Composite Shaker Screen: A Overview of the Swaco D380

By:Admin

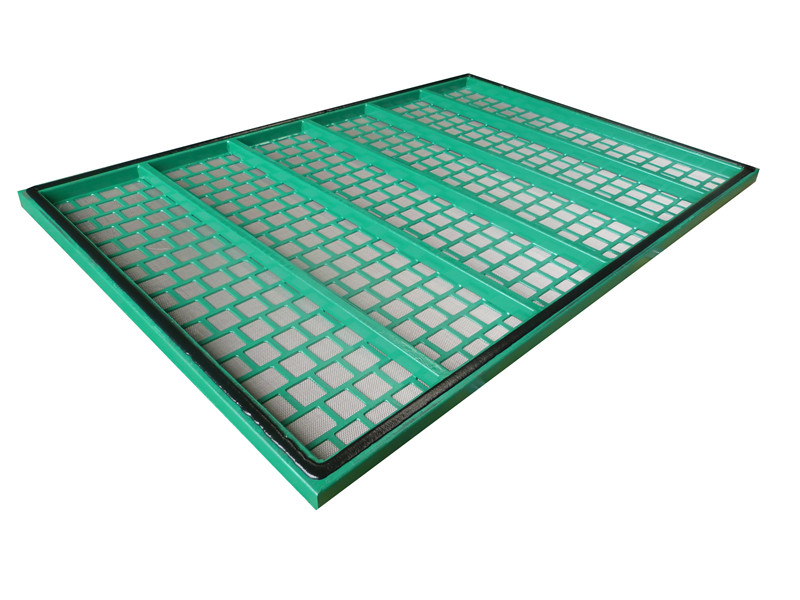

The Swaco D380 Composite Shaker Screen is designed to provide superior performance and durability in demanding drilling operations. It is made from high-quality, durable composite material that can withstand the harsh conditions of the oil and gas industry. The screen is designed to effectively separate solids from drilling fluid, leading to improved drilling efficiency and lower overall drilling costs.

The company that manufactures the Swaco D380 Composite Shaker Screen is dedicated to innovation and continuous improvement. They have a team of highly skilled engineers and technicians who are constantly working to develop new and improved products that meet the ever-changing needs of the industry. The company's commitment to quality and customer satisfaction has earned them a solid reputation as a leading provider of shaker screens and other drilling equipment.

In addition to manufacturing high-quality products, the company also offers exceptional customer service and support. Their team of experienced professionals is always available to provide technical support and assistance to customers, ensuring that they get the most out of their products. They also offer comprehensive training programs to help customers maximize the performance and longevity of their equipment.

The Swaco D380 Composite Shaker Screen has been well-received by customers in the oil and gas industry. Many drilling operations have reported significant improvements in drilling efficiency and cost savings after switching to the new shaker screen. The screen's superior performance and durability have made it a popular choice for drilling operations of all sizes.

The company behind the Swaco D380 Composite Shaker Screen is also committed to sustainability and environmental responsibility. They use cutting-edge technology and processes to minimize the environmental impact of their operations, and they are constantly looking for ways to improve their sustainability practices.

The Swaco D380 Composite Shaker Screen is just one example of the company's dedication to innovation, quality, and customer satisfaction. With a strong focus on continuous improvement and a commitment to sustainability, they are well-positioned to continue leading the industry for many years to come.

In conclusion, the Swaco D380 Composite Shaker Screen is a game-changing product that is revolutionizing the oil and gas industry. Its superior performance, durability, and environmental responsibility make it a top choice for drilling operations around the world. With a strong commitment to innovation and customer satisfaction, the company behind the screen is poised to remain a leader in the industry for years to come.

