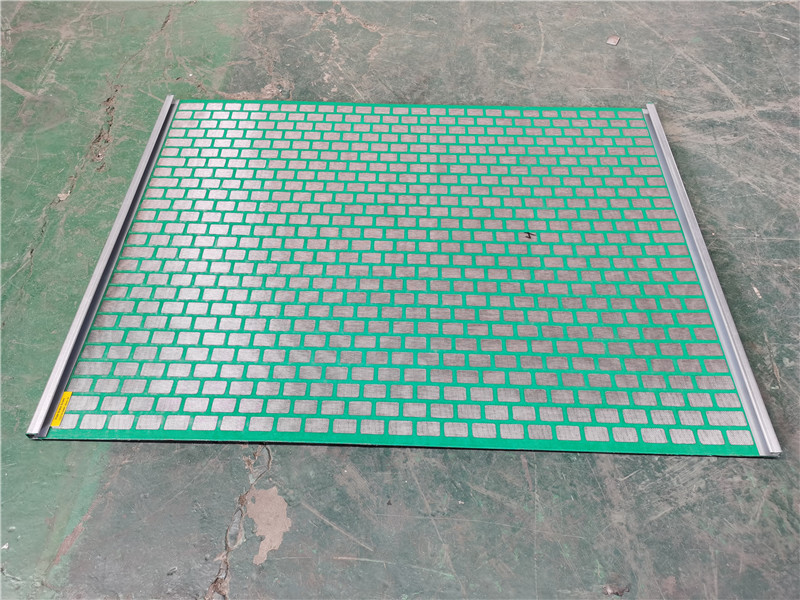

High-performance 48-30 PMD Screen for Derrick FLC2000

By:Admin

The company behind the Derrick FLC2000 48-30 PMD Screen is a renowned name in the oil and gas equipment manufacturing sector. With decades of experience and expertise in designing and producing high-quality equipment, the company has built a solid reputation for delivering reliable and efficient solutions to its clients. The company's commitment to innovation and excellence has made it a trusted partner for many businesses operating in the oil and gas industry.

The Derrick FLC2000 48-30 PMD Screen is a testament to the company's dedication to staying ahead of the curve. The screen boasts a range of advanced features that set it apart from traditional screens used in drilling operations. Its high-quality construction and durable materials ensure that it can withstand the harshest operating conditions, making it a reliable and long-lasting solution for companies in the oil and gas sector.

One of the key features of the Derrick FLC2000 48-30 PMD Screen is its superior performance in separating solids from drilling fluid. The screen's unique design and efficient filtration capabilities make it an essential component for ensuring the smooth operation of drilling equipment. It effectively removes unwanted solids, allowing the drilling fluid to be recycled and reused, thereby reducing waste and lowering operating costs for businesses.

In addition to its exceptional performance, the Derrick FLC2000 48-30 PMD Screen is also designed with ease of use in mind. Its user-friendly interface and maintenance-friendly design make it simple for operators to install and maintain, saving time and effort in the field. This added convenience is a significant advantage for businesses looking to streamline their operations and improve overall efficiency.

Furthermore, the company's dedication to customer satisfaction is evident in the support and services it provides to clients using the Derrick FLC2000 48-30 PMD Screen. The company offers comprehensive training and technical assistance to ensure that clients can maximize the performance and lifespan of the screen. This level of commitment to customer success sets the company apart as a reliable and trustworthy partner.

The Derrick FLC2000 48-30 PMD Screen is quickly becoming the go-to choice for businesses in the oil and gas drilling industry. Its superior performance, innovative features, and the backing of a reputable company have positioned it as a must-have solution for companies looking to optimize their drilling operations.

As the demand for efficient and reliable equipment continues to grow in the oil and gas sector, the Derrick FLC2000 48-30 PMD Screen has emerged as a top contender. Its proven track record and the strong reputation of the company behind it make it a compelling choice for businesses seeking to enhance their drilling operations.

