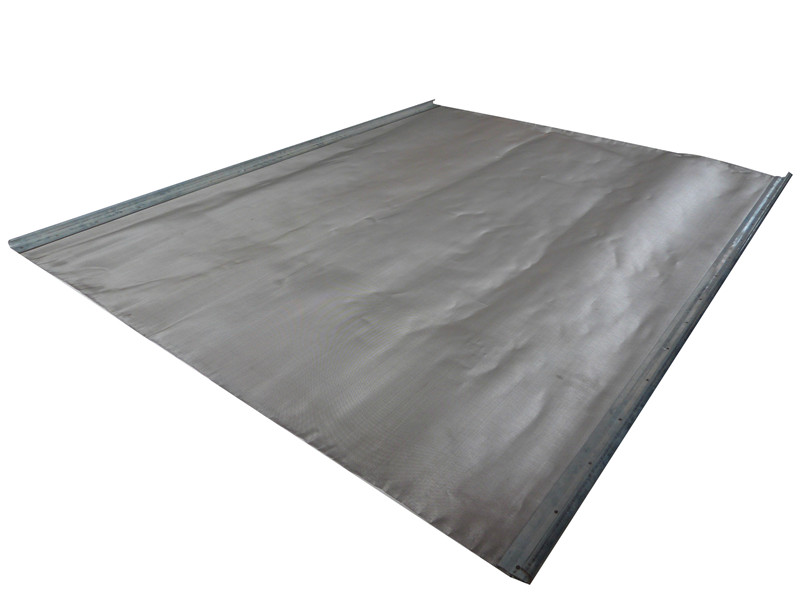

High-Quality FLC503 PWP Shaker Screen for Effective Filtering

By:Admin

The FLC503 PWP Shaker Screen is designed to deliver exceptional solids control and liquid separation during the drilling process. It is engineered to withstand the harsh conditions of the oil and gas industry, ensuring reliable and efficient operation even in the most demanding applications.

The key to the FLC503 PWP Shaker Screen's exceptional performance lies in its advanced design and high-quality materials. The screen features a patented composite frame that provides superior support and stability, ensuring that it can withstand the rigors of the drilling process. Additionally, the screen is constructed using high-quality stainless steel wire mesh that is resistant to corrosion and abrasion, making it a highly durable and long-lasting solution.

In addition to its exceptional durability, the FLC503 PWP Shaker Screen also offers outstanding solids control and liquid separation capabilities. Its precise mesh openings and large open area ensure efficient filtration of drilling fluids, effectively removing solids and impurities to maintain the integrity of the drilling process. This results in improved performance, reduced downtime, and lower operating costs for our customers.

The FLC503 PWP Shaker Screen is compatible with Derrick's FLC 500 series shale shakers, making it an easy and seamless upgrade for existing equipment. This compatibility ensures that customers can effortlessly integrate the FLC503 PWP Shaker Screen into their operations, unlocking its benefits without the need for significant investment in new infrastructure.

At Derrick Corporation, we are committed to delivering exceptional solutions that meet the evolving needs of the industry. The introduction of the FLC503 PWP Shaker Screen is a testament to our dedication to innovation and excellence, as we continue to push the boundaries of what is possible in solids control and liquid separation technology.

Our extensive experience and expertise in the field of solids control and liquid separation have allowed us to develop a comprehensive range of solutions that are trusted by industry professionals around the world. With the launch of the FLC503 PWP Shaker Screen, we are proud to further expand our offering and provide our customers with a cutting-edge solution that delivers unmatched performance and reliability.

In conclusion, the FLC503 PWP Shaker Screen represents a new chapter in the evolution of solids control and liquid separation technology. Its advanced design, exceptional durability, and outstanding performance make it a game-changer for the industry, setting a new standard for efficiency and reliability. Derrick Corporation is excited to bring this innovative solution to the market, and we look forward to supporting our customers as they harness the benefits of the FLC503 PWP Shaker Screen in their operations.