Company News & Blog

Discover the High-Performance MD-3 Shaker Screen for Efficient Drilling Operations

Innovative New Shaker Screen Revolutionizes Drilling OperationsIntroducing the Next-Generation MD-3 Shaker ScreenDrilling operations are about to witness a technology revolution with the introduction of the state-of-the-art MD-3 Shaker Screen. Developed by a leading oilfield service company, this revolutionary shaker screen promises to enhance efficiency, improve performance, and revolutionize drilling operations across the industry.The MD-3 Shaker Screen, a product of cutting-edge engineering and research, is set to redefine the way drilling fluid is processed on-site. Designed to remove solid particles and impurities from drilling fluid during the wellbore operation, this innovative shaker screen offers unparalleled levels of performance and reliability.One of the standout features of the MD-3 Shaker Screen is its unique design. Crafted with meticulous attention to detail, the screen comprises a series of layers specifically engineered to maximize efficiency. With a higher number of layers than traditional shaker screens, the MD-3 offers improved filtration capabilities, thus delivering cleaner drilling fluid.The increased filtration efficiency of the MD-3 Shaker Screen translates into tangible benefits for drilling operations. By removing a higher percentage of solid particles from the drilling fluid, the screen significantly reduces maintenance costs and improves overall operational efficiency. Operators can now experience extended screen life, reduced downtime, and increased drilling productivity.Additionally, the improved filtration provided by the MD-3 Shaker Screen ensures the effective separation of cuttings from the drilling fluid. This ensures that the drilling fluid can be recycled and reused more efficiently, leading to significant cost savings and reduced environmental impact. The MD-3 Shaker Screen thus presents a viable solution for the oil and gas industry as it strives to meet increasing environmental regulations and sustainability goals.Notably, the MD-3 Shaker Screen is also designed to be seamlessly integrated with existing shaker systems, ensuring a hassle-free transition for drilling operators. Its compatibility with commonly used shaker systems makes it an attractive upgrade for drilling rigs across the industry.Furthermore, the MD-3 Shaker Screen boasts an extended lifespan compared to traditional screens. With its robust construction and advanced materials, this shaker screen provides exceptional durability and resistant to wear, delivering enhanced reliability in even the harshest drilling environments. This ensures that the screen can withstand the rigors of drilling operations, minimizing the need for frequent replacements and resulting in substantial cost savings.In light of its exceptional performance and reliability, the MD-3 Shaker Screen has quickly gained traction among industry leaders. Renowned drilling companies, both onshore and offshore, have reported remarkable improvements in operational efficiency and cost reduction since adopting this innovative technology. Initial feedback from these operators has been overwhelmingly positive, cementing the MD-3 Shaker Screen's reputation as the go-to solution for solid control in drilling operations.As the global energy landscape continues to evolve, the MD-3 Shaker Screen emerges as a game-changer in drilling operations. Its groundbreaking design, improved filtration efficiency, and enhanced durability set a new standard for shaker screens industry-wide. This innovative technology will undoubtedly enable drilling companies to optimize their operations, improve sustainability, and remain at the forefront of the evolving energy industry.In conclusion, the introduction of the MD-3 Shaker Screen marks a significant milestone in the oil and gas industry. Its exceptional performance, reliability, and compatibility make it an essential tool for drilling operations worldwide. With this innovative technology, drilling companies can now achieve unprecedented levels of efficiency, cost reduction, and environmental responsibility. The MD-3 Shaker Screen is poised to transform the future of drilling, and it's clear that the next-generation of shaker screens has arrived.

