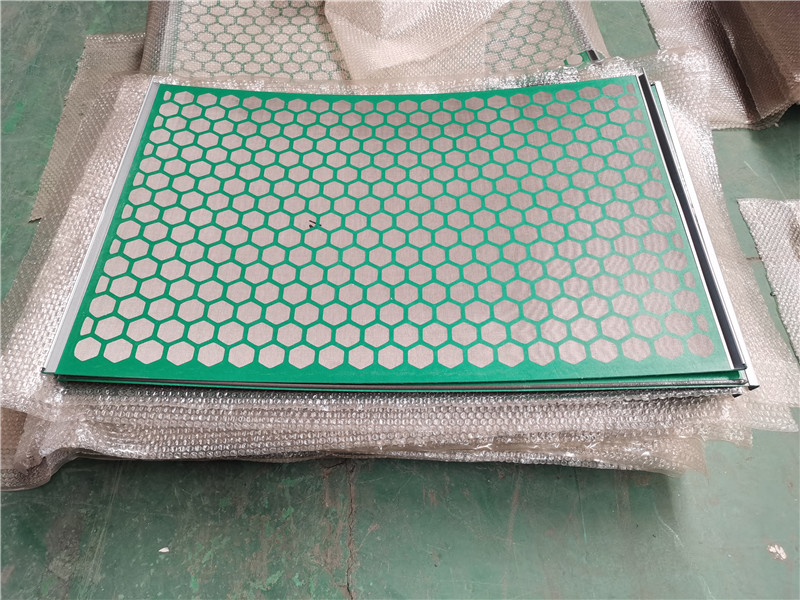

High-Quality and Durable Shaker Screen for Improved Performance

By:Admin

The VSM300 Shaker Screen is a vital component in the drilling process, as it is designed to effectively remove solid particles from drilling fluid. This ensures that the drilling mud remains in optimal condition, which in turn leads to improved drilling efficiency and reduced operational costs. The VSM300 Shaker Screen is highly durable and is capable of withstanding the rigorous demands of the oil and gas sector, making it the preferred choice for many leading companies in the industry.

The company behind the VSM300 Shaker Screen has a rich history of delivering high-performance solutions to the oil and gas sector. With a team of skilled engineers and industry experts, the company has continuously strived to enhance its product offerings and provide unmatched customer service. The company's commitment to quality and excellence has earned them a strong reputation in the market, with many clients relying on their products to meet their operational needs.

In addition to the VSM300 Shaker Screen, the company offers a comprehensive range of solid control equipment, including shale shakers, mud cleaners, centrifuges, and degassers. Each product is designed and manufactured with precision, ensuring that it meets the highest standards of quality and performance. With a focus on innovation and continuous improvement, the company has been able to stay ahead of the competition and remain a trusted partner for many in the oil and gas industry.

The VSM300 Shaker Screen, in particular, has been widely acclaimed for its exceptional performance and durability. Its unique design and advanced technology allow for efficient and effective solid control, enabling drilling operations to run smoothly and efficiently. The screen is capable of handling high volumes of drilling fluid while effectively separating solid particles, making it an indispensable tool for any drilling operation.

Moreover, the company's commitment to sustainability and environmental responsibility is evident in the design and manufacturing of the VSM300 Shaker Screen. By ensuring that drilling fluid is properly treated and recycled, the screen plays a crucial role in minimizing the environmental impact of drilling operations. This commitment to sustainability aligns with the industry's increasing focus on environmental stewardship and responsible practices.

As the global demand for oil and gas continues to rise, the need for efficient and reliable solid control equipment has never been greater. The VSM300 Shaker Screen, with its proven track record and industry-leading performance, is well-positioned to meet this demand and play a crucial role in the success of drilling operations around the world.

In conclusion, the VSM300 Shaker Screen has established itself as a top-tier product in the oil and gas industry, thanks to its unmatched performance, durability, and environmental sustainability. As the company behind this groundbreaking technology continues to push the boundaries of innovation, it is poised to remain a leading force in the solid control equipment sector for years to come. With a strong commitment to excellence and customer satisfaction, the company is well-equipped to meet the evolving needs of the oil and gas industry and continue to set new standards for quality and performance.