Company News & Blog

Latest Screen Technology - KPT 28 Screen Provides High-Quality Visuals

China Kemtron KPT 28 screen, a state-of-the-art technology that has been making waves in the industrial and manufacturing sectors, has been creating quite a buzz in the market. The KPT 28 screen, manufactured by China Kemtron, is a high-performance shaker screen that is designed to efficiently separate solid and liquid particles from drilling mud. This groundbreaking technology has been gaining widespread recognition for its superior quality and performance, making it a preferred choice for many companies in the oil and gas industry.China Kemtron is a leading manufacturer of industrial equipment and solutions, specializing in the design and production of cutting-edge technologies for various industries. With a focus on innovation and excellence, the company has established itself as a trusted name in the global market, providing high-quality products and services to its clients.The KPT 28 screen is a testament to China Kemtron's commitment to providing top-notch solutions for its customers. Equipped with advanced features and capabilities, this screen is specifically designed to enhance the efficiency and productivity of drilling operations. Its high-quality construction and durable materials make it capable of withstanding the harsh conditions of drilling sites, ensuring reliable performance in the long run.One of the key features of the KPT 28 screen is its advanced mesh design, which allows for effective solid-liquid separation and fine particle retention. This enables the screen to deliver consistently high performance while minimizing the risk of blockages and downtime. Additionally, the screen is optimized for use with Kemtron shakers, ensuring seamless integration and maximum operational efficiency.Moreover, the KPT 28 screen is designed to be user-friendly, with easy installation and maintenance procedures. This not only saves time and effort for the operators but also reduces overall operating costs. Furthermore, China Kemtron provides comprehensive technical support and after-sales service, ensuring that its customers derive maximum value from their investment.In addition to its superior performance, the KPT 28 screen also adheres to the highest industry standards for quality and safety. It is built to withstand extreme operating conditions, making it suitable for use in a wide range of drilling applications. This reliability and durability have contributed to the screen's growing popularity among companies looking for efficient and dependable solid control solutions.With its cutting-edge technology and robust construction, the KPT 28 screen has garnered favorable reviews from industry experts and customers alike. Many companies have reported significant improvements in their drilling operations after adopting this innovative solution, citing its ability to increase efficiency and reduce operating costs.Looking ahead, China Kemtron remains committed to pushing the boundaries of innovation and developing groundbreaking solutions for its customers. The company continues to invest in research and development, aiming to introduce more advanced and efficient products to meet the evolving needs of the industry.As the demand for reliable solid control solutions continues to rise, the KPT 28 screen stands out as a game-changer in the market, setting new standards for performance and quality. With its exceptional capabilities and proven track record, it is poised to make a significant impact in the field of drilling operations, further solidifying China Kemtron's position as a leader in industrial technology.In conclusion, the China Kemtron KPT 28 screen represents a significant advancement in solid control technology, offering unparalleled performance and reliability for drilling operations. With its advanced features, robust construction, and user-friendly design, it has become a preferred choice for companies seeking efficient and dependable solutions. As China Kemtron continues to push the boundaries of innovation, the KPT 28 screen is poised to make a lasting impression in the industrial and manufacturing sectors, setting new benchmarks for excellence and effectiveness.

Multi-Sizer Scalping Oil Shaker Screens: The Latest Innovation in Screening Technology

