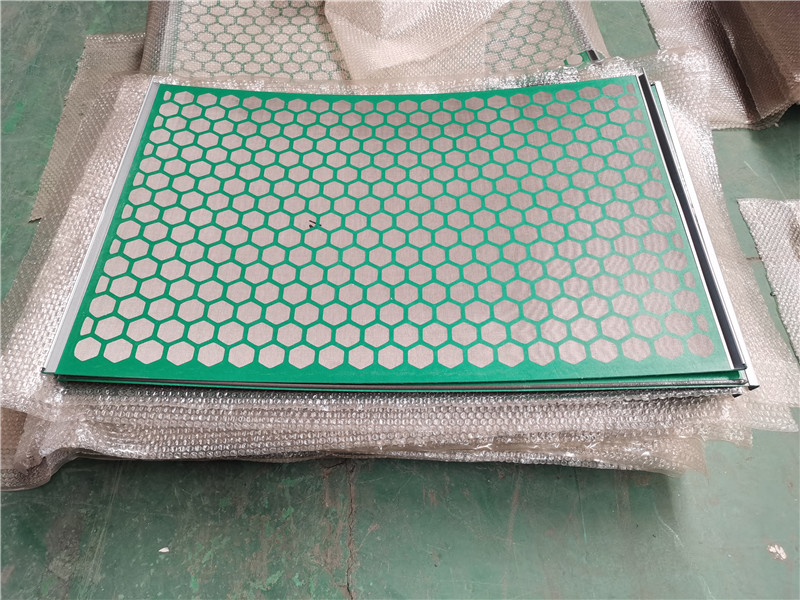

Durable and Effective 1050x695 Shaker Screen for Efficient Solid Control

By:Admin

{Company Name} was founded with a vision to revolutionize the oil and gas industry by providing innovative and reliable solutions for drilling operations. Their team of experienced engineers and professionals work tirelessly to develop cutting-edge technologies that meet the evolving needs of the industry. The company takes pride in its state-of-the-art manufacturing facilities, where quality control measures are enforced at every stage of production to ensure that their products meet the highest standards of performance and durability.

The 1050x695 shaker screen offered by {Company Name} is a testament to their commitment to excellence. These screens are meticulously designed and constructed to deliver superior performance in demanding drilling environments. The precise mesh size and quality materials used in the manufacture of these screens ensure efficient filtration of solids while maintaining the integrity of the drilling fluid. As a result, drilling operations can proceed without interruptions, leading to increased productivity and cost savings for their clients.

In addition to their dedication to quality, {Company Name} also places a strong emphasis on sustainability and environmental responsibility. The materials used in their shaker screens are carefully selected to minimize environmental impact, and the company constantly explores innovative ways to reduce waste and energy consumption in their manufacturing processes. By choosing {Company Name} as their supplier, clients can be assured that they are supporting a company that values sustainability and ethical business practices.

Furthermore, {Company Name} prides itself on providing excellent customer service and technical support. Their team of experts is readily available to offer guidance and assistance to clients, ensuring that they are able to maximize the performance of the shaker screens. Whether it's providing recommendations for specific drilling conditions or offering prompt maintenance and repair services, {Company Name} is dedicated to going above and beyond to meet the needs of their clients.

{Company Name} has built a strong reputation for reliability and innovation in the oil and gas industry, and their 1050x695 shaker screen is a prime example of their commitment to delivering exceptional products. As the demand for efficient and sustainable drilling solutions continues to grow, {Company Name} stands ready to meet the challenges of the industry and continue providing cutting-edge technologies that drive success for their clients.

In conclusion, {Company Name} is a leading provider of high-quality shaker screens for the oil and gas industry, offering innovative solutions that enhance drilling operations. Their 1050x695 shaker screen exemplifies their dedication to excellence, sustainability, and customer satisfaction. With a focus on quality, innovation, and environmental responsibility, {Company Name} is well positioned to remain a key player in the industry for years to come.

