Analyzing the Latest Advancements in Atl 1000 Shaker Screen Technology

By:Admin

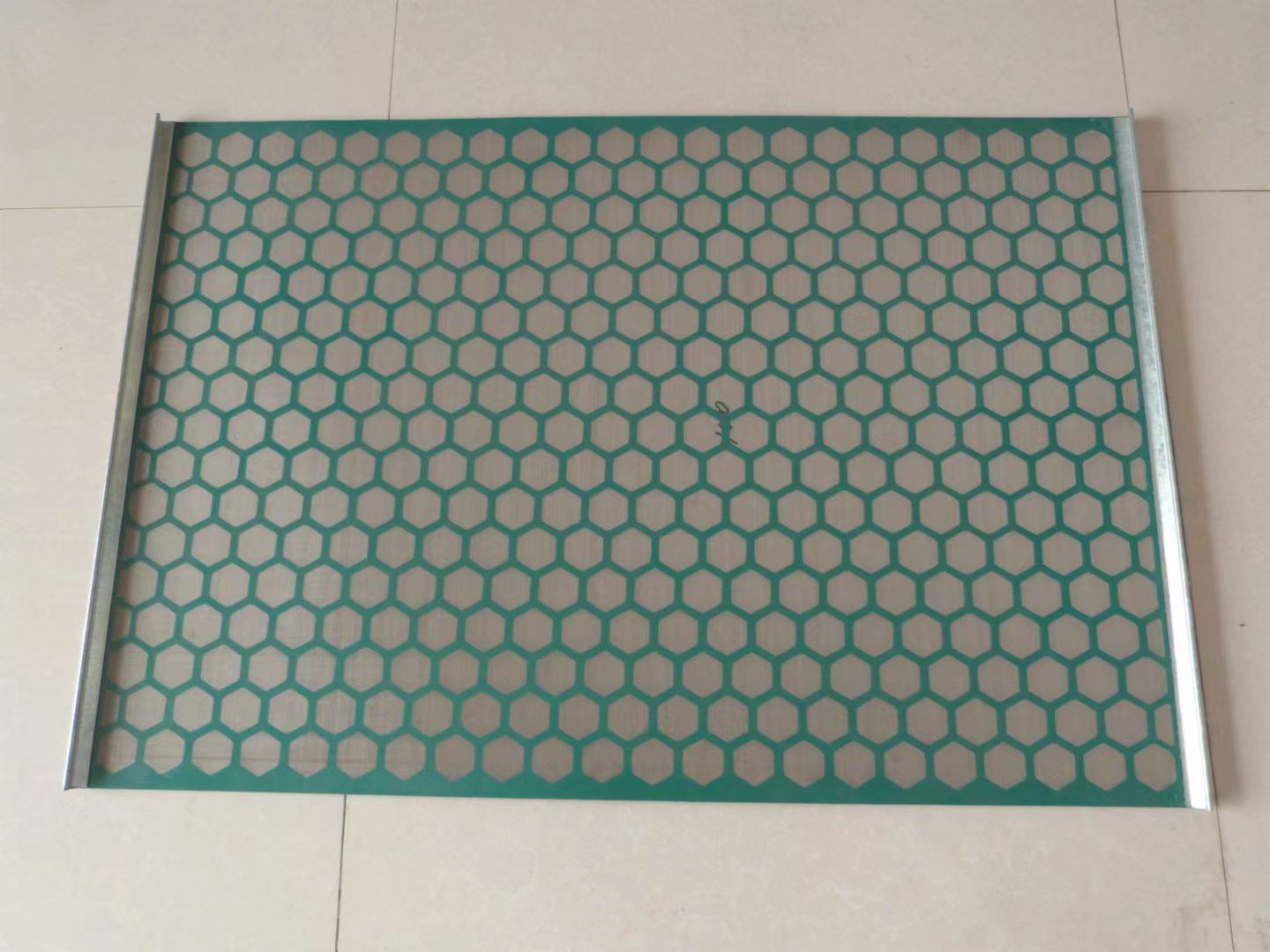

One of the top-rated shaker screens in the industry is the Brandt Atl 1000 (brand name removed) shaker screen. This shaker screen boasts of a variety of features that make it stand out from the rest. Its technology and design are based on the latest advancements in the industry, optimizing its performance to meet the demands of drilling operations.