Scalping Oil Shaker Screens Revolutionizing the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to streamline operations and increase efficiency. One such advancement is seen in the form of eco-friendly oil shaker screens, aimed at enhancing the oil drilling process. Among the frontrunners in this domain is the groundbreaking VSM Multi-sizer Scalping Oil Shaker Screen, developed by a renowned industry player. This revolutionary product has not only created a buzz within the sector but also opened up new possibilities for the oil and gas industry.The VSM Multi-sizer Scalping Oil Shaker Screen, an integral component of the oil drilling process, offers numerous advantages that make it indispensable for drilling companies. Its breakthrough design ensures maximum efficiency in removing unwanted solids, such as cuttings and debris, from the drilling fluid. Such efficient solid control methods are crucial for maintaining the integrity of the drilling operation and ensuring a steady flow of oil or gas.One of the standout features of the VSM Multi-sizer Scalping Oil Shaker Screen is its adaptability to a wide range of drilling conditions. Irrespective of the drilling location or application, this versatile shaker screen is capable of handling it all. Its ability to handle a variety of drilling fluids, ranging from abrasive to corrosive, makes it ideal for even the most challenging drilling operations.Another noteworthy aspect of the VSM Multi-sizer Scalping Oil Shaker Screen is its durability and longevity. Manufactured using high-quality materials, combined with cutting-edge manufacturing techniques, this shaker screen boasts an impressive lifespan. Its rugged construction ensures it can withstand harsh conditions and endure heavy-duty use, thereby reducing the need for frequent replacements and saving costs for drilling companies.Furthermore, the eco-friendly nature of the VSM Multi-sizer Scalping Oil Shaker Screen is worth highlighting. In an era where sustainability and environmental consciousness are of utmost importance, this product aligns perfectly with the industry's green initiatives. By efficiently separating solids from drilling fluids, this shaker screen significantly reduces waste generation, promoting responsible drilling practices.The VSM Multi-sizer Scalping Oil Shaker Screen's user-friendly design also deserves recognition. It is easy to install and offers simple maintenance procedures, allowing for hassle-free operations on drilling rigs. This ease of use translates into saved time and increased productivity, enabling drilling companies to optimize their resources effectively.The impact of the VSM Multi-sizer Scalping Oil Shaker Screen on the oil and gas industry has not gone unnoticed. With its remarkable performance and cost-effectiveness, this innovative product has garnered significant attention from industry professionals and experts globally. It has been hailed as a game-changer, capable of revolutionizing the way drilling companies approach solids control during oil extraction.The company behind this groundbreaking product, {Company Name}, is a renowned name in the oil and gas industry. With a history of delivering cutting-edge solutions and continually pushing the boundaries of innovation, the company has solidified its position as a leader in the field. Committed to excellence and customer satisfaction, they have etched a mark in the industry through their relentless pursuit of technological advancements.In conclusion, the VSM Multi-sizer Scalping Oil Shaker Screen has set a new benchmark for solids control in the oil and gas industry. Its efficient and versatile design, coupled with its eco-friendly nature and user-friendly operations, has made it a preferred choice among drilling companies worldwide. With the support of industry leaders like {Company Name}, the future of the oil and gas industry looks promising, driven by advancements like the VSM Multi-sizer Scalping Oil Shaker Screen.