Company News & Blog

Revolutionary Shale Shaker Screen for Enhanced Fluid Systems Efficiency

Title: Innovative Shale Shaker Screen Revolutionizes Fluid Systems in Oil and Gas IndustryIntroduction:The oil and gas industry has always relied on cutting-edge technologies to enhance efficiency and productivity. Fluid Systems INC, a leading provider of oilfield equipment, continues to push the boundaries of innovation with their latest breakthrough: the FSI 5000 Shale Shaker Screen. Designed to optimize performance and minimize downtime, this revolutionary product promises to transform the way drilling operations are conducted across the globe.Paragraph 1: Background on the Importance of Shale Shaker ScreensShale shaker screens play a crucial role in the oil and gas industry, separating solids from drilling fluids during the drilling process. These screens are responsible for removing cuttings and sediments, ensuring that the drilling mud remains clean and efficient. The quality and performance of shale shaker screens directly impact drilling operations, making it imperative for companies to invest in advanced technologies that can enhance productivity.Paragraph 2: Introduction to Fluid Systems INCFluid Systems INC (FSI) has been at the forefront of developing innovative technologies for the oil and gas industry for over three decades. With a strong focus on research and development, FSI has gained a reputation for delivering reliable and high-quality equipment. Their commitment to customer satisfaction and industry-leading services make them a trusted partner for clients worldwide.Paragraph 3: The FSI 5000 Shale Shaker ScreenThe FSI 5000 Shale Shaker Screen is the latest addition to Fluid Systems INC's product portfolio. This cutting-edge screen is designed to maximize separation efficiency and minimize overall cost.Utilizing advanced manufacturing techniques and materials, the FSI 5000 Shale Shaker Screen offers superior wear resistance and durability. It is specifically engineered to withstand demanding drilling conditions, ensuring longevity and extended service life. The screen's robust construction eliminates the need for frequent replacements, reducing downtime and costs associated with maintenance.Paragraph 4: Key Features and Benefitsa) Enhanced Filtration: The FSI 5000 Shale Shaker Screen utilizes a state-of-the-art mesh design, improving the separation efficiency of solids from drilling fluids. The screen's optimized openings prevent blockages and ensure optimal flow rates, enhancing filtration performance.b) Longer Service Life: With its durable construction, the FSI 5000 Shale Shaker Screen offers an extended lifespan compared to conventional screens. This not only saves on replacement costs but also reduces the frequency of interruptions during drilling operations, resulting in enhanced productivity.c) Easy Installation: Fluid Systems INC has prioritized user-friendliness with the FSI 5000 Shale Shaker Screen. The screen can be easily installed and maintained, minimizing downtime and maximizing operational efficiency.d) Customization: FSI enables clients to choose from a range of mesh sizes to suit specific drilling requirements. Whether it is higher capacities or better particle separation, the FSI 5000 Shale Shaker Screen can be tailored to meet the unique needs of each operation.Paragraph 5: Industry ImpactThe introduction of the FSI 5000 Shale Shaker Screen is expected to have a substantial impact on the oil and gas industry. Fluid Systems INC's innovative product addresses several pain points commonly faced in drilling operations, offering a more efficient and cost-effective solution. With reduced maintenance and enhanced filtration performance, drilling companies can optimize their operations, leading to increased profitability.Paragraph 6: Future OutlookFluid Systems INC continues to invest in research and development, aiming to revolutionize the oil and gas industry with their cutting-edge technologies. By constantly pushing the boundaries of innovation, FSI strives to improve efficiency, reduce costs, and develop sustainable solutions for the global oil and gas sector. The FSI 5000 Shale Shaker Screen is just one example of their commitment to delivering superior products that meet evolving industry needs.Conclusion:As the oil and gas industry continues to evolve and face new challenges, it is crucial for companies like Fluid Systems INC to develop innovative technologies that enhance operational efficiency. With the introduction of the FSI 5000 Shale Shaker Screen, Fluid Systems INC has once again proven their dedication to driving progress in the industry. By providing cutting-edge solutions, they empower drilling companies to optimize their operations, reduce costs, and achieve higher productivity.

