High-Quality Shaker Screen for Effective Solid Control in Oil and Gas Industry

By:Admin

[Company Name], a leading manufacturer and supplier of equipment and materials for the mining industry, has recently introduced a new line of high-quality shaker screens to enhance the efficiency and productivity of mining operations. The GNZS-853/833 shaker screens are designed to effectively separate solid particles from drilling mud, ensuring a smooth and uninterrupted drilling process.

With years of experience in providing innovative solutions for the mining sector, [Company Name] has established itself as a trusted partner for companies seeking reliable and efficient equipment. The introduction of the GNZS-853/833 shaker screens further reinforces the company's commitment to delivering top-quality products that meet the specific needs of its customers.

The GNZS-853/833 shaker screens are built to withstand the tough demands of the mining industry. Constructed using high-strength materials, these screens are capable of handling high-capacity loads without compromising on performance. The advanced design of the screens allows for efficient separation of solid particles, resulting in cleaner drilling mud and improved overall operations.

One of the key features of the GNZS-853/833 shaker screens is their versatility. Designed to fit a wide range of shaker models, these screens can be easily integrated into existing equipment, making them a cost-effective solution for mining companies looking to upgrade their operations. The screens are also easy to install and maintain, minimizing downtime and ensuring continuous productivity.

In addition to their durability and versatility, the GNZS-853/833 shaker screens are engineered for optimal performance. The precise design of the screens ensures effective particle separation, leading to a reduction in waste and improved overall efficiency. By using these screens, mining companies can expect to achieve higher throughput and lower operating costs, ultimately resulting in increased profitability.

[Company Name] understands the importance of reliable equipment in the mining industry, which is why the company is dedicated to providing top-of-the-line solutions that meet the highest standards of quality and performance. The GNZS-853/833 shaker screens are a testament to this commitment, offering mining companies a reliable and efficient tool for enhancing their operations.

As part of its comprehensive service, [Company Name] also provides expert technical support and assistance to help customers choose the right equipment for their specific needs. The company's team of experienced professionals is readily available to offer guidance and advice on integrating the GNZS-853/833 shaker screens into existing operations, ensuring a seamless transition and maximum benefit.

With the introduction of the GNZS-853/833 shaker screens, [Company Name] continues to set the standard for quality and innovation in the mining industry. The company's dedication to providing cutting-edge solutions underscores its position as a leader in the field, and mining companies can rely on [Company Name] to deliver the equipment they need to achieve their operational goals.

In conclusion, the GNZS-853/833 shaker screens represent a significant advancement in the mining industry, offering companies a reliable and efficient solution for improving their operations. Backed by [Company Name]'s reputation for excellence and its commitment to customer satisfaction, these screens are set to make a positive impact on the way mining companies handle drilling mud and solid particle separation. As the mining sector continues to evolve, [Company Name] remains at the forefront, providing the tools and support that companies need to succeed.

