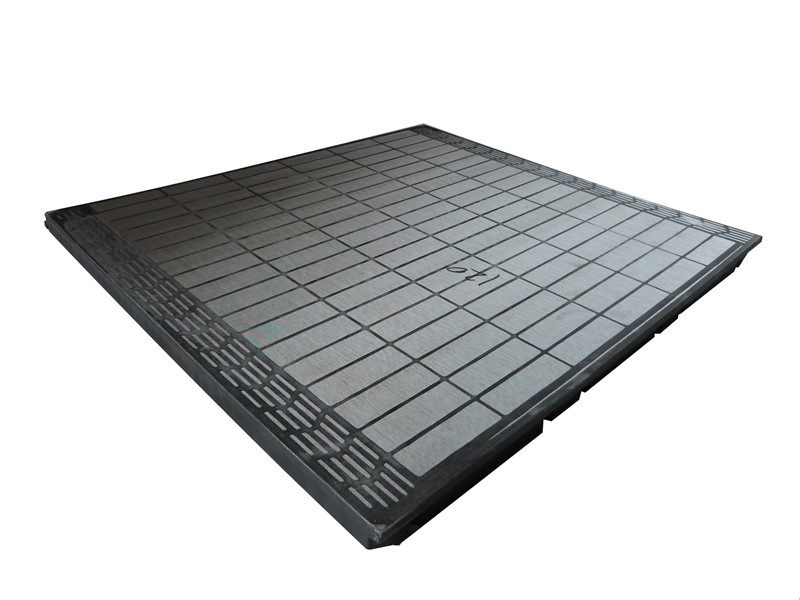

High-Quality Shaker Screen for Derrick FLC500 at Competitive Prices

By:Admin

The FLC500 Shaker Screen is engineered with the latest technology and high-quality materials to ensure maximum durability and longevity. This new addition to the Derrick product line is specifically designed to fit the FLC500 series shakers, providing a seamless integration and enhanced performance. With its advanced design and precision engineering, the FLC500 Shaker Screen is capable of handling a wide range of drilling applications, making it an ideal choice for a variety of drilling operations.

One of the key features of the FLC500 Shaker Screen is its robust construction, which is designed to withstand the rigors of the most demanding drilling environments. The screen is manufactured using high-quality composite materials, ensuring excellent resistance to wear and abrasion. This not only extends the lifespan of the screen, but also reduces maintenance costs and downtime, contributing to overall cost savings for drilling operations.

In addition to its durability, the FLC500 Shaker Screen is also designed to deliver exceptional performance. The screen features a high conductance design, which allows for efficient fluid handling and solids removal. This ultimately results in improved drilling fluid quality and reduced waste, contributing to a more sustainable and environmentally-friendly drilling process.

Furthermore, the FLC500 Shaker Screen is engineered to maximize the screening area, allowing for increased throughput and improved solids control. This increased screening area enables the screen to effectively separate solids from drilling fluids, leading to enhanced overall drilling performance. Additionally, the screen's precise opening size and mesh design ensure optimal particle removal, resulting in cleaner drilling fluids and improved drilling efficiency.

To ensure the highest level of quality and performance, the FLC500 Shaker Screen undergoes rigorous testing and quality assurance procedures. Derrick Corporation is committed to delivering superior products to its customers, and the FLC500 Shaker Screen is no exception. Each screen is thoroughly inspected to meet the company's strict quality standards, providing customers with confidence and peace of mind in their drilling operations.

The introduction of the FLC500 Shaker Screen further solidifies Derrick Corporation's position as a leading provider of innovative and high-performance drilling equipment. With a strong track record of delivering cutting-edge solutions to the global oil and gas industry, Derrick Corporation continues to push the boundaries of technology and engineering, setting new standards for drilling efficiency and productivity.

As drilling operations continue to evolve and become increasingly demanding, the need for advanced and reliable equipment has never been greater. The FLC500 Shaker Screen represents a significant advancement in shaker screen technology, offering unparalleled performance and durability to meet the challenges of today's drilling industry.

In conclusion, the introduction of the FLC500 Shaker Screen is a testament to Derrick Corporation's ongoing commitment to innovation and excellence. With its exceptional performance, durability, and efficiency, the FLC500 Shaker Screen is poised to make a significant impact on drilling operations worldwide, providing customers with a superior solution for their solids control needs.