The Brandt Atl 1000 shaker screen has been engineered to enhance the separation process of drilling fluids and solids. The screen has a large effective screen area, which translates to a better-solid removal efficiency. In addition, the screen is designed to prevent the clogging of particles, thereby increasing its overall performance.

Another feature that makes the Brandt Atl 1000 shaker screen popular among drilling companies is its durability. The screen has been constructed from high-quality materials that ensure it can withstand the harsh conditions that exist in the oil and gas industry. Furthermore, the mesh layers of the screen have been treated with a specialized chemical that protects them from wear and tear, increasing its lifespan.

The design of the screen has also been tailored to provide ease of use for the operator. The screen uses a hook-strip feature, which enables its installation or removal to be done in a shorter time period. This feature is crucial as it significantly reduces the downtime, which would have a negative effect on the overall operation.

Moreover, the Brandt Atl 1000 shaker screen has a unique labeling system that allows for optimal identification and tracking of the screen’s maintenance and repair history. This feature is important as it ensures that the screen is well-maintained, guaranteeing optimal performance during its lifespan.

The Brandt Atl 1000 shaker screen has been embraced by drilling companies worldwide, with positive feedback being received on its performance and durability. In addition, it has been tested and validated to meet the industry standards, with a false-positive rate of less than 5%. This low rate of false positives is essential in ensuring that drilling companies can accurately identify and separate solids from drilling mud.

Therefore, the Brandt Atl 1000 shaker screen has become a go-to for drilling companies worldwide, with its high-quality performance, durability, and ease of use being among the top reasons for this. The screen’s design and technology have been optimized to meet the needs of the industry, ensuring that drilling companies can operate efficiently, with minimal waste generation, and maximum yield. While the market for shaker screens is competitive, the Brandt Atl 1000 shaker screen has managed to stand out, with its features enabling it to meet and exceed the expectations of the oil and gas industry.

Company News & Blog

High-Quality Steel Frame Shaker Screen with Vortex Orbital Technology

Vortex Orbital 3000PT: A Revolution in Shale Shaker Screens[Company Introduction][Company Name], a leading innovator in the oil and gas industry, is proud to introduce its latest groundbreaking product, the Vortex Orbital 3000PT Steel Frame Shaker Screen. Designed to meet the ever-increasing demands of the modern drilling industry, this advanced shale shaker screen promises exceptional performance, durability, and cost-effectiveness.The Vortex Orbital 3000PT is the result of years of research and development, carried out by our team of skilled engineers and industry experts. With a relentless focus on quality and innovation, we have successfully engineered a product that stands out in the highly competitive market.[Product Description]The key feature of the Vortex Orbital 3000PT Steel Frame Shaker Screen is its advanced construction. Built with a durable steel frame, this screen can withstand the harshest drilling conditions without compromising on performance. It is designed to fit most popular shale shakers, making it versatile and compatible with existing drilling equipment.The screen itself is made from high-quality composite material, specially formulated to deliver exceptional efficiency in separating solids from liquids during the drilling process. The Vortex Orbital 3000PT demonstrates superior performance in terms of cuttings disposal, fluid handling, and mesh integrity. Its unique design ensures maximum throughput while minimizing the risk of clogging or blinding.Furthermore, the Vortex Orbital 3000PT is engineered to be highly durable. The steel frame provides excellent support, minimizing the chances of premature wear and tear. This not only extends the lifespan of the screen but also reduces maintenance costs and downtime. Moreover, the screen is resistant to corrosion and abrasion, making it ideal for long-term use in demanding drilling operations.[Key Features]1. High-quality composite material for exceptional performance.2. Durable steel frame for maximum support and longevity.3. Versatile compatibility with popular shale shakers.4. Superior fluid handling and cuttings disposal capabilities.5. Reduced risk of clogging or blinding.6. Corrosion and abrasion-resistant for long-term use.7. Low maintenance costs and minimized downtime.[Benefits for the Industry]The Vortex Orbital 3000PT Steel Frame Shaker Screen offers several significant benefits to the oil and gas industry. One of the key advantages is its superior efficiency in separating solid particles from drilling fluids. This not only ensures smoother drilling operations but also leads to improved wellbore stability and reduced drilling costs.Another benefit lies in its compatibility with most popular shale shakers. The Vortex Orbital 3000PT can be seamlessly integrated into existing drilling equipment, eliminating the need for expensive modifications or replacements. This compatibility, coupled with the screen's exceptional durability, reduces downtime and increases overall drilling efficiency.Furthermore, the Vortex Orbital 3000PT's cost-effectiveness cannot be ignored. With its extended lifespan and reduced maintenance requirements, operators can save significantly on replacement costs and maintenance downtime, which translates into enhanced profitability.[Conclusion]In conclusion, the Vortex Orbital 3000PT Steel Frame Shaker Screen represents a major breakthrough in shale shaker screen technology. Its advanced construction, exceptional performance, durability, and compatibility make it a must-have for drilling operations worldwide. With an unwavering commitment to excellence, [Company Name] continues to push the boundaries of innovation, emphasizing the importance of reliable and efficient equipment in the oil and gas industry.