Company News & Blog

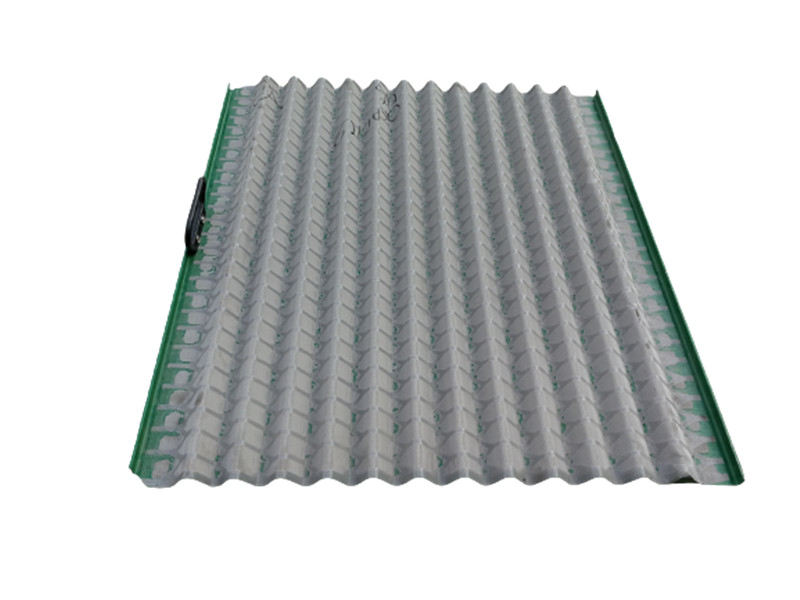

High-quality Replacement Wave Screens for Hyperpool Shakers

The demand for efficient and high-quality solid control equipment in the oil and gas industry has led to the development of advanced technology to enhance the performance of drilling operations. One such innovation is the Replacement Wave Screens for Derrock Hyperpool Shakers, which is set to revolutionize the way solid control equipment is used in drilling operations.This new technology promises to deliver improved efficiency and cost-effectiveness for oil and gas companies, as it can significantly enhance the performance of drilling operations. These screens are designed to fit seamlessly into Derrock Hyperpool Shakers, which are widely used in the industry for solid control during drilling operations.The Replacement Wave Screens are manufactured using state-of-the-art technology and high-quality materials, ensuring a longer lifespan and superior performance compared to traditional screens. The unique wave design of the screens allows for increased capacity and efficiency, resulting in better solid control and reduced maintenance costs.In addition to the innovative design, these replacement screens are also easy to install and maintain, making them an ideal choice for drilling operations. The company behind this advanced technology has a strong track record in providing reliable and cutting-edge solutions for the oil and gas industry.With a team of experienced engineers and industry experts, the company is committed to delivering top-notch products and services that meet the evolving needs of the oil and gas sector. The Replacement Wave Screens for Derrock Hyperpool Shakers are a testament to this commitment, as they are designed to improve the overall performance and cost-effectiveness of drilling operations.Furthermore, the company's dedication to quality and customer satisfaction sets them apart in the industry. They prioritize customer feedback and constantly strive to innovate and improve their products to meet the changing demands of the market. This customer-centric approach has earned them a solid reputation as a leading provider of solid control equipment and services.In addition to offering innovative products, the company also provides comprehensive support and services to ensure that their clients get the most out of their equipment. From installation and training to maintenance and troubleshooting, the company's team of experts is dedicated to assisting their clients every step of the way.The Replacement Wave Screens for Derrock Hyperpool Shakers are just one example of the company's commitment to driving excellence and innovation in the oil and gas industry. As the demand for efficient and reliable solid control equipment continues to grow, this new technology is expected to play a pivotal role in enhancing drilling operations around the world.The company's dedication to delivering high-quality products and exceptional customer service makes them a trusted partner for oil and gas companies seeking advanced solutions for their drilling operations. With the Replacement Wave Screens for Derrock Hyperpool Shakers, the company is set to raise the bar for solid control equipment in the industry and set new standards for efficiency and performance.In conclusion, the Replacement Wave Screens for Derrock Hyperpool Shakers represent a significant advancement in solid control technology for the oil and gas industry. Backed by a company with a strong reputation for excellence and innovation, these screens are poised to revolutionize the way drilling operations are conducted, delivering improved efficiency, cost-effectiveness, and overall performance for oil and gas companies around the world.