Company News & Blog

High-Quality KPT 28 Shaker Screen for China Oil and Gas Industry

China Kemtron KPT 28 Shaker Screen has officially launched its latest product, the KPT 28 Shaker Screen. The KPT 28 is designed to maximize solids control efficiency while minimizing the costs associated with drilling operations. This latest addition to the company's product line demonstrates their commitment to providing industry-leading solutions for the oil and gas drilling industry.The KPT 28 Shaker Screen is engineered for superior performance and durability. It is constructed with high-quality materials that are able to withstand the harsh conditions of drilling operations. With its advanced design, the KPT 28 is capable of efficiently separating solids from drilling fluid, leading to increased efficiency and cost savings.The company behind the KPT 28 Shaker Screen, China Kemtron, is a leading manufacturer and supplier of solids control equipment for the oil and gas industry. With over 20 years of experience in the industry, China Kemtron has established a reputation for delivering innovative and reliable products to their customers. Their dedication to research and development has allowed them to stay ahead of industry trends and deliver cutting-edge solutions to their clients.In addition to the quality and performance of their products, China Kemtron is also known for their exceptional customer service and support. They work closely with their clients to understand their specific needs and provide tailored solutions to meet those requirements. This customer-centric approach has earned them the trust and loyalty of many drilling companies around the world.The launch of the KPT 28 Shaker Screen further solidifies China Kemtron's position as a leader in the solids control industry. This new product is expected to set new benchmarks for performance and reliability in the field of solids control equipment. With the KPT 28, drilling companies can expect improved efficiency, reduced downtime, and ultimately, cost savings."We are thrilled to introduce the KPT 28 Shaker Screen to the market," said a spokesperson for China Kemtron. "This product represents the culmination of extensive research and development, and we are confident that it will deliver exceptional value to our customers. We are committed to providing the best solutions for the industry, and the KPT 28 is a testament to that commitment."The KPT 28 Shaker Screen is available in various sizes to fit different models of shale shakers, making it versatile and compatible with a wide range of drilling operations. It is designed to be easy to install and maintain, further adding to its appeal for drilling companies.As the oil and gas industry continues to evolve, the demand for high-performance solids control equipment is on the rise. Companies are constantly seeking ways to improve efficiency and reduce costs, and the KPT 28 Shaker Screen is designed to help them achieve these goals.With its advanced design, superior performance, and exceptional durability, the KPT 28 Shaker Screen is set to become a go-to choice for drilling companies around the world. China Kemtron's commitment to excellence and innovation has once again come to the forefront with the launch of this impressive new product.

Highly Efficient Multi-sizer Primary Screen for Versatile Screening Needs

VSM Multi-sizer Primary screen is a revolutionary new product that is set to change the way primary screening is conducted in the mining and aggregates industries. This innovative technology has been developed by a leading global provider of equipment and services for the mining and construction industries. With a strong commitment to innovation and sustainability, the company has a track record of developing cutting-edge solutions that improve the efficiency and productivity of its customers' operations.The VSM Multi-sizer Primary screen is designed to address the challenges of primary screening in the mining and aggregates industries. It offers a unique combination of high capacity, efficiency, and accuracy, making it an ideal solution for a wide range of applications. The screen is capable of handling large volumes of material, while also providing superior separation and classification capabilities. This allows operators to achieve higher throughput and better quality end products, ultimately leading to improved operational efficiency and profitability.One of the key features of the VSM Multi-sizer Primary screen is its modular design, which enables easy customization to suit the specific requirements of each application. This flexibility ensures that the screen can be tailored to meet the diverse needs of different operations, from small-scale quarries to large mining operations. Furthermore, the screen is equipped with advanced technologies that optimize the screening process, such as adjustable stroke and speed settings, as well as cushioned mounting for reduced vibration and noise levels.In addition to its technical capabilities, the VSM Multi-sizer Primary screen is also designed with sustainability in mind. It incorporates features that minimize environmental impact, such as low power consumption and reduced maintenance requirements. This aligns with the company's commitment to providing solutions that not only improve operational efficiency, but also contribute to a more sustainable future for the industry.The development of the VSM Multi-sizer Primary screen underscores the company's dedication to continuous innovation and customer-centric approach. By leveraging its expertise in screening technology and understanding of customer needs, the company has been able to deliver a product that sets new standards for primary screening in the mining and aggregates industries. This reflects the company's broader mission to drive progress through sustainable and efficient solutions that empower its customers to succeed in their respective fields.The VSM Multi-sizer Primary screen is already generating significant interest from the industry, with several installations planned in the coming months. Customers are eager to harness the benefits of this advanced screening technology, which promises to enhance their operations and deliver tangible results. With its proven track record of delivering high-quality solutions and its commitment to excellence, the company is well-positioned to meet the growing demand for the VSM Multi-sizer Primary screen and continue driving innovation in the mining and aggregates industries.Overall, the introduction of the VSM Multi-sizer Primary screen represents a significant milestone for the company and the industry as a whole. With its unrivaled combination of capacity, efficiency, and sustainability, this innovative technology is poised to reshape the landscape of primary screening and deliver lasting value to customers around the world. As the company continues to push the boundaries of what is possible, the VSM Multi-sizer Primary screen stands as a testament to its ongoing commitment to driving progress and empowering its customers for success.