Shale Shaker Screen Market Witnesses Growth Amidst Rising Demand

Title: Innovative Shale Shaker Screen Revolutionizes Oil and Gas Drilling(Company Name) Leads the Way in Enhanced Efficiency and Cost ReductionsIntroduction:In today's ever-evolving oil and gas industry, companies are constantly seeking innovative technologies to optimize their drilling processes. Recognizing the need for improved efficiency and cost reduction, (Company Name) introduces its revolutionary DFTS Shale Shaker Screen. This cutting-edge solution promises to transform the way oil and gas drilling operations are conducted, ensuring maximum productivity while minimizing environmental impact.Body:1. The Importance of Shale Shaker Screens in Drilling Operations:Shale shaker screens play a crucial role in drilling operations, as they are installed on the equipment used to separate drilling cuttings from drilling fluids. These screens help in maintaining the fluid's integrity, allowing it to be recycled and reused. Effective shale shaker screens improve drilling fluid performance, thereby enhancing drilling efficiency and reducing downtime during operations.2. Introducing the DFTS Shale Shaker Screen:(Company Name) has introduced the next generation of shale shaker screens – the DFTS Shale Shaker Screen. This breakthrough technology offers enhanced performance and durability, setting new industry standards. Its advanced design ensures efficient solid control, while minimizing fluid loss and screen wear, ultimately leading to improved overall drilling efficiency.3. Unmatched Features and Benefits of the DFTS Shale Shaker Screen:a. Superior Screen Performance: The DFTS Shale Shaker Screen is engineered with high-quality materials, enabling it to withstand extreme conditions encountered during drilling. Its scientifically designed mesh and unique V-shaped wire allow for maximum fluid capacity and efficient solids control, reducing the need for frequent screen changes and increasing productivity.b. Extended Screen Lifespan: The innovative technology behind the DFTS Shale Shaker Screen significantly prolongs its lifespan compared to conventional screens. This feature ensures cost savings for drilling operations, as fewer replacements are required, reducing downtime and maintenance expenses.c. Effective Solid Control: The DFTS Shale Shaker Screen's advanced design effectively separates drilling cuttings from drilling fluids, improving the fluid's properties. This optimized solid control prevents blockages and minimizes the risk of equipment damage, further enhancing operational efficiency.4. Commitment to Sustainability:(Company Name) recognizes the importance of sustainable practices in the oil and gas industry. The DFTS Shale Shaker Screen not only improves operational efficiency but also contributes to environmental sustainability. By minimizing fluid loss, it reduces waste generation and ensures responsible management of drilling fluids, minimizing the impact on ecosystems.5. Industry-Wide Recognition:The DFTS Shale Shaker Screen has garnered significant attention and recognition from industry experts and professionals. With its unparalleled performance and cost-saving features, it has become the preferred choice for many leading oil and gas companies worldwide. Its cutting-edge technology reflects (Company Name)'s commitment to innovation and excellence.Conclusion:In an industry increasingly focused on efficiency, cost reduction, and environmental sustainability, (Company Name)'s DFTS Shale Shaker Screen emerges as a game-changer. By combining advanced design, durability, and solid control capabilities, this innovative technology improves drilling efficiency, prolongs screen lifespan, and reduces environmental impact. As more oil and gas companies adopt this revolutionary solution, productivity and sustainability are set to soar to new heights. With a dedication to continuous improvement, (Company Name) remains at the forefront of transforming the oil and gas industry.