In conclusion, the Derrick FLC2000 48-30 PMD Screen, combined with the expertise and support of a leading company in the oil and gas equipment manufacturing sector, is setting new standards for performance and reliability in the industry. Its advanced features, user-friendly design, and commitment to customer satisfaction make it a standout solution for businesses seeking to improve their drilling operations. With the Derrick FLC2000 48-30 PMD Screen, companies can expect to achieve greater efficiency, lower operating costs, and ultimately, a more successful and sustainable business.

Company News & Blog

Guide to Oil Vibrating Screen: Uses, Benefits, and Maintenance

Oil Vibrating Screen is a vital piece of equipment in the oil and gas industry, used to separate solids from liquids in drilling operations. It's an essential tool for maintaining the efficiency and reliability of drilling operations. One of the leading manufacturers of Oil Vibrating Screens is {}. The company has been in the industry for over a decade and has built a strong reputation for producing high-quality, durable, and reliable vibrating screens for use in the oil and gas sector. They have a wide range of products to cater to the varying needs of their clients, from standard vibrating screens to custom-designed solutions for specific applications. The company takes pride in its ability to provide innovative and cost-effective solutions to its customers, making them a preferred choice in the industry.Recently, the company has introduced a new range of Oil Vibrating Screens that are designed to offer even greater efficiency and performance. These new screens are equipped with the latest technology to enhance their functionality and durability, ensuring reliable operation even in the most challenging drilling environments.The new range of Oil Vibrating Screens from {} features improved screen panels that are more resistant to wear and tear, ensuring a longer lifespan and reduced maintenance costs for their customers. The screens also come with enhanced vibration mechanisms that deliver higher G-forces, improving the separation of solids and liquids and increasing the overall efficiency of the drilling process.In addition to the technical improvements, the new range of screens also incorporates advanced control systems that allow for better monitoring and adjustment of the screening process, further optimizing performance and ensuring consistent and reliable operation.The company's commitment to innovation and continuous improvement is reflected in the new range of Oil Vibrating Screens, which is set to raise the bar in terms of performance, reliability, and cost-effectiveness in the industry.In a statement, a spokesperson for {} said, "We are excited to introduce our latest range of Oil Vibrating Screens, which represents a significant step forward in terms of technology and performance. Our team has worked tirelessly to develop these new screens, incorporating the latest advancements to ensure that they meet and exceed the expectations of our customers. We are confident that these new screens will make a positive impact on the efficiency and productivity of drilling operations for our clients."The company's dedication to quality and reliability has made them a trusted partner for many companies in the oil and gas sector. With the introduction of their new range of Oil Vibrating Screens, they are poised to further strengthen their position as a leading provider of screening solutions for the industry.As the global demand for oil and gas continues to grow, the need for efficient and reliable drilling operations becomes increasingly important. High-quality equipment, such as Oil Vibrating Screens, plays a crucial role in ensuring the smooth and successful operation of drilling activities, making companies like {} an invaluable asset to the industry.With their latest advancements in technology and their unwavering commitment to customer satisfaction, {}. is well-positioned to continue leading the way in providing innovative and high-performance solutions for the oil and gas sector. Their new range of Oil Vibrating Screens is testament to their dedication to excellence and to meeting the evolving needs of their customers in the industry.