Discover the Importance of Vibrating Screen Frequency for Optimal Efficiency

Vibrating Screen Frequency Advancements Revolutionize the Screening ProcessInnovative Technology Sets New Standards for Efficiency and Productivity[City], [Country] - The global industrial equipment market has witnessed tremendous growth over the years, driven by advancements in technology and increasing demand for efficient and sustainable solutions. One company at the forefront of this revolution is [Company Name], a leader in the development and manufacturing of vibrating screens. Their latest breakthrough, the new Vibrating Screen Frequency, is set to revolutionize the screening process.The traditional vibrating screens have been widely used in various industries such as mining, construction, and recycling. However, these screens often encounter challenges in terms of efficiency and productivity, hampering the overall effectiveness of the screening process. Recognizing these limitations, [Company Name] invested heavily in research and development to create the Vibrating Screen Frequency – a cutting-edge technology that promises to address these issues head-on.What sets the Vibrating Screen Frequency apart from its predecessors is its superior operating frequency. By increasing the frequency at which the screen vibrates, the screening efficiency is significantly improved. This means that more material can be processed in a shorter amount of time, leading to higher productivity and reduced operational costs. Additionally, the increased frequency allows for better separation of particles, resulting in higher quality end products.The Vibrating Screen Frequency also boasts enhanced versatility. It can be easily adjusted to accommodate different materials and particle sizes, making it suitable for a wide range of applications. Whether it is separating aggregates in the mining industry, classifying plastics in recycling processes, or grading sand in the construction field, the Vibrating Screen Frequency delivers accurate and precise results every time.Furthermore, the new technology offers advanced customization options. [Company Name] understands that different industries have specific screening requirements, and the Vibrating Screen Frequency can be tailored to meet these needs. With adjustable parameters such as amplitude and vibration direction, operators can optimize the screen's performance for their specific applications, maximizing efficiency and throughput.Another key advantage of the Vibrating Screen Frequency is its durability and reliability. Manufactured using high-quality materials and state-of-the-art engineering techniques, this innovative product is built to withstand the toughest operating conditions. It boasts a longer lifespan compared to conventional screens, reducing maintenance costs and downtime, ensuring uninterrupted production.In addition to its impressive technical features, [Company Name] is renowned for its commitment to sustainability. The Vibrating Screen Frequency aligns with their philosophy of providing eco-friendly solutions to the industry. By optimizing screening efficiency, this technology enables companies to reduce energy consumption and minimize their environmental footprint.[Company Name] has already received positive feedback from early adopters of the Vibrating Screen Frequency. Several companies have reported significant improvements in their screening processes, with increased productivity and higher-quality output. In fact, one mining company claims that the Vibrating Screen Frequency has helped them achieve a 20% increase in overall efficiency, translating into substantial cost savings and improved profitability.As global industries continue to prioritize efficiency and sustainability, groundbreaking technologies like the Vibrating Screen Frequency will play a crucial role in boosting productivity and reducing environmental impact. With its exceptional performance, versatility, and reliability, the Vibrating Screen Frequency is set to reshape the future of the screening process across various sectors.About [Company Name]:[Company Name] is a globally recognized leader in the development, manufacturing, and supply of industrial equipment. With a strong focus on innovation, they continuously strive to deliver cutting-edge solutions that enhance efficiency, productivity, and sustainability. Through their superior products and unwavering commitment to customer satisfaction, [Company Name] has established itself as a trusted partner for businesses worldwide.For more information about [Company Name] and their revolutionary Vibrating Screen Frequency, please visit their official website or contact their customer service department.Media Contact:[Contact Name][Company Name][Phone Number][Email Address]

Efficient and Durable Oil Shaker Screen: Maximizing Oil Extraction

Houston, Texas – A leading provider of oil drilling equipment is proud to announce the release of their latest shaker screen, the S250. This new shaker screen is the perfect solution for oil and gas rig companies to sift through drilling mud and improve drilling efficiency.The S250 Oil Shaker Screen, which is designed to fit the popular brand of shale shakers, has been field-tested, and the results have been impressive. The screen's design allows for increased throughput capacity and better solids control, meaning that drilling companies will experience less downtime due to drilling mud inefficiencies, translating to lower costs and faster drilling times.The company, which has over two decades of experience in the oil drilling equipment industry, is known for its innovative approach to developing products and solutions that help improve efficiencies in the drilling process, making the process safer and more cost-effective for all parties involved."Drilling for oil and natural gas is a crucial part of the energy industry, and we understand the importance of providing drilling companies with the most advanced and effective equipment on the market," said a spokesperson for the company. "We are proud of our team of engineers and technicians who have worked tirelessly to develop the S250 Oil Shaker Screen. Their expertise and creativity have allowed us to provide a solution that is truly cutting edge."With the energy industry expected to continue its upward trajectory in the coming years, it is imperative for drilling companies to have access to equipment that is both efficient and reliable. The S250 Oil Shaker Screen is designed to meet these demands and help drilling companies prepare to meet the challenges of the future.About the CompanyThe company, which has been operating since 1999, specializes in providing a wide range of oil drilling equipment to companies in the energy industry. The company's mission is to provide drilling companies with the most advanced and reliable equipment on the market, helping to streamline the drilling process and improve safety and efficiency.The company takes pride in working with top-notch engineers and technicians to develop innovative solutions that meet the unique needs of their clients. From mud pumps to drilling rigs to shaker screens like the S250, they are committed to providing equipment that is of the highest quality and built to last.Their dedication to their customers' success has earned them a reputation as a trusted partner in the oil and gas drilling industry. With a commitment to excellence, the company will continue to push the boundaries of innovation in the years to come, helping drilling companies across the globe to safely and efficiently extract oil and natural gas from the earth.