High-quality Shaker Screen for Swaco Mongoose/Meerkat Available

Swaco Mongoose/Meerkat Shaker Screen, a top-of-the-line shaker screen technology, has been making waves in the oilfield industry for its efficient and effective performance. The shaker screens are designed to provide superior solids control and separation, ensuring optimal efficiency and productivity in drilling operations.This innovative technology is the brainchild of a leading company in the oil and gas industry, which has been at the forefront of developing cutting-edge equipment and solutions for the energy sector. With a strong emphasis on research and development, the company has consistently delivered high-quality products that meet the evolving needs of oilfield operations.The Swaco Mongoose/Meerkat Shaker Screen is a testament to the company's commitment to excellence and innovation. It is engineered to deliver exceptional performance in terms of solids control and fluid handling, allowing for the efficient removal of drilled solids and ensuring the smooth operation of drilling equipment. With its durable construction and high-quality materials, the shaker screen is designed to withstand the demanding conditions of oilfield operations, delivering reliable performance in all types of drilling environments.One of the key features of the Swaco Mongoose/Meerkat Shaker Screen is its advanced technology that allows for effective solids control and fluid handling. The screen is designed to effectively separate solids from drilling fluids, ensuring that the drilling process is not hindered by the presence of contaminants. This results in improved drilling efficiency and reduced downtime, leading to significant cost savings for operators.In addition to its superior performance, the Swaco Mongoose/Meerkat Shaker Screen is also designed for easy installation and maintenance. Its user-friendly design allows for quick and hassle-free screen replacement, minimizing downtime and maximizing productivity. This makes it an ideal choice for operators looking to streamline their operations and improve overall efficiency.The company behind the Swaco Mongoose/Meerkat Shaker Screen has a strong reputation for providing top-quality products and exceptional customer service. With a global presence and a strong network of distributors and service centers, the company ensures that its customers receive the support they need, wherever they are located. This commitment to customer satisfaction has made the company a trusted partner for oilfield operators around the world.As the oil and gas industry continues to evolve and face new challenges, the demand for innovative and reliable equipment remains high. The Swaco Mongoose/Meerkat Shaker Screen is a clear example of the type of technology that is needed to meet these challenges, providing operators with a competitive edge and the confidence to tackle even the most demanding drilling environments.In conclusion, the Swaco Mongoose/Meerkat Shaker Screen is a game-changer in the oilfield industry, offering unmatched performance, durability, and ease of use. With the backing of a reputable and forward-thinking company, this innovative technology is set to become a staple in drilling operations around the world, helping operators achieve greater efficiency and productivity.

Multi-Sizer Scalping Oil Shaker Screens: The Latest Innovation in Screening Technology

Scalping Oil Shaker Screens Revolutionizing the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to streamline operations and increase efficiency. One such advancement is seen in the form of eco-friendly oil shaker screens, aimed at enhancing the oil drilling process. Among the frontrunners in this domain is the groundbreaking VSM Multi-sizer Scalping Oil Shaker Screen, developed by a renowned industry player. This revolutionary product has not only created a buzz within the sector but also opened up new possibilities for the oil and gas industry.The VSM Multi-sizer Scalping Oil Shaker Screen, an integral component of the oil drilling process, offers numerous advantages that make it indispensable for drilling companies. Its breakthrough design ensures maximum efficiency in removing unwanted solids, such as cuttings and debris, from the drilling fluid. Such efficient solid control methods are crucial for maintaining the integrity of the drilling operation and ensuring a steady flow of oil or gas.One of the standout features of the VSM Multi-sizer Scalping Oil Shaker Screen is its adaptability to a wide range of drilling conditions. Irrespective of the drilling location or application, this versatile shaker screen is capable of handling it all. Its ability to handle a variety of drilling fluids, ranging from abrasive to corrosive, makes it ideal for even the most challenging drilling operations.Another noteworthy aspect of the VSM Multi-sizer Scalping Oil Shaker Screen is its durability and longevity. Manufactured using high-quality materials, combined with cutting-edge manufacturing techniques, this shaker screen boasts an impressive lifespan. Its rugged construction ensures it can withstand harsh conditions and endure heavy-duty use, thereby reducing the need for frequent replacements and saving costs for drilling companies.Furthermore, the eco-friendly nature of the VSM Multi-sizer Scalping Oil Shaker Screen is worth highlighting. In an era where sustainability and environmental consciousness are of utmost importance, this product aligns perfectly with the industry's green initiatives. By efficiently separating solids from drilling fluids, this shaker screen significantly reduces waste generation, promoting responsible drilling practices.The VSM Multi-sizer Scalping Oil Shaker Screen's user-friendly design also deserves recognition. It is easy to install and offers simple maintenance procedures, allowing for hassle-free operations on drilling rigs. This ease of use translates into saved time and increased productivity, enabling drilling companies to optimize their resources effectively.The impact of the VSM Multi-sizer Scalping Oil Shaker Screen on the oil and gas industry has not gone unnoticed. With its remarkable performance and cost-effectiveness, this innovative product has garnered significant attention from industry professionals and experts globally. It has been hailed as a game-changer, capable of revolutionizing the way drilling companies approach solids control during oil extraction.The company behind this groundbreaking product, {Company Name}, is a renowned name in the oil and gas industry. With a history of delivering cutting-edge solutions and continually pushing the boundaries of innovation, the company has solidified its position as a leader in the field. Committed to excellence and customer satisfaction, they have etched a mark in the industry through their relentless pursuit of technological advancements.In conclusion, the VSM Multi-sizer Scalping Oil Shaker Screen has set a new benchmark for solids control in the oil and gas industry. Its efficient and versatile design, coupled with its eco-friendly nature and user-friendly operations, has made it a preferred choice among drilling companies worldwide. With the support of industry leaders like {Company Name}, the future of the oil and gas industry looks promising, driven by advancements like the VSM Multi-sizer Scalping Oil Shaker Screen.