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

High-Quality Oil Shake Screen for Effective Solid Control

Swaco Oil Shake Screen is a revolutionary product that has been developed by a leading oilfield equipment company. This innovative shake screen has been designed to address the challenges faced by the oil and gas industry in the process of separating solids and fluids during the drilling process. The shake screen is a critical component of the shale shakers used in drilling operations, and the Swaco Oil Shake Screen has set a new standard in terms of efficiency and performance.The Swaco Oil Shake Screen utilizes advanced technology and high-quality materials to deliver exceptional results in separating solids from drilling fluids. It has been engineered to withstand the harsh conditions of drilling operations and to provide reliable and consistent performance. The shake screen is designed to effectively remove large solids and debris from the drilling fluids, allowing for the efficient and smooth operation of the shale shakers.One of the key features of the Swaco Oil Shake Screen is its high-capacity design, which enables it to handle large volumes of drilling fluids while effectively separating solids. This high-capacity capability is crucial in ensuring the smooth and uninterrupted flow of drilling operations, as it helps prevent blockages and downtime. Additionally, the shake screen is designed to be easily replaceable, which contributes to both time and cost savings for drilling operators.The Swaco Oil Shake Screen is also known for its durability and longevity, thanks to its robust construction and high-quality materials. This ensures that the shake screen can withstand the rigorous demands of drilling operations and continue to deliver reliable performance over an extended period of time. Its exceptional durability makes it a cost-effective solution for oil and gas companies, as it reduces the frequency of replacements and maintenance.Furthermore, the Swaco Oil Shake Screen has been designed with a focus on environmental sustainability. The shake screen is engineered to minimize waste and reduce the environmental impact of drilling operations by efficiently separating solids from the drilling fluids. This aligns with the industry's increasing focus on sustainability and environmental responsibility.The company behind the development of the Swaco Oil Shake Screen is a respected leader in the oilfield equipment industry. With a track record of delivering high-quality and reliable products, the company has established a strong reputation for excellence and innovation. The development of the Swaco Oil Shake Screen is a testament to the company's commitment to addressing the evolving needs of the oil and gas industry with cutting-edge solutions.The company's dedication to research and development has been instrumental in the creation of the Swaco Oil Shake Screen, which represents a significant advancement in the field of shale shaker technology. The shake screen has undergone rigorous testing and validation to ensure its performance, reliability, and durability, and it has exceeded industry standards in all these aspects.In conclusion, the Swaco Oil Shake Screen is a game-changing product that has redefined the capabilities of shale shaker technology in the oil and gas industry. Its advanced design, high capacity, durability, and environmental sustainability make it a standout solution for separating solids from drilling fluids. Combined with the strong reputation and innovative spirit of the company behind its development, the Swaco Oil Shake Screen is poised to make a significant impact on the efficiency and reliability of drilling operations.

Replacement Shaker Screen for King Cobra/Hybrid Models

Due to the increasing demand for efficient and reliable equipment in the oil and gas industry, our company is proud to introduce the latest innovation in shaker screen technology - the Replacement Shaker Screen for Brandt King Cobra/Hybrid. This new product is designed to revolutionize the solids control process and improve the overall performance of shakers in drilling operations.With a focus on durability, longevity, and superior performance, our Replacement Shaker Screen for Brandt King Cobra/Hybrid is manufactured using the highest quality materials and the latest in screen manufacturing technology. This ensures that our screens are able to withstand the most demanding drilling conditions, while also delivering consistent and reliable performance.The Replacement Shaker Screen for Brandt King Cobra/Hybrid is engineered to provide increased throughput, longer screen life, and improved conductance, resulting in more effective solid removal and drier discharge solids. This ultimately leads to reduced operating costs and improved efficiency in the drilling process.Our company understands the importance of reliability and efficiency in drilling operations, which is why we have invested heavily in research and development to create the most advanced shaker screens on the market. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to providing our customers with the best possible solutions for their solids control needs.In addition to the exceptional performance of our shaker screens, our company also prides itself on providing unparalleled customer service and support. We work closely with our customers to understand their specific requirements and to ensure that our products meet and exceed their expectations. Our team of experienced professionals is dedicated to providing technical support, troubleshooting, and on-site assistance to help our customers get the most out of our products.Furthermore, our company is dedicated to environmental sustainability, and our Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed with this in mind. By improving the efficiency of solids control and reducing waste, our screens contribute to a more environmentally friendly drilling process.With a strong focus on quality, performance, and customer satisfaction, our company is proud to offer the Replacement Shaker Screen for Brandt King Cobra/Hybrid as the latest addition to our range of industry-leading solids control solutions. We are confident that this new product will set a new standard for shaker screen performance and reliability in the oil and gas industry.As we continue to innovate and develop new technologies, our goal is to remain at the forefront of the industry and to provide our customers with the most advanced and effective solutions for their solids control needs. We are dedicated to driving progress and excellence in the oil and gas sector, and the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to delivering superior products and service.In conclusion, the Replacement Shaker Screen for Brandt King Cobra/Hybrid represents a significant advancement in shaker screen technology, and our company is proud to bring this innovative solution to the market. With its exceptional performance, durability, and environmental benefits, this new product is set to improve the efficiency and reliability of solids control in drilling operations. We are excited to offer this revolutionary shaker screen to our customers and to continue leading the way in providing cutting-edge solutions for the oil and gas industry.

