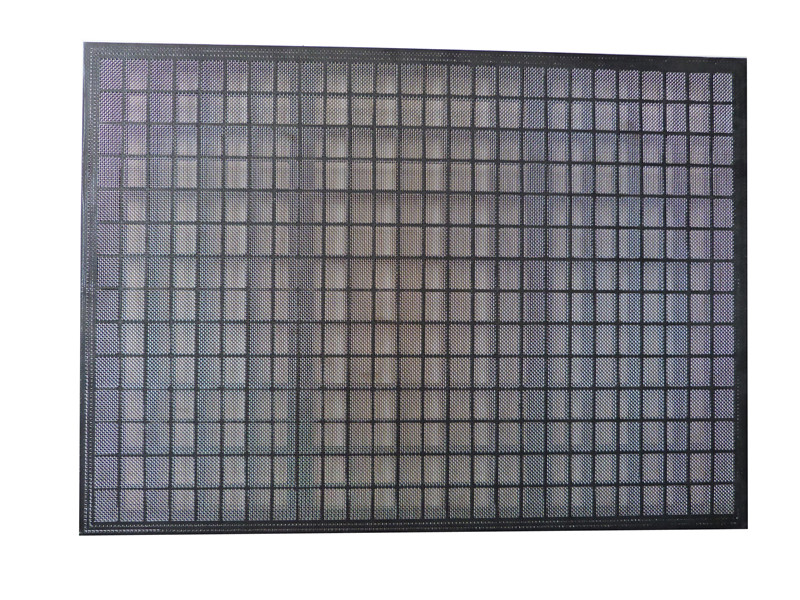

High Performance Mongoose Screen and Shaker Screen for Efficient Solids Control

By:Admin

The Mongoose Shaker Screen is a high-quality, durable and reliable product that is designed to withstand the most demanding drilling conditions. Its advanced design and construction ensure that it provides superior performance and longevity, reducing downtime and increasing productivity on the drilling site. Our commitment to quality and innovation is evident in every aspect of the Mongoose Shaker Screen, from its superior materials to its precise manufacturing processes.

The Mongoose Shaker Screen is engineered to deliver exceptional performance in a wide range of drilling applications, including both onshore and offshore operations. Its innovative design allows for more efficient separation of drilling fluid and solids, reducing waste and improving overall drilling performance. The result is a cleaner, more efficient drilling process that saves time and money for our clients.

In addition to its superior performance, the Mongoose Shaker Screen is also designed with ease of use and maintenance in mind. Its user-friendly design allows for quick and simple installation, while its durable construction ensures long-lasting performance with minimal maintenance requirements. This means that our clients can focus on their drilling operations with confidence, knowing that they have a reliable and efficient solution in place.

Furthermore, our commitment to environmental sustainability is reflected in the design of the Mongoose Shaker Screen. By reducing the amount of drilling waste and improving drilling efficiency, our product helps to minimize the environmental impact of drilling operations. This aligns with our company's values and commitment to responsible and sustainable business practices.

At [Company Name], we are dedicated to delivering the highest quality products and services to our clients. The launch of the Mongoose Shaker Screen is a testament to our ongoing dedication to innovation and excellence in the oil and gas industry. We are confident that this new product will deliver exceptional value to our clients, helping them to improve their drilling operations and achieve greater success in their business endeavors.

In conclusion, the Mongoose Shaker Screen represents a significant advancement in drilling technology, designed to enhance efficiency, reliability, and sustainability in drilling operations. With its superior performance, ease of use, and environmental benefits, it is set to become a leading solution in the oil and gas industry. We are excited to bring this innovative product to our clients and look forward to the positive impact it will have on their drilling operations.