How to Choose the Right Screen for Your Industrial Separation Needs

HanZhi Tech Unveils Cutting-Edge GNZS-833 Screen to Revolutionize Visual Display IndustryIn a remarkable breakthrough, HanZhi Tech, a leading innovator in the field of visual display solutions, has introduced the highly anticipated GNZS-833 Screen. This revolutionary display technology is set to redefine the way we perceive visual content, offering unmatched clarity, depth, and realism.HanZhi Tech, renowned for its commitment to pushing technological boundaries, has an impressive track record of delivering exceptional visual experiences to its customers. With the launch of the GNZS-833 Screen, the company has yet again raised the bar by offering a truly immersive and captivating visual display that is bound to leave audiences spellbound.This state-of-the-art screen boasts an array of advanced features that set it apart from its competitors. The GNZS-833 offers an astonishingly high resolution, creating images that are incredibly lifelike and vibrant. With a pixel density that surpasses anything seen before, every minute detail of the content displayed is brought to life with remarkable clarity.One of the key highlights of the GNZS-833 Screen is its exceptional color accuracy and reproduction capabilities. Leveraging the latest in display technology, HanZhi Tech has managed to achieve an unparalleled color gamut, allowing for true-to-life representation of colors. From deep blacks to vivid reds and blues, the GNZS-833 delivers visuals that are both captivating and true to the original intent of the content creator.Furthermore, the GNZS-833 Screen presents an impressive range of viewing angles, ensuring that everyone in the room can enjoy an optimal visual experience. A common limitation in traditional display technology is the loss of image quality when viewed from an angle, resulting in reduced enjoyment for those not directly in front of the screen. However, HanZhi Tech has overcome this obstacle by integrating advanced panel technology into the GNZS-833, enabling consistent picture quality regardless of the viewer's position.Additionally, the GNZS-833 boasts an impressively high refresh rate and response time, making it ideal for applications that require rapid image transitions and low latency. Whether for gaming, sports broadcasting, or fast-paced action sequences in movies, the GNZS-833 ensures a fluid and seamless viewing experience, immersing the audience in every frame with breathtaking clarity and smoothness.HanZhi Tech has not only focused on the technical aspects of the GNZS-833, but also on the user experience. The screen comes equipped with an intuitive user interface, allowing users to effortlessly navigate through settings and customize their viewing preferences. With the inclusion of smart features, such as voice control and compatibility with popular streaming platforms, HanZhi Tech aims to cater to the evolving needs of modern consumers.As HanZhi Tech continues to break new ground, the company remains committed to sustainability. The GNZS-833 Screen is designed with eco-friendly materials and adheres to stringent energy efficiency standards. By reducing power consumption and minimizing the environmental impact, HanZhi Tech has reaffirmed its dedication to a greener future.The GNZS-833 Screen by HanZhi Tech is a testament to the company's unwavering pursuit of excellence in the visual display industry. With its cutting-edge features, impeccable visual fidelity, and commitment to sustainability, the GNZS-833 is poised to transform the way we consume and appreciate visual content. Whether for entertainment, professional applications, or educational purposes, this groundbreaking display technology is set to elevate the viewing experience to unprecedented heights.