Top 5 Must-Have Tools for Efficient Oilfield Operations

Title: Oilfield Equipment Supplier Embraces Innovation and Continues to Thrive in the MarketIntroduction:Oilfield Equipment, an industry-leading supplier of high-quality oilfield equipment and services, has been a driving force in the oil and gas sector for over a decade. With a strong commitment to innovation, cutting-edge technology, and exceptional customer service, Oilfield Equipment has successfully carved a niche for itself in the competitive market. This article explores the key factors contributing to the company's success and highlights its dedication to providing top-of-the-line equipment and solutions to the oil and gas industry.Growing Amidst Technological Advancements:As the oil and gas sector continues to evolve and adapt to the growing demands of the global market, Oilfield Equipment has remained at the forefront of technological advancements. The company consistently invests in research and development to offer state-of-the-art equipment that not only enhances efficiency but also ensures greater safety measures for the workforce in the field.By collaborating with leading technology providers, Oilfield Equipment has successfully integrated automation and data analytics into its product offerings, enabling clients to optimize their operational performance. Through the use of advanced sensors, real-time data monitoring, and artificial intelligence-driven systems, the company's equipment enables oilfield operators to make informed, data-driven decisions, resulting in improved productivity and reduced downtime.Commitment to Quality and Reliability:Oilfield Equipment's unwavering commitment to delivering high-quality and reliable products has cemented its position as a trusted supplier in the industry. The company adheres to strict manufacturing standards, leveraging its extensive expertise to design and engineer equipment that meets the specific requirements of oilfield operations.Stringent quality control measures are implemented throughout the production process, ensuring that every piece of equipment that bears the Oilfield Equipment name is built to withstand the demanding conditions of the oilfield environment. This dedication to quality has earned the company a loyal customer base who rely on their products to enhance their operational efficiency and profitability.Customer-Centric Approach:Recognizing the importance of building strong and lasting partnerships with clients, Oilfield Equipment maintains a customer-centric approach in all aspects of its business. The company works closely with its customers to understand their unique needs and challenges, providing tailored solutions that address their specific requirements.Oilfield Equipment's team of highly skilled professionals offers comprehensive support from initial consultation to delivery and beyond. Their technical expertise and prompt customer service ensure that clients receive all the assistance they need, be it equipment selection, installation, maintenance, or troubleshooting.Sustainable Solutions and Environmental Responsibility:In line with the growing global focus on sustainability, Oilfield Equipment has integrated environmentally responsible practices into its operations. The company is committed to minimizing its ecological footprint by developing energy-efficient equipment and exploring alternative energy solutions.Furthermore, the company ensures adherence to all relevant environmental regulations and continues to invest in innovative technologies that reduce emissions and optimize resource utilization. By prioritizing sustainability, Oilfield Equipment not only contributes to the long-term viability of the oil and gas industry but also demonstrates its commitment to preserving the planet for future generations.Future Prospects and Outlook:Looking ahead, Oilfield Equipment is poised to leverage its extensive industry experience and robust technological capabilities to capture new opportunities in emerging markets. The company's solid reputation, commitment to innovation, and customer-centric approach position it favorably within the industry, ensuring continued growth and success.In conclusion, Oilfield Equipment stands as a leading supplier of high-quality oilfield equipment and services, driven by innovation, reliability, customer focus, and sustainability. Through its constant pursuit of excellence, the company has established a strong foothold within the oil and gas sector, and its future prospects remain promising in an ever-evolving industry.

