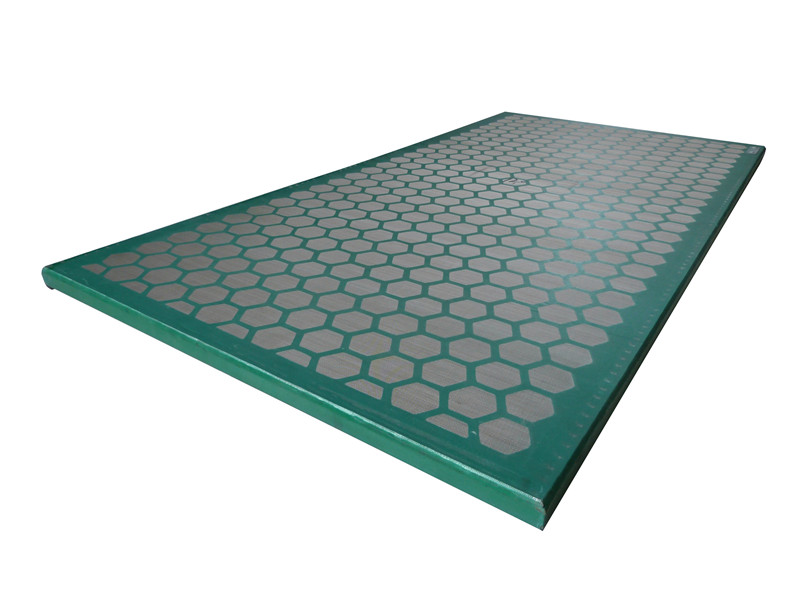

High-Quality 250 Shaker Screen for Derrick S Shakers

By:Admin

The Derrick S 250 Shaker Screen features a high-capacity composite frame that is lightweight yet durable, allowing for easy installation and maintenance. Its advanced design includes a patented, integrated seal that eliminates the need for adhesives, reducing the risk of leakage and ensuring a secure fit for the screen. Additionally, the screen is engineered with an enhanced screen panel tensioning system, providing consistent tension across the entire screen surface, resulting in improved solids conveyance and higher throughput.

The innovative technology incorporated into the Derrick S 250 Shaker Screen offers significant advantages over traditional screens, including increased fluid capacity and faster solids conveyance, ultimately leading to more efficient and cost-effective operations for customers. The screen also features an optimized mesh configuration that maximizes the screening area, resulting in improved solids removal and finer particle separation.

In addition, the Derrick S 250 Shaker Screen is compatible with a wide range of shaker models, making it a versatile solution for various drilling operations. Its ability to adapt to different shaker configurations allows customers to achieve optimal performance and tailor the screen to their specific needs.

Derrick Corporation has a rich history of providing innovative solutions for the oil and gas industry. With over 70 years of experience, the company has continually set the standard for high-performance separation and filtration equipment. Derrick's commitment to research and development has led to numerous advancements in technology, allowing customers to improve their operations and achieve greater efficiency.

The Derrick S 250 Shaker Screen is the latest example of Derrick Corporation's dedication to delivering cutting-edge solutions to its customers. By combining advanced engineering principles with a deep understanding of industry needs, Derrick continues to lead the way in providing reliable and efficient equipment for the oil and gas sector.

"We are thrilled to introduce the Derrick S 250 Shaker Screen to the market," said a spokesperson from Derrick Corporation. "This innovative product is the result of our ongoing commitment to pushing the boundaries of what is possible in separation technology. We believe that the Derrick S 250 Shaker Screen will provide our customers with a competitive edge by delivering superior performance and reliability in their operations."

The launch of the Derrick S 250 Shaker Screen represents a significant milestone for Derrick Corporation and further solidifies its position as a trusted partner for the oil and gas industry. With its unwavering dedication to excellence and a proven track record of success, Derrick Corporation continues to set the standard for separation and filtration equipment, helping customers around the world achieve their operational goals.

