and standards.The Food Grade Vibrating Shaker from {} is designed to deliver exceptional performance, reliability, and efficiency in food processing operations. One of its key features is its unique vibratory motion, which effectively separates and sorts food products while ensuring gentle handling to prevent any damage or contamination. This helps to safeguard the integrity of the final product and maintain its overall quality. Additionally, the shaker is constructed using high-quality food-grade materials, making it safe for use in direct contact with food products and ensuring compliance with food safety regulations.Furthermore, the Food Grade Vibrating Shaker is highly versatile and can be customized to meet the specific requirements of different food processing applications. Whether it is used for sorting, grading, or de-dusting food products, this equipment offers unparalleled flexibility and precision to meet the diverse needs of food processing companies. Its modular design and advanced control system allow for easy integration into existing production lines, making it a seamless addition to any food processing operation.The Food Grade Vibrating Shaker is also equipped with advanced safety features and hygiene standards to uphold the highest level of food safety. Its easy-to-clean design and sanitary construction ensure that it can be maintained to the highest standards of cleanliness, minimizing the risk of cross-contamination and ensuring the overall safety and quality of the processed food products. This emphasis on food safety underscores {}'s commitment to delivering solutions that prioritize consumer well-being and satisfaction.In addition to its technical capabilities, {} brings a wealth of expertise and experience to the table. With a proven track record in providing innovative solutions to the food processing industry, {} has established itself as a trusted partner for companies seeking to enhance their production capabilities. Their team of experts works closely with clients to understand their specific needs and challenges, providing tailored solutions that address their unique requirements and goals.As the food industry continues to evolve and consumer expectations for quality and safety remain high, the demand for advanced equipment like the Food Grade Vibrating Shaker is only expected to grow. With its focus on innovation, reliability, and food safety, {} is well-positioned to meet this demand and support food processing companies in their pursuit of excellence.In conclusion, the Food Grade Vibrating Shaker from {} represents a significant advancement in food processing technology, offering a comprehensive solution to ensure the quality and safety of food products. With its advanced features, versatile capabilities, and commitment to food safety, this equipment serves as a testament to {}'s dedication to providing cutting-edge solutions that empower food processing companies to achieve new levels of success.

4'X5' Shale Shaker Screen: A Comprehensive Guide

Shale shaker screens are an essential component of the oil drilling process, used to remove large solids and debris from drilling fluid. These screens play a crucial role in maintaining the efficiency of the drilling operation and ensuring the quality of the drilling fluid. As such, the choice of shaker screens is of utmost importance to oil and gas companies.One company that has been making waves in the industry is a leading manufacturer of high-quality shaker screens. With a commitment to excellence and innovation, the company has established itself as a trusted supplier of premium shaker screens to oil and gas companies around the world. Their dedication to quality and customer satisfaction has made them a go-to choice for many drilling operations.Recently, the company introduced its latest product – the brandt 4'X5' shale shaker screen. This new addition to their product line promises to deliver superior performance and durability, further solidifying the company's position as a top player in the industry. The brandt 4'X5' shale shaker screen is designed to effectively remove solids and impurities from drilling fluid, ensuring the smooth operation of the drilling process.What sets this new shale shaker screen apart is its advanced design and engineering. The company has leveraged the latest technology and materials to create a screen that is highly efficient and long-lasting. With a focus on durability, the brandt 4'X5' shale shaker screen is built to withstand the harsh conditions of drilling operations, making it a reliable and cost-effective solution for oil and gas companies.In addition to its exceptional performance, the brandt 4'X5' shale shaker screen is also easy to install and maintain. This user-friendly design saves time and effort, allowing drilling operations to run smoothly and efficiently. Furthermore, the company offers excellent customer support, ensuring that clients receive the assistance they need to maximize the performance of their shaker screens.The introduction of the brandt 4'X5' shale shaker screen is further evidence of the company's commitment to innovation and excellence. By continuously pushing the boundaries of shaker screen technology, they are helping oil and gas companies improve their drilling processes and achieve better results. The brandt 4'X5' shale shaker screen is a testament to the company's dedication to meeting the evolving needs of the industry.In response to the introduction of the brandt 4'X5' shale shaker screen, industry experts have expressed excitement and optimism. Many see this new product as a game-changer that will set new standards for shaker screen performance and reliability. With its cutting-edge design and impressive capabilities, the brandt 4'X5' shale shaker screen is expected to make a significant impact in the oil and gas industry.As oil and gas companies continue to seek ways to improve their drilling operations, the brandt 4'X5' shale shaker screen offers a compelling solution. Its superior performance, durability, and user-friendly design make it a valuable asset for any drilling operation. With this latest innovation, the company has once again demonstrated its leadership in the shaker screen market.In conclusion, the introduction of the brandt 4'X5' shale shaker screen represents a significant milestone for the company and the oil and gas industry as a whole. With its advanced technology and exceptional performance, this new product is poised to make a lasting impact and further solidify the company's reputation as a premier supplier of shaker screens. As drilling operations continue to evolve, the brandt 4'X5' shale shaker screen stands ready to meet the challenges of the industry and deliver outstanding results for its clients.