Company News & Blog

High-Quality Steel Frame Shaker Screen with Vortex Orbital Technology

Vortex Orbital 3000PT: A Revolution in Shale Shaker Screens[Company Introduction][Company Name], a leading innovator in the oil and gas industry, is proud to introduce its latest groundbreaking product, the Vortex Orbital 3000PT Steel Frame Shaker Screen. Designed to meet the ever-increasing demands of the modern drilling industry, this advanced shale shaker screen promises exceptional performance, durability, and cost-effectiveness.The Vortex Orbital 3000PT is the result of years of research and development, carried out by our team of skilled engineers and industry experts. With a relentless focus on quality and innovation, we have successfully engineered a product that stands out in the highly competitive market.[Product Description]The key feature of the Vortex Orbital 3000PT Steel Frame Shaker Screen is its advanced construction. Built with a durable steel frame, this screen can withstand the harshest drilling conditions without compromising on performance. It is designed to fit most popular shale shakers, making it versatile and compatible with existing drilling equipment.The screen itself is made from high-quality composite material, specially formulated to deliver exceptional efficiency in separating solids from liquids during the drilling process. The Vortex Orbital 3000PT demonstrates superior performance in terms of cuttings disposal, fluid handling, and mesh integrity. Its unique design ensures maximum throughput while minimizing the risk of clogging or blinding.Furthermore, the Vortex Orbital 3000PT is engineered to be highly durable. The steel frame provides excellent support, minimizing the chances of premature wear and tear. This not only extends the lifespan of the screen but also reduces maintenance costs and downtime. Moreover, the screen is resistant to corrosion and abrasion, making it ideal for long-term use in demanding drilling operations.[Key Features]1. High-quality composite material for exceptional performance.2. Durable steel frame for maximum support and longevity.3. Versatile compatibility with popular shale shakers.4. Superior fluid handling and cuttings disposal capabilities.5. Reduced risk of clogging or blinding.6. Corrosion and abrasion-resistant for long-term use.7. Low maintenance costs and minimized downtime.[Benefits for the Industry]The Vortex Orbital 3000PT Steel Frame Shaker Screen offers several significant benefits to the oil and gas industry. One of the key advantages is its superior efficiency in separating solid particles from drilling fluids. This not only ensures smoother drilling operations but also leads to improved wellbore stability and reduced drilling costs.Another benefit lies in its compatibility with most popular shale shakers. The Vortex Orbital 3000PT can be seamlessly integrated into existing drilling equipment, eliminating the need for expensive modifications or replacements. This compatibility, coupled with the screen's exceptional durability, reduces downtime and increases overall drilling efficiency.Furthermore, the Vortex Orbital 3000PT's cost-effectiveness cannot be ignored. With its extended lifespan and reduced maintenance requirements, operators can save significantly on replacement costs and maintenance downtime, which translates into enhanced profitability.[Conclusion]In conclusion, the Vortex Orbital 3000PT Steel Frame Shaker Screen represents a major breakthrough in shale shaker screen technology. Its advanced construction, exceptional performance, durability, and compatibility make it a must-have for drilling operations worldwide. With an unwavering commitment to excellence, [Company Name] continues to push the boundaries of innovation, emphasizing the importance of reliable and efficient equipment in the oil and gas industry.

Quality Shaker Screens for Mongoose Shale Shakers

In recent news, (company name) has announced the release of their latest product, the (product name). This innovative screen is designed to provide improved efficiency and performance for the oil and gas industry, making it an essential tool for drilling operations.The (product name) is designed to fit the popular (product type) models and is constructed with high-quality materials to ensure durability in even the most demanding drilling environments. Its advanced technology allows for efficient solids control and fluid handling, making it a valuable asset for any drilling operation.The (product name) features a unique design that is engineered to maximize throughput and screen life, ultimately reducing the overall cost of operations. Its high-capacity composite frame provides increased support and resistance to wear and tear, making it a reliable and long-lasting solution for solids control.Furthermore, the (product name) is designed to offer quick and easy installation, reducing downtime and increasing productivity on the drilling site. Its superior performance and reliability make it an ideal choice for operators looking to improve their drilling efficiency and reduce overall operating costs.Additionally, (company name) has a long-standing reputation for delivering innovative and reliable products to the oil and gas industry. With a commitment to quality and customer satisfaction, they have become a trusted partner for drilling operations around the world.The company's extensive experience and expertise in the industry have allowed them to develop cutting-edge solutions that address the unique challenges faced by oil and gas operators. The introduction of the (product name) further demonstrates their dedication to providing industry-leading products and services.In addition to their exceptional product offerings, (company name) also provides comprehensive support and service to ensure that their customers receive the maximum benefit from their products. Their team of experts is available to provide technical assistance, training, and maintenance services to keep operations running smoothly.As the oil and gas industry continues to evolve, (company name) remains at the forefront of innovation, delivering solutions that meet the changing needs of the industry. The release of the (product name) further solidifies their position as a leader in the field of drilling equipment and technology.In conclusion, the (product name) from (company name) is a game-changing solution for the oil and gas industry, offering unmatched performance, reliability, and efficiency for drilling operations. With its advanced design and durable construction, it is sure to become an essential tool for operators looking to optimize their operations and reduce costs. As the industry continues to demand high-performance equipment, (company name) remains committed to providing the innovative solutions that operators need to succeed.