Company News & Blog

High Quality Vortex Oil Shaker Screen for Efficient Oil and Gas Solids Control

Vortex oil shaker screen technology has been making waves in the oil and gas industry with its innovative approach to separating solids and liquids. This cutting-edge technology has been gaining popularity due to its efficiency and reliability, making it a top choice for many oil and gas companies worldwide.The Vortex oil shaker screen is designed to efficiently separate solids and liquids in various drilling operations. This technology utilizes a series of screens with different mesh sizes to effectively separate particles of different sizes, ensuring that drilling fluids are properly cleaned and maintained for optimal performance. The result is a more efficient and cost-effective drilling process, as well as reduced environmental impact.One of the key features of the Vortex oil shaker screen is its durable construction, which is designed to withstand the harsh conditions of oil and gas drilling. The screens are made from high-quality materials that are resistant to corrosion and wear, ensuring long-lasting performance and reliability. This design also minimizes downtime and maintenance costs, making it a cost-effective solution for oil and gas companies.In addition to its innovative design, the Vortex oil shaker screen also boasts a user-friendly interface, making it easy to operate and maintain. This user-friendly design allows for quick and easy screen changes, reducing downtime and increasing overall productivity. Furthermore, the technology is designed to be compatible with various drilling equipment, making it a versatile solution for a wide range of drilling operations.The Vortex oil shaker screen is also backed by a team of experts who provide comprehensive support and maintenance services. This ensures that companies using this technology can rely on prompt assistance and expertise to keep their operations running smoothly. The company's commitment to customer satisfaction and support further enhances the appeal of the Vortex oil shaker screen in the oil and gas industry.Moreover, the Vortex oil shaker screen is designed with sustainability in mind, as it helps reduce the environmental impact of drilling operations. By effectively separating solids and liquids, this technology helps minimize waste and reduces the need for disposal, contributing to a more environmentally friendly drilling process.As a result of its numerous benefits, the Vortex oil shaker screen has gained recognition and trust from oil and gas companies worldwide. Its advanced technology, durability, user-friendly design, and environmental sustainability make it a top choice for companies looking to improve their drilling operations.{Company name}, the manufacturer of the Vortex oil shaker screen, has a strong track record in the oil and gas industry. The company is known for its commitment to innovation, quality, and customer satisfaction, and has built a reputation for delivering high-performance solutions for drilling operations. With its extensive expertise and experience, {Company name} is a trusted partner for oil and gas companies seeking reliable and efficient technologies.In conclusion, the Vortex oil shaker screen has emerged as a game-changer in the oil and gas industry, offering a reliable and efficient solution for separating solids and liquids in drilling operations. With its innovative design, durability, user-friendly interface, and environmental sustainability, this technology has earned the trust and recognition of companies worldwide. Backed by the expertise and support of {Company name}, the Vortex oil shaker screen is set to continue making a positive impact on the oil and gas industry.

Discover the Latest Innovation in Shale Shaker Screen Technology with the Kemtron 28 Series