Ultimate Guide to Shale Shaker Screen – Exploring Flc2000 Technology

Title: Cutting-Edge Shale Shaker Screen Revolutionizes Oil and Gas IndustryIntroduction:In today's rapidly evolving oil and gas industry, advancements in technology play a crucial role in optimizing drilling processes and ensuring the efficient extraction of valuable resources. One such breakthrough innovation is the Flc2000 Shale Shaker Screen, a cutting-edge solution that has revolutionized shale shaker performance. Developed by a leading industry player (company name), this state-of-the-art screen offers unparalleled efficiency and reliability, transforming drilling operations globally.Paragraph 1:The Flc2000 Shale Shaker Screen, designed and manufactured by (company name), has garnered significant attention due to its exceptional performance and cost-saving features. This innovative solution boasts advanced features such as enhanced solids separation, superior screen life, and increased operating efficiency. The Flc2000 screen's design incorporates meticulous engineering coupled with high-quality materials to ensure reliability and longevity.Paragraph 2:Compared to conventional shale shaker screens, the Flc2000 screen offers greatly improved solids separation capabilities. With its unique design, this screen effectively separates drilling cuttings from the drilling fluid, resulting in cleaner and drier solids. This not only maximizes drilling efficiency but also reduces the environmental impact of drilling operations by minimizing waste generation.Paragraph 3:Another key advantage of the Flc2000 Shale Shaker Screen is its extended screen life. Traditional screens often suffer from premature failure or excessive wear due to the harsh drilling conditions encountered in the industry. However, the implementation of advanced manufacturing techniques and durable materials ensures that the Flc2000 screen maintains optimal performance for extended periods, significantly reducing downtime and replacement costs.Paragraph 4:Efficiency is a top priority in the oil and gas industry, and the Flc2000 Shale Shaker Screen has raised the bar in this regard. Incorporating cutting-edge technology, the screen enhances the overall operational efficiency of shale shakers. Its unique design minimizes the number of required screen changes, meaning less downtime during drilling operations. This increased uptime translates into substantial cost savings and improved productivity for drilling companies.Paragraph 5:The Flc2000 Shale Shaker Screen has been widely adopted by industry leaders worldwide, rendering positive results in diverse drilling environments. Its adaptability spans across various drilling applications, including oil and gas exploration, geothermal drilling, and directional drilling. The screen's compatibility with different shale shaker models further adds to its versatility, making it a versatile choice for drilling operations of all scales.Paragraph 6:Furthermore, the Flc2000 Shale Shaker Screen offers a user-friendly experience. Its installation and maintenance procedures are straightforward and can be implemented easily by field personnel. The screen's robust construction ensures resistance to common issues such as blinding and plugging, enabling continuous operation even in challenging conditions.Conclusion:In conclusion, the Flc2000 Shale Shaker Screen stands as a game-changing solution in the oil and gas industry. By combining advanced technology, superior design, and exceptional performance, this screen has transformed drilling operations worldwide. The Flc2000's ability to enhance solids separation, extend screen life, and optimize operational efficiency has made it an invaluable asset for drilling companies seeking to maximize their productivity, reduce costs, and minimize environmental impact. The Flc2000 Shale Shaker Screen continues to set new standards for excellence, ultimately propelling the oil and gas industry toward a more efficient and sustainable future.

High Quality Composite Shaker Screen: The Ultimate Solution for Efficient Filtration