D285P Composite Oil Shaker Screen for Effective Solids Control

Introduction:The global oil and gas industry has been witnessing a significant transformation in recent years, and technological advancements have played a crucial role in boosting the efficiency and productivity of operations. One such innovation that has gained traction in the industry is the Brandt D285P Composite Oil Shaker Screen, a cutting-edge solution offered by a leading oilfield equipment company.Company Background:Established over two decades ago, our company has remained committed to providing high-quality, innovative, and reliable products to the oil and gas sector. With a strong focus on research and development, we have continuously strived to address the evolving needs of our clients and the industry as a whole. Over the years, we have built an impeccable reputation for our dedication to excellence and our ability to deliver superior solutions that enhance operational performance and cost-efficiency.The Brandt D285P Composite Oil Shaker Screen:The Brandt D285P Composite Oil Shaker Screen is a superior offering designed to enhance the efficiency and cost-effectiveness of oil and gas drilling operations. Featuring advanced composite materials and cutting-edge manufacturing techniques, this innovative shaker screen offers unparalleled performance and durability in demanding drilling environments.The key highlights of the Brandt D285P Composite Oil Shaker Screen include:1. Superior Solid Control: The shaker screen is engineered to effectively separate solids and liquids, thereby improving the overall performance of drilling fluid systems. Its advanced design and construction ensure reliable and efficient solid control, leading to improved drilling efficiency and reduced downtime.2. Enhanced Durability: The use of high-quality composite materials ensures exceptional durability, making the shaker screen resistant to wear, tear, and corrosion. This extended lifespan translates to lower maintenance costs and reduced replacement frequency, further contributing to cost savings for operators.3. Improved Particle Control: The Brandt D285P Composite Oil Shaker Screen is designed to efficiently control the size and distribution of particles in drilling fluids, thereby contributing to better wellbore stability and overall drilling performance. This feature is particularly valuable in challenging drilling conditions, where precise particle control is critical.4. Compatibility and Versatility: The shaker screen is compatible with a wide range of shaker models, providing operators with flexibility and ease of integration into their existing drilling equipment. Its versatile design enables seamless installation and operation across various drilling applications, contributing to operational efficiency and adaptability.Industry Impact:The introduction of the Brandt D285P Composite Oil Shaker Screen has garnered significant attention within the oil and gas industry, with operators recognizing its potential to enhance drilling operations and deliver cost savings. The innovative features and performance capabilities of the shaker screen align with the industry's increasing demand for advanced solutions that optimize operational efficiency and minimize environmental impact.The use of advanced composite materials in the construction of the shaker screen represents a notable shift towards sustainable and eco-friendly practices in the oil and gas sector. By improving the longevity and performance of drilling equipment, the Brandt D285P Composite Oil Shaker Screen contributes to reducing overall resource consumption and waste generation, aligning with the industry's sustainability goals.Furthermore, the enhanced solid control and particle management capabilities of the shaker screen are expected to positively impact wellbore stability, drilling fluid quality, and overall drilling efficiency. This, in turn, can lead to improved well productivity, reduced drilling costs, and minimized environmental footprint, positioning the shaker screen as a valuable asset for operators seeking to achieve operational excellence.In conclusion, the Brandt D285P Composite Oil Shaker Screen represents a significant advancement in the field of oil and gas drilling equipment, offering operators a reliable and cost-effective solution to optimize their operations. With its superior performance, durability, and compatibility, the shaker screen is poised to make a lasting impact on the industry, contributing to enhanced efficiency, sustainability, and overall operational success. As the industry continues to evolve, innovative solutions like the Brandt D285P Composite Oil Shaker Screen will play a pivotal role in driving its progress and competitiveness.