Title: Groundbreaking Kemtron 28 Series Shale Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the ever-evolving world of oil and gas exploration, the demand for reliable and efficient shale shaker screens has never been higher. Addressing this need, a leading industry player introduces their latest innovation - the Kemtron 28 Series Shale Shaker Screens. Designed to deliver exceptional performance, these screens are set to revolutionize the oil and gas industry, offering enhanced productivity and cost-efficiency. Let us delve deeper into the remarkable features that make the Kemtron 28 Series a game-changer.Unparalleled Quality and Durability:One of the most remarkable aspects of the Kemtron 28 Series Shale Shaker Screens is their superior build quality and exceptional durability. Constructed using advanced materials and cutting-edge manufacturing techniques, these screens offer a level of resilience and longevity that surpasses industry standards. Their innovative design ensures resistance to wear, abrasion, and corrosion, thereby minimizing replacement frequency and reducing maintenance costs for oil and gas companies.Optimized Performance:The Kemtron 28 Series Shale Shaker Screens are engineered to deliver exceptional performance by maximizing solids control efficiency. Their precise mesh sizes and configuration enable the screens to efficiently separate and remove solid particles from drilling fluids, ensuring the production of cleaner and higher-quality fluid. This not only enhances the drilling process but also minimizes the risk of equipment failures, ultimately leading to improved operational efficiency and reduced downtime.Enhanced Operational Efficiency:The incorporation of the Kemtron 28 Series Shale Shaker Screens into an oil and gas operation brings with it a multitude of benefits that lead to enhanced operational efficiency. The screens' exceptional solids control efficiency reduces the volume of drilling fluid required, resulting in significant cost savings. Furthermore, by maintaining optimal fluid viscosity, the screens contribute to improved drilling speed and accuracy, ultimately reducing overall project timelines. These combined factors propel the oil and gas industry towards faster, more efficient operations.Eco-Friendly Solution:Sustainability is a key consideration in the modern oil and gas industry, and the Kemtron 28 Series Shale Shaker Screens deliver in this area as well. By effectively separating solids from drilling fluids, these screens minimize the environmental impact of drilling activities. Clean drilling fluids can be effectively recycled, reducing the volume of waste generated and mitigating the potential harm to ecosystems. The adoption of the Kemtron 28 Series screens not only enhances operational efficiency but also demonstrates a commitment to responsible environmental practices.Unparalleled Support and Service:Recognizing the importance of seamless customer support, the company behind the Kemtron 28 Series Shale Shaker Screens prides itself on its dedicated after-sales service. With a global network of technical experts and service centers, customers can rest assured that their queries and concerns will be promptly addressed. This comprehensive support ensures that the screens continue to operate at their best, maximizing their potential and delivering exceptional value to oil and gas companies around the world.Conclusion:The introduction of the Kemtron 28 Series Shale Shaker Screens has caused ripples of excitement throughout the oil and gas industry. Boasting unparalleled quality, optimized performance, enhanced operational efficiency, and a commitment to sustainability, these screens have quickly become the go-to choice for industry professionals. As oil and gas companies strive for greater productivity while prioritizing environmental responsibility, the Kemtron 28 Series Shale Shaker Screens emerge as a groundbreaking solution that will shape the future of the industry.

High-quality Oil Shaker Screens for Effective Filtration and Separation

The oil and gas industry is a crucial part of the global economy, and companies in this sector are constantly striving to improve their efficiency and productivity. One such company that has been making waves in the industry is a leading provider of oil shaker screens, an essential component in the oil and gas drilling process.The company, headquartered in the United States, has been at the forefront of innovation in oil shaker screen technology. Their products are designed to efficiently separate solids from drilling fluid and are used in various drilling applications, including oil and gas exploration, well construction, and environmental remediation.One of the company's flagship products is the Swaco Oil Shaker Screen, which has gained a reputation for its exceptional performance and durability. The screen is designed to withstand the harsh conditions of drilling operations and is engineered to deliver high throughput and maximum solids removal efficiency. Its unique design and advanced manufacturing techniques have made it a preferred choice for many drilling operators around the world.In addition to the Swaco Oil Shaker Screen, the company offers a wide range of screens for different shaker models, including hook strip, pretensioned, and framed screens. These screens are made from high-quality materials and are precision-engineered to meet the specific requirements of different drilling applications.The company's commitment to quality and innovation has earned it a loyal customer base and a strong reputation in the industry. Its products are known for their reliable performance, long service life, and cost-effectiveness. Moreover, the company prides itself on its exceptional customer service and technical support, ensuring that its clients receive the best possible solutions for their drilling needs.In addition to its product offerings, the company also provides comprehensive training and support services to help drilling operators optimize the performance of their shaker screens. This includes on-site technical assistance, maintenance and repair services, and custom engineering solutions to address specific drilling challenges.Furthermore, the company is dedicated to sustainability and environmental responsibility, and it continually seeks to develop new technologies and processes that minimize the environmental impact of drilling operations. Its commitment to sustainability extends to its product development, where it strives to use eco-friendly materials and manufacturing practices.As the global demand for energy continues to rise, the oil and gas industry will continue to play a crucial role in meeting this demand. Companies like this leading provider of oil shaker screens will be instrumental in helping the industry operate more efficiently and sustainably. With their advanced technology, exceptional products, and unwavering commitment to customer satisfaction, they are well-positioned to continue as a driving force in the oil and gas sector.In conclusion, the company's Swaco Oil Shaker Screen and other products have set new standards for performance, reliability, and environmental responsibility in the oil and gas industry. Their dedication to innovation, quality, and customer service has solidified their position as a trusted partner for drilling operators worldwide. As the industry continues to evolve, this leading provider of oil shaker screens will undoubtedly remain at the forefront, providing cutting-edge solutions that meet the evolving needs of the oil and gas sector.