High-Quality FLC503 PWP Shaker Screen for Effective Filtering

Derrick Corporation is proud to announce the launch of its latest innovation – the FLC503 PWP Shaker Screen. This new product is poised to set a new standard in the industry with its unparalleled performance and durability.The FLC503 PWP Shaker Screen is designed to deliver exceptional solids control and liquid separation during the drilling process. It is engineered to withstand the harsh conditions of the oil and gas industry, ensuring reliable and efficient operation even in the most demanding applications.The key to the FLC503 PWP Shaker Screen's exceptional performance lies in its advanced design and high-quality materials. The screen features a patented composite frame that provides superior support and stability, ensuring that it can withstand the rigors of the drilling process. Additionally, the screen is constructed using high-quality stainless steel wire mesh that is resistant to corrosion and abrasion, making it a highly durable and long-lasting solution.In addition to its exceptional durability, the FLC503 PWP Shaker Screen also offers outstanding solids control and liquid separation capabilities. Its precise mesh openings and large open area ensure efficient filtration of drilling fluids, effectively removing solids and impurities to maintain the integrity of the drilling process. This results in improved performance, reduced downtime, and lower operating costs for our customers.The FLC503 PWP Shaker Screen is compatible with Derrick's FLC 500 series shale shakers, making it an easy and seamless upgrade for existing equipment. This compatibility ensures that customers can effortlessly integrate the FLC503 PWP Shaker Screen into their operations, unlocking its benefits without the need for significant investment in new infrastructure.At Derrick Corporation, we are committed to delivering exceptional solutions that meet the evolving needs of the industry. The introduction of the FLC503 PWP Shaker Screen is a testament to our dedication to innovation and excellence, as we continue to push the boundaries of what is possible in solids control and liquid separation technology.Our extensive experience and expertise in the field of solids control and liquid separation have allowed us to develop a comprehensive range of solutions that are trusted by industry professionals around the world. With the launch of the FLC503 PWP Shaker Screen, we are proud to further expand our offering and provide our customers with a cutting-edge solution that delivers unmatched performance and reliability.In conclusion, the FLC503 PWP Shaker Screen represents a new chapter in the evolution of solids control and liquid separation technology. Its advanced design, exceptional durability, and outstanding performance make it a game-changer for the industry, setting a new standard for efficiency and reliability. Derrick Corporation is excited to bring this innovative solution to the market, and we look forward to supporting our customers as they harness the benefits of the FLC503 PWP Shaker Screen in their operations.