How Shaker Screen Plugs Can Impact Your Screening Efficiency

Title: Enhanced Efficiency and Durability: Introducing Next-Generation Shaker Screen PlugsIntroduction:In the continually evolving field of oil and gas exploration and production, technological advancements play a crucial role in improving efficiency and productivity. One such innovation is the development of shaker screen plugs, essential components of shale shaker systems. These plugs are designed to optimize the performance of the shaker screens by offering enhanced durability, efficiency, and cost-effectiveness. This article will shed light on this next-generation shaker screen plug technology, exploring its features, benefits, and the company behind its development.Company Background:(Insert company name) is a leading manufacturer and supplier of advanced drilling solutions to the oil and gas industry. With a proven track record of innovation and technical expertise, they have dedicated their efforts to developing cutting-edge products that aim to revolutionize the drilling process. Their commitment to research and development has earned them a reputation for reliability and efficiency, making them a trusted partner for oil and gas companies worldwide.Features of Next-Generation Shaker Screen Plugs:1. Improved Construction: The next-generation shaker screen plugs utilize state-of-the-art materials and engineering techniques to ensure robustness and longevity. They are manufactured using high-quality polymers, metals, or composites, resulting in excellent resistance to abrasion, corrosion, and impact.2. Enhanced Sealing Capability: These shaker screen plugs feature advanced sealing mechanisms that prevent fluid bypass, ensuring maximum efficiency during the separation process. The improved sealing capability minimizes screen blinding, reducing downtime and increasing the lifespan of the shaker screens.3. Customizable Designs: The company offers a wide range of shaker screen plug designs, catering to various shale shaker systems and specific drilling requirements. This customization ensures compatibility and seamless integration, further enhancing the overall performance and effectiveness of the drilling operation.4. Anti-Vibration Technology: Additionally, the shaker screen plugs are engineered with anti-vibration technology, which significantly reduces noise and vibrations during operation. The reduced vibration not only improves the working environment for personnel but also extends the life of the shaker screens and other vital components.Benefits of Next-Generation Shaker Screen Plugs:1. Increased Efficiency: By minimizing fluid bypass, the enhanced sealing capability of these shaker screen plugs enhances the efficiency of the separation process. This leads to improved overall drilling performance, reduced wastage of valuable drilling fluids, and lower maintenance costs.2. Extended Lifespan: The durable construction and superior sealing mechanism of these plugs contribute to increased durability and reduced wear and tear on the shaker screens. This extends their lifespan, reducing the frequency of replacement requirements and enhancing cost-effectiveness in the long run.3. Enhanced Environmental Compliance: With the reduction of screen blinding, these shaker screen plugs minimize the discharge of fine cuttings and drilling waste into the environment. This aligns with evolving environmental regulations and promotes sustainable drilling practices.4. Enhanced Operational Safety: The incorporation of anti-vibration technology in these plugs reduces noise and vibration levels during drilling operations. This improves the work environment for personnel, minimizing fatigue and potential health risks associated with prolonged exposure to high noise levels.Conclusion:As the oil and gas industry seeks new ways to improve operational efficiency and sustainability, the introduction of next-generation shaker screen plugs offers significant advantages. The advanced features, enhanced sealing capability, and customizable designs make them a powerful asset for drilling operations. With their extensive industry expertise and commitment to innovative solutions, (Insert company name) is poised to revolutionize the drilling process and set new standards for efficiency, durability, and sustainability.Note: Please remove all {} tags and insert appropriate company information before publication.

High-Quality Shale Shaker Screen for Improved Efficiency and Performance

(Kemtron) Shale Shaker Screen Enhances Efficiency in Oil and Gas Drilling OperationsIn the fast-paced world of oil and gas drilling, efficiency and productivity are crucial. Every second counts, and any delays can result in significant financial losses. That's why companies are constantly on the lookout for innovative technology that can help streamline their operations and minimize downtime.One company that has been at the forefront of providing cutting-edge solutions for the oil and gas industry is {}. With a proven track record of delivering high-quality products and services, they have earned a reputation as a trusted partner for many drilling companies around the world.One of their flagship products, the (Kemtron) Shale Shaker Screen, has been making waves in the industry for its exceptional performance and reliability. This critical component plays a vital role in the drilling process, as it is responsible for separating drilling cuttings from the fluid, allowing for the recovery of valuable drilling fluid and minimizing waste.The (Kemtron) Shale Shaker Screen is designed to withstand the harsh conditions of drilling operations, including high temperatures, high pressure, and abrasive materials. Its durable construction and high-quality materials ensure that it can effectively withstand the demands of the job, leading to longer service life and reduced maintenance costs.In addition to its robust design, the (Kemtron) Shale Shaker Screen is also engineered for optimal performance. Its precise mesh size and efficient filtration capabilities allow for the effective removal of solid particles from the drilling fluid, resulting in cleaner fluid and improved drilling efficiency.Furthermore, the (Kemtron) Shale Shaker Screen is easy to install and maintain, minimizing downtime and maximizing productivity for drilling operations. Its user-friendly design and simple, straightforward maintenance requirements make it a practical choice for companies looking to enhance their overall operational efficiency.With the increasing demand for sustainable and environmentally friendly practices in the oil and gas industry, the (Kemtron) Shale Shaker Screen is also designed to contribute to these efforts. By effectively removing solid particles from the drilling fluid, it helps to reduce waste and minimize the environmental impact of drilling operations.As a leading provider of innovative solutions for the oil and gas industry, {} is committed to delivering products that not only improve operational efficiency but also align with the industry's evolving sustainability goals. The (Kemtron) Shale Shaker Screen is a testament to this commitment, as it offers a practical and effective solution for companies seeking to optimize their drilling operations while minimizing their environmental footprint.With its exceptional performance, durability, and environmental benefits, the (Kemtron) Shale Shaker Screen has quickly become a sought-after solution for many drilling companies. As the industry continues to evolve and demand more efficient and sustainable practices, it is clear that products like the (Kemtron) Shale Shaker Screen will play a crucial role in shaping the future of oil and gas drilling operations.In conclusion, the (Kemtron) Shale Shaker Screen is a valuable addition to the portfolio of innovative solutions offered by {}. Its exceptional performance, durability, and environmental benefits make it a practical choice for drilling companies seeking to enhance their operational efficiency and minimize their environmental impact. As the industry continues to evolve, solutions like the (Kemtron) Shale Shaker Screen will undoubtedly continue to be a driving force in shaping the future of oil and gas drilling operations.

