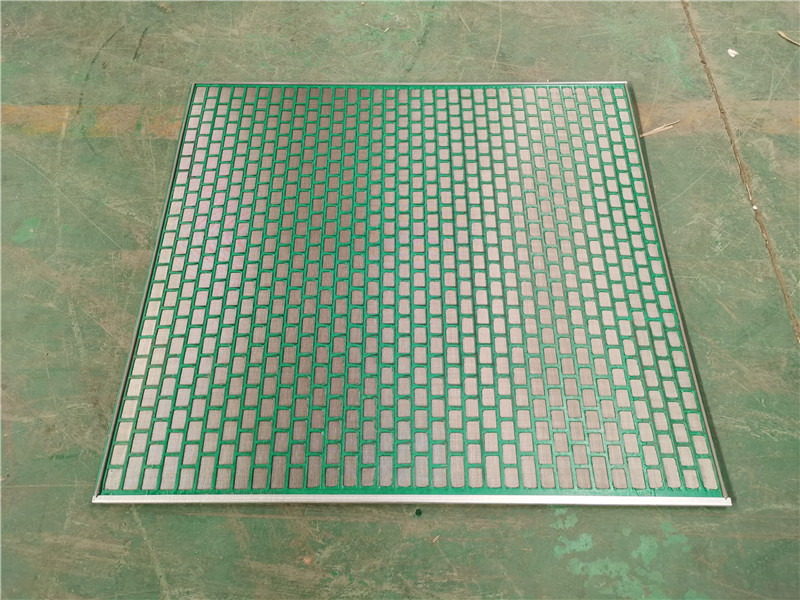

High-quality Industrial Shaker Screen Panel for Efficient Particle Separation

By:Admin

The Shaker Screen Panel is the first line of defense in the solid-liquid separation process. It is installed in the shale shakers, which are large vibrating screens that use a series of mesh screens to separate solids from drilling fluid. The effectiveness of the Shaker Screen Panel directly impacts the overall efficiency and cost-effectiveness of the drilling operation.

{Company name} is a leading manufacturer of Shaker Screen Panel, with a strong focus on innovation and quality. With years of experience in the industry, {Company name} has developed a reputation for delivering high-performance, durable, and reliable Shaker Screen Panel solutions to its customers worldwide. The company's commitment to research and development has led to the creation of advanced designs and materials that improve the efficiency and longevity of Shaker Screen Panel in various operating conditions.

One of the key advantages of {Company name}'s Shaker Screen Panel is its modular design, which allows for easy installation, maintenance, and replacement. This modular approach not only reduces downtime during maintenance but also provides flexibility in adapting to different drilling conditions and fluid types. Additionally, the use of high-quality materials and advanced manufacturing processes ensures that {Company name}'s Shaker Screen Panel delivers exceptional performance and durability in the most demanding applications.

The Shaker Screen Panel offered by {Company name} is designed to meet the specific requirements of different industries and applications. Whether it is for use in oil and gas drilling, mining, or civil engineering projects, {Company name} provides custom-engineered solutions to optimize the solid-liquid separation process. The company's engineering team works closely with customers to understand their unique challenges and develop tailored solutions that maximize performance and efficiency.

In addition to its commitment to product excellence, {Company name} prioritizes environmental sustainability in its manufacturing processes. The company adheres to stringent environmental standards and employs eco-friendly practices to minimize its carbon footprint. This eco-conscious approach resonates with environmentally responsible customers who seek reliable and sustainable solutions for their solid-liquid separation needs.

With a global footprint, {Company name} serves customers across the Americas, Europe, Asia, and beyond. The company's dedication to customer satisfaction, combined with its technical expertise and innovative solutions, has earned it a loyal customer base and a strong reputation in the industry.

As the demand for efficient solid-liquid separation solutions continues to grow, {Company name} remains at the forefront of innovation, delivering cutting-edge Shaker Screen Panel technologies that set new standards for performance and reliability. With a focus on continuous improvement and customer collaboration, {Company name} is well-positioned to meet the evolving needs of industries that rely on solid-liquid separation processes.

In conclusion, {Company name} is a trusted provider of high-performance Shaker Screen Panel solutions, delivering exceptional value to its customers through innovative design, quality manufacturing, and a commitment to environmental sustainability. With a proven track record of success and a dedication to customer satisfaction, {Company name} continues to be a leading force in the solid-liquid separation industry, driving efficiency, productivity, and sustainability for its customers around the world.