Primary Shaker Screen for VSM300 - All You Need to Know

VSM300 Primary Shaker Screen: A Breakthrough Innovation in the Oil and Gas IndustryThe oil and gas industry has been a vital part of the global economy for many years, and as technology continues to advance, so does the need for more efficient and reliable equipment to meet the growing demand for energy resources. One such equipment that has been making waves in the industry is the VSM300 Primary Shaker Screen, a breakthrough innovation that has revolutionized the way drilling waste is managed.The VSM300 Primary Shaker Screen is a high-performance vibrating screen designed specifically for solids control in the oil and gas drilling industry. It is a critical component of the drilling fluids system and is used to separate and remove large drilling cuttings from the drilling fluid, allowing for the reuse of the fluid and the proper disposal of the cuttings. The VSM300 Primary Shaker Screen is known for its exceptional performance, durability, and reliability, making it a popular choice among drilling contractors and operators worldwide.The VSM300 Primary Shaker Screen is manufactured by a leading company in the oil and gas industry that specializes in providing high-quality solid control equipment and solutions to the global market. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of developing cutting-edge technologies that help enhance the efficiency and sustainability of drilling operations.The VSM300 Primary Shaker Screen is an excellent example of the company's commitment to innovation and quality. It is designed to withstand the harsh conditions of drilling operations, including high temperatures, extreme pressures, and abrasive drilling fluids. The screen is made from high-quality materials that are resistant to wear and corrosion, ensuring long-term performance and reliability in the field.One of the key features of the VSM300 Primary Shaker Screen is its unique design, which is optimized for maximum efficiency and productivity. The screen is equipped with a dual-deck design, which allows for increased capacity and better performance in separating solids from the drilling fluid. This design also helps reduce the amount of energy and resources required to process drilling waste, making it a more sustainable solution for managing drilling cuttings.In addition to its superior performance, the VSM300 Primary Shaker Screen is also designed for ease of use and maintenance. It is equipped with quick-release tensioning systems that make it easy to install and replace the screen panels, reducing downtime and increasing productivity on the rig. The screen is also compatible with a wide range of shaker models, making it a versatile solution for different drilling applications.As the demand for energy continues to grow, the oil and gas industry is under increasing pressure to find more sustainable and environmentally friendly solutions for drilling operations. The VSM300 Primary Shaker Screen is a perfect example of how innovation in equipment design can help address these challenges and contribute to the industry's efforts to reduce its environmental footprint.With its exceptional performance, durability, and sustainability, the VSM300 Primary Shaker Screen has become a preferred choice for drilling contractors and operators around the world. It has helped improve the efficiency and reliability of drilling operations, while also contributing to reducing the environmental impact of drilling waste.As the oil and gas industry continues to evolve, the VSM300 Primary Shaker Screen is expected to play a crucial role in helping meet the growing demand for energy resources while also promoting sustainability and environmental responsibility. With its advanced technology and innovative design, this breakthrough innovation is set to be a game-changer in the solid control equipment market for years to come.

Top Tips for Screen Replacement: Everything You Need to Know

Screen Replacement Company Aims to Revolutionize the Electronic Repair IndustryIn today's technology-driven world, electronic devices have become an integral part of our everyday lives. From smartphones and laptops to tablets and smartwatches, keeping these devices in optimal condition is crucial for staying connected and productive. However, accidents happen, and screens often bear the brunt of such mishaps. Cracked or broken screens not only affect the functionality of the devices but also detract from their aesthetics. This is where screen replacement services come into play, and one company is aiming to revolutionize this industry.Company X, a leading provider of electronic repair services, is on a mission to redefine the way screen replacement is done. With a commitment to excellence and a focus on delivering exceptional customer experiences, Company X has quickly established itself as a trusted name in the electronic repair industry. The company's team of highly skilled technicians is adept at working with a wide range of electronic devices, from smartphones and tablets to laptops and gaming consoles. Their expertise, combined with state-of-the-art equipment and premium quality replacement parts, enables them to deliver seamless screen replacement services that meet the highest standards of quality and precision.One of the key differentiators that set Company X apart from competitors is their dedication to customer satisfaction. From the moment a customer walks through the door, they are greeted with a warm and friendly atmosphere, where their needs are listened to and addressed with care. Whether it's a shattered smartphone screen or a cracked laptop display, Company X's technicians approach each repair with a meticulous attention to detail, ensuring that the device is returned to its original state of functionality and aesthetics. Additionally, the company offers a warranty on all replacement parts and services, giving customers peace of mind knowing that their investment is protected.Furthermore, Company X is committed to environmental sustainability, and this is reflected in their approach to electronic repair. By offering screen replacement services, the company is helping to extend the lifespan of electronic devices, reducing the need for premature replacements and minimizing electronic waste. In a time when electronic waste is a pressing global concern, Company X's eco-friendly approach is a step in the right direction, showcasing their commitment to corporate social responsibility.In line with their vision to revolutionize the electronic repair industry, Company X has also invested in advanced training and development programs for their technicians. This ensures that the team stays abreast of the latest technological advancements and repair techniques, enabling them to tackle even the most complex screen replacement challenges with ease. As a result, customers can have full confidence in the capabilities of Company X's technicians, knowing that their devices are in capable hands.Looking ahead, Company X has ambitious plans for expansion, aiming to reach more customers and establish a wider presence in the electronic repair market. With a growing demand for reliable and professional screen replacement services, the company is well-positioned to capitalize on this opportunity and make a positive impact on the industry. By continually raising the bar for excellence and innovation, Company X is laying the groundwork for a future where electronic repair is synonymous with quality, reliability, and sustainability.In conclusion, Company X's dedication to excellence, customer satisfaction, and environmental sustainability sets a new standard for the electronic repair industry. By offering top-notch screen replacement services and maintaining a customer-centric approach, the company has carved out a niche for itself as a trusted leader in the market. With a focus on continuous improvement and expansion, Company X is poised to shape the future of electronic repair, one screen replacement at a time.