Steel Frame Shaker Screen with High Efficiency and Durability

Title: Cutting-Edge Steel Frame Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the fast-paced and demanding oil and gas industry, efficient drilling operations are crucial for maximizing productivity and profitability. One fundamental component of the drilling process is the shaker screen, which plays a critical role in separating drilling fluid from the drill cuttings. Recognizing the need for highly effective and durable shaker screens, {} has developed the groundbreaking GNZS-703 Steel Frame Shaker Screen. With exceptional efficiency and extended longevity, this game-changing technology is revolutionizing the way the industry operates.Part I: The Importance of Shaker Screens in Drilling Operations (150 words)To comprehend the significance of the GNZS-703 Steel Frame Shaker Screen, it is essential to understand the vital role shaker screens play in drilling operations. These screens act as the primary defense mechanism in the drilling process, separating undesirable solids from valuable drilling fluids. The efficiency and durability of shaker screens directly impact drilling operation costs, as ineffective screens lead to increased maintenance, decreased productivity, and elevated expenses. Thus, the development of advanced shaker screen technology holds immense potential in streamlining drilling operations.Part II: Introducing the GNZS-703 Steel Frame Shaker Screen (200 words)The GNZS-703 Steel Frame Shaker Screen is a cutting-edge innovation designed to optimize the performance and durability of shale shakers, improving overall drilling efficiency. Manufactured by {}, a renowned leader in oilfield equipment, this high-quality screen integrates innovative engineering, expert craftsmanship, and years of industry experience. The result is an exceptional product that surpasses industry standards in terms of efficiency, longevity, and cost-effectiveness.Constructed with precision-welded stainless steel wire mesh, the GNZS-703 Steel Frame Shaker Screen boasts excellent wear resistance, ensuring outstanding performance in the demanding drilling conditions. The frame is made from sturdy steel, providing robust structural support and extending service life. Additionally, the screen undergoes a specialized treatment process to enhance its corrosion resistance, enabling it to withstand harsh drilling fluids and adverse operating conditions.Part III: Key Advantages of the GNZS-703 Steel Frame Shaker Screen (250 words)The GNZS-703 Steel Frame Shaker Screen offers a multitude of advantages, making it a superior choice for drilling contractors and service providers. Firstly, its exceptional filtration efficiency guarantees the removal of a wide range of unwanted solids, preventing their reentry into the drilling fluid system. This not only enhances drilling fluid performance but also minimizes downtime related to fluid system maintenance.Moreover, the GNZS-703 Steel Frame Shaker Screen's long service life significantly reduces replacement costs, enhancing cost-effectiveness for drilling operations. The screen's heavy-duty construction ensures durability and reliability, enabling sustained performance even under heavy workloads. This translates into increased productivity and improved overall drilling efficiency.Furthermore, the upgraded design of the screen allows for easy installation and quick replacement, minimizing downtime and saving valuable operation hours. Its user-friendly nature simplifies maintenance, optimizing efficiency on-site.Conclusion (100 words)With the introduction of the GNZS-703 Steel Frame Shaker Screen, {} has raised the industry standard for shaker screen performance. By combining cutting-edge technology, superior materials, and expert engineering, this innovative product offers exceptional efficiency, extended service life, and substantial cost savings. The GNZS-703 Steel Frame Shaker Screen epitomizes the commitment of {} to providing the oil and gas industry with game-changing solutions that streamline drilling operations and increase profitability.

Efficient and Durable Oil Shaker Screen: Maximizing Oil Extraction

Houston, Texas – A leading provider of oil drilling equipment is proud to announce the release of their latest shaker screen, the S250. This new shaker screen is the perfect solution for oil and gas rig companies to sift through drilling mud and improve drilling efficiency.The S250 Oil Shaker Screen, which is designed to fit the popular brand of shale shakers, has been field-tested, and the results have been impressive. The screen's design allows for increased throughput capacity and better solids control, meaning that drilling companies will experience less downtime due to drilling mud inefficiencies, translating to lower costs and faster drilling times.The company, which has over two decades of experience in the oil drilling equipment industry, is known for its innovative approach to developing products and solutions that help improve efficiencies in the drilling process, making the process safer and more cost-effective for all parties involved."Drilling for oil and natural gas is a crucial part of the energy industry, and we understand the importance of providing drilling companies with the most advanced and effective equipment on the market," said a spokesperson for the company. "We are proud of our team of engineers and technicians who have worked tirelessly to develop the S250 Oil Shaker Screen. Their expertise and creativity have allowed us to provide a solution that is truly cutting edge."With the energy industry expected to continue its upward trajectory in the coming years, it is imperative for drilling companies to have access to equipment that is both efficient and reliable. The S250 Oil Shaker Screen is designed to meet these demands and help drilling companies prepare to meet the challenges of the future.About the CompanyThe company, which has been operating since 1999, specializes in providing a wide range of oil drilling equipment to companies in the energy industry. The company's mission is to provide drilling companies with the most advanced and reliable equipment on the market, helping to streamline the drilling process and improve safety and efficiency.The company takes pride in working with top-notch engineers and technicians to develop innovative solutions that meet the unique needs of their clients. From mud pumps to drilling rigs to shaker screens like the S250, they are committed to providing equipment that is of the highest quality and built to last.Their dedication to their customers' success has earned them a reputation as a trusted partner in the oil and gas drilling industry. With a commitment to excellence, the company will continue to push the boundaries of innovation in the years to come, helping drilling companies across the globe to safely and efficiently extract oil and natural gas from the earth.