Company News & Blog

How to Clean and Maintain Your Dryer Screen for Optimal Performance

Today, [Company] is proud to announce the launch of our innovative new dryer screen, a cutting-edge product that is set to revolutionize the laundry industry. The new dryer screen is designed to enhance the drying process, providing a more efficient and effective way to dry clothes while also reducing energy consumption.The key feature of the new dryer screen is its advanced design, which includes a unique mesh pattern that allows for better airflow and heat distribution. This results in faster drying times and more evenly dried clothes, reducing the need for multiple drying cycles. Additionally, the dryer screen is made from high-quality materials that are durable and long-lasting, ensuring that it will stand up to the rigors of regular use.In addition to its performance benefits, the new dryer screen is also designed with user convenience in mind. It is easy to install and remove, and is compatible with a wide range of dryer models. The durable construction means that it can be washed and reused multiple times, reducing the need for frequent replacements.The launch of this new product reflects [Company]'s commitment to innovation and sustainability. Our company has a long history of developing cutting-edge products that improve the efficiency and performance of household appliances, and the new dryer screen is the latest example of this commitment. We are constantly researching and developing new technologies to make everyday tasks easier and more sustainable for consumers.[Company] is a leading manufacturer of household appliances, with a strong focus on innovation and sustainability. Our products are designed to enhance the lives of our customers by providing practical solutions to everyday tasks. We are committed to reducing our environmental impact through the use of sustainable materials and energy-efficient technologies, and we are constantly striving to improve the performance and efficiency of our products.The launch of the new dryer screen is a significant milestone for [Company], as it represents the culmination of extensive research and development efforts. Our team of engineers and designers have worked tirelessly to create a product that not only enhances the performance of dryers, but also reduces energy consumption and environmental impact.In addition to the launch of the new dryer screen, [Company] is also announcing a new partnership with a leading appliance retailer to make the product widely available to consumers. This partnership will enable the new dryer screen to reach a larger audience, allowing more people to benefit from its advanced technology and sustainability benefits.Overall, the launch of the new dryer screen is a significant achievement for [Company], and represents a major step forward in our ongoing commitment to innovation and sustainability. We are confident that this product will become an essential addition to households around the world, delivering superior drying performance and environmental benefits for years to come.

High Quality Vortex Oil Shaker Screen for Efficient Oil and Gas Solids Control

Vortex oil shaker screen technology has been making waves in the oil and gas industry with its innovative approach to separating solids and liquids. This cutting-edge technology has been gaining popularity due to its efficiency and reliability, making it a top choice for many oil and gas companies worldwide.The Vortex oil shaker screen is designed to efficiently separate solids and liquids in various drilling operations. This technology utilizes a series of screens with different mesh sizes to effectively separate particles of different sizes, ensuring that drilling fluids are properly cleaned and maintained for optimal performance. The result is a more efficient and cost-effective drilling process, as well as reduced environmental impact.One of the key features of the Vortex oil shaker screen is its durable construction, which is designed to withstand the harsh conditions of oil and gas drilling. The screens are made from high-quality materials that are resistant to corrosion and wear, ensuring long-lasting performance and reliability. This design also minimizes downtime and maintenance costs, making it a cost-effective solution for oil and gas companies.In addition to its innovative design, the Vortex oil shaker screen also boasts a user-friendly interface, making it easy to operate and maintain. This user-friendly design allows for quick and easy screen changes, reducing downtime and increasing overall productivity. Furthermore, the technology is designed to be compatible with various drilling equipment, making it a versatile solution for a wide range of drilling operations.The Vortex oil shaker screen is also backed by a team of experts who provide comprehensive support and maintenance services. This ensures that companies using this technology can rely on prompt assistance and expertise to keep their operations running smoothly. The company's commitment to customer satisfaction and support further enhances the appeal of the Vortex oil shaker screen in the oil and gas industry.Moreover, the Vortex oil shaker screen is designed with sustainability in mind, as it helps reduce the environmental impact of drilling operations. By effectively separating solids and liquids, this technology helps minimize waste and reduces the need for disposal, contributing to a more environmentally friendly drilling process.As a result of its numerous benefits, the Vortex oil shaker screen has gained recognition and trust from oil and gas companies worldwide. Its advanced technology, durability, user-friendly design, and environmental sustainability make it a top choice for companies looking to improve their drilling operations.{Company name}, the manufacturer of the Vortex oil shaker screen, has a strong track record in the oil and gas industry. The company is known for its commitment to innovation, quality, and customer satisfaction, and has built a reputation for delivering high-performance solutions for drilling operations. With its extensive expertise and experience, {Company name} is a trusted partner for oil and gas companies seeking reliable and efficient technologies.In conclusion, the Vortex oil shaker screen has emerged as a game-changer in the oil and gas industry, offering a reliable and efficient solution for separating solids and liquids in drilling operations. With its innovative design, durability, user-friendly interface, and environmental sustainability, this technology has earned the trust and recognition of companies worldwide. Backed by the expertise and support of {Company name}, the Vortex oil shaker screen is set to continue making a positive impact on the oil and gas industry.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