As the oil and gas industry continues to evolve, the demand for advanced and efficient separation equipment remains high. With the introduction of the Derrick S 250 Shaker Screen, Derrick Corporation has once again demonstrated its ability to innovate and meet the ever-changing needs of its customers. The company's commitment to excellence and its relentless pursuit of technological advancement ensure that Derrick Corporation will remain a driving force in the industry for years to come.

Company News & Blog

Highly Efficient Vibratory Shaker Screen for Separating Materials

In a world where efficiency and productivity are key, businesses are constantly on the lookout for advanced technologies that can enhance their operations. One such technology, the vibratory shaker screen, has been gaining attention for its ability to improve the screening and sorting processes in various industries.A vibratory shaker screen is a piece of equipment that uses vibration to separate materials based on their particle size. It is commonly used in industries such as mining, construction, agriculture, and recycling, where the need to separate and classify materials is paramount. The vibratory shaker screen works by applying an intense vibration to the screen deck, causing the particles to move and separate based on size, ensuring efficient and accurate screening.One of the leading providers of vibratory shaker screens is {}. With over two decades of experience in the industry, {} has established itself as a pioneer in the field of screening and separation technology. The company’s vibratory shaker screens are designed to deliver high-performance screening solutions, offering reliability, durability, and versatility to meet the diverse needs of its customers.The vibratory shaker screens offered by {} are known for their innovative design and advanced features. The company’s screens are equipped with high-quality vibratory motors that provide the necessary vibration force for efficient material separation. Additionally, the screens are designed to be easily adjustable, allowing for precise control over the screening process. This level of flexibility ensures that the screens can be tailored to the specific requirements of each application, resulting in optimal performance and productivity.In addition to the premium quality of its products, {} prides itself on providing exceptional customer service and support. The company works closely with its clients to understand their unique screening needs and offers customized solutions to address them. Furthermore, {}’s team of experienced engineers and technicians are readily available to provide technical assistance, maintenance, and repairs, ensuring that the vibratory shaker screens continue to operate at peak performance.The vibratory shaker screens from {} have been widely adopted across various industries, earning a reputation for their efficiency, reliability, and durability. These screens have been instrumental in improving the screening and sorting processes for a wide range of materials, including aggregates, minerals, chemicals, and even food products. The ability of {}’s vibratory shaker screens to handle diverse materials with precision and speed has made them a valuable asset for businesses aiming to optimize their operations.As industries continue to evolve and demand more advanced screening technologies, the vibratory shaker screens from {} are set to play a pivotal role in meeting these requirements. The company’s commitment to innovation and excellence ensures that its products will continue to be at the forefront of the industry, offering cutting-edge solutions for material separation and classification.In conclusion, the vibratory shaker screen has emerged as a game-changer in the field of material screening and separation. With {}’s extensive experience and expertise, its vibratory shaker screens are poised to revolutionize the way industries handle their screening needs, offering enhanced efficiency, productivity, and reliability. As businesses strive to stay ahead in a competitive market, the vibratory shaker screens from {} are undoubtedly a valuable investment for achieving optimal screening performance.