Latest Innovation in Shaker Screen Technology: Derrick's HYP PMD Shaker Screen

Derrick Corporation, a global leader in the production of high-performance separation and filtration equipment, has recently introduced its latest innovation in solids control technology - the HYP PMD Shaker Screen. This new product is set to revolutionize the industry with its advanced features and superior performance.The HYP PMD Shaker Screen is designed to provide enhanced efficiency and durability, making it a standout choice for operators looking to optimize their solids control operations. The screen is built with a unique composite frame that offers increased structural integrity and longevity, while also reducing weight and overall cost. This innovative design ensures that the screen can withstand the demanding conditions of drilling operations, resulting in reduced downtime and maintenance costs.In addition to its robust construction, the HYP PMD Shaker Screen also features an advanced pretension screen design that maximizes the usable screen area, leading to improved solids removal and higher fluid processing capacity. This design allows for increased productivity and efficiency, ultimately leading to cost savings and improved overall operational performance.One of the key advantages of the HYP PMD Shaker Screen is its ability to deliver exceptional cuttings dryness, thanks to the proprietary screen cloth technology employed by Derrick Corporation. This technology ensures that the screen can effectively separate and remove solids from drilling fluids, resulting in drier cuttings and reduced waste disposal costs. Additionally, the high-quality screen cloth is engineered to withstand the abrasive nature of drilling fluids, ensuring prolonged screen life and consistent performance.Derrick Corporation is proud to offer the HYP PMD Shaker Screen as part of its comprehensive range of solids control solutions, which also includes shale shakers, desanders, desilters, and other related equipment. With decades of experience in the industry, Derrick Corporation has established itself as a trusted partner for operators seeking to improve their solids control and waste management processes.“At Derrick Corporation, we are dedicated to pushing the boundaries of innovation to deliver cutting-edge solutions that address the evolving needs of the industry,” said a spokesperson for the company. “The introduction of the HYP PMD Shaker Screen is a testament to our commitment to providing our customers with reliable, high-performance equipment that helps them achieve their operational goals.”The HYP PMD Shaker Screen is now available for purchase and is supported by Derrick Corporation's global network of service centers, ensuring that customers can access prompt technical support and aftermarket services wherever their operations may be located. The company is also offering comprehensive training and education programs to help customers optimize the performance of the HYP PMD Shaker Screen and other Derrick equipment.As the industry continues to demand more efficient and effective solids control solutions, the HYP PMD Shaker Screen is poised to make a significant impact by providing operators with a reliable, high-performance tool for their operations. With its advanced features, durable construction, and superior performance, this innovative product is set to raise the bar for solids control technology and lead the way to a more efficient and sustainable future for the industry.