The GNZS-703 Composite Shaker Screen has recently made waves in the oil and gas industry, as it offers enhanced performance and durability compared to traditional shaker screens. Developed by a leading manufacturer of solids control equipment, the GNZS-703 Composite Shaker Screen is becoming increasingly popular among drilling contractors and operators for its efficiency in separating solids from drilling fluid.The company behind the innovative shaker screen has been a key player in the solids control equipment market for over a decade. With a strong focus on research and development, the company has continuously introduced cutting-edge technologies and products to meet the ever-evolving needs of the industry. Their commitment to quality and customer satisfaction has earned them a solid reputation as a reliable and innovative supplier in the oil and gas sector.The GNZS-703 Composite Shaker Screen is a testament to the company's dedication to advancement in solids control equipment. Made with high-quality composite materials, the shaker screen offers superior resistance to abrasion and corrosion, resulting in longer service life and reduced maintenance costs. Its unique design also provides a larger effective screening area, leading to improved efficiency in solids control and fluid handling.One of the key advantages of the GNZS-703 Composite Shaker Screen is its versatility. It is compatible with a wide range of shaker models, making it an ideal choice for drilling operations across different locations and environments. Furthermore, the screen's fine mesh layers are designed to effectively remove solid particles from drilling fluid, ensuring the quality and performance of the fluid throughout the drilling process.In addition to its technical superiority, the GNZS-703 Composite Shaker Screen is also designed with practicality in mind. Its lightweight construction and easy installation make it convenient for onsite handling and replacement, reducing downtime and labor costs. This has made it a favored choice among drilling contractors looking to optimize their operations and minimize operational disruptions.The company's commitment to environmental responsibility is also reflected in the GNZS-703 Composite Shaker Screen. By effectively removing solid particles from drilling fluid, the shaker screen contributes to the reduction of waste and the efficient management of drilling waste, aligning with the industry's push towards sustainable and environmentally conscious practices.With the increasing demand for efficient solids control equipment in the oil and gas industry, the GNZS-703 Composite Shaker Screen has quickly gained traction in the market. Its proven performance and reliability have earned it the trust of drilling contractors and operators, leading to its widespread adoption in various drilling operations.As the oil and gas industry continues to evolve, the company behind the GNZS-703 Composite Shaker Screen remains committed to innovation and excellence. With a strong focus on research and development, they are constantly pushing the boundaries of solids control technology to deliver solutions that address the evolving needs of the industry. The success of the GNZS-703 Composite Shaker Screen is a testament to their ongoing dedication to providing high-quality and efficient equipment for the oil and gas sector.

Discover the Benefits of Secondary Screens for the VSM 300

VSM 300 Secondary Screen Enhances Efficiency in Oil and Gas Drilling OperationsOil and gas drilling operations require high-performance equipment to ensure maximum efficiency and productivity. The VSM 300 Secondary Screen, developed by a leading global provider of oilfield equipment, has been gaining recognition for its exceptional performance in the industry.The VSM 300 Secondary Screen is designed to be used in combination with a primary shale shaker in drilling operations. Its advanced technology and innovative design make it an essential component for separating solids from drilling fluid, also known as mud, in order to maintain the desired properties of the mud and to prevent environmental contamination.One of the key features of the VSM 300 Secondary Screen is its superior screening capacity, which allows for the efficient removal of fine solids and impurities from the drilling fluid. This capability significantly reduces the risk of equipment damage and improves overall drilling efficiency.In addition, the VSM 300 Secondary Screen is constructed with durable and reliable materials, ensuring its longevity and minimal maintenance requirements. This reliability is essential for drilling operations, as any downtime can result in considerable financial losses.Furthermore, the VSM 300 Secondary Screen is designed to be easy to install and operate, minimizing the need for specialized training and expertise. This user-friendly approach is highly valued in the industry, where operational simplicity is crucial for maintaining a smooth and efficient workflow.The VSM 300 Secondary Screen has also been engineered to be compatible with a wide range of drilling fluids, making it a versatile solution for various drilling operations. Its adaptability and flexibility have contributed to its widespread adoption across the oil and gas industry.Moreover, the company behind the VSM 300 Secondary Screen has a strong track record of providing high-quality equipment and solutions for the oil and gas sector. With a commitment to innovation and customer satisfaction, the company has earned a reputation as a trusted and reliable partner for drilling operators worldwide.In addition to the VSM 300 Secondary Screen, the company offers a comprehensive range of products and services to support drilling operations, including primary shale shakers, mud cleaners, centrifuges, and other essential equipment. This integrated approach allows drilling operators to source all their requirements from a single, reputable supplier, streamlining their procurement process and ensuring seamless compatibility between various components.Furthermore, the company has a global presence, with a network of service centers and support facilities strategically located in key regions. This extensive coverage enables the company to provide timely assistance and technical support to its customers, ensuring the uninterrupted operation of their equipment and the continuity of their drilling activities.The company also places a strong emphasis on research and development, continuously striving to enhance the performance and efficiency of its products. This commitment to innovation ensures that its offerings remain at the forefront of technological advancements in the oil and gas industry, meeting the evolving needs and challenges of drilling operations.In conclusion, the VSM 300 Secondary Screen, developed by a reputed provider of oilfield equipment, stands out as a high-performance and reliable solution for enhancing efficiency in oil and gas drilling operations. With its advanced technology, durability, ease of use, and compatibility with various drilling fluids, the VSM 300 Secondary Screen has earned its place as a trusted and valuable asset for the industry.As drilling activities continue to expand and evolve, the VSM 300 Secondary Screen and the company behind it are well-positioned to support the sector's ongoing success, contributing to the achievement of operational excellence and environmental stewardship.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Latest Developments in Shale Shaker Screen Technology Discussed in Recent News