Top Primary Screens for NOV VSM 300 Shale Shakers

Leading provider of oilfield equipment and technology, NOV, introduces a new high-quality primary screen that promises to revolutionize the oil and gas industry. The NOV VSM 300 Primary Screen offers exceptional performance and efficiency, making it a game-changer for oilfield operations.The primary screen is a critical component of the shale shaker, which is an essential tool used in the drilling process to separate drilling fluid and solids. With its advanced design and construction, the NOV VSM 300 Primary Screen delivers superior performance in separating solids from drilling fluid, ultimately improving overall drilling efficiency and reducing waste.The key features of the NOV VSM 300 Primary Screen include a patented composite frame that is lighter, more durable, and more reliable than traditional metal frames. This innovative design also minimizes the risk of screen failure and extends the screen's lifespan, resulting in cost savings for oilfield operators.In addition to its durable frame, the NOV VSM 300 Primary Screen utilizes an advanced screening technology that enhances fluid handling capacity and achieves better solids separation. This leads to improved drilling efficiency and reduced downtime, ultimately increasing productivity on the rig.The NOV VSM 300 Primary Screen also features an easy-to-install and quick-change design, which allows for rapid screen replacement and maintenance, further reducing downtime and optimizing operational efficiency.This new primary screen is the latest addition to NOV's comprehensive portfolio of oilfield equipment and technology, which includes a wide range of solutions for drilling, completion, production, and intervention operations.With a global presence and a strong commitment to innovation and excellence, NOV is a trusted partner for oil and gas companies seeking to enhance their operational performance and achieve sustainable growth."We are thrilled to introduce the NOV VSM 300 Primary Screen to the market," said a spokesperson for NOV. "This new addition to our product lineup reflects our ongoing dedication to providing cutting-edge solutions that address the evolving needs of the oil and gas industry. We believe that this primary screen will deliver significant value to our customers by improving drilling efficiency and reducing operational costs."The NOV VSM 300 Primary Screen is now available for purchase and is poised to make a significant impact on oilfield operations worldwide. With its advanced technology, durable construction, and user-friendly design, this primary screen is set to become the industry standard for efficient and reliable solids control.As the oil and gas industry continues to evolve and adapt to new challenges, NOV remains at the forefront, leading the way with innovative solutions that drive success and sustainability for its customers.NOV's commitment to excellence and its unwavering dedication to providing best-in-class products and services position the company as a trusted partner for oilfield operators looking to optimize their operations and maximize their profitability.With the introduction of the NOV VSM 300 Primary Screen, NOV is once again demonstrating its leadership in delivering groundbreaking technology that sets new standards for performance, reliability, and efficiency in the oil and gas industry. This primary screen is set to redefine the way solids control is handled in drilling operations, setting a new benchmark for operational excellence and success.