Nov FL2000 Shaker Screens Get High-Powered Upgrades with Cobra Mesh Replacement

report on the benefits and features of the FL2000 Nov Cobra Mesh Replacement Shaker Screens.The oil and gas industry is continually evolving and advancing, with new technology and equipment improving the efficiency and safety of drilling operations. The drilling process is a complex but critical step in oil and gas extraction, requiring specialized and reliable equipment to ensure optimal results. One crucial component of this equipment is the shaker screen, which is used to separate drilling cuttings from the drilling fluids. The FL2000 Nov Cobra Mesh Replacement Shaker Screens offer numerous benefits and features that make them a valuable addition to any drilling operation.These shaker screens are designed to be a direct replacement for the original equipment manufacturer (OEM) screens, specifically the different model cobra shale shaker screens. They are compatible with both the NOV Brandt Cobra and King Cobra shale shakers. Made with high-quality materials and advanced technology, these screens deliver superior performance and durability.One of the key features of the FL2000 Nov Cobra Mesh Replacement Shaker Screens is their use of multi-layered stainless steel wire mesh screens, which are stacked and tightly bonded to increase their strength and resistance to wear and tear. The wire mesh design also provides excellent filtration, removing unwanted solids and debris while allowing drilling fluids to flow through easily. Another significant advantage of these shaker screens is their ability to save drilling companies time and money. With their durable construction and high-quality materials, the FL2000 Nov Cobra Mesh Replacement Shaker Screens can last up to two to three times longer than traditional screens. This longer lifespan means less downtime and replacement costs, allowing drilling operations to run more smoothly and efficiently. Additionally, the innovative design of these shaker screens makes them easy to install and remove, improving overall safety and minimizing the risk of accidents and injuries on the job site. Their lightweight construction and modular design also allow for quick and hassle-free replacement or repair when necessary, minimizing downtime and associated costs. The FL2000 Nov Cobra Mesh Replacement Shaker Screens are also designed with the environment in mind, as they reduce waste and minimize the impact of drilling operations on the natural world. Using these screens helps to reduce the amount of drilling fluids that are lost during the separation process, which is not only more efficient but also helps to minimize the amount of waste and pollution generated by drilling operations. Overall, the FL2000 Nov Cobra Mesh Replacement Shaker Screens are an excellent choice for any drilling operation that values durability, reliability, and efficiency. With their advanced design and high-quality materials, they provide superior performance and longevity, making them a cost-effective and practical investment for any drilling company. In conclusion, the oil and gas industry requires reliable equipment to perform efficient drilling operations. The FL2000 Nov Cobra Mesh Replacement Shaker Screens offer several benefits and features that make them an essential component of any drilling operation. These screens are durable, environmentally friendly, and easy to install and remove, making them a practical solution for any drilling rig. With the use of these screens, drilling companies can improve their efficiency and reduce costs while minimizing their environmental impact.