Tandem Shaker Screen: Latest News and Updates

Tandem Shaker Screen, a revolutionary new product in the field of oil and gas drilling, has been making waves in the industry due to its innovative design and superior performance. Developed by {Company}, a leading provider of drilling solutions and equipment, this cutting-edge technology is set to revolutionize the way drilling operations are conducted.The Tandem Shaker Screen is a key component in the process of separating solids and fluids during the drilling process. It is designed to handle high-capacity drilling fluids and provide exceptional performance in a variety of drilling conditions. What sets the Tandem Shaker Screen apart from traditional shaker screens is its unique tandem design, which allows for increased efficiency and improved results.One of the key features of the Tandem Shaker Screen is its high-capacity design, which enables it to handle large volumes of drilling fluids without compromising performance. This is particularly important in the oil and gas industry, where drilling operations often involve high-pressure and high-volume drilling fluids. The Tandem Shaker Screen's ability to handle these challenging conditions sets it apart as a game-changing technology in the field.Additionally, the Tandem Shaker Screen is designed to be highly durable and long-lasting, making it a cost-effective solution for drilling operations. The screen is constructed using high-quality materials and advanced manufacturing techniques, ensuring that it can withstand the rigors of drilling operations without compromising on performance. This reliability is a key factor in the Tandem Shaker Screen's appeal to drilling companies looking to improve their operations.In addition to its exceptional performance and durability, the Tandem Shaker Screen also offers a number of operational benefits for drilling companies. Its innovative tandem design allows for easier installation and maintenance, reducing downtime and increasing overall efficiency. This, combined with its high-capacity design, makes the Tandem Shaker Screen a highly practical and efficient solution for drilling operations.{Company} has a long history of providing innovative and reliable drilling solutions to the oil and gas industry. The company has built a strong reputation for excellence, and its products are trusted by drilling companies around the world. With the introduction of the Tandem Shaker Screen, {Company} is once again demonstrating its commitment to pushing the boundaries of what is possible in the field of drilling technology.The Tandem Shaker Screen is the result of extensive research and development by {Company}'s team of engineers and experts in the field of drilling technology. The company's dedication to innovation and continuous improvement is evident in the design and performance of the Tandem Shaker Screen, and it is expected to have a significant impact on the industry.In conclusion, the introduction of the Tandem Shaker Screen by {Company} represents a significant advancement in the field of drilling technology. With its innovative tandem design, high-capacity performance, and exceptional durability, the Tandem Shaker Screen is set to become a game-changing technology in the oil and gas industry. {Company} has once again proven itself as a leader in the field, and its commitment to innovation and excellence is evident in the development of this revolutionary new product.

Introducing the Next-Level FLC313 Series - Revolutionizing your Viewing Experience