Composite Shaker Screen: New Technology for Improved Performance

Elgin KPT-28 Composite Shaker Screen, a state-of-the-art innovation in the oil and gas industry, has emerged as a game-changer with its exceptional performance and durability. The shaker screen, developed by a leading provider of solid and liquid separation products, has garnered widespread attention for its unmatched efficiency in separating solid materials from drilling fluid.The company behind this ground-breaking technology has a long-standing reputation for delivering high-quality products and services to various industries. With a strong focus on innovation and customer satisfaction, the company has become a trusted name in the field of solid and liquid separation.The Elgin KPT-28 Composite Shaker Screen stands out for its advanced composite frame and high-quality stainless steel wire mesh. This combination of materials ensures superior performance and longer lifespan, making it a cost-effective solution for drilling operations. Additionally, its unique design allows for increased throughput and better particle retention, contributing to improved overall efficiency in the separation process.One of the key advantages of the Elgin KPT-28 Composite Shaker Screen is its ability to withstand high vibration levels and harsh operating conditions. This resilience is particularly valuable in demanding drilling environments, where the equipment is exposed to extreme forces and abrasive materials. The shaker screen's robust construction and reliable performance make it an ideal choice for operators looking to minimize maintenance and replacement costs.Furthermore, the innovative design of the Elgin KPT-28 Composite Shaker Screen contributes to a more environmentally friendly approach to solid and liquid separation. By enhancing the efficiency of the separation process, the screen reduces the amount of waste generated and promotes sustainable practices in the oil and gas industry.In addition to its technical excellence, the company's commitment to customer support and service further distinguishes the Elgin KPT-28 Composite Shaker Screen. The company provides comprehensive assistance to its clients, offering expert advice, timely maintenance, and responsive troubleshooting to ensure the optimal performance of its products.The advanced technology and exceptional performance of the Elgin KPT-28 Composite Shaker Screen have garnered recognition from industry professionals and clients alike. The screen has been widely acclaimed for its contribution to operational efficiency, cost savings, and environmental sustainability in the oil and gas sector.With its unwavering dedication to innovation and customer satisfaction, the company has solidified its position as a leading provider of solid and liquid separation solutions. The unrivaled performance of the Elgin KPT-28 Composite Shaker Screen underscores the company's reputation for delivering excellence in the most demanding industrial settings.As the oil and gas industry continues to evolve, the demand for reliable and efficient separation equipment remains critical. The Elgin KPT-28 Composite Shaker Screen has demonstrated its capacity to meet and exceed these demands, setting a new standard for solid and liquid separation technology.In conclusion, the Elgin KPT-28 Composite Shaker Screen has established itself as a pioneering solution in the oil and gas industry, offering unparalleled performance, durability, and environmental sustainability. With the backing of a reputable and customer-oriented company, this innovative technology is poised to shape the future of solid and liquid separation, delivering value and efficiency to operators worldwide.