High Performance Shaker Screen with FSI 5000 Technology

The oil and gas industry is constantly evolving, with new technologies and innovations driving the sector forward. One of the key components of the industry is the use of shale shakers to separate drilling cuttings from drilling fluid. This process is crucial in maintaining the efficiency and effectiveness of drilling operations.In this regard, the FSI 5000 Shaker Screen has been making waves in the industry. This cutting-edge technology has been designed to provide superior performance and durability, making it a game-changer in the field of shale shaker screens. The FSI 5000 Shaker Screen is engineered to meet the demanding requirements of the oil and gas industry, and its innovative design sets it apart from traditional shaker screens.The FSI 5000 Shaker Screen is manufactured by a leading company in the oil and gas sector, known for its commitment to quality and excellence. With a strong focus on research and development, this company has been at the forefront of technological advancements in the industry. The FSI 5000 Shaker Screen is a testament to their dedication to innovation and their relentless pursuit of excellence.One of the key features of the FSI 5000 Shaker Screen is its advanced composite frame, which provides exceptional strength and longevity. This not only enhances the performance of the shaker screen, but also reduces the overall cost of ownership for the end user. The innovative design of the FSI 5000 Shaker Screen is a result of extensive research and development, ensuring that it meets the highest standards of quality and reliability.In addition to its superior performance, the FSI 5000 Shaker Screen is also designed with ease of use in mind. Its user-friendly interface and simple maintenance procedures make it an ideal choice for busy drilling operations. This allows for seamless integration into existing shaker systems, minimizing downtime and maximizing efficiency.The FSI 5000 Shaker Screen has already garnered rave reviews from industry professionals who have praised its durability and effectiveness. Its ability to withstand the rigors of the oil and gas sector and deliver consistent performance has made it a popular choice among drilling contractors and operators.Furthermore, the company behind the FSI 5000 Shaker Screen is known for its commitment to customer satisfaction. They offer comprehensive support and service to ensure that their clients get the most out of their investment. This includes technical assistance, training, and ongoing maintenance programs to keep the FSI 5000 Shaker Screen operating at its peak performance.In conclusion, the FSI 5000 Shaker Screen is a groundbreaking innovation that is set to revolutionize the oil and gas industry. Its advanced design, superior performance, and exceptional durability make it a top choice for drilling operations around the world. Combined with the company's dedication to quality and customer satisfaction, the FSI 5000 Shaker Screen is poised to become an indispensable asset in the oil and gas sector.

Industry News: Upgraded Shale Shaker Screens for Efficient Solids Control on S250 Shakers

Shale Shaker Screen for S250: The New Breakthrough in Oil and Gas Drilling IndustryThe oil and gas drilling industry has been facing increasing pressure to improve its operational efficiency as the oil prices continue to fluctuate. With the need to maximize production and minimize costs, operators are consistently seeking new technology to improve the drilling process. One of the biggest challenges in the drilling industry is the proper handling of drilled cuttings and mud away from the borehole. This is where the shale shaker screen comes in.A shale shaker screen is an essential component of drilling equipment that is used to screen the drilling fluid and cuttings from the borehole. The shale shaker screen is designed to handle a high capacity of solids to ensure that the drilling fluid is well controlled and to extend the life of the drilling equipment through efficient solids removal. A new technology, the shale shaker screen for S250, has been developed to solve the problem of inefficient solids control during drilling operations.The S250 shale shaker screen is a breakthrough technology in the oil and gas industry. It is designed to replace the conventional screens and improve the shale shaker's performance with its advanced capabilities. The shale shaker screen for S250 is manufactured using advanced techniques to ensure its durability and longevity. It is made from high-quality stainless steel mesh, ensuring its resistance to wear and tear, and it has been tested under the harshest drilling conditions to ensure its efficiency in dealing with high-speed cuttings.The shale shaker screen for S250 provides significant operational and financial benefits. With its high-capacity performance, it reduces the overall cost of drilling operations by reducing the number of screens required for the operation. The shale shaker screen for S250 is also easy to install and replace, reducing the downtime of the drilling operation, which results in higher efficiency and faster drilling times.The company behind the development of the S250 shale shaker screen has a reputation for excellence. The company has been providing cutting-edge technology solutions for drilling, exploration, and production operations for more than a decade. Its mission is to provide customized solutions that optimize operational efficiency in the oil and gas industry. The S250 shale shaker screen is a testament to the company's commitment to providing innovative solutions that meet the needs of the industry.In conclusion, the shale shaker screen for S250 is a game-changer in the drilling industry. It is designed to improve the efficiency of the drilling operation by providing a high-capacity, durable and efficient solution for solids removal. Its advanced capabilities result in reduced screen usage and faster drilling times, leading to significant operational and financial benefits. The company behind the development of the S250 shale shaker screen is dedicated to delivering innovative technology solutions that help the drilling industry achieve peak performance. The future of the drilling industry is bright with advancements like the shale shaker screen for S250, and the industry can expect even more breakthroughs in the years to come as we continue to push the limits of innovation.