High-Quality Shaker Screen for Fluid Systems in Demand

Fluid Systems Inc, a leading provider of industrial filtration and separation products, has developed a new and innovative shaker screen that is set to revolutionize the industry. This new product, the [Need to remove brand name] Shaker Screen, is designed to provide unparalleled efficiency and performance in various applications such as oil and gas drilling, mining, and industrial separation processes.The [Need to remove brand name] Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced by industries in achieving effective solid-liquid separation. With a focus on improving efficiency and reducing operational costs, Fluid Systems Inc has successfully engineered a shaker screen that boasts superior performance and durability.The key feature of the [Need to remove brand name] Shaker Screen lies in its advanced design and construction, which allows for increased throughput and better separation of solids from drilling fluids. This results in improved operational efficiency and reduced wastage of valuable resources. Additionally, the shaker screen is built to withstand the harshest operating conditions, ensuring long-term reliability and performance."We are proud to introduce the [Need to remove brand name] Shaker Screen to the market," said a spokesperson for Fluid Systems Inc. "This product represents a significant advancement in solid-liquid separation technology, and we believe it will greatly benefit our customers by improving their operational efficiency and reducing downtime."In addition to its innovative design, the [Need to remove brand name] Shaker Screen is also available in a range of sizes and configurations to cater to the specific requirements of different industries. This ensures that customers can find a solution that best fits their needs, further enhancing the product's versatility and applicability.Furthermore, Fluid Systems Inc has invested in rigorous testing and quality control measures to ensure that the [Need to remove brand name] Shaker Screen meets the highest standards of performance and reliability. By conducting extensive field trials and customer feedback sessions, the company has been able to fine-tune the product to deliver optimal results in real-world operating conditions.Beyond the product itself, Fluid Systems Inc is also committed to providing exceptional customer support and service. The company's team of experienced engineers and technical experts are on hand to offer guidance and assistance to customers, ensuring that they are able to maximize the benefits of the [Need to remove brand name] Shaker Screen in their operations.With its innovative design, superior performance, and commitment to customer satisfaction, the [Need to remove brand name] Shaker Screen is set to make a significant impact in the field of solid-liquid separation. As industries continue to seek more efficient and cost-effective solutions, Fluid Systems Inc is poised to lead the way with its cutting-edge product offerings.As the global demand for reliable and efficient separation technologies continues to grow, Fluid Systems Inc remains dedicated to pushing the boundaries of innovation and delivering solutions that empower industries to thrive in a competitive marketplace. The [Need to remove brand name] Shaker Screen is a testament to the company's unwavering commitment to excellence and its ability to meet the evolving needs of its customers.