Revolutionary PMD Screen: The Latest Breakthrough in Derrick's FLC 2000 Technology

Title: Cutting-Edge PMD Screen Unveiled - Revolutionizing Display TechnologyIntroduction:In an era driven by constant technological advancements, Derrick Technologies, a leading player in the industry, has recently revealed a groundbreaking PMD screen. This cutting-edge display technology is set to revolutionize the way we interact with devices, providing users with a seamless and enhanced visual experience. With its innovative features and superior performance, the Derrick FLC 2000 PMD screen is poised to become the new industry standard.[Company Introduction]Derrick Technologies is a trailblazer in the field of display technology, boasting a rich history of providing groundbreaking and innovative solutions. With a deep commitment to pushing the boundaries of visual experiences, the company has consistently delivered state-of-the-art products that have garnered praise and recognition worldwide.Renowned for its extensive research and development facilities, Derrick Technologies has assembled a team of top-notch experts who are dedicated to creating cutting-edge display solutions. With a focus on constant innovation, the company aims to transform the way we interact with digital devices, enhancing their usability and performance.The Derrick FLC 2000 PMD Screen:The Derrick FLC 2000 PMD screen is a game-changer in the world of display technology. Raising the bar for visual quality, this revolutionary screen offers unparalleled levels of clarity, vibrancy, and sharpness. Its advanced pixel management technology ensures the delivery of lifelike images and videos, providing an immersive experience to users.One of the standout features of the FLC 2000 PMD screen is its exceptional brightness. With a peak luminance of 2000 nits, this display effectively eliminates glare and provides superior visibility even in the brightest outdoor environments. This makes it an ideal choice for various applications, including digital signage, outdoor displays, and automotive displays.Moreover, the FLC 2000 PMD screen incorporates cutting-edge anti-reflective technology, significantly reducing reflections and optimizing viewing angles. This ensures that users can enjoy crystal-clear visuals without any distractions or distortions caused by ambient light.Derrick Technologies has also prioritized sustainability in the development of the FLC 2000 PMD screen. By utilizing energy-efficient LED backlighting and intelligent power management systems, the screen minimizes power consumption without compromising on performance. By doing so, Derrick Technologies sets a new benchmark for eco-friendly display solutions.The applications for the FLC 2000 PMD screen are vast and diverse. From enhancing the visual experience in outdoor advertising and digital signage applications to providing safer and more immersive driving experiences through automotive displays, this technology is set to revolutionize a wide range of industries.Looking Ahead:The introduction of the Derrick FLC 2000 PMD screen marks a significant milestone in the evolution of display technology. Derrick Technologies' commitment to pushing the boundaries of visual experiences, coupled with its emphasis on sustainability, reinforces their position as an industry leader.With its exceptional brightness, superior visual quality, and eco-friendly design, the FLC 2000 PMD screen is poised to set a new standard for display technology. Its innovative features promise to enhance user experiences across various sectors, revolutionizing the way we consume visual content.As Derrick Technologies continues to innovate and develop cutting-edge solutions, it is spearheading a future where display technology becomes more immersive, sustainable, and user-centric. The FLC 2000 PMD screen's unveiling is just the beginning of an exciting chapter in the company's quest to redefine the way we perceive and interact with digital displays.