Oil Composite Frame Shale Shaker Screen: A Durable Solution for Swaco Mongoose

Swaco, a leading provider of oilfield equipment and services, has recently announced the launch of their new Mongoose Oil Composite Frame Shale Shaker Screen. This innovative product is designed to enhance the efficiency and performance of shale shakers in oil and gas drilling operations.The Mongoose Oil Composite Frame Shale Shaker Screen is a result of Swaco’s commitment to continuous innovation and product development. With a focus on improving the overall drilling process, Swaco has designed this new shaker screen to deliver superior performance and reliability in a variety of drilling conditions.The Mongoose Oil Composite Frame Shale Shaker Screen is built using advanced composite materials that are specifically engineered to withstand the demanding conditions of oil and gas drilling operations. This results in a longer lifespan and reduced maintenance requirements, ultimately leading to lower operating costs for drilling companies.One of the key features of the Mongoose Oil Composite Frame Shale Shaker Screen is its ability to effectively separate solids from drilling fluid. By efficiently removing unwanted debris and particles, the shaker screen helps to maintain the quality of the drilling fluid, leading to improved drilling efficiency and reduced environmental impact.In addition to its performance benefits, the Mongoose Oil Composite Frame Shale Shaker Screen is also designed for ease of installation and maintenance. Its lightweight frame and durable construction make it easy to handle and replace, saving valuable time and effort for drilling crews.As part of the company’s commitment to sustainability, Swaco has also ensured that the Mongoose Oil Composite Frame Shale Shaker Screen is fully recyclable. This reflects the company's dedication to reducing the environmental impact of oil and gas drilling operations.The launch of the Mongoose Oil Composite Frame Shale Shaker Screen further solidifies Swaco’s position as a leading provider of high-quality equipment and services for the oil and gas industry. With a strong focus on innovation and customer satisfaction, Swaco continues to deliver cutting-edge solutions that meet the evolving needs of the industry.In addition to the Mongoose Oil Composite Frame Shale Shaker Screen, Swaco offers a comprehensive range of products and services for oil and gas drilling operations. This includes a variety of other shale shaker screens, as well as mud cleaners, centrifuges, and other equipment essential for efficient drilling operations.With a global network of operations and a team of experienced professionals, Swaco is well-equipped to support drilling operations in even the most challenging environments. The company's commitment to delivering high-quality products and reliable services has earned the trust of drilling companies worldwide.In conclusion, the launch of the Mongoose Oil Composite Frame Shale Shaker Screen represents a significant milestone for Swaco and the oil and gas industry as a whole. With its innovative design, superior performance, and focus on sustainability, this new product is set to make a positive impact on drilling operations around the world. As Swaco continues to push the boundaries of technology and efficiency in the oil and gas industry, it remains a reliable partner for all drilling companies looking to achieve success in their operations.