High-Quality FLC313M Screen: What You Need to Know

Derrick Corporation, a leading global provider of high-quality separation and filtration equipment, has recently launched its latest innovation – the FLC313M screen. This new addition to the company’s extensive product line promises to revolutionize the way the oil and gas industry approaches solids control and dewatering.The FLC313M screen is designed to deliver superior performance and efficiency in separating solids from drilling fluid. Its advanced design features a unique combination of high-quality materials and innovative engineering, resulting in increased throughput and reduced operating costs for customers. With a focus on durability and reliability, this screen is built to withstand the demands of the most challenging drilling environments.One of the standout features of the FLC313M screen is its versatility. Suitable for both onshore and offshore applications, this screen excels in a wide range of operating conditions, including high temperature and high-pressure environments. Its ability to consistently deliver exceptional performance in such diverse settings sets it apart from other products currently available on the market.Furthermore, Derrick Corporation is committed to providing best-in-class customer service and support. The launch of the FLC313M screen is part of the company’s ongoing effort to meet the evolving needs of its global customer base. By offering innovative solutions that enhance efficiency and productivity, Derrick Corporation continues to solidify its position as a trusted partner to the oil and gas industry.In addition to the FLC313M screen, Derrick Corporation offers a comprehensive range of separation and filtration equipment, including shakers, hydrocyclones, and centrifuges. With a proven track record of delivering high-performance solutions, the company has established itself as a leader in the field of solids control and dewatering.The development and launch of the FLC313M screen underscore Derrick Corporation’s dedication to innovation and excellence. By staying at the forefront of technological advancements, the company remains well-positioned to address the evolving needs of the oil and gas industry. As the industry continues to seek more efficient and cost-effective solutions, Derrick Corporation is poised to provide the cutting-edge equipment required to meet these demands.In conclusion, the introduction of the FLC313M screen represents a significant milestone for Derrick Corporation. With its unmatched performance, durability, and versatility, this new addition to the company’s product line is set to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to push the boundaries of innovation, customers can expect to benefit from the superior quality and reliability that have become synonymous with the company’s brand.About Derrick Corporation:Derrick Corporation is a global provider of high-quality separation and filtration equipment for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner to its global customer base. Derrick Corporation is committed to delivering best-in-class equipment and solutions that enhance efficiency and productivity in solids control and dewatering applications.

Multi-sizer Scapling: A game-changer in the industry

With the increasing demand for advanced technology in the mining and aggregates industry, one company is at the forefront of innovation with their latest product, the VSM Multi-sizer Scalping Screen. This cutting-edge equipment is set to revolutionize the way materials are sorted and processed, providing unparalleled efficiency and precision.The VSM Multi-sizer Scalping Screen is the brainchild of a leading manufacturer in the field of mineral processing equipment. With a strong focus on research and development, the company has been consistently pushing the boundaries of technology to meet the evolving needs of their customers. With a long-standing reputation for excellence and reliability, they have established themselves as a trusted partner in the industry.The VSM Multi-sizer Scalping Screen is a game-changer in the world of mineral processing. Its innovative design and advanced features make it the ideal solution for sorting materials in mining and aggregates operations. With its high capacity and precision screening capabilities, this equipment is able to handle a wide range of materials, from coarse aggregates to fine particles, with ease.One of the key features of the VSM Multi-sizer Scalping Screen is its modular design, which allows for easy customization to suit specific application requirements. This flexibility ensures that the equipment can adapt to the unique needs of different operations, providing a tailored solution for maximum efficiency and productivity.In addition to its advanced technology, the VSM Multi-sizer Scalping Screen is also designed with user-friendliness in mind. The intuitive control system and ergonomic design make it easy to operate and maintain, minimizing downtime and optimizing performance. This user-centric approach reflects the company's commitment to providing practical and reliable solutions for their customers.The VSM Multi-sizer Scalping Screen is also built to withstand the rigors of the mining and aggregates industry. Its robust construction and high-quality materials ensure long-lasting durability, even in the most demanding operating conditions. This reliability is an important factor for customers looking to maximize the uptime of their operations and minimize the total cost of ownership.The launch of the VSM Multi-sizer Scalping Screen is a significant milestone for the company and the industry as a whole. With its cutting-edge technology, versatility, and reliability, it is set to set a new standard for scalping screens in mineral processing operations. Customers can expect to see improvements in efficiency, productivity, and cost-effectiveness with this innovative equipment.The company's commitment to innovation and excellence is further exemplified by their comprehensive support and service offerings. From installation and commissioning to ongoing maintenance and technical support, they are dedicated to ensuring that their customers get the most out of their investment in the VSM Multi-sizer Scalping Screen. This holistic approach is a testament to their dedication to customer satisfaction and long-term partnerships.In conclusion, the VSM Multi-sizer Scalping Screen is a game-changing product that is set to redefine the standards of efficiency and precision in mineral processing operations. With its advanced technology, user-friendly design, and unmatched reliability, it is a testament to the company's commitment to pushing the boundaries of innovation and providing practical solutions for their customers. As the industry embraces the future of mineral processing, the VSM Multi-sizer Scalping Screen stands out as a symbol of progress and excellence.