Nov FL2000 Shaker Screens Get High-Powered Upgrades with Cobra Mesh Replacement

report on the benefits and features of the FL2000 Nov Cobra Mesh Replacement Shaker Screens.The oil and gas industry is continually evolving and advancing, with new technology and equipment improving the efficiency and safety of drilling operations. The drilling process is a complex but critical step in oil and gas extraction, requiring specialized and reliable equipment to ensure optimal results. One crucial component of this equipment is the shaker screen, which is used to separate drilling cuttings from the drilling fluids. The FL2000 Nov Cobra Mesh Replacement Shaker Screens offer numerous benefits and features that make them a valuable addition to any drilling operation.These shaker screens are designed to be a direct replacement for the original equipment manufacturer (OEM) screens, specifically the different model cobra shale shaker screens. They are compatible with both the NOV Brandt Cobra and King Cobra shale shakers. Made with high-quality materials and advanced technology, these screens deliver superior performance and durability.One of the key features of the FL2000 Nov Cobra Mesh Replacement Shaker Screens is their use of multi-layered stainless steel wire mesh screens, which are stacked and tightly bonded to increase their strength and resistance to wear and tear. The wire mesh design also provides excellent filtration, removing unwanted solids and debris while allowing drilling fluids to flow through easily. Another significant advantage of these shaker screens is their ability to save drilling companies time and money. With their durable construction and high-quality materials, the FL2000 Nov Cobra Mesh Replacement Shaker Screens can last up to two to three times longer than traditional screens. This longer lifespan means less downtime and replacement costs, allowing drilling operations to run more smoothly and efficiently. Additionally, the innovative design of these shaker screens makes them easy to install and remove, improving overall safety and minimizing the risk of accidents and injuries on the job site. Their lightweight construction and modular design also allow for quick and hassle-free replacement or repair when necessary, minimizing downtime and associated costs. The FL2000 Nov Cobra Mesh Replacement Shaker Screens are also designed with the environment in mind, as they reduce waste and minimize the impact of drilling operations on the natural world. Using these screens helps to reduce the amount of drilling fluids that are lost during the separation process, which is not only more efficient but also helps to minimize the amount of waste and pollution generated by drilling operations. Overall, the FL2000 Nov Cobra Mesh Replacement Shaker Screens are an excellent choice for any drilling operation that values durability, reliability, and efficiency. With their advanced design and high-quality materials, they provide superior performance and longevity, making them a cost-effective and practical investment for any drilling company. In conclusion, the oil and gas industry requires reliable equipment to perform efficient drilling operations. The FL2000 Nov Cobra Mesh Replacement Shaker Screens offer several benefits and features that make them an essential component of any drilling operation. These screens are durable, environmentally friendly, and easy to install and remove, making them a practical solution for any drilling rig. With the use of these screens, drilling companies can improve their efficiency and reduce costs while minimizing their environmental impact.

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Top Primary Screens for the NOV VSM300: Enhancing Efficiency and Performance