Oil Shale Shaker Screen GNZS-703: All you need to know about it

Oil and gas industry is a crucial part of the global economy. With the continuous development and progress, there is a growing demand for advanced equipment and technology to ensure efficient and safe operation. One of the crucial components in the oil and gas drilling process is the shale shaker screen.Recently, the GNZS-703 Oil Shale Shaker Screen, developed by a leading company in the industry, has been making waves in the market. This innovative product has been designed to improve the efficiency and performance of oil and gas drilling operations, setting a new standard for shale shaker screens.The GNZS-703 Oil Shale Shaker Screen is a result of extensive research and development by the company, which has been a pioneer in providing cutting-edge solutions for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a reliable and trusted partner for oil and gas companies around the world.The GNZS-703 Oil Shale Shaker Screen is engineered to deliver superior performance in separating and filtering drilling cuttings during the oil and gas drilling process. Its unique design and advanced technology ensure maximum efficiency and productivity, while also reducing downtime and maintenance costs for drilling operations.One of the key features of the GNZS-703 Oil Shale Shaker Screen is its durable and wear-resistant construction, which allows it to withstand the harsh conditions of drilling operations. This ensures a longer service life and lower replacement costs for oil and gas companies, contributing to overall cost savings and improved profitability.Additionally, the GNZS-703 Oil Shale Shaker Screen is designed for easy installation and maintenance, making it a practical and convenient solution for drilling operations. Its efficient performance and user-friendly design have garnered positive feedback from industry professionals, further solidifying its reputation as a leading product in the market.The company behind the GNZS-703 Oil Shale Shaker Screen has a rich history and extensive expertise in providing high-quality equipment and services for the oil and gas industry. With a strong commitment to continuous improvement and innovation, the company has been at the forefront of developing advanced solutions to meet the evolving needs of the industry.In addition to the GNZS-703 Oil Shale Shaker Screen, the company offers a comprehensive range of products and services, including shale shakers, mud cleaners, and other drilling equipment. Its commitment to excellence and customer satisfaction has earned the company a solid reputation as a reliable and trusted partner for oil and gas companies worldwide.The GNZS-703 Oil Shale Shaker Screen is just one example of the company's dedication to providing cutting-edge solutions for the oil and gas industry. With a focus on performance, reliability, and cost-effectiveness, the company continues to set new standards and push the boundaries of innovation in the industry.As the oil and gas industry continues to evolve and expand, the demand for advanced equipment and technology will only continue to grow. With its proven track record and commitment to excellence, the company is well-positioned to meet the ever-changing needs of the industry and play a key role in driving progress and success for oil and gas companies around the world.In conclusion, the GNZS-703 Oil Shale Shaker Screen, developed by a leading company in the industry, represents a new standard of excellence in the oil and gas drilling process. With its advanced technology, durable construction, and user-friendly design, this innovative product is set to make a significant impact on the efficiency and productivity of drilling operations. As the company continues to push the boundaries of innovation and provide cutting-edge solutions, it is poised to play a crucial role in driving progress and success for the oil and gas industry.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