Upgrading Your Shaker Screens: Tips for Replacing and Choosing the Right Screens

Replacement Shaker Screens Transforming the Oil and Gas IndustryIn the ever-evolving oil and gas industry, technological advancements play a crucial role in optimizing efficiency and productivity. And one company at the forefront of this transformation is a leading innovator in the field of replacement shaker screens. By combining cutting-edge technology with a deep understanding of industry needs, this company is revolutionizing the way drilling fluids are filtered and processed.With global demand for oil and gas continuing to rise, drilling operations have become more complex and challenging. The extraction process involves drilling deep into the earth's crust, often in harsh and remote locations. Consequently, drilling contractors face numerous challenges in order to maintain profitable operations. Ensuring efficient solid control systems is a critical aspect of successful drilling, as it directly impacts the overall performance and longevity of drilling equipment.Replacement shaker screens are an integral component of a drilling rig's solid control system. They are used to filter out unwanted solids from drilling fluids, a process known as shale shaker. Shaker screens play a vital role in maintaining the quality and integrity of the drilling fluids, as well as protecting downstream equipment such as centrifuges and pumps. Hence, the durability, effectiveness, and efficiency of these screens are of utmost importance.The innovator in question has a long-standing reputation for producing high-quality replacement shaker screens that surpass industry standards. Their commitment to continuous research and development has led to breakthrough technologies that address the industry's most pressing challenges. By leveraging advanced engineering techniques, this company has created screens that excel in terms of durability, efficiency, and performance.One of the key features that sets these replacement shaker screens apart is the utilization of composite materials. By combining carefully selected grades of stainless steel with engineered polymer frames, these screens exhibit enhanced resistance to wear and corrosion. This ensures a longer lifespan, resulting in reduced maintenance costs and increased overall productivity.Moreover, the company's innovative screen design maximizes the usable screen area, significantly improving fluid handling capacity. This not only facilitates faster drilling operations but also minimizes the chance of screen blinding, a common issue faced by drilling contractors. With decreased screen blinding, operators are able to maintain optimal fluid flow rates, enhancing the overall efficiency of the drilling process.Furthermore, these replacement screens are meticulously engineered to deliver accurate particle separation. They employ advanced mesh technology that enables precise cut points, ensuring that only the desired solids are filtered out. This level of finesse in separation allows drilling contractors to better manage the drilling fluids' composition, thereby delivering superior drilling performance.The company's commitment to customer satisfaction extends beyond the quality of their products. They provide comprehensive technical support and responsive customer service, ensuring that their clients' specific needs are met. In an industry where downtime can have costly repercussions, this level of support is invaluable.To further enhance their service offering, the company actively collaborates with drilling contractors to develop customized solutions. By understanding the unique challenges faced by each client, they are able to tailor their screens to specific drilling conditions, thereby optimizing performance and efficiency. This collaborative approach has earned the company a loyal customer base and cemented their position as a trusted partner in the oil and gas industry.With replacement shaker screens playing such a vital role in the oil and gas sector, the technological advancements offered by this innovative company are poised to transform the industry. By improving durability, maximizing fluid handling capacity, enhancing particle separation accuracy, and providing exceptional customer support, they are revolutionizing the solid control process. As drilling operations continue to evolve, these replacement shaker screens serve as a testament to the power of innovation in shaping the future of the oil and gas industry.