release for an oil drilling companyIn the oil drilling industry, having reliable and efficient equipment is crucial in ensuring the success of a drilling operation. One of the most important equipment in this business is the drilling screening system. XYZ Oil Drilling Company understands the importance of having top-of-the-line drilling screening systems that can withstand and operate under the harshest conditions. That is why the company is proud to announce an addition to its equipment line-up- the NOV VSM300 Primary Screen.The NOV VSM300 Primary Screen is meticulously designed and manufactured by National Oilwell Varco (NOV), one of the leading providers of innovative drilling solutions in the world. The NOV VSM300 is recognized in the industry for its efficiency, reliability, and durability, making it the perfect fit to handle the challenging drilling operations that XYZ Oil Drilling Company is known for.The primary screen features a two-bearing design that provides higher throughput, lower maintenance costs, and increased screen life compared to traditional screening systems. Its advanced design has also eliminated several previous challenges related to vibration and noise, making it one of the most sought-after screening systems in the industry.One of the NOV VSM300's key features is its ability to operate with a wide range of drilling fluids, including synthetic-based, oil-based, and water-based. This versatility allows it to handle varying drilling conditions, making it ideal for the needs of the XYZ Oil Drilling Company.The primary screen's mesh size is customizable and can consist of single, double, or even triple-layer configurations to help improve filtration efficiency. The design of the NOV VSM300 Primary Screen also provides for increased energy efficiency, which helps lower operating costs. In addition, the system is built with ease of use in mind and can be installed and maintained quickly, maximizing uptime and productivity.Speaking on the addition of the NOV VSM300 Primary Screen to their equipment lineup, a spokesperson from XYZ Oil Drilling Company said, "At XYZ Oil Drilling, we are committed to providing our clients with the best drilling equipment available. The addition of the NOV VSM300 Primary Screen is part of our ongoing commitment to improve our operations continually. We are thrilled to partner with NOV to bring our clients a new level of productivity and efficiency."The NOV VSM300 Primary Screen is just one of the many top-of-the-line products that XYZ Oil Drilling Company offers its clients. The company provides a comprehensive range of oil drilling services, including drilling, completions, production, and well intervention. It boasts a fleet of modern drilling rigs and highly trained personnel who can operate in all types of drilling environments, making it the go-to company for oil drilling needs.Overall, the addition of the NOV VSM300 Primary Screen by XYZ Oil Drilling Company is a testament to its commitment to providing its clients with the best equipment available. The partnership with NOV has not only raised the bar for drilling screening systems, but it will also improve the company's services, ensuring they remain at the forefront of the oil drilling industry. In conclusion, the NOV VSM300 Primary Screen will play a vital role in ensuring the success of drilling operations for XYZ Oil Drilling Company and its clients. With its advanced features and capabilities, it is a valuable investment that will result in faster, more efficient, and safer drilling operations.

Analyzing the Latest Advancements in Atl 1000 Shaker Screen Technology

In the world of drilling and oil production, the utilization of efficient and high-quality equipment has been a major factor in ensuring the success of operations. Among these pieces of equipment is the shaker screen, which plays a vital role in optimizing the drilling process. A shaker screen is essentially a sieve, which separates the drilling fluids from the solids, thereby decreasing the waste generation and allowing the recyclability of drilling mud. As such, the quality and performance of shaker screens are of utmost importance to companies in the oil and gas industry.One of the top-rated shaker screens in the industry is the Brandt Atl 1000 (brand name removed) shaker screen. This shaker screen boasts of a variety of features that make it stand out from the rest. Its technology and design are based on the latest advancements in the industry, optimizing its performance to meet the demands of drilling operations.The Brandt Atl 1000 shaker screen has been engineered to enhance the separation process of drilling fluids and solids. The screen has a large effective screen area, which translates to a better-solid removal efficiency. In addition, the screen is designed to prevent the clogging of particles, thereby increasing its overall performance.Another feature that makes the Brandt Atl 1000 shaker screen popular among drilling companies is its durability. The screen has been constructed from high-quality materials that ensure it can withstand the harsh conditions that exist in the oil and gas industry. Furthermore, the mesh layers of the screen have been treated with a specialized chemical that protects them from wear and tear, increasing its lifespan.The design of the screen has also been tailored to provide ease of use for the operator. The screen uses a hook-strip feature, which enables its installation or removal to be done in a shorter time period. This feature is crucial as it significantly reduces the downtime, which would have a negative effect on the overall operation.Moreover, the Brandt Atl 1000 shaker screen has a unique labeling system that allows for optimal identification and tracking of the screen’s maintenance and repair history. This feature is important as it ensures that the screen is well-maintained, guaranteeing optimal performance during its lifespan.The Brandt Atl 1000 shaker screen has been embraced by drilling companies worldwide, with positive feedback being received on its performance and durability. In addition, it has been tested and validated to meet the industry standards, with a false-positive rate of less than 5%. This low rate of false positives is essential in ensuring that drilling companies can accurately identify and separate solids from drilling mud.Therefore, the Brandt Atl 1000 shaker screen has become a go-to for drilling companies worldwide, with its high-quality performance, durability, and ease of use being among the top reasons for this. The screen’s design and technology have been optimized to meet the needs of the industry, ensuring that drilling companies can operate efficiently, with minimal waste generation, and maximum yield. While the market for shaker screens is competitive, the Brandt Atl 1000 shaker screen has managed to stand out, with its features enabling it to meet and exceed the expectations of the oil and gas industry.