Steel Frame Shaker Screen with High Efficiency and Durability

Title: Cutting-Edge Steel Frame Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the fast-paced and demanding oil and gas industry, efficient drilling operations are crucial for maximizing productivity and profitability. One fundamental component of the drilling process is the shaker screen, which plays a critical role in separating drilling fluid from the drill cuttings. Recognizing the need for highly effective and durable shaker screens, {} has developed the groundbreaking GNZS-703 Steel Frame Shaker Screen. With exceptional efficiency and extended longevity, this game-changing technology is revolutionizing the way the industry operates.Part I: The Importance of Shaker Screens in Drilling Operations (150 words)To comprehend the significance of the GNZS-703 Steel Frame Shaker Screen, it is essential to understand the vital role shaker screens play in drilling operations. These screens act as the primary defense mechanism in the drilling process, separating undesirable solids from valuable drilling fluids. The efficiency and durability of shaker screens directly impact drilling operation costs, as ineffective screens lead to increased maintenance, decreased productivity, and elevated expenses. Thus, the development of advanced shaker screen technology holds immense potential in streamlining drilling operations.Part II: Introducing the GNZS-703 Steel Frame Shaker Screen (200 words)The GNZS-703 Steel Frame Shaker Screen is a cutting-edge innovation designed to optimize the performance and durability of shale shakers, improving overall drilling efficiency. Manufactured by {}, a renowned leader in oilfield equipment, this high-quality screen integrates innovative engineering, expert craftsmanship, and years of industry experience. The result is an exceptional product that surpasses industry standards in terms of efficiency, longevity, and cost-effectiveness.Constructed with precision-welded stainless steel wire mesh, the GNZS-703 Steel Frame Shaker Screen boasts excellent wear resistance, ensuring outstanding performance in the demanding drilling conditions. The frame is made from sturdy steel, providing robust structural support and extending service life. Additionally, the screen undergoes a specialized treatment process to enhance its corrosion resistance, enabling it to withstand harsh drilling fluids and adverse operating conditions.Part III: Key Advantages of the GNZS-703 Steel Frame Shaker Screen (250 words)The GNZS-703 Steel Frame Shaker Screen offers a multitude of advantages, making it a superior choice for drilling contractors and service providers. Firstly, its exceptional filtration efficiency guarantees the removal of a wide range of unwanted solids, preventing their reentry into the drilling fluid system. This not only enhances drilling fluid performance but also minimizes downtime related to fluid system maintenance.Moreover, the GNZS-703 Steel Frame Shaker Screen's long service life significantly reduces replacement costs, enhancing cost-effectiveness for drilling operations. The screen's heavy-duty construction ensures durability and reliability, enabling sustained performance even under heavy workloads. This translates into increased productivity and improved overall drilling efficiency.Furthermore, the upgraded design of the screen allows for easy installation and quick replacement, minimizing downtime and saving valuable operation hours. Its user-friendly nature simplifies maintenance, optimizing efficiency on-site.Conclusion (100 words)With the introduction of the GNZS-703 Steel Frame Shaker Screen, {} has raised the industry standard for shaker screen performance. By combining cutting-edge technology, superior materials, and expert engineering, this innovative product offers exceptional efficiency, extended service life, and substantial cost savings. The GNZS-703 Steel Frame Shaker Screen epitomizes the commitment of {} to providing the oil and gas industry with game-changing solutions that streamline drilling operations and increase profitability.