Enhancing Shale Shaker Performance with High-Quality Screens

**Title:** Innovative Shale Shaker Screen Revolutionizes Oil and Gas Industry **Introduction**In an era where technological advancements play a critical role in shaping industries, the oil and gas sector has not been left behind. As the demand for energy continues to rise, companies are constantly seeking new and innovative solutions to enhance efficiency and productivity in the extraction process. In this regard, Kemtron Shale Shaker Screen has emerged as a game-changing solution, revolutionizing the oil and gas industry.**Company Introduction**Kemtron Shale Shaker Screen, a leading provider of quality oilfield equipment, specializes in the design and manufacture of cutting-edge shale shaker screens. With a commitment to excellence and an unwavering focus on meeting industry demands, the company has earned a stellar reputation for delivering superior products that optimize drilling operations.Leveraging years of research and development, Kemtron Shale Shaker Screen has become synonymous with innovation, constantly pushing the boundaries of technology. Their team of skilled engineers and technicians work tirelessly to develop advanced solutions that enhance performance, prolong equipment life, and reduce downtime for companies operating in the oil and gas industry.**Revolutionizing the Shale Shaker Screen**The shale shaker screen plays a crucial role in the drilling process by filtering out solids and other debris from the drilling fluid, also known as drilling mud. This process is vital as it ensures the integrity of the drilling operation by preventing damage to downstream equipment, reducing the likelihood of wellbore instabilities, and optimizing well productivity.In the past, shale shaker screens were prone to premature failure due to factors such as wear and tear, inadequate filtration, and low durability. However, Kemtron Shale Shaker Screen has addressed these challenges head-on and revolutionized the industry with its state-of-the-art screens.The company's shale shaker screens are designed with advanced materials and innovative engineering to deliver unparalleled performance and longevity. By incorporating high-quality stainless steel wire cloth and a unique composite frame, their screens exhibit exceptional strength, corrosion resistance, and excellent filtration capabilities.Furthermore, Kemtron Shale Shaker Screen has implemented an advanced manufacturing process that ensures consistent quality and accuracy in screen production. Utilizing cutting-edge technology and stringent quality control measures, the company guarantees that each screen maintains precise dimensions, mesh sizes, and surface characteristics – resulting in improved efficiency and reliability.**Benefits for the Oil and Gas Industry**The introduction of Kemtron Shale Shaker Screen into the market has had a profound impact on the oil and gas industry. By choosing Kemtron's screens, companies can experience several significant benefits:1. Enhanced Filtration: The innovative design of the shale shaker screens provides superior particle separation, resulting in cleaner drilling fluid. This leads to increased drilling efficiencies, reduced fluid loss, and improved overall wellbore stability.2. Extended Service Life: The combination of durable stainless steel wire cloth and a composite frame ensures exceptional resistance to wear and tear. This extends the service life of the screens, reducing the frequency of replacements and associated costs.3. Cost-Effectiveness: Kemtron's screens contribute to cost savings by minimizing downtime due to screen failure and reducing the need for frequent replacements. Additionally, the improved filtration efficiency helps maintain the integrity of expensive downstream equipment, further reducing operational expenses.4. Environmentally Friendly: The high-quality screens contribute to a more sustainable drilling process by optimizing drilling fluid management, minimizing waste generation, and reducing the environmental impact of oil and gas exploration.**Conclusion**With their unwavering commitment to innovation and superior product quality, Kemtron Shale Shaker Screen has revolutionized the oil and gas industry. Their state-of-the-art shale shaker screens provide enhanced filtration, extended service life, cost-effectiveness, and environmental benefits, driving efficiency and productivity in drilling operations. As the industry continues to evolve, Kemtron remains at the forefront, continuously developing cutting-edge solutions that redefine industry standards and push the boundaries of excellence.