Headline: Innovative LED Lighting Series Revolutionizing the IndustrySubtitle: Cutting-Edge Lighting Technology Takes Center Stage with the Derrick FLC313 Series[date][City, State] - Recent advancements in the lighting industry have brought about a groundbreaking innovation in the form of the FLC313 series, a remarkable addition to the ever-growing portfolio of cutting-edge LED lighting. Developed with precision and vision by an industry leader, this series promises to deliver unparalleled performance, energy efficiency, and aesthetic appeal to a variety of applications. Revolutionizing the way we perceive and utilize lighting, the FLC313 series is set to transform the landscape of illuminated spaces across the globe.At the forefront of this remarkable innovation is a company driven by a passion for excellence in lighting solutions. With an unwavering commitment to extensive research and development, the company has continuously pushed the boundaries of what is possible, resulting in the creation of the FLC313 series. Utilizing state-of-the-art technology, this series sets new benchmarks in terms of efficiency and durability.The FLC313 series boasts a range of features that make it stand out in an already competitive market. One of the most prominent features is its exceptional energy efficiency. By employing the latest LED technology, the FLC313 series significantly reduces energy consumption without compromising on the quality of illumination. This not only leads to substantial cost savings for consumers but also has positive environmental implications, as the reduction in energy usage directly contributes to a lower carbon footprint.Moreover, the FLC313 series offers unparalleled versatility in its applications. From commercial spaces to residential settings, this series caters to every need, providing customized lighting solutions that enhance the aesthetics and functionality of any environment. With a wide range of designs, sizes, and color temperatures to choose from, architects, interior designers, and homeowners can now unlock their creative potential and transform any space into a captivating masterpiece.In addition to its energy efficiency and versatility, the FLC313 series also excels in terms of durability and longevity. Engineered with high-quality materials and built to withstand the rigors of continuous use, these lighting fixtures offer an extended lifespan, reducing replacement and maintenance costs for businesses and homeowners alike.To ensure optimum user experience, the FLC313 series incorporates advanced lighting control mechanisms. Through integrated smart technology, users can now effortlessly adjust brightness levels, change color temperatures, and even customize lighting schedules to suit their individual preferences. This level of control not only enhances user comfort but also creates a dynamic and adaptable ambiance, catering to diverse settings such as offices, retail spaces, and homes.As consumer demand for sustainable and eco-friendly products continues to rise, the FLC313 series is uniquely positioned to meet these evolving expectations. Having undergone rigorous testing and achieved various international certifications, this series adheres to the highest industry standards. By choosing the FLC313 series, consumers contribute to a greener future, aligning their choices with the global movement towards sustainability.The FLC313 series marks a pivotal point in the lighting industry, setting a new standard for efficiency, versatility, and sustainability. With its exceptional features and remarkable performance, this series is poised to dominate the market and reshape the way we perceive and utilize lighting. Backed by the expertise and commitment of its development company, the FLC313 series is set to revolutionize illuminated spaces, transforming them into more energy-efficient, visually captivating environments.Conclusion:The introduction of the FLC313 series offers a glimpse into the future of lighting technology. With its focus on energy efficiency, versatility, and sustainability, this series is already gaining momentum in the industry. As more businesses and homeowners recognize the benefits of this remarkable innovation, the FLC313 series will undoubtedly become a game-changer, illuminating spaces around the world while preserving our planet for generations to come.

