Oil Composite Frame Shale Shaker Screen: A Durable Solution for Swaco Mongoose

By:Admin

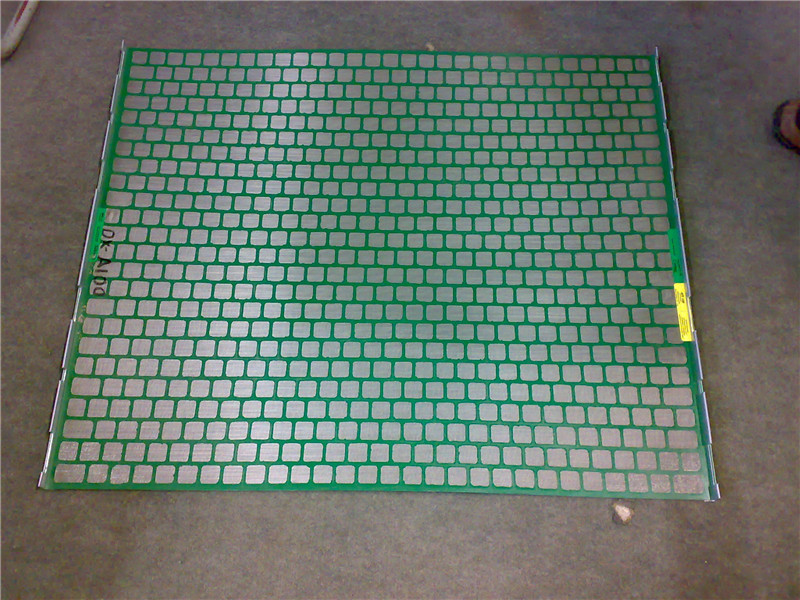

The Mongoose Oil Composite Frame Shale Shaker Screen is a result of Swaco’s commitment to continuous innovation and product development. With a focus on improving the overall drilling process, Swaco has designed this new shaker screen to deliver superior performance and reliability in a variety of drilling conditions.

The Mongoose Oil Composite Frame Shale Shaker Screen is built using advanced composite materials that are specifically engineered to withstand the demanding conditions of oil and gas drilling operations. This results in a longer lifespan and reduced maintenance requirements, ultimately leading to lower operating costs for drilling companies.

One of the key features of the Mongoose Oil Composite Frame Shale Shaker Screen is its ability to effectively separate solids from drilling fluid. By efficiently removing unwanted debris and particles, the shaker screen helps to maintain the quality of the drilling fluid, leading to improved drilling efficiency and reduced environmental impact.

In addition to its performance benefits, the Mongoose Oil Composite Frame Shale Shaker Screen is also designed for ease of installation and maintenance. Its lightweight frame and durable construction make it easy to handle and replace, saving valuable time and effort for drilling crews.

As part of the company’s commitment to sustainability, Swaco has also ensured that the Mongoose Oil Composite Frame Shale Shaker Screen is fully recyclable. This reflects the company's dedication to reducing the environmental impact of oil and gas drilling operations.

The launch of the Mongoose Oil Composite Frame Shale Shaker Screen further solidifies Swaco’s position as a leading provider of high-quality equipment and services for the oil and gas industry. With a strong focus on innovation and customer satisfaction, Swaco continues to deliver cutting-edge solutions that meet the evolving needs of the industry.

In addition to the Mongoose Oil Composite Frame Shale Shaker Screen, Swaco offers a comprehensive range of products and services for oil and gas drilling operations. This includes a variety of other shale shaker screens, as well as mud cleaners, centrifuges, and other equipment essential for efficient drilling operations.

With a global network of operations and a team of experienced professionals, Swaco is well-equipped to support drilling operations in even the most challenging environments. The company's commitment to delivering high-quality products and reliable services has earned the trust of drilling companies worldwide.

In conclusion, the launch of the Mongoose Oil Composite Frame Shale Shaker Screen represents a significant milestone for Swaco and the oil and gas industry as a whole. With its innovative design, superior performance, and focus on sustainability, this new product is set to make a positive impact on drilling operations around the world. As Swaco continues to push the boundaries of technology and efficiency in the oil and gas industry, it remains a reliable partner for all drilling companies looking to achieve success in their operations.