High-quality Oil Shaker Screen for FLC2000 Shakers

The oil and gas industry is a complex and demanding sector that requires cutting-edge technology and equipment to ensure smooth operations. One such essential piece of equipment is the FLC2000 Shaker screen, a vital component in the drilling process.The FLC2000 Shaker screen is a high-performance vibrating screen used to separate solids from liquids in the drilling mud. It is designed to efficiently remove solid particles from drilling fluids, which is a crucial step in the drilling process to ensure the integrity of the wellbore and protect downstream equipment.The FLC2000 Shaker screen, manufactured by a leading oilfield equipment company, is known for its durability, efficiency, and reliability. With a strong focus on quality and performance, the company has positioned itself as a trusted provider of drilling equipment and solutions to the oil and gas industry.The company behind the FLC2000 Shaker screen has a solid reputation for delivering innovative and high-quality products that meet the demanding requirements of the oil and gas sector. With a strong emphasis on research and development, the company has continuously improved and enhanced its product offerings to meet the evolving needs of the industry.In addition to the FLC2000 Shaker screen, the company also offers a comprehensive range of drilling equipment, including shale shakers, mud cleaners, centrifuges, and other solids control equipment. These products are designed to optimize drilling performance, reduce downtime, and minimize environmental impact, making them essential for efficient and sustainable drilling operations.The company's commitment to quality and customer satisfaction is evident in its rigorous testing and certification processes, ensuring that its products meet the highest industry standards. This dedication to excellence has earned the company the trust and confidence of leading oil and gas companies worldwide.Furthermore, the company's expertise in providing custom solutions and technical support sets it apart as a reliable partner for the oil and gas industry. Its team of experienced engineers and technicians are readily available to provide installation, maintenance, and troubleshooting services, ensuring that its customers' operations run smoothly and efficiently.With a global network of distribution and service centers, the company is well-positioned to provide timely support and reliable delivery of its products to customers around the world. This extensive network underscores the company's commitment to being a valuable and dependable partner to the oil and gas industry.In conclusion, the FLC2000 Shaker screen, combined with the company's extensive experience, technical expertise, and commitment to quality, exemplifies the essential role of advanced technology and equipment in the oil and gas industry. By consistently delivering reliable and innovative solutions, the company has established itself as a trusted provider of drilling equipment and solutions, contributing to the efficiency and sustainability of the oil and gas sector.

New and Efficient Mongoose Shaker Bringing Innovation to the Oil and Gas Industry

Swaco Mongoose Shaker: The Ultimate Solution for Efficient Solid Control in the Oil and Gas IndustryThe oil and gas industry is a vital sector of the global economy, providing the fuel that powers the world. As such, it is essential for companies in this industry to employ the latest technologies and equipment to ensure efficient and safe operations. One such piece of equipment that has revolutionized solid control in the oil and gas industry is the Swaco Mongoose Shaker.The Swaco Mongoose Shaker is a high-performance shale shaker that is designed to separate solid particles from drilling fluid. This is a critical process in the drilling operation, as it ensures that the drilling fluid is free from debris and can be reused, thus reducing waste and saving costs. The Swaco Mongoose Shaker is renowned for its efficiency and reliability, making it the go-to choice for many oil and gas companies around the world.The Swaco Mongoose Shaker is manufactured by a leading company in the oilfield equipment industry. With years of experience and a commitment to innovation, this company is dedicated to providing top-quality products that meet the needs of its customers. The Swaco Mongoose Shaker is a prime example of this commitment, as it has set a new standard for solid control in the oil and gas industry.One of the key features of the Swaco Mongoose Shaker is its dual-motion capability. This means that the shaker can operate in both linear and balanced elliptical motion, providing maximum performance in a variety of drilling conditions. This versatility is crucial in the ever-changing environment of the oil and gas industry, where different drilling operations may require different approaches to solid control.Another standout feature of the Swaco Mongoose Shaker is its advanced composite screens. These screens are designed to provide superior separation performance and longer lifespan, reducing the need for frequent replacements and saving costs for the oil and gas companies. Furthermore, the screens are quick and easy to install, minimizing downtime and maximizing productivity on the drilling site.In addition to its technical features, the Swaco Mongoose Shaker is also designed with user-friendliness in mind. The shaker is equipped with an adjustable deck angle and a quick-disconnect feature, allowing for easy and quick adjustments and maintenance. This ensures that the shaker can be operated efficiently by the drilling crew, without the need for extensive training or specialized skills.The Swaco Mongoose Shaker has made a significant impact on the oil and gas industry since its introduction. Its innovative design and high performance have enabled oil and gas companies to improve their solid control processes, leading to increased efficiency and cost savings. As a result, the Swaco Mongoose Shaker has become a preferred choice for many drilling operations around the world.In conclusion, the Swaco Mongoose Shaker is a game-changer in solid control for the oil and gas industry. Its advanced features, user-friendly design, and superior performance have set a new standard for shale shakers, providing essential support for drilling operations worldwide. With a commitment to innovation and excellence, the company behind the Swaco Mongoose Shaker continues to lead the way in providing top-quality equipment for the oil and gas industry.