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

Top Primary Screens for the NOV VSM300: Enhancing Efficiency and Performance

release for an oil drilling companyIn the oil drilling industry, having reliable and efficient equipment is crucial in ensuring the success of a drilling operation. One of the most important equipment in this business is the drilling screening system. XYZ Oil Drilling Company understands the importance of having top-of-the-line drilling screening systems that can withstand and operate under the harshest conditions. That is why the company is proud to announce an addition to its equipment line-up- the NOV VSM300 Primary Screen.The NOV VSM300 Primary Screen is meticulously designed and manufactured by National Oilwell Varco (NOV), one of the leading providers of innovative drilling solutions in the world. The NOV VSM300 is recognized in the industry for its efficiency, reliability, and durability, making it the perfect fit to handle the challenging drilling operations that XYZ Oil Drilling Company is known for.The primary screen features a two-bearing design that provides higher throughput, lower maintenance costs, and increased screen life compared to traditional screening systems. Its advanced design has also eliminated several previous challenges related to vibration and noise, making it one of the most sought-after screening systems in the industry.One of the NOV VSM300's key features is its ability to operate with a wide range of drilling fluids, including synthetic-based, oil-based, and water-based. This versatility allows it to handle varying drilling conditions, making it ideal for the needs of the XYZ Oil Drilling Company.The primary screen's mesh size is customizable and can consist of single, double, or even triple-layer configurations to help improve filtration efficiency. The design of the NOV VSM300 Primary Screen also provides for increased energy efficiency, which helps lower operating costs. In addition, the system is built with ease of use in mind and can be installed and maintained quickly, maximizing uptime and productivity.Speaking on the addition of the NOV VSM300 Primary Screen to their equipment lineup, a spokesperson from XYZ Oil Drilling Company said, "At XYZ Oil Drilling, we are committed to providing our clients with the best drilling equipment available. The addition of the NOV VSM300 Primary Screen is part of our ongoing commitment to improve our operations continually. We are thrilled to partner with NOV to bring our clients a new level of productivity and efficiency."The NOV VSM300 Primary Screen is just one of the many top-of-the-line products that XYZ Oil Drilling Company offers its clients. The company provides a comprehensive range of oil drilling services, including drilling, completions, production, and well intervention. It boasts a fleet of modern drilling rigs and highly trained personnel who can operate in all types of drilling environments, making it the go-to company for oil drilling needs.Overall, the addition of the NOV VSM300 Primary Screen by XYZ Oil Drilling Company is a testament to its commitment to providing its clients with the best equipment available. The partnership with NOV has not only raised the bar for drilling screening systems, but it will also improve the company's services, ensuring they remain at the forefront of the oil drilling industry. In conclusion, the NOV VSM300 Primary Screen will play a vital role in ensuring the success of drilling operations for XYZ Oil Drilling Company and its clients. With its advanced features and capabilities, it is a valuable investment that will result in faster, more efficient, and safer drilling operations.

Introducing a High-Quality Shale Shaker Screen for Optimal Efficiency and Performance