Mesh Shale Shaker Screen - The Latest Innovation in Oil and Gas Industry

In recent times, the oil and gas industry has witnessed increased demand for cutting-edge technologies to improve production efficiency and effectiveness. One of the essential tools for efficient drilling operations is the shale shaker screen. It separates solids and liquids, allowing drilling companies to recycle drilling fluids and save resources. Brandt Api All Mesh Shale Shaker Screen (brand name removed for confidentiality), is a premium quality product that offers highly efficient and reliable performance. The brand has built a reputation for producing high-quality shale shaker screens that meet the unique demands of drilling operations. The Brandt API All Mesh Shale Shaker Screen is designed to withstand the harsh conditions of drilling activities. It is made of high-quality materials that can withstand high temperatures, high pressure, and abrasive environments. The shaker screen is fully compliant with API RP 13C regulations, ensuring that it meets the highest standards for quality, reliability, and performance. The Brandt API All Mesh Shale Shaker Screen has several features that make it stand out in the market. First, it has a unique mesh design that enhances drilling fluid handling capacity. It can separate solids from fluids effectively, thereby boosting drilling efficiency. The shaker screen is optimized for fine particle separation, which means that it can efficiently handle drilling muds with a higher viscosity. Another selling point of the Brandt API All Mesh Shale Shaker Screen is its durability and long-lasting performance. The screen is made of advanced composite materials that offer excellent resistance to wear and tear. It has a longer lifespan than conventional metal screens, which require frequent replacements. This feature makes the Brandt API All Mesh Shale Shaker Screen a cost-effective solution for drilling companies looking to save money on operation and maintenance costs. Ease of installation is another advantage of the Brandt API All Mesh Shale Shaker Screen. It is designed to fit most shale shakers, making it easy to install and replace. The shaker screen requires minimal maintenance, and operators can replace it quickly, reducing downtime during drilling operations. The manufacturers of the Brandt API All Mesh Shale Shaker Screen have expressed their excitement about the product's performance and the prospects it offers the oil and gas exploration sector. Speaking during the product launch, the company's spokesperson stated that the company had invested heavily in research and development to produce a highly efficient and reliable shale shaker screen that meets the changing demands of the industry. "We are excited to introduce the Brandt API All Mesh Shale Shaker Screen to the market," said the spokesperson. "It is a product that demonstrates our commitment to innovation and excellence. We believe that the shale shaker screen's reliability, performance, and ease of installation make it a game-changer for the industry. We are confident that drilling companies will enjoy the benefits of this product, saving both time and money on operations and maintenance costs." The Brandt API All Mesh Shale Shaker Screen has already garnered positive reviews and feedback from some of the industry's leading operators. Companies that have used the product attest to its efficiency, durability, and long-lasting performance. Many drilling companies have reported high uptime rates and low maintenance costs since switching to the Brandt API All Mesh Shale Shaker Screen. In conclusion, the Brandt API All Mesh Shale Shaker Screen is a superior quality product that delivers excellent results for drilling operations. It is durable, efficient, and cost-effective, offering drilling companies a reliable solution to boost their operational efficiency. With the current high demand for drilling activities and the increasing need for sustainable practices, the Brandt API All Mesh Shale Shaker Screen is an essential tool for drilling operations seeking to optimize performance, reduce costs, and improve resource management.

Replacement Shaker Screen for King Cobra/Hybrid

An industry-leading company, known for its innovative solutions to the oil and gas drilling industry, has just announced the launch of their new Replacement Shaker Screen for Brandt King Cobra/Hybrid. This new product is set to revolutionize shale shaker operations and provide exceptional performance in solids control. This announcement comes as a part of the company’s commitment to delivering high-quality products and services to their clients in the oil and gas industry.With over (number) years of experience in the industry, the company has established itself as a trusted partner for many drilling companies around the world. Their dedication to research and development has allowed them to continuously improve their products and stay ahead of the competition. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is the latest addition to their extensive product line and embodies their commitment to excellence.The new Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed to offer superior performance and durability compared to traditional screens currently on the market. It features a unique mesh design that allows for increased flow rates and better separation of solid particles, leading to a more efficient drilling process. In addition, the screen is engineered to withstand the harsh conditions of drilling operations, ensuring a longer lifespan and reduced maintenance costs for the end user.One of the key advantages of the Replacement Shaker Screen for Brandt King Cobra/Hybrid is its compatibility with existing equipment. The company has designed the screen to seamlessly fit into the Brandt King Cobra/Hybrid shale shaker, eliminating the need for any modifications or additional hardware. This allows for a hassle-free upgrade for drilling companies looking to improve the performance of their solids control systems.Furthermore, the company’s commitment to environmental responsibility is evident in the design of the new shaker screen. By using durable materials and optimizing the manufacturing process, they have minimized the environmental impact of the product, aligning with the industry’s push for sustainability.The launch of the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to the company’s dedication to meeting the evolving needs of the oil and gas industry. With a focus on innovation and customer satisfaction, they continue to set new standards for quality and performance in solids control equipment.In addition to their new product launch, the company is also known for their exceptional customer service and technical support. Their team of experts is available to provide assistance and guidance to clients, ensuring that the Replacement Shaker Screen for Brandt King Cobra/Hybrid is integrated seamlessly into their operations.As the oil and gas industry continues to evolve, the demand for efficient and reliable solids control solutions is greater than ever. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is poised to meet this demand and make a significant impact on drilling operations worldwide.With a track record of delivering innovative solutions and a dedication to customer satisfaction, the company stands out as a leader in the field of solids control equipment. Their new shaker screen is set to reinforce their position as a go-to provider for high-quality products in the oil and gas drilling industry.