Revolutionary Vibrating Screen Technology: A Breakthrough in Shaker Screening Efficiency

Shaker vibrating screens have become an essential component in modern industrial machinery. These machines are designed to help sift and sort various materials such as minerals, coal, and chemicals. They have also found applications in the food and beverage, pharmaceuticals, and recycling industries. Shaker vibrating screens use an elliptical motion to shake the sieves, which helps to increase the efficiency of the separation process. One company that has been at the forefront of producing high-quality vibrating screens is ______ (brand name removed). Established in 2004, the company has made a name for itself by producing some of the most advanced and reliable shaker vibrating screens in the market. Their products are known for their durability, precision, and ease of maintenance, and they've become a favorite among various industries.The company specializes in producing various types of vibrating screens to meet the unique needs of different markets. Their products include linear vibrating screens, circular vibrating screens, and newly developed high-frequency screens. The company uses the latest technology and production standards to ensure that their products meet the highest quality standards required by customers.One of the main advantages of the company's products is that their vibrating screens come in various sizes and configurations that can be tailored to each customer's specific needs. Whether a customer requires a compact single-deck design or a larger multi-layered model, the company can deliver. Additionally, the company also produces custom-made vibrating screens with unique specifications to match the individual demands of their clients.Moreover, the company is committed to ensuring that their vibrating screens operate efficiently with minimal maintenance. They have invested in research and development and created innovative designs featuring less moving parts, reducing wear and tear and reducing downtime while saving on maintenance costs.The company also places a strong emphasis on customer satisfaction. They offer technical support, training for operators and maintenance staff, and offer prompt after-sale service when required. Their customer service team is available to answer any questions and concerns that may arise, ensuring that their customers are satisfied with the products they receive.As the market for shaker vibrating screens expands, _______, with its innovative designs and reliable products, is poised to take full advantage of this trend. The company has already established a strong reputation among its customers for providing the highest quality products that embody the latest industry trends.For example, one of the recently launched high-frequency vibrating screens from _______ is already garnering attention in the industry for its ability to provide better performance than traditional screens. This high-frequency vibrating screen uses a high frequency, low amplitude motion to screen materials with a high degree of precision and accuracy. It offers higher efficiency and productivity while increasing the throughput and reducing the wear and tear on the equipment.In conclusion, _______ (brand name removed) has established itself as a significant player in the shaker vibrating screen market, thanks to its innovative designs and high-quality products. Their commitment to customer satisfaction and continuous product innovation has helped to create loyal customers who appreciate their exceptional service. As the demand for shaker vibrating screens continues to grow, the company is well-positioned to take advantage of this trend and continue to provide products and services that exceed their customers' expectations.