Highly Efficient FLC500 Series Screen for Industries - A Must-Have Equipment

Modern drilling operations require cutting-edge equipment to ensure efficiency and effectiveness. One such important equipment is the Derrick FLC500 Series Screen, which plays a crucial role in the solid control system of drilling rigs. At {} (company name), we are proud to offer this top-of-the-line product to our clients in the oil and gas industry.The Derrick FLC500 Series Screen is designed to effectively remove large solids from the drilling fluid, commonly known as mud, during the drilling process. This is a critical function as it ensures that the drilling fluid remains in top condition for optimal performance. The solid control system, of which the screen is a key component, also helps to minimize waste and reduce environmental impact by recycling the drilling fluid.At {}, we understand the importance of reliable and efficient equipment in the oil and gas industry. That's why we have partnered with leading manufacturers, including Derrick, to provide our clients with the best products on the market. The Derrick FLC500 Series Screen is a testament to our commitment to offering high-quality solutions that meet the evolving needs of the industry.One of the standout features of the Derrick FLC500 Series Screen is its innovative design, which allows for easy installation and maintenance. This is a crucial aspect for our clients, as it minimizes downtime and ensures that their operations run smoothly. Additionally, the screen is highly durable, able to withstand the harsh conditions typically found on drilling rigs.In addition to its practical features, the Derrick FLC500 Series Screen also offers impressive performance. Its high-capacity design allows for efficient solid removal, while its precise cut point ensures that the drilling fluid is properly conditioned for the drilling process. This translates to improved overall efficiency and cost savings for our clients.At {}, we take pride in not only offering top-quality products, but also providing excellent customer service. Our team of experts is dedicated to supporting our clients every step of the way, from product selection to installation and ongoing maintenance. We understand the unique challenges of the oil and gas industry, and we are committed to helping our clients overcome them.Furthermore, as a company that values sustainability, we recognize the importance of responsible waste management in drilling operations. The solid control system, with the Derrick FLC500 Series Screen at its core, plays a crucial role in reducing environmental impact by effectively managing drilling waste. This aligns with our commitment to offering solutions that are both efficient and environmentally friendly.In conclusion, the Derrick FLC500 Series Screen is a crucial component of the solid control system in modern drilling operations. Its innovative design, impressive performance, and durability make it a standout product in the industry. At {}, we are proud to offer this top-of-the-line solution to our clients, backed by our commitment to excellence and customer satisfaction. With the Derrick FLC500 Series Screen, our clients can expect improved efficiency, cost savings, and environmental responsibility in their drilling operations.

Discover the Tremendous Advantages of the NOV Cobra LCL-3D Shakers Screen

Rising demand for oil drilling activities has led to an increase in the use of shaker screens in the oil and gas industry. Shaker screens are critical components used in the separation of solids from liquids during the drilling process.To meet the growing demand for shaker screens, numerous companies have entered the market with innovative products that promise better efficiency, longer life, and reduced maintenance. Among these companies, one stands out, offering exceptional quality products and services – the leading manufacturer of shaker screens, Brandt / NOV.Recently, Brandt / NOV has introduced a new shaker screen model, the Cobra LCL-3D, which is a breakthrough in the industry. The new technology comes with unique features that enhance its functionality and durability while increasing overall drilling efficiency.The Cobra LCL-3D shaker screen is designed to maximize the flow of drilling fluids through the screen while maintaining high handling capacity. The screen also comes with an advanced composite frame that is lighter and easier to handle, reducing operational downtime during installation and removal.The primary layer of the Cobra LCL-3D screen is made from premium mesh, which ensures that the screen can handle heavier loads during the drilling process. The panel is also designed with a wedge-shaped screen aperture, which reduces the risk of clogging. The company's innovative technology provides customers with improved shaker screen performance, longer life, and considerably lower operating costs.Brandt / NOV is committed to providing its customers with quality products and exceptional services. The company's team of experts works closely with its clients to ensure that the products meet their needs and exceed their expectations. Anytime clients work with Brandt / NOV, they can trust that they will receive quality products that are backed by unmatched customer service and support.With the introduction of the Cobra LCL-3D shaker screen, Brandt / NOV has set itself apart as an industry leader in the manufacturing of shaker screens. The new model brings cutting-edge technology to the market, providing drilling companies with efficient and cost-effective options that will translate into cost savings for their operations. Brandt / NOV understands that customer satisfaction is crucial to its success. Thus, the company continuously seeks new and innovative ways to provide its clients with exceptional products and service. With the launch of the Cobra LCL-3D shaker screen, the company has shown its commitment to excellence, providing customers with top-quality technology that will deliver maximum results.Brandt / NOV stands out in the market as a reliable and innovative company that has revolutionized the manufacturing of shaker screens. The company has an excellent reputation for providing customers with quality products and services at competitive prices. With the launch of the Cobra LCL-3D shaker screen, Brandt / NOV has set a new standard in the industry, providing customers with a solution that addresses critical issues such as durability, efficiency, and cost-effectiveness.In conclusion, the Cobra LCL-3D shaker screen from Brandt / NOV is a breakthrough in the manufacturing of shaker screens. The new technology comes with unique features that will improve drilling efficiency, reduce operational downtime, and result in considerable cost savings for drilling companies. Brandt / NOV has once again demonstrated its leadership and commitment to innovation, providing its customers with top-quality products and services that will deliver the desired results.