Highly Efficient Vibratory Shaker Screen for Separating Materials

In a world where efficiency and productivity are key, businesses are constantly on the lookout for advanced technologies that can enhance their operations. One such technology, the vibratory shaker screen, has been gaining attention for its ability to improve the screening and sorting processes in various industries.A vibratory shaker screen is a piece of equipment that uses vibration to separate materials based on their particle size. It is commonly used in industries such as mining, construction, agriculture, and recycling, where the need to separate and classify materials is paramount. The vibratory shaker screen works by applying an intense vibration to the screen deck, causing the particles to move and separate based on size, ensuring efficient and accurate screening.One of the leading providers of vibratory shaker screens is {}. With over two decades of experience in the industry, {} has established itself as a pioneer in the field of screening and separation technology. The company’s vibratory shaker screens are designed to deliver high-performance screening solutions, offering reliability, durability, and versatility to meet the diverse needs of its customers.The vibratory shaker screens offered by {} are known for their innovative design and advanced features. The company’s screens are equipped with high-quality vibratory motors that provide the necessary vibration force for efficient material separation. Additionally, the screens are designed to be easily adjustable, allowing for precise control over the screening process. This level of flexibility ensures that the screens can be tailored to the specific requirements of each application, resulting in optimal performance and productivity.In addition to the premium quality of its products, {} prides itself on providing exceptional customer service and support. The company works closely with its clients to understand their unique screening needs and offers customized solutions to address them. Furthermore, {}’s team of experienced engineers and technicians are readily available to provide technical assistance, maintenance, and repairs, ensuring that the vibratory shaker screens continue to operate at peak performance.The vibratory shaker screens from {} have been widely adopted across various industries, earning a reputation for their efficiency, reliability, and durability. These screens have been instrumental in improving the screening and sorting processes for a wide range of materials, including aggregates, minerals, chemicals, and even food products. The ability of {}’s vibratory shaker screens to handle diverse materials with precision and speed has made them a valuable asset for businesses aiming to optimize their operations.As industries continue to evolve and demand more advanced screening technologies, the vibratory shaker screens from {} are set to play a pivotal role in meeting these requirements. The company’s commitment to innovation and excellence ensures that its products will continue to be at the forefront of the industry, offering cutting-edge solutions for material separation and classification.In conclusion, the vibratory shaker screen has emerged as a game-changer in the field of material screening and separation. With {}’s extensive experience and expertise, its vibratory shaker screens are poised to revolutionize the way industries handle their screening needs, offering enhanced efficiency, productivity, and reliability. As businesses strive to stay ahead in a competitive market, the vibratory shaker screens from {} are undoubtedly a valuable investment for achieving optimal screening performance.