Primary Shaker Screen for VSM300 - All You Need to Know

VSM300 Primary Shaker Screen: A Breakthrough Innovation in the Oil and Gas IndustryThe oil and gas industry has been a vital part of the global economy for many years, and as technology continues to advance, so does the need for more efficient and reliable equipment to meet the growing demand for energy resources. One such equipment that has been making waves in the industry is the VSM300 Primary Shaker Screen, a breakthrough innovation that has revolutionized the way drilling waste is managed.The VSM300 Primary Shaker Screen is a high-performance vibrating screen designed specifically for solids control in the oil and gas drilling industry. It is a critical component of the drilling fluids system and is used to separate and remove large drilling cuttings from the drilling fluid, allowing for the reuse of the fluid and the proper disposal of the cuttings. The VSM300 Primary Shaker Screen is known for its exceptional performance, durability, and reliability, making it a popular choice among drilling contractors and operators worldwide.The VSM300 Primary Shaker Screen is manufactured by a leading company in the oil and gas industry that specializes in providing high-quality solid control equipment and solutions to the global market. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of developing cutting-edge technologies that help enhance the efficiency and sustainability of drilling operations.The VSM300 Primary Shaker Screen is an excellent example of the company's commitment to innovation and quality. It is designed to withstand the harsh conditions of drilling operations, including high temperatures, extreme pressures, and abrasive drilling fluids. The screen is made from high-quality materials that are resistant to wear and corrosion, ensuring long-term performance and reliability in the field.One of the key features of the VSM300 Primary Shaker Screen is its unique design, which is optimized for maximum efficiency and productivity. The screen is equipped with a dual-deck design, which allows for increased capacity and better performance in separating solids from the drilling fluid. This design also helps reduce the amount of energy and resources required to process drilling waste, making it a more sustainable solution for managing drilling cuttings.In addition to its superior performance, the VSM300 Primary Shaker Screen is also designed for ease of use and maintenance. It is equipped with quick-release tensioning systems that make it easy to install and replace the screen panels, reducing downtime and increasing productivity on the rig. The screen is also compatible with a wide range of shaker models, making it a versatile solution for different drilling applications.As the demand for energy continues to grow, the oil and gas industry is under increasing pressure to find more sustainable and environmentally friendly solutions for drilling operations. The VSM300 Primary Shaker Screen is a perfect example of how innovation in equipment design can help address these challenges and contribute to the industry's efforts to reduce its environmental footprint.With its exceptional performance, durability, and sustainability, the VSM300 Primary Shaker Screen has become a preferred choice for drilling contractors and operators around the world. It has helped improve the efficiency and reliability of drilling operations, while also contributing to reducing the environmental impact of drilling waste.As the oil and gas industry continues to evolve, the VSM300 Primary Shaker Screen is expected to play a crucial role in helping meet the growing demand for energy resources while also promoting sustainability and environmental responsibility. With its advanced technology and innovative design, this breakthrough innovation is set to be a game-changer in the solid control equipment market for years to come.