Scalping Screen for VSM300: News and Updates

Brandt / NOV VSM300 Scalping Screen is a high-efficiency, multi-functional scalping screen. It is designed to provide the ultimate in flexibility and adaptability. The screen is capable of handling a wide range of material from heavy duty scalping to precision screening. This makes it an ideal solution for a variety of industries including mining, aggregate, construction, and recycling.The key feature of the Brandt / NOV VSM300 Scalping Screen is its versatility. It can effectively screen a wide range of materials including aggregates, coal, and ores. This flexibility makes it an invaluable tool for any operation involved in material handling.In addition to its versatility, the Brandt / NOV VSM300 Scalping Screen is also known for its efficiency. The screen is equipped with high-performance, heavy-duty bearings that provide long-term reliability and low maintenance. This ensures that the screen can operate at maximum efficiency with minimal downtime.The screen is also designed with ease of use in mind. It features a user-friendly control system that allows operators to easily adjust settings and configure the screen to meet their specific needs. This makes the Brandt / NOV VSM300 Scalping Screen an ideal choice for operations of all sizes.In addition to its performance and ease of use, the Brandt / NOV VSM300 Scalping Screen is also designed with durability in mind. It is constructed with high-quality materials and components that are built to withstand the rigors of heavy-duty use. This ensures that the screen will continue to perform reliably even in the most demanding of environments.To support the efficient operation of the Brandt / NOV VSM300 Scalping Screen, the company provides comprehensive service and support. This includes installation, training, and ongoing maintenance to ensure that the screen continues to perform at its best.The Brandt / NOV VSM300 Scalping Screen is backed by a team of industry experts who are dedicated to providing superior customer service. They are committed to understanding the unique needs of each customer and providing tailored solutions to meet those needs.In summary, the Brandt / NOV VSM300 Scalping Screen is a high-performance, versatile, and durable screening solution that is ideal for a wide range of industries. Its efficiency, ease of use, and durability make it a valuable asset for any operation involved in material handling.In addition to its impressive performance, the company is also committed to providing excellent customer service and support. This ensures that customers can rely on the Brandt / NOV VSM300 Scalping Screen to meet their needs now and in the future.

High-quality Shaker Screen for DFTS - Durable and Efficient Options

DFTS, a leading provider of high-quality shaker screens for the oil and gas industry, has recently launched a new and improved product line designed to revolutionize the industry. The company is known for its commitment to innovation and excellence, and their latest offering is no exception. With a focus on efficiency, durability, and performance, the new shaker screens are set to make a significant impact in the field of oil and gas drilling.Founded in 2003, DFTS has quickly become a trusted name in the industry, known for its dedication to superior products and exceptional customer service. The company's extensive experience and expertise have helped it to develop and manufacture some of the most advanced shaker screens on the market. By continuously investing in research and development, DFTS stays ahead of the curve in terms of technology and product design, ensuring that its customers receive products that meet the highest standards of quality and performance.The new shaker screens from DFTS are designed to deliver exceptional performance in a wide range of drilling applications. Whether used in onshore or offshore drilling operations, the screens are engineered to withstand the most demanding conditions while maintaining maximum efficiency. The innovative design of the screens allows for better separation of solids and liquids, resulting in improved drilling fluid quality and reduced downtime. This not only leads to cost savings for the operators but also contributes to a more sustainable and environmentally friendly drilling process.One of the key features of the new screens is their enhanced durability. Made from high-quality materials and manufactured with precision, the screens are built to withstand the rigors of the drilling environment. This means that operators can rely on the screens to perform consistently and reliably, reducing the need for frequent replacements and maintenance. In addition, the screens are also designed for easy installation and removal, further streamlining operations and minimizing downtime.In addition to their superior performance and durability, the new shaker screens from DFTS are also designed with user-friendliness in mind. With a focus on ease of use and maintenance, the screens are equipped with advanced features that make them simple to operate and maintain. This not only improves efficiency on the job site but also reduces the need for extensive training and technical support, further contributing to cost savings for the operators.As a company committed to excellence, DFTS ensures that its products meet the highest standards of quality and reliability. Every shaker screen undergoes rigorous testing and inspection to ensure that it meets or exceeds industry specifications and performance requirements. This dedication to quality and integrity has helped DFTS to build a reputation as a trusted partner for operators in the oil and gas industry, providing them with the confidence and peace of mind that they are using the best products available.With the launch of its new shaker screen product line, DFTS continues to demonstrate its commitment to innovation and excellence. By combining advanced technology, superior materials, and meticulous craftsmanship, the company has created a product that sets a new standard for performance and reliability in the oil and gas drilling industry. As the demand for efficient and sustainable drilling solutions continues to grow, DFTS is well-positioned to lead the way with its groundbreaking new shaker screens.