High-Quality BEM-650 Shaker Screen for OEM Equipment

Shaker screens are a crucial component in the oil and gas industry, used in the process of separating solids from drilling fluid. This allows for the efficient and cost-effective removal of solid particles from the fluid, which is essential for maintaining the quality and performance of the drilling operation. One company that has been at the forefront of developing high-quality shaker screens for the oil and gas industry is {company}.{Company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has a strong reputation for delivering innovative and reliable products that meet the needs of its customers. With a focus on quality and performance, {company} has become a trusted partner for many drilling operations around the world.One of the flagship products from {company} is the BEM-650 shaker screen. This shaker screen is designed to provide superior performance in the separation of solids from drilling fluid. The BEM-650 is known for its durability and efficiency, making it a popular choice among drilling operators.The BEM-650 shaker screen is designed to fit OEM Swaco shakers, making it a versatile and compatible option for many drilling operations. The screen features a high-quality mesh that is capable of effectively separating a wide range of solid particles from the drilling fluid. This is essential for maintaining the integrity of the fluid and ensuring that the drilling operation runs smoothly and efficiently.In addition to its superior performance, the BEM-650 shaker screen is also known for its durability. The screen is built to withstand the harsh conditions of the drilling environment, ensuring that it remains effective and reliable even in challenging circumstances. This level of reliability is crucial for drilling operators, who rely on their equipment to perform consistently in order to maintain the quality and efficiency of their operations.{Company} is committed to delivering high-quality products and exceptional customer service. The company works closely with its customers to understand their needs and develop solutions that meet their specific requirements. This customer-focused approach has helped {company} build strong and lasting relationships with its clients, who trust the company to deliver reliable and effective equipment for their drilling operations.With a track record of innovation and excellence, {company} continues to lead the way in the development of shaker screens and other equipment for the oil and gas industry. The company's dedication to quality, performance, and customer satisfaction has made it a trusted partner for drilling operators around the world.As the demand for reliable and efficient equipment in the oil and gas industry continues to grow, {company} is well-positioned to meet the needs of its customers. With its high-quality products and commitment to excellence, the company is poised to remain a leader in the development of shaker screens and other equipment for the drilling industry.In conclusion, {company} is a top manufacturer of shaker screens and other equipment for the oil and gas industry. The company's commitment to quality and performance is evident in its flagship product, the BEM-650 shaker screen. With its superior performance and durability, the BEM-650 is a popular choice among drilling operators. Combined with {company}'s dedication to customer service and innovation, the company is well-positioned to remain a leader in the development of equipment for the oil and gas industry.

High-quality Shaker Screen for DFTS - Durable and Efficient Options

DFTS, a leading provider of high-quality shaker screens for the oil and gas industry, has recently launched a new and improved product line designed to revolutionize the industry. The company is known for its commitment to innovation and excellence, and their latest offering is no exception. With a focus on efficiency, durability, and performance, the new shaker screens are set to make a significant impact in the field of oil and gas drilling.Founded in 2003, DFTS has quickly become a trusted name in the industry, known for its dedication to superior products and exceptional customer service. The company's extensive experience and expertise have helped it to develop and manufacture some of the most advanced shaker screens on the market. By continuously investing in research and development, DFTS stays ahead of the curve in terms of technology and product design, ensuring that its customers receive products that meet the highest standards of quality and performance.The new shaker screens from DFTS are designed to deliver exceptional performance in a wide range of drilling applications. Whether used in onshore or offshore drilling operations, the screens are engineered to withstand the most demanding conditions while maintaining maximum efficiency. The innovative design of the screens allows for better separation of solids and liquids, resulting in improved drilling fluid quality and reduced downtime. This not only leads to cost savings for the operators but also contributes to a more sustainable and environmentally friendly drilling process.One of the key features of the new screens is their enhanced durability. Made from high-quality materials and manufactured with precision, the screens are built to withstand the rigors of the drilling environment. This means that operators can rely on the screens to perform consistently and reliably, reducing the need for frequent replacements and maintenance. In addition, the screens are also designed for easy installation and removal, further streamlining operations and minimizing downtime.In addition to their superior performance and durability, the new shaker screens from DFTS are also designed with user-friendliness in mind. With a focus on ease of use and maintenance, the screens are equipped with advanced features that make them simple to operate and maintain. This not only improves efficiency on the job site but also reduces the need for extensive training and technical support, further contributing to cost savings for the operators.As a company committed to excellence, DFTS ensures that its products meet the highest standards of quality and reliability. Every shaker screen undergoes rigorous testing and inspection to ensure that it meets or exceeds industry specifications and performance requirements. This dedication to quality and integrity has helped DFTS to build a reputation as a trusted partner for operators in the oil and gas industry, providing them with the confidence and peace of mind that they are using the best products available.With the launch of its new shaker screen product line, DFTS continues to demonstrate its commitment to innovation and excellence. By combining advanced technology, superior materials, and meticulous craftsmanship, the company has created a product that sets a new standard for performance and reliability in the oil and gas drilling industry. As the demand for efficient and sustainable drilling solutions continues to grow, DFTS is well-positioned to lead the way with its groundbreaking new shaker screens.