High-Quality and Durable Shaker Screen for Improved Performance

VSM300 Shaker Screen has gained significant recognition in the oil and gas industry due to its high efficiency and reliability in the field of solid control equipment. The company, known for its innovative approach and cutting-edge technology, has been at the forefront of providing top-quality products and services to its global clientele.The VSM300 Shaker Screen is a vital component in the drilling process, as it is designed to effectively remove solid particles from drilling fluid. This ensures that the drilling mud remains in optimal condition, which in turn leads to improved drilling efficiency and reduced operational costs. The VSM300 Shaker Screen is highly durable and is capable of withstanding the rigorous demands of the oil and gas sector, making it the preferred choice for many leading companies in the industry.The company behind the VSM300 Shaker Screen has a rich history of delivering high-performance solutions to the oil and gas sector. With a team of skilled engineers and industry experts, the company has continuously strived to enhance its product offerings and provide unmatched customer service. The company's commitment to quality and excellence has earned them a strong reputation in the market, with many clients relying on their products to meet their operational needs.In addition to the VSM300 Shaker Screen, the company offers a comprehensive range of solid control equipment, including shale shakers, mud cleaners, centrifuges, and degassers. Each product is designed and manufactured with precision, ensuring that it meets the highest standards of quality and performance. With a focus on innovation and continuous improvement, the company has been able to stay ahead of the competition and remain a trusted partner for many in the oil and gas industry.The VSM300 Shaker Screen, in particular, has been widely acclaimed for its exceptional performance and durability. Its unique design and advanced technology allow for efficient and effective solid control, enabling drilling operations to run smoothly and efficiently. The screen is capable of handling high volumes of drilling fluid while effectively separating solid particles, making it an indispensable tool for any drilling operation.Moreover, the company's commitment to sustainability and environmental responsibility is evident in the design and manufacturing of the VSM300 Shaker Screen. By ensuring that drilling fluid is properly treated and recycled, the screen plays a crucial role in minimizing the environmental impact of drilling operations. This commitment to sustainability aligns with the industry's increasing focus on environmental stewardship and responsible practices.As the global demand for oil and gas continues to rise, the need for efficient and reliable solid control equipment has never been greater. The VSM300 Shaker Screen, with its proven track record and industry-leading performance, is well-positioned to meet this demand and play a crucial role in the success of drilling operations around the world.In conclusion, the VSM300 Shaker Screen has established itself as a top-tier product in the oil and gas industry, thanks to its unmatched performance, durability, and environmental sustainability. As the company behind this groundbreaking technology continues to push the boundaries of innovation, it is poised to remain a leading force in the solid control equipment sector for years to come. With a strong commitment to excellence and customer satisfaction, the company is well-equipped to meet the evolving needs of the oil and gas industry and continue to set new standards for quality and performance.

High-quality Shaker Screen for Kemtron 48 - A Comprehensive Review

Kemtron 48 Shaker Screen: The Ultimate Solution for Solid Control in the Oil and Gas IndustryIn the fast-paced world of oil and gas exploration, every second counts. From drilling to extraction, each step of the process requires precision and efficiency. A key aspect of this process is the management of solid control, which is essential for ensuring the smooth functioning of drilling operations. This is where the Kemtron 48 Shaker Screen comes in. The Kemtron 48 Shaker Screen is a revolutionary product that has been designed to effectively manage solid control in the oil and gas industry. It is a vital component of the Kemtron 48 Shale Shaker, which is known for its high-performance and reliability. The shaker screen is made of high-quality stainless steel wire mesh and is designed to effectively separate solid particles from drilling fluid. This not only ensures the smooth functioning of drilling operations but also protects downstream equipment and reduces waste disposal costs.One of the key features of the Kemtron 48 Shaker Screen is its superior durability. Made of high-quality materials, it is designed to withstand the harsh conditions of the oil and gas industry. It is also easy to install and maintain, making it a cost-effective solution for solid control. In addition, the screen has a large screening area, which allows for high capacity and efficiency. This means that operators can achieve optimal performance and productivity with the Kemtron 48 Shaker Screen.The Kemtron 48 Shaker Screen is also designed with versatility in mind. It can be used with a wide range of drilling fluids and is compatible with various types of shakers. This means that it can be seamlessly integrated into existing operations, minimizing downtime and disruption. This is crucial in the oil and gas industry, where every minute of downtime can result in significant financial losses.In addition to its technical capabilities, the Kemtron 48 Shaker Screen is also backed by exceptional customer support. The company behind the product is known for its commitment to customer satisfaction and has a team of experts who are dedicated to providing support and assistance to clients. This means that operators can rely on the company not only for top-of-the-line products but also for reliable service and support.The Kemtron 48 Shaker Screen has already made a significant impact in the oil and gas industry. Its innovative design and superior performance have helped operators around the world achieve greater efficiency and productivity in their drilling operations. From onshore to offshore projects, the Kemtron 48 Shaker Screen has proven to be an indispensable tool for solid control.Looking to the future, the company is committed to further enhancing the capabilities of the Kemtron 48 Shaker Screen. With ongoing research and development, the company aims to continually improve the product and adapt to the evolving needs of the industry. This includes exploring new materials, technologies, and designs to ensure that the Kemtron 48 Shaker Screen remains at the forefront of solid control solutions.In conclusion, the Kemtron 48 Shaker Screen is a game-changer for the oil and gas industry. Its advanced design, superior durability, and exceptional performance make it the ultimate solution for solid control. Backed by a commitment to customer satisfaction and continuous innovation, the company behind the product has established itself as a leader in the industry. As the demand for efficient solid control solutions continues to grow, the Kemtron 48 Shaker Screen is poised to play a crucial role in shaping the future of the oil and gas industry.