Oil Shale Shaker Screen: Latest News and Updates

Scomi Oil Shale Shaker Screen, a leading global provider of oilfield products and services, has recently introduced a new and advanced shale shaker screen technology that promises to revolutionize the oil and gas drilling industry. This innovative solution is set to have a significant impact on the efficiency and effectiveness of shale shaker operations, leading to improved performance and cost savings for oil and gas companies around the world.The new shale shaker screen technology has been developed and engineered by Scomi Oil's team of experts, who have a deep understanding of the challenges and demands of the oil and gas drilling industry. By leveraging cutting-edge materials and state-of-the-art manufacturing processes, the company has created a product that offers superior performance, durability, and reliability. This is a major breakthrough in the industry, as shale shaker screens play a critical role in the drilling process, separating drilling cuttings from drilling fluid to enable the recovery of valuable resources.One of the key features of the new shale shaker screen technology is its advanced design, which allows for increased throughput and improved cuttings conveyance. This means that the screens are able to handle higher volumes of drilling cuttings and provide more effective separation, ultimately leading to greater efficiency and productivity on the drilling rig. In addition, the screens are designed to be highly durable and long-lasting, reducing the need for frequent replacements and minimizing downtime and maintenance costs for oil and gas companies.Another significant advantage of Scomi Oil's new shale shaker screen technology is its ability to deliver consistent and reliable performance in a wide range of drilling conditions. Whether drilling in challenging environments such as high temperature, high pressure, or abrasive formations, the screens are able to maintain their integrity and effectiveness, ensuring smooth and efficient drilling operations. This is particularly important for oil and gas companies operating in diverse and demanding geological settings, where the quality and performance of drilling equipment can have a direct impact on the success and profitability of drilling projects.Furthermore, Scomi Oil's shale shaker screen technology has been designed with sustainability in mind, aligning with the industry's increasing focus on environmental responsibility and regulatory compliance. The screens are manufactured using materials that are environmentally friendly and non-toxic, minimizing the environmental impact of drilling operations. In addition, the screens are engineered to optimize the use of drilling fluid, reducing waste and improving the overall sustainability of the drilling process.The introduction of Scomi Oil's advanced shale shaker screen technology is a testament to the company's commitment to innovation and excellence in the oil and gas industry. As a global leader in oilfield products and services, Scomi Oil continues to invest in research and development to bring new and advanced solutions to market, providing its customers with the tools they need to succeed in a rapidly evolving and competitive industry.With its new shale shaker screen technology, Scomi Oil is poised to deliver significant benefits to oil and gas companies worldwide, helping them achieve higher levels of efficiency, productivity, and sustainability in their drilling operations. As the industry continues to face challenges and opportunities, Scomi Oil remains at the forefront of innovation, driving progress and performance in the global oil and gas sector.

High-Quality Frame Shaker Screen for Improved Performance

Scomi Frame Shaker Screen Revolutionizes the Oil and Gas IndustryIn the fast-paced and competitive world of oil and gas exploration and drilling, companies are constantly seeking innovative solutions to improve efficiency and productivity. One such solution that has been making waves in the industry is the Scomi frame shaker screen. This revolutionary product has earned a reputation for its superior performance and reliability, making it a popular choice among oil and gas companies worldwide.Scomi, a global leader in oilfield services and equipment, has been at the forefront of innovation in the industry for over two decades. The company is known for developing cutting-edge technologies that help improve operational efficiency and reduce costs for its clients. With a strong focus on research and development, Scomi has been able to consistently deliver high-quality products that meet the ever-evolving needs of the oil and gas industry.The Scomi frame shaker screen is a perfect example of the company's commitment to innovation and excellence. Designed to fit all major shaker models, this advanced screening solution offers superior performance and durability, making it an ideal choice for demanding drilling applications. The screen's innovative design and construction allow for increased efficiency in solids control, leading to improved drilling fluid recovery and reduced waste.One of the key features of the Scomi frame shaker screen is its high conductance and non-blanked area, which allows for increased fluid capacity and improved solids removal. This results in enhanced efficiency during the drilling process, ultimately leading to cost savings for oil and gas companies. Additionally, the screen's durable construction and long lifespan make it a cost-effective solution for clients looking to optimize their operations.Another standout feature of the Scomi frame shaker screen is its compatibility with a wide range of drilling applications, including both onshore and offshore operations. This versatility makes it a valuable asset for companies operating in diverse environments, allowing them to maximize the performance of their shaker systems regardless of the specific challenges they may face.Moreover, Scomi's commitment to quality and customer satisfaction is evident in its rigorous testing and quality control processes. The company's state-of-the-art facilities and team of experienced engineers ensure that every frame shaker screen that leaves its production line meets the highest standards of performance and reliability. This dedication to excellence has earned Scomi a loyal customer base and a strong reputation as a trusted provider of oilfield equipment and services.As the oil and gas industry continues to evolve and demand for efficient drilling solutions grows, products like the Scomi frame shaker screen are playing a crucial role in driving innovation and progress. With its proven track record of performance and reliability, this revolutionary screening solution is poised to continue making a significant impact on the industry, helping companies achieve greater efficiency and productivity in their operations.In conclusion, the Scomi frame shaker screen is a game-changer for the oil and gas industry, offering a combination of high performance, durability, and versatility that sets it apart from other screening solutions. As the demand for efficient and cost-effective drilling equipment continues to rise, Scomi's innovative product is well-positioned to meet the evolving needs of the industry and help companies achieve their operational goals. With its unwavering commitment to excellence and customer satisfaction, Scomi is poised to remain a leading provider of cutting-edge solutions for the oil and gas sector for years to come.