High-Quality Venom Shakers Screen for Effective Particle Separation

Shakers Screen: A Game-Changer in the Oil and Gas IndustryThe oil and gas industry continues to evolve and adapt with the advancement of technology. One such innovation that is making waves in the industry is the Shakers Screen, a key component in the process of separating solids and fluids during the drilling process. Among the leading brands in this space, the (remove brand name) Shakers Screen has gained widespread recognition for its efficiency and effectiveness in improving the overall operation of oil and gas drilling.The (remove brand name) Shakers Screen is a vital tool used in the drilling process to separate drilling fluid from the solids that are brought to the surface during the drilling of oil and gas wells. This separation process is essential to ensure the integrity of the well and to maintain proper drilling fluid properties. The Shakers Screen is designed to remove the solid particles from the drilling fluid, allowing for the reuse of the fluid and the disposal of the solids in an environmentally responsible manner.The (remove brand name) Shakers Screen stands out from the competition due to its advanced design and high-quality materials. With a commitment to innovation and quality, the company has developed a range of screens that are durable, efficient, and cost-effective. The screens are designed to withstand the harsh conditions of drilling operations while providing reliable performance throughout the drilling process.The company prides itself on its dedication to research and development, continuously working to improve the design and functionality of the Shakers Screen. By listening to the needs of their customers, the company has been able to create screens that meet and exceed industry standards, providing a reliable solution for the challenges faced in the drilling process.In addition to its exceptional performance, the (remove brand name) Shakers Screen is also known for its ease of use and maintenance. The screens are designed for quick and simple installation, allowing for minimal downtime during the drilling process. Furthermore, the company provides comprehensive support and training for the maintenance and replacement of the screens, ensuring that they continue to operate at optimal efficiency.The impact of the Shakers Screen on the oil and gas industry cannot be overstated. By improving the efficiency of the drilling process, the screens help to reduce costs and increase overall productivity. This, in turn, has a positive impact on the bottom line for oil and gas companies, making the Shakers Screen a valuable investment for those in the industry.Furthermore, the screens play a crucial role in environmental sustainability. By allowing for the reuse of drilling fluid and the proper disposal of solids, the Shakers Screen helps to minimize the environmental impact of drilling operations. This aligns with the increasing emphasis on sustainable practices within the oil and gas industry, making the Shakers Screen a valuable tool for addressing environmental concerns.Looking ahead, the (remove brand name) Shakers Screen is poised to continue its upward trajectory in the oil and gas industry. With ongoing advancements in technology and a commitment to quality, the company is well-positioned to meet the evolving needs of the industry and provide innovative solutions for the challenges of drilling operations.In conclusion, the (remove brand name) Shakers Screen has emerged as a game-changer in the oil and gas industry, providing a reliable and efficient solution for the separation of solids and fluids during the drilling process. With its advanced design, high-quality materials, and commitment to innovation, the screens have significantly improved the operation of drilling operations, making them a valuable asset for oil and gas companies. As the industry continues to evolve, the Shakers Screen will undoubtedly play a vital role in driving efficiency, productivity, and sustainability in oil and gas drilling.