High-Quality Oil Shake Screen for Effective Solid Control

Swaco Oil Shake Screen is a revolutionary product that has been developed by a leading oilfield equipment company. This innovative shake screen has been designed to address the challenges faced by the oil and gas industry in the process of separating solids and fluids during the drilling process. The shake screen is a critical component of the shale shakers used in drilling operations, and the Swaco Oil Shake Screen has set a new standard in terms of efficiency and performance.The Swaco Oil Shake Screen utilizes advanced technology and high-quality materials to deliver exceptional results in separating solids from drilling fluids. It has been engineered to withstand the harsh conditions of drilling operations and to provide reliable and consistent performance. The shake screen is designed to effectively remove large solids and debris from the drilling fluids, allowing for the efficient and smooth operation of the shale shakers.One of the key features of the Swaco Oil Shake Screen is its high-capacity design, which enables it to handle large volumes of drilling fluids while effectively separating solids. This high-capacity capability is crucial in ensuring the smooth and uninterrupted flow of drilling operations, as it helps prevent blockages and downtime. Additionally, the shake screen is designed to be easily replaceable, which contributes to both time and cost savings for drilling operators.The Swaco Oil Shake Screen is also known for its durability and longevity, thanks to its robust construction and high-quality materials. This ensures that the shake screen can withstand the rigorous demands of drilling operations and continue to deliver reliable performance over an extended period of time. Its exceptional durability makes it a cost-effective solution for oil and gas companies, as it reduces the frequency of replacements and maintenance.Furthermore, the Swaco Oil Shake Screen has been designed with a focus on environmental sustainability. The shake screen is engineered to minimize waste and reduce the environmental impact of drilling operations by efficiently separating solids from the drilling fluids. This aligns with the industry's increasing focus on sustainability and environmental responsibility.The company behind the development of the Swaco Oil Shake Screen is a respected leader in the oilfield equipment industry. With a track record of delivering high-quality and reliable products, the company has established a strong reputation for excellence and innovation. The development of the Swaco Oil Shake Screen is a testament to the company's commitment to addressing the evolving needs of the oil and gas industry with cutting-edge solutions.The company's dedication to research and development has been instrumental in the creation of the Swaco Oil Shake Screen, which represents a significant advancement in the field of shale shaker technology. The shake screen has undergone rigorous testing and validation to ensure its performance, reliability, and durability, and it has exceeded industry standards in all these aspects.In conclusion, the Swaco Oil Shake Screen is a game-changing product that has redefined the capabilities of shale shaker technology in the oil and gas industry. Its advanced design, high capacity, durability, and environmental sustainability make it a standout solution for separating solids from drilling fluids. Combined with the strong reputation and innovative spirit of the company behind its development, the Swaco Oil Shake Screen is poised to make a significant impact on the efficiency and reliability of drilling operations.