VSM 300 Secondary Oil Shaker Screen: A Guide to Choosing the Best Option

Global Oil Shaker Screen Company is proud to announce its latest innovation, the VSM 300 Secondary Oil Shaker Screen. This new product is designed to offer superior performance and efficiency in the oil drilling and extraction process, further solidifying our position as a leader in the industry.The VSM 300 Secondary Oil Shaker Screen is a high-quality replacement screen that is compatible with the VSM 300 shale shaker. It is designed to effectively remove solids from drilling fluid while ensuring maximum efficiency and durability. This new product is the result of extensive research and development, as well as feedback from our customers in the oil and gas industry.One of the key features of the VSM 300 Secondary Oil Shaker Screen is its advanced composite frame, which provides increased strength and longer service life compared to traditional metal frames. This innovative design reduces the risk of screen failure and ensures that the screen can withstand the demanding conditions of oil drilling operations. Additionally, the screen is manufactured using high-quality materials that are resistant to corrosion and abrasion, further enhancing its longevity and performance.In addition to its durability, the VSM 300 Secondary Oil Shaker Screen also offers superior solids control capabilities. The screen features a unique layered design that effectively separates solids from drilling fluid, allowing for the efficient removal of unwanted particles. This not only helps to maintain the quality of the drilling fluid but also reduces the wear and tear on downstream equipment, resulting in cost savings and improved operational efficiency.Furthermore, the VSM 300 Secondary Oil Shaker Screen is engineered to provide a high conductance rate, ensuring that drilling fluid can flow through the screen at an optimal rate. This helps to prevent blockages and ensures that the drilling process can continue uninterrupted, ultimately leading to increased productivity and reduced downtime.As a global leader in the oil and gas industry, Global Oil Shaker Screen Company is committed to providing high-quality products and exceptional service to our customers. Our team of experienced engineers and technicians are dedicated to developing innovative solutions that meet the evolving needs of the industry, and the VSM 300 Secondary Oil Shaker Screen is a testament to this commitment.With the introduction of the VSM 300 Secondary Oil Shaker Screen, Global Oil Shaker Screen Company is continuing its legacy of excellence and innovation in the oil and gas industry. This new product showcases our dedication to providing superior solutions for solids control and fluid management, and we are confident that it will deliver exceptional performance in a wide range of drilling applications.In conclusion, the VSM 300 Secondary Oil Shaker Screen is a testament to Global Oil Shaker Screen Company's dedication to innovation and excellence in the oil and gas industry. With its advanced design, superior durability, and unmatched performance, this new product is set to revolutionize solids control in oil drilling operations, providing our customers with a reliable and efficient solution for their fluid management needs. As we look to the future, Global Oil Shaker Screen Company remains committed to pushing the boundaries of innovation and delivering value to our customers around the world.