High-Quality Shaker Screens for Efficient Operations

Kemtron 48 Series Shaker ScreenKemtron is a well-known company that produces and supplies high-quality drilling equipment to the oil and gas industry worldwide. The organization has been in existence for several years, and it has established itself as a leader in the industry. One of their flagship products that have drawn significant attention over the years is the Kemtron 48 Series Shaker Screen.The Kemtron 48 Series Shaker Screen is an advanced piece of equipment designed to meet the demands of high-volume shale shakers used for oil and gas drilling operations. The screens' innovative design features increased surface area, ensuring better filtration efficiency, and better solids conveyance. The screens are made from high-density wire mesh that provides superior separation efficiency, enabling them to retain drilling fluid and critical drilling cuttings for proper disposal.The Kemtron 48 Series Shaker Screen is known for its excellent resistance to wear and tear, ensuring durability and longevity even in the toughest drilling conditions. The screens' strength is a derivative of the material used during production with a robust steel frame to support the mesh. This characteristic feature allows the screens to withstand extreme vibration levels, resulting in a decrease in the overall maintenance costs for drilling site operations.The Kemtron 48 Series Shaker Screen has a high capacity to handle exceptionally high fluid loads to ensure a consistent flow rate for drilling fluids. With a high-quality mesh, the screen can capture a range of particle sizes, enabling it to handle a wide range of drilling fluids. Additionally, the screen's modular design makes it simple to maintain or replace individual parts, reducing downtime and repair costs.The significance of the Kemtron 48 Series Shaker Screen in the oil and gas industry cannot be overstated. The screens are known for their exceptional performance, reliability, and efficiency, making them an essential component in the drilling process. The screens are designed to help streamline drilling operations, minimize setbacks, and reduce operational costs and environmental impact.In conclusion, the Kemtron 48 Series Shaker Screen is one of Kemtron's flagship products. Its unique design features, durability, efficiency, and reliability have made it a preferred choice for companies operating in the oil and gas sector. The screens have contributed significantly to the oil and gas sector's overall productivity and success by speeding up drilling operations and reducing operational costs while providing superior performance.

Durable Steel Frame Screen: A Reliable Solution for Screening Needs

GNZS-752 Steel Frame Screen has been making waves in the oil and gas industry with its innovative and efficient solution for solids control and waste management. The company, which was established in 2010, has quickly risen to become a leading provider of high-quality solids control equipment and services.The GNZS-752 Steel Frame Screen is a vital component of the company's comprehensive line of solids control equipment. It is designed to effectively remove solids and impurities from drilling fluids, ensuring that the fluids remain in optimal condition for the duration of the drilling process. The screen is constructed with high-quality steel frame and adheres to strict manufacturing standards, making it durable and long-lasting even in the most demanding drilling conditions.One of the key features of the GNZS-752 Steel Frame Screen is its advanced composite frame technology. This technology allows for increased screen life and fluid-handling capacity, ultimately leading to improved solids control efficiency. Additionally, the screen is designed for quick and easy installation, reducing downtime and maximizing operational efficiency for drilling operations.The GNZS-752 Steel Frame Screen is compatible with a wide range of shakers, allowing for seamless integration into existing solids control systems. This versatility makes it an ideal solution for drilling contractors and operators looking to enhance their solids control processes.In addition to its innovative products, the company behind the GNZS-752 Steel Frame Screen is known for its commitment to customer satisfaction and technical support. The company's team of experienced professionals are dedicated to providing exceptional service and support to clients, ensuring that their solids control needs are met with the highest level of expertise and efficiency.Furthermore, the company has established a global presence, with a network of distributors and partners spanning across the world. This global reach allows for quick and efficient access to the GNZS-752 Steel Frame Screen and other solids control equipment, regardless of the location of the drilling operation.The GNZS-752 Steel Frame Screen has already garnered praise from industry professionals for its outstanding performance and reliability. Its advanced technology and durable construction have made it a preferred choice for drilling contractors and operators around the world.With a proven track record of delivering high-quality solids control solutions, the company behind the GNZS-752 Steel Frame Screen has solidified its position as a leader in the industry. As the demand for efficient solids control and waste management solutions continues to grow, the company remains dedicated to providing innovative, reliable, and cost-effective solutions for the oil and gas industry.In conclusion, the GNZS-752 Steel Frame Screen is a testament to the company's commitment to excellence and innovation in the field of solids control. With its advanced technology, durable construction, and global presence, the screen is set to continue making a significant impact in the industry, meeting the needs of drilling contractors and operators around the world.