High-quality Shaker Screen for FSI 5000 Series" becomes "High-performance Shaker Screen for 5000 Series

FSI 5000 Series Shaker Screen is Making Waves in the Oil and Gas IndustryThe oil and gas industry is constantly evolving, and the demand for efficient and reliable equipment has never been greater. FSI 5000 Series Shaker Screen is a leading provider of cutting-edge solutions for the oil and gas industry, and their innovative products are making waves in the market.FSI 5000 Series Shaker Screen offers a wide range of products designed to meet the unique needs of their customers. Their FSI 5000 Series Shaker Screen, in particular, has been garnering attention for its exceptional performance and durability. This shaker screen is designed to effectively remove solids from drilling fluid, ensuring high-quality performance and extended service life.The FSI 5000 Series Shaker Screen is built to withstand the toughest conditions, making it an ideal choice for demanding oil and gas applications. Its advanced design and construction allow for efficient and consistent performance, even in the most challenging environments. This has made it a top choice for companies looking to improve their operations and achieve greater productivity.In addition to its exceptional performance, the FSI 5000 Series Shaker Screen is also designed with ease of use in mind. Its user-friendly design and simple installation process make it a practical choice for companies looking to streamline their operations and minimize downtime. This has made it a popular choice among oil and gas professionals who value efficiency and reliability in their equipment.FSI 5000 Series Shaker Screen is proud to offer a range of products and services that are tailored to the unique needs of their customers. With a strong focus on innovation and customer satisfaction, they are committed to providing the highest quality solutions for the oil and gas industry. Their team of experts works closely with customers to understand their specific requirements and develop customized solutions that deliver exceptional results.As a leading provider of shaker screens and other equipment, FSI 5000 Series Shaker Screen has earned a reputation for excellence in the oil and gas industry. Their commitment to quality, innovation, and customer satisfaction has set them apart as a trusted partner for companies looking to maximize their performance and efficiency. With a dedication to continuous improvement and a focus on customer success, FSI 5000 Series Shaker Screen is poised for even greater success in the years to come.The oil and gas industry is constantly evolving, and companies need reliable equipment that can keep up with the demands of the market. FSI 5000 Series Shaker Screen is at the forefront of this evolution, offering cutting-edge solutions that are designed to deliver exceptional performance and reliability. With a commitment to innovation and customer satisfaction, they are poised to continue making waves in the oil and gas industry for years to come.