Top Primary Screens for the NOV VSM300: Enhancing Efficiency and Performance

release for an oil drilling companyIn the oil drilling industry, having reliable and efficient equipment is crucial in ensuring the success of a drilling operation. One of the most important equipment in this business is the drilling screening system. XYZ Oil Drilling Company understands the importance of having top-of-the-line drilling screening systems that can withstand and operate under the harshest conditions. That is why the company is proud to announce an addition to its equipment line-up- the NOV VSM300 Primary Screen.The NOV VSM300 Primary Screen is meticulously designed and manufactured by National Oilwell Varco (NOV), one of the leading providers of innovative drilling solutions in the world. The NOV VSM300 is recognized in the industry for its efficiency, reliability, and durability, making it the perfect fit to handle the challenging drilling operations that XYZ Oil Drilling Company is known for.The primary screen features a two-bearing design that provides higher throughput, lower maintenance costs, and increased screen life compared to traditional screening systems. Its advanced design has also eliminated several previous challenges related to vibration and noise, making it one of the most sought-after screening systems in the industry.One of the NOV VSM300's key features is its ability to operate with a wide range of drilling fluids, including synthetic-based, oil-based, and water-based. This versatility allows it to handle varying drilling conditions, making it ideal for the needs of the XYZ Oil Drilling Company.The primary screen's mesh size is customizable and can consist of single, double, or even triple-layer configurations to help improve filtration efficiency. The design of the NOV VSM300 Primary Screen also provides for increased energy efficiency, which helps lower operating costs. In addition, the system is built with ease of use in mind and can be installed and maintained quickly, maximizing uptime and productivity.Speaking on the addition of the NOV VSM300 Primary Screen to their equipment lineup, a spokesperson from XYZ Oil Drilling Company said, "At XYZ Oil Drilling, we are committed to providing our clients with the best drilling equipment available. The addition of the NOV VSM300 Primary Screen is part of our ongoing commitment to improve our operations continually. We are thrilled to partner with NOV to bring our clients a new level of productivity and efficiency."The NOV VSM300 Primary Screen is just one of the many top-of-the-line products that XYZ Oil Drilling Company offers its clients. The company provides a comprehensive range of oil drilling services, including drilling, completions, production, and well intervention. It boasts a fleet of modern drilling rigs and highly trained personnel who can operate in all types of drilling environments, making it the go-to company for oil drilling needs.Overall, the addition of the NOV VSM300 Primary Screen by XYZ Oil Drilling Company is a testament to its commitment to providing its clients with the best equipment available. The partnership with NOV has not only raised the bar for drilling screening systems, but it will also improve the company's services, ensuring they remain at the forefront of the oil drilling industry. In conclusion, the NOV VSM300 Primary Screen will play a vital role in ensuring the success of drilling operations for XYZ Oil Drilling Company and its clients. With its advanced features and capabilities, it is a valuable investment that will result in faster, more efficient, and safer drilling operations.

New and Innovative 26-Inch Screen Released in Latest Tech News

Kemtron 26 Screen, a leading provider of advanced display solutions, has recently unveiled their latest cutting-edge technology in the form of a high-performance screen that is set to revolutionize the display industry. With a focus on delivering exceptional image quality and ultimate user experience, the new Kemtron 26 Screen represents a significant leap forward in display technology.The Kemtron 26 Screen features a stunning 26-inch display with a resolution of 3840 x 2160 pixels, delivering crystal-clear images with vivid colors and incredible detail. This level of resolution is unprecedented in a screen of this size, making it ideal for a wide range of applications including professional use in design, editing, and content creation, as well as for immersive entertainment experiences.One of the key features of the Kemtron 26 Screen is its advanced HDR (High Dynamic Range) technology, which enables it to deliver a wider range of colors and greater contrast, resulting in a more lifelike and immersive viewing experience. This makes the screen ideal for content creators and consumers who demand the utmost in visual quality.The Kemtron 26 Screen also boasts a refresh rate of 120Hz, ensuring smooth and fluid motion, making it perfect for gaming and other fast-paced applications. Additionally, the screen features a low input lag, minimizing the delay between input from the user and the corresponding action on the screen, further enhancing the overall responsiveness and performance of the display.In terms of design, the Kemtron 26 Screen has been meticulously crafted to be sleek and modern, with a slim profile and minimal bezels, making it an attractive addition to any professional or home setup. The screen is also equipped with a range of connectivity options including multiple HDMI and DisplayPort inputs, as well as built-in speakers and a headphone jack for a complete audio-visual experience.Speaking about the launch of the new Kemtron 26 Screen, the company's CEO stated, "We are thrilled to introduce our latest display technology that sets new standards for image quality and performance. The Kemtron 26 Screen represents the culmination of years of research and development, and we are confident that it will exceed the expectations of even the most discerning users."The CEO further added, "At Kemtron, we are committed to pushing the boundaries of display technology and delivering innovative solutions that empower our customers to unleash their creativity and fully immerse themselves in their work and entertainment. With the Kemtron 26 Screen, we are proud to offer a display that truly redefines what is possible."The Kemtron 26 Screen is set to be available for purchase in the coming months, and it is expected to attract attention from professionals in creative industries, as well as enthusiasts who seek the best in display technology. With its exceptional image quality, advanced features, and elegant design, the Kemtron 26 Screen is poised to make a significant impact in the display market and cement Kemtron's position as a leader in the industry.