Title: Innovation in Shale Shaker Screen Technology Revolutionizes the Drilling IndustryIntroduction:Shale shaker screens play a vital role in the oil and gas drilling industry. They are designed to efficiently filter out solid particles from drilling fluids, allowing for the retrieval of valuable resources. One company that has made significant strides in shale shaker screen innovation is Kemtron, a leading manufacturer and supplier of drilling equipment and accessories. With their latest technological breakthrough, the KTL-26 Shale Shaker Screen, Kemtron is revolutionizing the drilling industry by improving separation efficiency, reducing downtime, and optimizing drilling operations.Opening Paragraph:The KTL-26 Shale Shaker Screen, developed by Kemtron, represents a leap forward in drilling equipment technology. This state-of-the-art shale shaker screen is designed to deliver unparalleled performance, setting new industry standards for separation efficiency and cost-effectiveness. By effectively removing solid particles from drilling fluids, the KTL-26 ensures smooth operations, higher productivity, and increased profitability for drilling companies worldwide.Efficient Separation and Improved Downtime:The key advantage of the KTL-26 Shale Shaker Screen lies in its enhanced separation capabilities. With an intricate mesh design and advanced material composition, this screen offers superior filtration efficiency, effectively separating fine particles from drilling fluids. Its robust construction and high-quality materials ensure longevity and durability, reducing downtime due to frequent replacements and repairs.Additionally, the KTL-26's innovative design minimizes blinding and plugging, a common issue faced by traditional shale shaker screens. Its self-cleaning mechanism efficiently clears blockages, maintaining a consistent flow of drilling fluids and preventing disruptions to drilling operations. This unique feature significantly reduces downtime and increases the efficiency of drilling activities, ultimately saving time and costs for drilling companies.Optimized Drilling Operations:The KTL-26 Shale Shaker Screen is engineered to optimize drilling operations by delivering improved drilling fluid processing capabilities. The screen's precise particle separation not only eliminates harmful solids from drilling fluids, but also ensures the retention of valuable additives. This allows drilling companies to maintain the desired fluid properties, leading to improved drilling efficiency and higher quality wellbores.Furthermore, the KTL-26's design offers flexibility in adjusting the screen’s drying capacity and cut point, catering to varying drilling conditions. Drilling operations can now adapt to different formations, improving overall drilling performance and reducing the risk of outage due to unforeseen challenges.Environmental Sustainability:In addition to its impeccable performance, the KTL-26 Shale Shaker Screen also prioritizes environmental sustainability. Made from environmentally friendly materials and manufactured using eco-conscious processes, this screen reduces the carbon footprint typically associated with drilling activities. Kemtron's commitment to sustainable solutions aligns with the growing industry demand for eco-friendly practices, making the KTL-26 a responsible choice for environmentally conscious drilling companies.Conclusion:Kemtron's KTL-26 Shale Shaker Screen represents a significant advancement in shale shaker screen technology. Its improved separation efficiency, reduced downtime, and optimized drilling operations provide a competitive edge to drilling companies worldwide. By setting new industry standards, Kemtron continues to lead the way in enhancing drilling processes while prioritizing environmental sustainability. The KTL-26 Shale Shaker Screen is a testament to Kemtron's commitment to innovation, efficiency, and long-term success in the oil and gas drilling industry.

High-quality Oil Shaker Screen for FLC2000 Shakers

The oil and gas industry is a complex and demanding sector that requires cutting-edge technology and equipment to ensure smooth operations. One such essential piece of equipment is the FLC2000 Shaker screen, a vital component in the drilling process.The FLC2000 Shaker screen is a high-performance vibrating screen used to separate solids from liquids in the drilling mud. It is designed to efficiently remove solid particles from drilling fluids, which is a crucial step in the drilling process to ensure the integrity of the wellbore and protect downstream equipment.The FLC2000 Shaker screen, manufactured by a leading oilfield equipment company, is known for its durability, efficiency, and reliability. With a strong focus on quality and performance, the company has positioned itself as a trusted provider of drilling equipment and solutions to the oil and gas industry.The company behind the FLC2000 Shaker screen has a solid reputation for delivering innovative and high-quality products that meet the demanding requirements of the oil and gas sector. With a strong emphasis on research and development, the company has continuously improved and enhanced its product offerings to meet the evolving needs of the industry.In addition to the FLC2000 Shaker screen, the company also offers a comprehensive range of drilling equipment, including shale shakers, mud cleaners, centrifuges, and other solids control equipment. These products are designed to optimize drilling performance, reduce downtime, and minimize environmental impact, making them essential for efficient and sustainable drilling operations.The company's commitment to quality and customer satisfaction is evident in its rigorous testing and certification processes, ensuring that its products meet the highest industry standards. This dedication to excellence has earned the company the trust and confidence of leading oil and gas companies worldwide.Furthermore, the company's expertise in providing custom solutions and technical support sets it apart as a reliable partner for the oil and gas industry. Its team of experienced engineers and technicians are readily available to provide installation, maintenance, and troubleshooting services, ensuring that its customers' operations run smoothly and efficiently.With a global network of distribution and service centers, the company is well-positioned to provide timely support and reliable delivery of its products to customers around the world. This extensive network underscores the company's commitment to being a valuable and dependable partner to the oil and gas industry.In conclusion, the FLC2000 Shaker screen, combined with the company's extensive experience, technical expertise, and commitment to quality, exemplifies the essential role of advanced technology and equipment in the oil and gas industry. By consistently delivering reliable and innovative solutions, the company has established itself as a trusted provider of drilling equipment and solutions, contributing to the efficiency and sustainability of the oil and gas sector.