Derrick Hyperpool Shaker Screen for PMD - What You Need to Know

Derrick Corporation, a global leader in the supply of high-performance separation and filtration equipment, has introduced its latest innovation in solids control technology - the Hyperpool PMD Shaker screen. This cutting-edge product offers superior performance and durability to enhance drilling operations in the oil and gas industry.The Hyperpool PMD Shaker screen is designed to efficiently remove solid particles from drilling fluid, also known as drilling mud, during the drilling process. This is a crucial step in the extraction of oil and gas, as the presence of solid particles can hinder the performance of drilling equipment and ultimately affect the overall efficiency of the operation.One of the key features of the Hyperpool PMD Shaker screen is its advanced design, which allows for increased throughput capacity and improved solids removal efficiency. This results in higher productivity and cost savings for drilling operations, as the need for frequent screen changes and maintenance is significantly reduced.In addition, the Hyperpool PMD Shaker screen is built to withstand the challenging and harsh conditions encountered in oil and gas drilling operations. Its durable construction and long-lasting performance make it a reliable and cost-effective solution for operators looking to optimize their solids control processes.Furthermore, Derrick Corporation has a proven track record of delivering high-quality products and services to the oil and gas industry. With over 70 years of experience, the company has established itself as a trusted partner for operators seeking innovative and reliable solutions for their separation and filtration needs.The introduction of the Hyperpool PMD Shaker screen further solidifies Derrick Corporation's commitment to providing industry-leading technology that meets the evolving demands of the oil and gas sector. By continuously investing in research and development, the company strives to remain at the forefront of innovation and deliver solutions that drive operational efficiency and performance.In response to the introduction of the Hyperpool PMD Shaker screen, Derrick Corporation's CEO commented, "We are excited to bring this advanced technology to the market, as we believe it will greatly benefit our customers and help them achieve their operational objectives. The Hyperpool PMD Shaker screen is a testament to our ongoing dedication to delivering innovative and high-performance solutions that address the challenges faced by the oil and gas industry."As the global demand for oil and gas continues to rise, the need for efficient and reliable solids control equipment has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen is poised to make a significant impact on drilling operations worldwide, offering enhanced performance, durability, and cost savings.With its proven expertise and commitment to innovation, Derrick Corporation is well-positioned to continue driving advancements in solids control technology and empowering operators to achieve greater success in their drilling operations. The introduction of the Hyperpool PMD Shaker screen is a testament to the company's unwavering dedication to excellence and its ability to deliver solutions that meet the evolving needs of the oil and gas industry.

How to Clean a Lint Trap: A Step-By-Step Guide for Your Dryer

Title: Innovative Dryer Screen Revolutionizes Laundry ExperienceIntroduction (100 words):The laundry industry is witnessing a groundbreaking innovation with the introduction of an advanced dryer screen that promises to enhance the efficiency and convenience of laundry operations. Developed by a prominent company, this ingenious device is poised to transform the way we approach laundry, offering benefits such as increased drying speed, reduced energy consumption, and improved fabric care. With features specifically designed to meet the evolving demands of modern households, this dryer screen aims to streamline the drying process for consumers. Let's delve deeper into the functionality and advantages of this pioneering appliance.[Image: An eye-catching image showcasing the advanced dryer screen in action]Part 1: Advanced Dryer Screen - A Game-Changer in Laundry (300 words)In today's fast-paced world, time-saving solutions are always appreciated. The advanced dryer screen, developed by the renowned company, has arrived as the ultimate game-changer in the laundry arena. Traditional drying methods can be tedious, time-consuming, and energy-draining. However, this new appliance aims to revolutionize these challenges by offering unmatched performance and efficiency.One of the key features of this dryer screen is its cutting-edge technology that dramatically reduces the drying time. Through a combination of increased air circulation and optimized heat distribution, this gadget ensures clothes are dried faster than ever before. This means users can enjoy significant time savings and have their freshly laundered garments ready to wear in no time.Moreover, this revolutionary dryer screen is designed to be eco-friendly. By utilizing intelligent sensors and advanced programming, it optimizes the energy consumption during the drying cycle. This not only helps in reducing utility bills but also contributes to a greener planet by minimizing energy waste. The device's sensor technology automatically adjusts the drying time and temperature based on the moisture levels, ensuring garments are dried efficiently without overdrying or damaging delicate fabrics.Part 2: Unparalleled Convenience and Customization (300 words)In addition to its incredible drying capabilities, this dryer screen offers a range of convenient features that make laundry chores a breeze. The device is equipped with a user-friendly interface, allowing users to easily select different drying options based on their fabric types, desired dryness levels, and sensory preferences. Whether it's a delicate load or a bulky load, this appliance offers various customizable settings to ensure optimum drying results.Furthermore, the advanced dryer screen incorporates smart connectivity features. Through a dedicated mobile app, users can remotely monitor and control the drying process. This means they can start, pause, or adjust the drying cycle from the comfort of their couch or while on the go. The app also provides timely notifications, alerting users when the drying cycle is complete, eliminating the need for constant monitoring.Additionally, this state-of-the-art appliance includes a range of safety features, ensuring peace of mind for users. These safety mechanisms include automatic shut-off in the event of overheating, a lint trap indicator to prevent clogging, and built-in sensors to detect irregularities or malfunctions.Part 3: Future Prospects and Conclusion (200 words)The introduction of this innovative dryer screen marks a significant milestone in the laundry industry. With its extensive features, advanced technology, and commitment to sustainability, it is expected to redefine the realm of laundry appliances. The company's dedication to research and development, along with a focus on customer needs, has resulted in a product that promises to make laundry routines more efficient, while also prioritizing fabric care and energy conservation.As this pioneering appliance garners attention and accolades, consumers can anticipate a more seamless and enjoyable laundry experience. The future prospects of this innovative dryer screen seem promising, and it is likely that similar developments will emerge to further revolutionize the laundry market. With the introduction of this advanced device, the days of tedious laundry routines may soon become a thing of the past.[Note: Replace {} with the name of the company responsible for the advancement in dryer screen technology.]