New Study Reveals Surprising Results in Screen Time Study

Introducing: Innovative Screen Technology revolutionizes the way we interact with digital displays. This cutting-edge company, known for its advancements in screen technology, has developed a revolutionary new product that is set to change the way we interact with digital displays.The new technology, which is being hailed as a game-changer in the industry, uses a combination of high-resolution screens and advanced touch technology to create a more immersive and intuitive user experience. This means that users can now interact with digital displays in a way that was previously not possible, opening up new possibilities for a wide range of applications, from interactive retail displays to immersive entertainment experiences.One of the key features of this new technology is its ability to accurately detect touch input, allowing for a more natural and intuitive interaction with digital content. This means that users can now swipe, pinch, and zoom with greater precision and accuracy, making for a more seamless and enjoyable user experience.In addition to its advanced touch capabilities, the new technology also offers unparalleled image quality, with vibrant colors and crisp details that bring digital content to life. This means that the technology is perfectly suited for a wide range of applications, from high-resolution digital signage to immersive virtual reality experiences.Furthermore, the company's commitment to sustainability is reflected in its manufacturing processes. By using energy-efficient materials and reducing waste, the company's products have a lower environmental impact than traditional screens, making this innovation not only advanced but also environmentally friendly.The impact of this new technology is already being felt in the industry, with major players taking notice and incorporating the technology into their own products and experiences. This speaks to the potential for this technology to become a standard feature in the digital display market, further solidifying the company's position as a leader in the industry.In conclusion, the new screen technology developed by the company is set to revolutionize the way we interact with digital displays, offering an unparalleled combination of advanced touch capabilities, high-resolution image quality, and sustainability. With its potential to become a standard feature in the industry, this innovation is poised to change the way we engage with digital content, opening up new possibilities for a wide range of applications. As the company continues to push the boundaries of screen technology, it is clear that the future of digital displays is brighter than ever.

High-Quality D380 Shaker Screen for Efficient Solid Control Operations

Shale shakers are essential tools used in the oil and gas industry for separating solids from drilling fluid. They play a crucial role in the drilling process by removing large solids from the drilling fluid, allowing the fluid to be recycled and reused. Therefore, the quality and efficiency of shale shaker screens are of utmost importance in ensuring smooth and productive drilling operations.In this regard, the Swaco D380 shaker screen has gained widespread recognition for its exceptional performance and durability. Manufactured by a leading company in the industry, this shaker screen is designed to withstand the most demanding drilling conditions while delivering consistent and reliable performance.The Swaco D380 shaker screen features a high-quality stainless steel wire mesh that is tightly woven to ensure maximum filtration efficiency. The screen is further reinforced with multiple layers of support mesh and a durable frame to withstand the high levels of vibration and impact encountered during drilling operations. This robust construction not only enhances the longevity of the screen but also ensures consistent performance in separating solids from the drilling fluid.One of the key advantages of the Swaco D380 shaker screen is its ability to provide a larger effective screening area, allowing for increased throughput and improved solids removal. This is particularly beneficial in high-volume drilling operations where the efficient removal of solids is critical to maintaining the integrity of the drilling fluid and the overall success of the operation.Additionally, the Swaco D380 shaker screen is designed for compatibility with a wide range of shale shaker models, making it a versatile and cost-effective solution for drilling contractors and operators. This compatibility ensures that the screen can be easily integrated into existing equipment, minimizing downtime and optimizing operational efficiency.Furthermore, the company behind the Swaco D380 shaker screen is committed to upholding the highest quality standards in its manufacturing processes. With state-of-the-art facilities and a team of experienced engineers and technicians, the company ensures that each screen meets strict quality control measures, resulting in a product that consistently meets and exceeds industry requirements.In line with its commitment to quality, the company also provides comprehensive technical support and assistance to its customers, ensuring that the Swaco D380 shaker screen is installed and maintained correctly for optimal performance. This level of support is indicative of the company's dedication to customer satisfaction and its understanding of the critical role that the shaker screen plays in the overall drilling process.As the oil and gas industry continues to evolve and demand grows for more efficient and reliable drilling technologies, the Swaco D380 shaker screen remains a trusted solution for operators seeking to enhance their drilling operations. Its superior performance, durability, and compatibility make it an indispensable tool for achieving maximum solids control and fluid management.In conclusion, the Swaco D380 shaker screen, manufactured by a leading company in the industry, stands as a testament to the commitment to quality, innovation, and customer satisfaction. With its exceptional performance and reliability, this shaker screen continues to set the standard for excellence in the field of solids control, contributing to the success of drilling operations worldwide.