Title: DFE PWP Shale Shaker Screen Revolutionizes Drilling OperationsIntroduction:DFE PWP Shale Shaker Screen, manufactured by an industry-leading company (name removed), is making significant strides in the oil and gas industry. With its cutting-edge technology and superior performance, this revolutionary shale shaker screen is transforming drilling operations across the globe. By combining innovative design with enhanced durability, it promises to improve the efficiency and productivity of oil and gas exploration activities. In this news article, we will delve into the key features of the DFE PWP Shale Shaker Screen and explore its impact on the industry.1. High-Quality Design and Functionality:The DFE PWP Shale Shaker Screen boasts an exceptional design that sets it apart from traditional screens. Crafted with precision using top-grade materials, this screen offers unparalleled filtration efficiency and durability. The advanced technology integrated into its construction promotes optimal solids removal, ensuring efficient mud separation during the drilling process. By facilitating effective drilling fluid management, the DFE PWP Shale Shaker Screen significantly minimizes waste and decreases operational costs.2. Extended Service Life:One of the standout features of the DFE PWP Shale Shaker Screen is its extended service life. The screen is equipped with wear-resistant composite materials that can withstand rigorous drilling conditions and abrasive substances. This enhanced durability translates into lower replacement costs and reduced downtime for maintenance, benefiting drilling companies of all sizes. The prolonged service life of the DFE PWP Shale Shaker Screen ultimately leads to improved operational efficiency and higher profitability.3. Increased Operational Efficiency:The DFE PWP Shale Shaker Screen's innovative design contributes to enhanced efficiency in drilling operations. It promotes faster and more efficient mud filtration, preventing blockage and ensuring continuous drilling progress. The screen's increased open area and precise particle separation minimize the loss of valuable drilling fluid, optimizing the overall drilling process. With this screen, operators can achieve higher penetration rates, reduced non-productive time, and improved wellbore stability, ultimately leading to significant cost savings.4. Compatibility and Versatility:The DFE PWP Shale Shaker Screen offers compatibility with various shale shaker models, ensuring versatility and ease of integration within existing drilling rigs. This versatility makes it a versatile and practical solution for drilling companies operating globally. The screen's easy installation and compatibility reduce downtime during screen replacement and enhance overall operational efficiency.5. Sustainable and Environmentally Friendly:Recognizing the importance of sustainable practices in the oil and gas industry, the DFE PWP Shale Shaker Screen is designed with environmental considerations in mind. By improving the efficiency of solids control and mud management, this screen reduces waste generation and helps minimize the environmental impact of drilling activities. The use of top-grade materials in its construction ensures its long-lasting durability, further contributing to sustainable drilling operations.Conclusion:The DFE PWP Shale Shaker Screen has emerged as a game-changer in the oil and gas industry, offering a range of benefits that significantly enhance drilling operations. Its advanced filtration technology, extended service life, increased efficiency, compatibility, and sustainable qualities make it an ideal choice for drilling companies looking to optimize productivity and reduce costs. As the oil and gas industry continues to evolve, the DFE PWP Shale Shaker Screen plays a crucial role in driving progress and setting new standards for excellence in drilling operations.