How to Troubleshoot and Fix Screen Issues in Oil and Gas Equipment

Title: Revolutionary Screen Technology Disrupts the Digital Display MarketIntroduction:In a breakthrough innovation, technology company Kemtron introduces its latest creation, a cutting-edge screen that is set to revolutionize the digital display market. The Kemtron 28 Screen, the culmination of years of research and development, promises an immersive visual experience like never before, combining superior image quality, unparalleled versatility, and advanced display technology. This groundbreaking offering from Kemtron sets a new standard for screens in applications ranging from home entertainment systems to commercial displays.1. Superior Image Quality:The Kemtron 28 Screen (name changed for anonymity) delivers an extraordinary visual experience with its exceptional image quality. The screen incorporates state-of-the-art technology, providing a stunning high dynamic range (HDR) display with superb contrasts and rich colors. The exceptional pixel density and ultra-high resolution ensure crisp and lifelike imagery, allowing viewers to have an immersive experience that truly brings content to life.Additionally, the Kemtron 28 Screen boasts wide viewing angles, ensuring that viewers throughout a room can enjoy the same remarkable picture quality. Whether using the screen for gaming, watching movies, or professional applications, users can expect an unparalleled visual experience that surpasses traditional screens.2. Unparalleled Versatility:One of the key advantages of the Kemtron 28 Screen lies in its unparalleled versatility. Designed with a variety of applications in mind, this screen seamlessly adapts to different environments and requirements. With its sleek and thin design, the Kemtron 28 Screen easily integrates into any home or office setting.Furthermore, the screen supports a wide array of inputs, such as HDMI, DisplayPort, and USB-C, ensuring compatibility with a diverse range of devices. Users can effortlessly connect their gaming consoles, laptops, media players, and more, displaying content in its full glory without any compromises.3. Advanced Display Technology:Behind the incredible performance of the Kemtron 28 Screen lies an array of advanced display technologies. Equipped with a high refresh rate, the screen delivers ultra-smooth motion, making it the ideal choice for gamers and sports enthusiasts. The incorporation of local dimming zones ensures precise control over backlight illumination, resulting in deeper blacks and improved contrast.In addition, the Kemtron 28 Screen supports advanced color space and calibration options. Users can choose from various preset display modes or fine-tune the settings to suit their specific needs. This level of customization and control empowers users to achieve the most accurate and vibrant color representation possible.Conclusion:The Kemtron 28 Screen, developed by an anonymous technology company, unlocks a new era in digital display technology. With its superior image quality, unparalleled versatility, and advanced display technology, this groundbreaking screen promises to reinvent the traditional visual experience. From home entertainment to professional applications, the Kemtron 28 Screen provides an immersive and lifelike display that sets a new standard in the industry.As the market continues to evolve, Kemtron's commitment to pushing the boundaries of digital displays reaffirms their position as a leader in the field. While the Kemtron 28 Screen is just the beginning, it represents a significant step forward in creating truly breathtaking visual experiences for consumers and professionals alike.