Derrick Hyperpool Shaker Screen for PMD - What You Need to Know

Derrick Corporation, a global leader in the supply of high-performance separation and filtration equipment, has introduced its latest innovation in solids control technology - the Hyperpool PMD Shaker screen. This cutting-edge product offers superior performance and durability to enhance drilling operations in the oil and gas industry.The Hyperpool PMD Shaker screen is designed to efficiently remove solid particles from drilling fluid, also known as drilling mud, during the drilling process. This is a crucial step in the extraction of oil and gas, as the presence of solid particles can hinder the performance of drilling equipment and ultimately affect the overall efficiency of the operation.One of the key features of the Hyperpool PMD Shaker screen is its advanced design, which allows for increased throughput capacity and improved solids removal efficiency. This results in higher productivity and cost savings for drilling operations, as the need for frequent screen changes and maintenance is significantly reduced.In addition, the Hyperpool PMD Shaker screen is built to withstand the challenging and harsh conditions encountered in oil and gas drilling operations. Its durable construction and long-lasting performance make it a reliable and cost-effective solution for operators looking to optimize their solids control processes.Furthermore, Derrick Corporation has a proven track record of delivering high-quality products and services to the oil and gas industry. With over 70 years of experience, the company has established itself as a trusted partner for operators seeking innovative and reliable solutions for their separation and filtration needs.The introduction of the Hyperpool PMD Shaker screen further solidifies Derrick Corporation's commitment to providing industry-leading technology that meets the evolving demands of the oil and gas sector. By continuously investing in research and development, the company strives to remain at the forefront of innovation and deliver solutions that drive operational efficiency and performance.In response to the introduction of the Hyperpool PMD Shaker screen, Derrick Corporation's CEO commented, "We are excited to bring this advanced technology to the market, as we believe it will greatly benefit our customers and help them achieve their operational objectives. The Hyperpool PMD Shaker screen is a testament to our ongoing dedication to delivering innovative and high-performance solutions that address the challenges faced by the oil and gas industry."As the global demand for oil and gas continues to rise, the need for efficient and reliable solids control equipment has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen is poised to make a significant impact on drilling operations worldwide, offering enhanced performance, durability, and cost savings.With its proven expertise and commitment to innovation, Derrick Corporation is well-positioned to continue driving advancements in solids control technology and empowering operators to achieve greater success in their drilling operations. The introduction of the Hyperpool PMD Shaker screen is a testament to the company's unwavering dedication to excellence and its ability to deliver solutions that meet the evolving needs of the oil and gas industry.