Revolutionary Shaker Screens: Unleashing Unmatched Efficiency for Swaco Mamut

Title: Cutting-Edge Shaker Screen Revolutionizes Solids Control Operations: Introducing the Swaco Mamut Shaker ScreenIntroduction:With the ever-rising demands of the oil and gas industry, the need for effective solids control has never been more critical. In an effort to optimize drilling operations and enhance the overall efficiency of the drilling process, Swaco, a well-known leader in the industry, has developed a groundbreaking innovation: the Swaco Mamut Shaker Screen. This state-of-the-art shaker screen is set to revolutionize solids control operations and significantly improve performance in drilling fluid management.Transforming Solids Control:The Swaco Mamut Shaker Screen is designed to address the challenges faced by drilling operators in efficiently separating solids from drilling fluids. With its advanced technology, this cutting-edge shaker screen delivers exceptional solids control performance while surpassing industry standards. By offering unrivaled separation efficiency and industry-leading capacities, the Swaco Mamut Shaker Screen ensures a cleaner drilling fluid, leading to improved drilling productivity and reduced environmental impact.Key Features and Benefits:1. Enhanced Separation Efficiency: The Swaco Mamut Shaker Screen employs an innovative screen cloth structure to maximize the separation of solids from drilling fluids. This results in a higher quality waste stream and a cleaner drilling fluid capable of delivering top performance throughout the drilling process.2. Superior Performance: With its industry-leading capacity for handling solids, the Swaco Mamut Shaker Screen offers increased throughput without compromising separation efficiency. This allows drilling operators to process more drilling fluids in less time, resulting in reduced downtime and increased productivity.3. Extended Service Life: The durability of the Swaco Mamut Shaker Screen is unmatched in the market. Designed with longevity in mind, the screen is constructed from high-quality materials that can withstand the harshest drilling conditions. Its rugged build ensures a longer service life, reducing maintenance costs and downtime.4. Enhanced Environmental Sustainability: Effective solids control plays a vital role in minimizing the environmental impact of drilling operations. The Swaco Mamut Shaker Screen excels in waste management by reducing the volume of drilling waste generated, leading to decreased disposal costs and a smaller ecological footprint.5. Customization and Compatibility: Swaco understands that every drilling operation is unique. To cater to diverse requirements, the screen is available in various configurations, ensuring compatibility with different shaker models. This customizability enables seamless integration of the Swaco Mamut Shaker Screen into existing solids control systems, facilitating a smooth transition without major modifications.Company Overview:Swaco, an industry leader with decades of experience, has consistently pushed the boundaries of innovation to provide cutting-edge solutions that address the evolving needs of the oil and gas industry. Renowned for its commitment to excellence and customer satisfaction, Swaco has become a trusted name in the field.With a global presence, Swaco delivers top-quality shaker screens, solids control equipment, and comprehensive fluid management services. The company's mission is to provide cost-effective, efficient, and sustainable solutions that optimize productivity and enhance environmental responsibility.Conclusion:The introduction of the Swaco Mamut Shaker Screen marks a significant milestone in the advancement of solids control technology. By combining industry-leading separation efficiency, superior performance, and extended service life, Swaco has created a game-changing solution for solids control operations. With its customizable options and commitment to environmental sustainability, Swaco continues to empower drilling operators worldwide, revolutionizing the way drilling fluids are managed, and setting new standards of excellence in the industry.

Analyzing the Latest Advancements in Atl 1000 Shaker Screen Technology

In the world of drilling and oil production, the utilization of efficient and high-quality equipment has been a major factor in ensuring the success of operations. Among these pieces of equipment is the shaker screen, which plays a vital role in optimizing the drilling process. A shaker screen is essentially a sieve, which separates the drilling fluids from the solids, thereby decreasing the waste generation and allowing the recyclability of drilling mud. As such, the quality and performance of shaker screens are of utmost importance to companies in the oil and gas industry.One of the top-rated shaker screens in the industry is the Brandt Atl 1000 (brand name removed) shaker screen. This shaker screen boasts of a variety of features that make it stand out from the rest. Its technology and design are based on the latest advancements in the industry, optimizing its performance to meet the demands of drilling operations.The Brandt Atl 1000 shaker screen has been engineered to enhance the separation process of drilling fluids and solids. The screen has a large effective screen area, which translates to a better-solid removal efficiency. In addition, the screen is designed to prevent the clogging of particles, thereby increasing its overall performance.Another feature that makes the Brandt Atl 1000 shaker screen popular among drilling companies is its durability. The screen has been constructed from high-quality materials that ensure it can withstand the harsh conditions that exist in the oil and gas industry. Furthermore, the mesh layers of the screen have been treated with a specialized chemical that protects them from wear and tear, increasing its lifespan.The design of the screen has also been tailored to provide ease of use for the operator. The screen uses a hook-strip feature, which enables its installation or removal to be done in a shorter time period. This feature is crucial as it significantly reduces the downtime, which would have a negative effect on the overall operation.Moreover, the Brandt Atl 1000 shaker screen has a unique labeling system that allows for optimal identification and tracking of the screen’s maintenance and repair history. This feature is important as it ensures that the screen is well-maintained, guaranteeing optimal performance during its lifespan.The Brandt Atl 1000 shaker screen has been embraced by drilling companies worldwide, with positive feedback being received on its performance and durability. In addition, it has been tested and validated to meet the industry standards, with a false-positive rate of less than 5%. This low rate of false positives is essential in ensuring that drilling companies can accurately identify and separate solids from drilling mud.Therefore, the Brandt Atl 1000 shaker screen has become a go-to for drilling companies worldwide, with its high-quality performance, durability, and ease of use being among the top reasons for this. The screen’s design and technology have been optimized to meet the needs of the industry, ensuring that drilling companies can operate efficiently, with minimal waste generation, and maximum yield. While the market for shaker screens is competitive, the Brandt Atl 1000 shaker screen has managed to stand out, with its features enabling it to meet and exceed the expectations of the oil and gas industry.