PWP Screens: Unveiling the Impressive Derrick 2000 Series Design

Derrick 2000 Series PWP Screens Revolutionize the Oil and Gas IndustryWith the constant advancements in technology, the oil and gas industry is constantly evolving. One of the latest breakthroughs in the industry is the introduction of the Derrick 2000 Series PWP Screens. These innovative screens have revolutionized the way oil and gas is extracted and processed, leading to increased efficiency and productivity in the field.The Derrick 2000 Series PWP Screens, developed by a leading global provider of solids control and fine screening equipment, are known for their exceptional performance and durability. These screens are used in various applications, including shale shakers, desanders, desilters, and mud cleaners. They have been designed to withstand the demanding conditions of the oil and gas industry, ensuring optimum performance and reliability in any drilling operation.One of the key features of the Derrick 2000 Series PWP Screens is their superior cut point integrity. The screens are constructed with a unique ribbed design that provides enhanced strength and durability. This prevents the screens from sagging or bending under high pressure, ensuring a consistent cut point throughout their lifespan. The screens also feature a patented crown design, which increases the screen's surface area and improves fluid handling capacity.In addition to their exceptional durability, the Derrick 2000 Series PWP Screens are also highly efficient. They are created using advanced manufacturing techniques and high-quality materials, ensuring precise and accurate separation of solids from liquids. This results in cleaner fluids and higher-quality drilling mud, which in turn leads to improved wellbore stability and increased oil and gas production.Furthermore, the Derrick 2000 Series PWP Screens are designed for easy installation and maintenance. They are compatible with various shale shaker models and can be quickly and easily replaced when needed. This allows operators to minimize downtime and maximize operational efficiency. The screens are also engineered to minimize blinding and plugging, reducing the need for frequent cleaning and replacement.The introduction of the Derrick 2000 Series PWP Screens has garnered significant attention and praise within the oil and gas industry. Several major oil companies have already adopted these screens in their operations and have reported significant improvements in productivity and cost savings. The screens have been particularly effective in shale drilling applications, where precise separation of cuttings from drilling fluid is crucial for efficient drilling operations.The benefits of the Derrick 2000 Series PWP Screens extend beyond operational efficiency and cost savings. With their advanced solid control technology, these screens also contribute to environmental sustainability. By effectively removing solids from drilling fluid, the screens reduce the environmental impact of drilling operations, minimizing the discharge of contaminated fluids into the environment.In conclusion, the Derrick 2000 Series PWP Screens have revolutionized the oil and gas industry with their exceptional performance and durability. These screens have proven to be highly efficient, reliable, and easy to maintain, resulting in increased productivity and cost savings for oil and gas companies. With their advanced solid control technology, they also contribute to environmental sustainability, making them a valuable asset in the industry's ongoing efforts to minimize its environmental footprint. As more companies recognize the benefits of these screens, their adoption is expected to become widespread, further transforming the way oil and gas extraction is conducted.

High-Quality FLC313M Screen: What You Need to Know

Derrick Corporation, a leading global provider of high-quality separation and filtration equipment, has recently launched its latest innovation – the FLC313M screen. This new addition to the company’s extensive product line promises to revolutionize the way the oil and gas industry approaches solids control and dewatering.The FLC313M screen is designed to deliver superior performance and efficiency in separating solids from drilling fluid. Its advanced design features a unique combination of high-quality materials and innovative engineering, resulting in increased throughput and reduced operating costs for customers. With a focus on durability and reliability, this screen is built to withstand the demands of the most challenging drilling environments.One of the standout features of the FLC313M screen is its versatility. Suitable for both onshore and offshore applications, this screen excels in a wide range of operating conditions, including high temperature and high-pressure environments. Its ability to consistently deliver exceptional performance in such diverse settings sets it apart from other products currently available on the market.Furthermore, Derrick Corporation is committed to providing best-in-class customer service and support. The launch of the FLC313M screen is part of the company’s ongoing effort to meet the evolving needs of its global customer base. By offering innovative solutions that enhance efficiency and productivity, Derrick Corporation continues to solidify its position as a trusted partner to the oil and gas industry.In addition to the FLC313M screen, Derrick Corporation offers a comprehensive range of separation and filtration equipment, including shakers, hydrocyclones, and centrifuges. With a proven track record of delivering high-performance solutions, the company has established itself as a leader in the field of solids control and dewatering.The development and launch of the FLC313M screen underscore Derrick Corporation’s dedication to innovation and excellence. By staying at the forefront of technological advancements, the company remains well-positioned to address the evolving needs of the oil and gas industry. As the industry continues to seek more efficient and cost-effective solutions, Derrick Corporation is poised to provide the cutting-edge equipment required to meet these demands.In conclusion, the introduction of the FLC313M screen represents a significant milestone for Derrick Corporation. With its unmatched performance, durability, and versatility, this new addition to the company’s product line is set to make a lasting impact on the oil and gas industry. As Derrick Corporation continues to push the boundaries of innovation, customers can expect to benefit from the superior quality and reliability that have become synonymous with the company’s brand.About Derrick Corporation:Derrick Corporation is a global provider of high-quality separation and filtration equipment for the oil and gas industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner to its global customer base. Derrick Corporation is committed to delivering best-in-class equipment and solutions that enhance efficiency and productivity in solids control and dewatering applications.