VSM Multi-sizer Primary Oil Shaker Screen for Efficient Oil Processing

Brandt VSM Multi-sizer Primary Oil Shaker Screen is a new and innovative product in the oil and gas industry. This advanced shaker screen is designed to improve the efficiency and performance of oil and gas drilling operations. The Brandt VSM Multi-sizer Primary Oil Shaker Screen is manufactured by a leading company that specializes in providing high-quality equipment for the oil and gas industry.The Brandt VSM Multi-sizer Primary Oil Shaker Screen is specifically designed to handle the high demands and challenges of oil and gas drilling. It is equipped with advanced technology and features that make it a reliable and effective solution for improving the performance of shaker screens in the industry. This new shaker screen is designed to be durable, efficient, and reliable, making it an ideal choice for oil and gas drilling operations.The company behind the Brandt VSM Multi-sizer Primary Oil Shaker Screen is known for its commitment to quality and innovation. With years of experience in the industry, the company has established itself as a leading provider of high-quality equipment and solutions for the oil and gas sector. The company's dedication to research and development has allowed it to create innovative products like the Brandt VSM Multi-sizer Primary Oil Shaker Screen, which is designed to meet the specific needs and challenges of the industry.The Brandt VSM Multi-sizer Primary Oil Shaker Screen is built to withstand the harsh conditions and demands of oil and gas drilling operations. It is designed to effectively remove solids and other impurities from drilling fluids, ensuring that the fluids remain clean and stable throughout the drilling process. This innovative shaker screen is also designed to be easy to install and maintain, reducing downtime and improving overall operational efficiency.One of the key features of the Brandt VSM Multi-sizer Primary Oil Shaker Screen is its multi-sizer capability, which allows it to handle a wide range of drilling fluid viscosities and flow rates. This makes it a versatile solution for different drilling conditions, allowing for consistent and reliable performance in various drilling operations. The shaker screen is also designed to maximize the use of available screen area, ensuring efficient and effective solid control during drilling operations.When it comes to environmental sustainability, the Brandt VSM Multi-sizer Primary Oil Shaker Screen is designed to minimize waste and energy consumption. It is built with durable materials that can withstand the rigors of drilling operations, reducing the need for frequent replacements and repairs. This not only saves time and money for drilling operators but also reduces the environmental impact of oil and gas drilling activities.In conclusion, the Brandt VSM Multi-sizer Primary Oil Shaker Screen is a cutting-edge solution for the oil and gas industry. With its advanced technology, durable construction, and versatile capabilities, this innovative shaker screen is poised to improve the efficiency and performance of oil and gas drilling operations. Backed by a reputable company with a strong track record of providing high-quality equipment, the Brandt VSM Multi-sizer Primary Oil Shaker Screen is set to become a game-changer in the industry.

VSM 300 Secondary Oil Shaker Screen: A Guide to Choosing the Best Option

Global Oil Shaker Screen Company is proud to announce its latest innovation, the VSM 300 Secondary Oil Shaker Screen. This new product is designed to offer superior performance and efficiency in the oil drilling and extraction process, further solidifying our position as a leader in the industry.The VSM 300 Secondary Oil Shaker Screen is a high-quality replacement screen that is compatible with the VSM 300 shale shaker. It is designed to effectively remove solids from drilling fluid while ensuring maximum efficiency and durability. This new product is the result of extensive research and development, as well as feedback from our customers in the oil and gas industry.One of the key features of the VSM 300 Secondary Oil Shaker Screen is its advanced composite frame, which provides increased strength and longer service life compared to traditional metal frames. This innovative design reduces the risk of screen failure and ensures that the screen can withstand the demanding conditions of oil drilling operations. Additionally, the screen is manufactured using high-quality materials that are resistant to corrosion and abrasion, further enhancing its longevity and performance.In addition to its durability, the VSM 300 Secondary Oil Shaker Screen also offers superior solids control capabilities. The screen features a unique layered design that effectively separates solids from drilling fluid, allowing for the efficient removal of unwanted particles. This not only helps to maintain the quality of the drilling fluid but also reduces the wear and tear on downstream equipment, resulting in cost savings and improved operational efficiency.Furthermore, the VSM 300 Secondary Oil Shaker Screen is engineered to provide a high conductance rate, ensuring that drilling fluid can flow through the screen at an optimal rate. This helps to prevent blockages and ensures that the drilling process can continue uninterrupted, ultimately leading to increased productivity and reduced downtime.As a global leader in the oil and gas industry, Global Oil Shaker Screen Company is committed to providing high-quality products and exceptional service to our customers. Our team of experienced engineers and technicians are dedicated to developing innovative solutions that meet the evolving needs of the industry, and the VSM 300 Secondary Oil Shaker Screen is a testament to this commitment.With the introduction of the VSM 300 Secondary Oil Shaker Screen, Global Oil Shaker Screen Company is continuing its legacy of excellence and innovation in the oil and gas industry. This new product showcases our dedication to providing superior solutions for solids control and fluid management, and we are confident that it will deliver exceptional performance in a wide range of drilling applications.In conclusion, the VSM 300 Secondary Oil Shaker Screen is a testament to Global Oil Shaker Screen Company's dedication to innovation and excellence in the oil and gas industry. With its advanced design, superior durability, and unmatched performance, this new product is set to revolutionize solids control in oil drilling operations, providing our customers with a reliable and efficient solution for their fluid management needs. As we look to the future, Global Oil Shaker Screen Company remains committed to pushing the boundaries of innovation and delivering value to our customers around the world.