New Factory Screen Technology: Enhancing Productivity and Efficiency

The Zs/z-2 Factory has announced the launch of their latest innovative screen, revolutionizing the way businesses display content. This state-of-the-art screen is a game-changer and is set to transform the digital display industry.The Zs/z-2 Factory is a leading company in the display technology sector and has been at the forefront of innovation for many years. They specialize in creating cutting-edge display solutions for businesses in various industries. With a strong focus on research and development, the company is constantly striving to push the boundaries of what is possible in the world of display technology.The new screen from the Zs/z-2 Factory offers a range of features that set it apart from traditional displays. Its ultra-high resolution and crystal-clear image quality provide a stunning visual experience for viewers. The screen is also built to be incredibly durable, with a rugged design that can withstand the rigors of daily use in commercial settings.One of the most impressive aspects of the new screen is its versatility. It is designed to be fully customizable, allowing businesses to tailor the display to meet their specific needs. Whether it's a large-scale digital advertising campaign or a small-scale informational display, the Zs/z-2 Factory screen can handle it all with ease.In addition to its impressive technical capabilities, the Zs/z-2 Factory screen is also designed with ease of use in mind. It features an intuitive interface that makes it simple for businesses to manage and update their content. This user-friendly design ensures that businesses can make the most of their digital displays without the need for extensive technical expertise.The launch of this new screen has generated a lot of excitement within the industry. Many businesses are already expressing interest in integrating the Zs/z-2 Factory screen into their operations. With its exceptional quality and versatility, it is poised to become the go-to choice for businesses looking to enhance their digital displays."We are thrilled to introduce our latest screen to the market," said a spokesperson for the Zs/z-2 Factory. "We believe that this new product will redefine the standard for digital displays and provide businesses with a powerful tool for engaging with their audience. With its advanced features and user-friendly design, we are confident that it will be a game-changer for businesses in a wide range of industries."The Zs/z-2 Factory has a strong track record of delivering high-quality display solutions to businesses around the world. Their commitment to innovation and excellence has earned them a reputation as a trusted leader in the industry. With the launch of their new screen, they are further solidifying their position as a driving force in the world of display technology.As businesses continue to seek out effective ways to connect with their audience, the Zs/z-2 Factory screen is poised to play a key role in shaping the future of digital displays. Its exceptional quality, versatility, and user-friendly design make it an ideal choice for businesses looking to make a lasting impression with their digital content.With the launch of their latest screen, the Zs/z-2 Factory is once again demonstrating their dedication to pushing the boundaries of what is possible in the world of display technology. As the industry continues to evolve, their commitment to innovation will ensure that they remain at the forefront of the market, delivering cutting-edge solutions to businesses around the world.

Latest PMD Screen Technology Boosts Derrick FLC 2000 Performance

Derrick Corporation, a global leader in providing innovative and cutting-edge solutions for the oil and gas industry, has recently unveiled its latest innovation, the FLC 2000 PMD Screen. This new and advanced product is set to revolutionize the field of solids control and separation, offering unmatched performance and efficiency for oil and gas drilling operations.The FLC 2000 PMD Screen is the result of years of research and development, aimed at addressing the challenges and demands of modern drilling operations. Equipped with state-of-the-art technology and engineering, this screen offers a range of features that set it apart from conventional screens in the market. Its advanced design allows for superior performance in separating solids and controlling the fluid properties, thereby ensuring smooth and efficient drilling operations.One of the key highlights of the FLC 2000 PMD Screen is its enhanced durability and longevity. Built using high-quality materials and advanced manufacturing processes, this screen is designed to withstand the rigors of the drilling environment, including high temperatures, abrasive materials, and heavy loads. This durability not only translates to cost savings for the operators but also ensures uninterrupted and reliable performance in the field.In addition to its durability, the FLC 2000 PMD Screen also offers superior performance in terms of solids control and separation. Its unique design and engineering allow for efficient removal of solids from the drilling fluid, leading to improved overall performance and reduced downtime. This is especially critical in challenging drilling environments, where the presence of solids can significantly impact the drilling process.The introduction of the FLC 2000 PMD Screen is a testament to Derrick Corporation's commitment to innovation and excellence in the oil and gas industry. With a legacy of over seven decades, the company has continuously strived to push the boundaries of technology and engineering, delivering solutions that meet the evolving needs of the industry. The FLC 2000 PMD Screen is a testament to this commitment, offering a product that not only meets but exceeds the expectations of the industry.Commenting on the launch of the FLC 2000 PMD Screen, Michael Wright, CEO of Derrick Corporation, said, "We are thrilled to introduce the FLC 2000 PMD Screen to the industry. This product represents the culmination of years of research, development, and engineering, aimed at delivering a solution that truly makes a difference in drilling operations. We are confident that the FLC 2000 PMD Screen will set a new benchmark for performance and efficiency, and we are excited to see the impact it will have in the field."The FLC 2000 PMD Screen is set to be available for purchase in the coming months, with Derrick Corporation working closely with its global network of partners and distributors to ensure widespread availability. With its unmatched performance, durability, and reliability, this screen is poised to become a game-changer in the field of solids control and separation, redefining the standards for drilling operations.As the oil and gas industry continues to evolve and face new challenges, innovations like the FLC 2000 PMD Screen will play a crucial role in driving efficiency, productivity, and performance. Derrick Corporation's commitment to excellence and its pioneering spirit are clearly evident in this latest offering, and it is set to make a significant impact in the industry.