Top 5 Must-Have Tools for Efficient Oilfield Operations

Title: Oilfield Equipment Supplier Embraces Innovation and Continues to Thrive in the MarketIntroduction:Oilfield Equipment, an industry-leading supplier of high-quality oilfield equipment and services, has been a driving force in the oil and gas sector for over a decade. With a strong commitment to innovation, cutting-edge technology, and exceptional customer service, Oilfield Equipment has successfully carved a niche for itself in the competitive market. This article explores the key factors contributing to the company's success and highlights its dedication to providing top-of-the-line equipment and solutions to the oil and gas industry.Growing Amidst Technological Advancements:As the oil and gas sector continues to evolve and adapt to the growing demands of the global market, Oilfield Equipment has remained at the forefront of technological advancements. The company consistently invests in research and development to offer state-of-the-art equipment that not only enhances efficiency but also ensures greater safety measures for the workforce in the field.By collaborating with leading technology providers, Oilfield Equipment has successfully integrated automation and data analytics into its product offerings, enabling clients to optimize their operational performance. Through the use of advanced sensors, real-time data monitoring, and artificial intelligence-driven systems, the company's equipment enables oilfield operators to make informed, data-driven decisions, resulting in improved productivity and reduced downtime.Commitment to Quality and Reliability:Oilfield Equipment's unwavering commitment to delivering high-quality and reliable products has cemented its position as a trusted supplier in the industry. The company adheres to strict manufacturing standards, leveraging its extensive expertise to design and engineer equipment that meets the specific requirements of oilfield operations.Stringent quality control measures are implemented throughout the production process, ensuring that every piece of equipment that bears the Oilfield Equipment name is built to withstand the demanding conditions of the oilfield environment. This dedication to quality has earned the company a loyal customer base who rely on their products to enhance their operational efficiency and profitability.Customer-Centric Approach:Recognizing the importance of building strong and lasting partnerships with clients, Oilfield Equipment maintains a customer-centric approach in all aspects of its business. The company works closely with its customers to understand their unique needs and challenges, providing tailored solutions that address their specific requirements.Oilfield Equipment's team of highly skilled professionals offers comprehensive support from initial consultation to delivery and beyond. Their technical expertise and prompt customer service ensure that clients receive all the assistance they need, be it equipment selection, installation, maintenance, or troubleshooting.Sustainable Solutions and Environmental Responsibility:In line with the growing global focus on sustainability, Oilfield Equipment has integrated environmentally responsible practices into its operations. The company is committed to minimizing its ecological footprint by developing energy-efficient equipment and exploring alternative energy solutions.Furthermore, the company ensures adherence to all relevant environmental regulations and continues to invest in innovative technologies that reduce emissions and optimize resource utilization. By prioritizing sustainability, Oilfield Equipment not only contributes to the long-term viability of the oil and gas industry but also demonstrates its commitment to preserving the planet for future generations.Future Prospects and Outlook:Looking ahead, Oilfield Equipment is poised to leverage its extensive industry experience and robust technological capabilities to capture new opportunities in emerging markets. The company's solid reputation, commitment to innovation, and customer-centric approach position it favorably within the industry, ensuring continued growth and success.In conclusion, Oilfield Equipment stands as a leading supplier of high-quality oilfield equipment and services, driven by innovation, reliability, customer focus, and sustainability. Through its constant pursuit of excellence, the company has established a strong foothold within the oil and gas sector, and its future prospects remain promising in an ever-evolving industry.