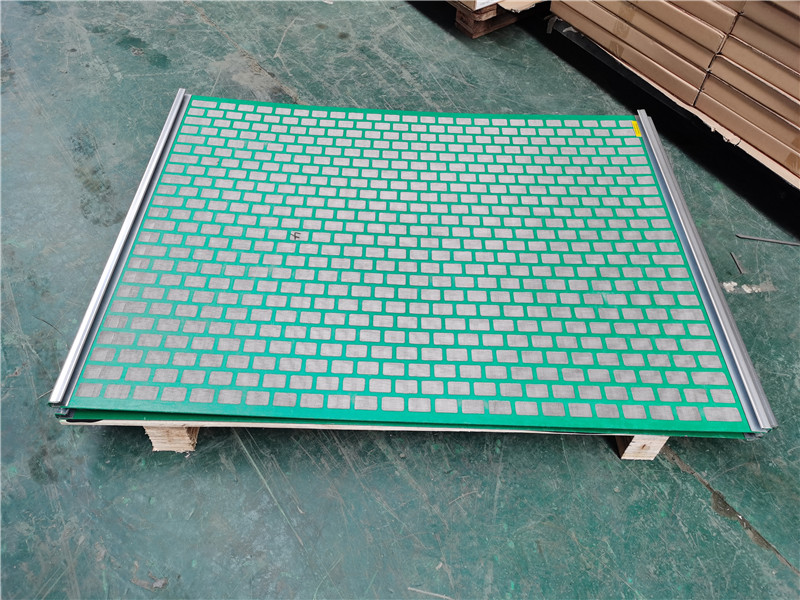

High-quality Flat Shaker Screens for Effective Filtration

Derrick Corporation Expands its Product Line with the Introduction of Flat Shaker ScreenHouston, TX - Derrick Corporation, a leading provider of high-quality separation and filtration solutions, has recently expanded its product line with the introduction of the Flat Shaker Screen. This new addition to Derrick's existing range of products is designed to meet the ever-growing demand for efficient and durable separation equipment in the oil and gas industry.The Flat Shaker Screen is a key component of the company's line of shakers and is designed to enhance the performance of drilling operations. It is specifically engineered to improve the efficiency and productivity of solid control systems, ensuring the removal of solid particles from drilling fluid to maintain the overall integrity and performance of the well.Derrick Corporation has a long-standing reputation for delivering innovative and reliable separation solutions to its customers. With over 70 years of experience in the industry, the company has continuously proven its commitment to providing superior equipment and services that meet the evolving needs of its clients.The introduction of the Flat Shaker Screen is a testament to Derrick's dedication to innovation and its response to the demands of the market. The new screen boasts an advanced design that incorporates cutting-edge technology to deliver maximum performance and longevity. Its durable construction and high-quality materials make it suitable for a wide range of applications, including both onshore and offshore drilling operations.In addition to its superior performance capabilities, the Flat Shaker Screen also provides significant cost-saving benefits. Its efficient design and reliable operation help to reduce maintenance requirements and downtime, resulting in lower overall operating costs for customers.Derrick Corporation's investment in the development of the Flat Shaker Screen underscores its commitment to providing comprehensive solutions that optimize the efficiency and effectiveness of separation processes in the oil and gas industry. The company remains steadfast in its mission to deliver products of the highest quality, supported by exceptional service and technical expertise.With a global presence and a network of experienced professionals, Derrick Corporation is well-positioned to meet the needs of its diverse customer base. The company's dedication to customer satisfaction is evident in its ongoing investment in research and development, ensuring that its products remain at the forefront of innovation and technological advancement.The introduction of the Flat Shaker Screen represents a significant milestone for Derrick Corporation and further solidifies its reputation as a leading provider of cutting-edge separation and filtration solutions. As the company continues to expand its product offerings, it remains committed to delivering superior performance, reliability, and value to its customers.For more information about Derrick Corporation and its range of separation and filtration solutions, please visit www.derrick.com.