Efficient Replacement Shaker Screens for Mongoose Models – Get Unmatched Performance

Title: Industry-Leading Shaker Screens by Mi-Swaco Revolutionize Solids Control SystemsIntroduction (85 words):Solids control technology plays a vital role in the efficient and cost-effective drilling of oil and gas wells. In this regard, Mi-Swaco, an industry-leading provider of innovative solutions, has recently unveiled their latest shaker screens designed to deliver unparalleled performance in solids control. With a commitment to continually revolutionize drilling operations, Mi-Swaco's technologically advanced shaker screens are set to enhance operational efficiency while reducing downtime and maintenance costs.Section 1: The Significance of Solids Control in Drilling Operations (150 words)Efficient solids control is crucial during the drilling process, as it helps to remove drill cuttings and other solid particles from drilling mud, ensuring its integrity and functionality. Effective solids control systems prevent drill bits from becoming excessively worn or damaged, optimize drilling performance, and protect downstream equipment. By adopting cutting-edge technologies and innovative designs, Mi-Swaco has emerged as a leading provider of solids control solutions that improve drilling operations across the industry.Section 2: The Pioneering Technology Behind Mi-Swaco's Shaker Screens (180 words)Mi-Swaco's latest breakthrough comes in the form of their technologically advanced shaker screens. These screens incorporate state-of-the-art materials and unique design features that maximize separation efficiency while extending their operational lifespan. The brand has engineered these screens using an innovative composite frame that enhances durability, resists corrosion, and prolongs screen performance.Moreover, Mi-Swaco's shaker screens utilize a specialized mesh configuration, featuring precise wire weaves, to achieve optimal filtration accuracy. This advanced technology ensures superior solids removal and improved fluid handling, guaranteeing an optimized drilling process. The screens' hassle-free installation and maintenance procedures further enhance their appeal, reducing downtime and increasing overall operational efficiency.Section 3: Mi-Swaco's Commitment to Continuous Innovation (130 words)Mi-Swaco has a robust track record of innovation in the drilling industry, driven by a commitment to enhancing solids control systems. Their team of experts consistently pushes the boundaries of technology to develop products that address specific industry challenges. With extensive research and development efforts, they continue to refine and optimize their shaker screens, aiming to make them the gold standard in the industry.Section 4: Operational and Economic Benefits of Mi-Swaco Shaker Screens (180 words)The implementation of Mi-Swaco's shaker screens provides a range of operational and cost benefits. By effectively separating solids from drilling mud, the screens improve drilling fluid properties, thereby increasing drilling efficiency and reducing the risk of equipment failure. Improved separation efficiency translates to reduced mud consumption and less waste disposal, resulting in significant cost savings for drilling operators.Additionally, the durability and extended lifespan of Mi-Swaco's shaker screens contribute to economies of scale. Reduced screen replacement frequency and minimal maintenance requirements lead to decreased downtime, ensuring uninterrupted drilling operations. This increased uptime, combined with the screens' innovative design features, ultimately leads to substantial cost savings over the long term.Conclusion (75 words):Mi-Swaco's innovative shaker screens are set to revolutionize solids control systems in the drilling industry. With their commitment to continuous improvement and cutting-edge technology, Mi-Swaco has developed a range of shaker screens that deliver superior performance, increased operational efficiency, and significant cost savings for drilling operators. By utilizing these advanced screens, drilling companies can optimize solids control, enhance drilling productivity, and ultimately drive success in the oil and gas industry.