Highly Durable Shaker Screen: A Key Component for Efficient Solid Control

The FSI 5000 Shaker Screen has been making waves in the oil and gas industry due to its exceptional performance and reliability. This innovative product has been designed to meet the demanding requirements of drilling operations, providing effective solids control and outstanding efficiency.The FSI 5000 Shaker Screen boasts a unique design that allows for efficient fluid processing and excellent cuttings removal. With its advanced technology and durable construction, this shaker screen has become a go-to solution for companies looking to improve their drilling processes and maximize productivity.The key to the exceptional performance of the FSI 5000 Shaker Screen lies in its high-quality materials and precision engineering. This product is designed to withstand the harshest drilling conditions, ensuring reliable and consistent operation in any environment. Its robust construction and innovative features make it a top choice for companies seeking a shaker screen that can deliver exceptional results while minimizing downtime and maintenance costs.With its superior performance and durability, the FSI 5000 Shaker Screen has quickly become the preferred choice for drilling operations around the world. Companies rely on this product to improve their solids control processes, enhance cuttings removal, and ultimately increase drilling efficiency. The FSI 5000 Shaker Screen has proven to be a valuable asset for companies looking to optimize their operations and achieve greater success in the field.In addition to its outstanding performance, the FSI 5000 Shaker Screen is also backed by a company with a strong track record of delivering reliable and innovative solutions for the oil and gas industry. This company has a long history of providing high-quality products and exceptional customer service, earning a reputation as a trusted partner for drilling operations of all sizes. With its commitment to excellence and dedication to meeting the needs of its customers, this company has built a solid foundation for success and continues to be a leader in the industry.The FSI 5000 Shaker Screen is just one example of the company's commitment to innovation and customer satisfaction. By combining cutting-edge technology with a focus on quality and reliability, this company continues to set the standard for excellence in the oil and gas industry. Its dedication to providing superior products and exceptional service has earned it the trust and loyalty of its customers, positioning it as a top choice for companies seeking reliable solutions for their drilling operations.As the oil and gas industry continues to evolve, companies are under increasing pressure to improve efficiency, reduce costs, and optimize their operations. The FSI 5000 Shaker Screen, along with the support of its dependable and reputable company, offers a solution that meets these challenges head-on. With its exceptional performance, durability, and strong track record, this product has become a key asset for companies looking to stay ahead in today's competitive market.In conclusion, the FSI 5000 Shaker Screen, combined with its reputable and reliable company, represents a powerful and effective solution for the oil and gas industry. With its exceptional performance, innovative design, and commitment to customer satisfaction, this product has quickly become a go-to choice for companies seeking to maximize their drilling operations. As companies continue to face increasing demands and competition, the FSI 5000 Shaker Screen offers a solution that delivers superior results and sets a new standard for excellence in the field.