D285P Composite Oil Shaker Screen for Effective Solids Control

Introduction:The global oil and gas industry has been witnessing a significant transformation in recent years, and technological advancements have played a crucial role in boosting the efficiency and productivity of operations. One such innovation that has gained traction in the industry is the Brandt D285P Composite Oil Shaker Screen, a cutting-edge solution offered by a leading oilfield equipment company.Company Background:Established over two decades ago, our company has remained committed to providing high-quality, innovative, and reliable products to the oil and gas sector. With a strong focus on research and development, we have continuously strived to address the evolving needs of our clients and the industry as a whole. Over the years, we have built an impeccable reputation for our dedication to excellence and our ability to deliver superior solutions that enhance operational performance and cost-efficiency.The Brandt D285P Composite Oil Shaker Screen:The Brandt D285P Composite Oil Shaker Screen is a superior offering designed to enhance the efficiency and cost-effectiveness of oil and gas drilling operations. Featuring advanced composite materials and cutting-edge manufacturing techniques, this innovative shaker screen offers unparalleled performance and durability in demanding drilling environments.The key highlights of the Brandt D285P Composite Oil Shaker Screen include:1. Superior Solid Control: The shaker screen is engineered to effectively separate solids and liquids, thereby improving the overall performance of drilling fluid systems. Its advanced design and construction ensure reliable and efficient solid control, leading to improved drilling efficiency and reduced downtime.2. Enhanced Durability: The use of high-quality composite materials ensures exceptional durability, making the shaker screen resistant to wear, tear, and corrosion. This extended lifespan translates to lower maintenance costs and reduced replacement frequency, further contributing to cost savings for operators.3. Improved Particle Control: The Brandt D285P Composite Oil Shaker Screen is designed to efficiently control the size and distribution of particles in drilling fluids, thereby contributing to better wellbore stability and overall drilling performance. This feature is particularly valuable in challenging drilling conditions, where precise particle control is critical.4. Compatibility and Versatility: The shaker screen is compatible with a wide range of shaker models, providing operators with flexibility and ease of integration into their existing drilling equipment. Its versatile design enables seamless installation and operation across various drilling applications, contributing to operational efficiency and adaptability.Industry Impact:The introduction of the Brandt D285P Composite Oil Shaker Screen has garnered significant attention within the oil and gas industry, with operators recognizing its potential to enhance drilling operations and deliver cost savings. The innovative features and performance capabilities of the shaker screen align with the industry's increasing demand for advanced solutions that optimize operational efficiency and minimize environmental impact.The use of advanced composite materials in the construction of the shaker screen represents a notable shift towards sustainable and eco-friendly practices in the oil and gas sector. By improving the longevity and performance of drilling equipment, the Brandt D285P Composite Oil Shaker Screen contributes to reducing overall resource consumption and waste generation, aligning with the industry's sustainability goals.Furthermore, the enhanced solid control and particle management capabilities of the shaker screen are expected to positively impact wellbore stability, drilling fluid quality, and overall drilling efficiency. This, in turn, can lead to improved well productivity, reduced drilling costs, and minimized environmental footprint, positioning the shaker screen as a valuable asset for operators seeking to achieve operational excellence.In conclusion, the Brandt D285P Composite Oil Shaker Screen represents a significant advancement in the field of oil and gas drilling equipment, offering operators a reliable and cost-effective solution to optimize their operations. With its superior performance, durability, and compatibility, the shaker screen is poised to make a lasting impact on the industry, contributing to enhanced efficiency, sustainability, and overall operational success. As the industry continues to evolve, innovative solutions like the Brandt D285P Composite Oil Shaker Screen will play a pivotal role in driving its progress and competitiveness.