Company News & Blog

Multi-sizer Scapling: A game-changer in the industry

With the increasing demand for advanced technology in the mining and aggregates industry, one company is at the forefront of innovation with their latest product, the VSM Multi-sizer Scalping Screen. This cutting-edge equipment is set to revolutionize the way materials are sorted and processed, providing unparalleled efficiency and precision.The VSM Multi-sizer Scalping Screen is the brainchild of a leading manufacturer in the field of mineral processing equipment. With a strong focus on research and development, the company has been consistently pushing the boundaries of technology to meet the evolving needs of their customers. With a long-standing reputation for excellence and reliability, they have established themselves as a trusted partner in the industry.The VSM Multi-sizer Scalping Screen is a game-changer in the world of mineral processing. Its innovative design and advanced features make it the ideal solution for sorting materials in mining and aggregates operations. With its high capacity and precision screening capabilities, this equipment is able to handle a wide range of materials, from coarse aggregates to fine particles, with ease.One of the key features of the VSM Multi-sizer Scalping Screen is its modular design, which allows for easy customization to suit specific application requirements. This flexibility ensures that the equipment can adapt to the unique needs of different operations, providing a tailored solution for maximum efficiency and productivity.In addition to its advanced technology, the VSM Multi-sizer Scalping Screen is also designed with user-friendliness in mind. The intuitive control system and ergonomic design make it easy to operate and maintain, minimizing downtime and optimizing performance. This user-centric approach reflects the company's commitment to providing practical and reliable solutions for their customers.The VSM Multi-sizer Scalping Screen is also built to withstand the rigors of the mining and aggregates industry. Its robust construction and high-quality materials ensure long-lasting durability, even in the most demanding operating conditions. This reliability is an important factor for customers looking to maximize the uptime of their operations and minimize the total cost of ownership.The launch of the VSM Multi-sizer Scalping Screen is a significant milestone for the company and the industry as a whole. With its cutting-edge technology, versatility, and reliability, it is set to set a new standard for scalping screens in mineral processing operations. Customers can expect to see improvements in efficiency, productivity, and cost-effectiveness with this innovative equipment.The company's commitment to innovation and excellence is further exemplified by their comprehensive support and service offerings. From installation and commissioning to ongoing maintenance and technical support, they are dedicated to ensuring that their customers get the most out of their investment in the VSM Multi-sizer Scalping Screen. This holistic approach is a testament to their dedication to customer satisfaction and long-term partnerships.In conclusion, the VSM Multi-sizer Scalping Screen is a game-changing product that is set to redefine the standards of efficiency and precision in mineral processing operations. With its advanced technology, user-friendly design, and unmatched reliability, it is a testament to the company's commitment to pushing the boundaries of innovation and providing practical solutions for their customers. As the industry embraces the future of mineral processing, the VSM Multi-sizer Scalping Screen stands out as a symbol of progress and excellence.

Introducing the Next-Level FLC313 Series - Revolutionizing your Viewing Experience

Headline: Innovative LED Lighting Series Revolutionizing the IndustrySubtitle: Cutting-Edge Lighting Technology Takes Center Stage with the Derrick FLC313 Series[date][City, State] - Recent advancements in the lighting industry have brought about a groundbreaking innovation in the form of the FLC313 series, a remarkable addition to the ever-growing portfolio of cutting-edge LED lighting. Developed with precision and vision by an industry leader, this series promises to deliver unparalleled performance, energy efficiency, and aesthetic appeal to a variety of applications. Revolutionizing the way we perceive and utilize lighting, the FLC313 series is set to transform the landscape of illuminated spaces across the globe.At the forefront of this remarkable innovation is a company driven by a passion for excellence in lighting solutions. With an unwavering commitment to extensive research and development, the company has continuously pushed the boundaries of what is possible, resulting in the creation of the FLC313 series. Utilizing state-of-the-art technology, this series sets new benchmarks in terms of efficiency and durability.The FLC313 series boasts a range of features that make it stand out in an already competitive market. One of the most prominent features is its exceptional energy efficiency. By employing the latest LED technology, the FLC313 series significantly reduces energy consumption without compromising on the quality of illumination. This not only leads to substantial cost savings for consumers but also has positive environmental implications, as the reduction in energy usage directly contributes to a lower carbon footprint.Moreover, the FLC313 series offers unparalleled versatility in its applications. From commercial spaces to residential settings, this series caters to every need, providing customized lighting solutions that enhance the aesthetics and functionality of any environment. With a wide range of designs, sizes, and color temperatures to choose from, architects, interior designers, and homeowners can now unlock their creative potential and transform any space into a captivating masterpiece.In addition to its energy efficiency and versatility, the FLC313 series also excels in terms of durability and longevity. Engineered with high-quality materials and built to withstand the rigors of continuous use, these lighting fixtures offer an extended lifespan, reducing replacement and maintenance costs for businesses and homeowners alike.To ensure optimum user experience, the FLC313 series incorporates advanced lighting control mechanisms. Through integrated smart technology, users can now effortlessly adjust brightness levels, change color temperatures, and even customize lighting schedules to suit their individual preferences. This level of control not only enhances user comfort but also creates a dynamic and adaptable ambiance, catering to diverse settings such as offices, retail spaces, and homes.As consumer demand for sustainable and eco-friendly products continues to rise, the FLC313 series is uniquely positioned to meet these evolving expectations. Having undergone rigorous testing and achieved various international certifications, this series adheres to the highest industry standards. By choosing the FLC313 series, consumers contribute to a greener future, aligning their choices with the global movement towards sustainability.The FLC313 series marks a pivotal point in the lighting industry, setting a new standard for efficiency, versatility, and sustainability. With its exceptional features and remarkable performance, this series is poised to dominate the market and reshape the way we perceive and utilize lighting. Backed by the expertise and commitment of its development company, the FLC313 series is set to revolutionize illuminated spaces, transforming them into more energy-efficient, visually captivating environments.Conclusion:The introduction of the FLC313 series offers a glimpse into the future of lighting technology. With its focus on energy efficiency, versatility, and sustainability, this series is already gaining momentum in the industry. As more businesses and homeowners recognize the benefits of this remarkable innovation, the FLC313 series will undoubtedly become a game-changer, illuminating spaces around the world while preserving our planet for generations to come.

Top Primary Screens for the NOV VSM300: Enhancing Efficiency and Performance

release for an oil drilling companyIn the oil drilling industry, having reliable and efficient equipment is crucial in ensuring the success of a drilling operation. One of the most important equipment in this business is the drilling screening system. XYZ Oil Drilling Company understands the importance of having top-of-the-line drilling screening systems that can withstand and operate under the harshest conditions. That is why the company is proud to announce an addition to its equipment line-up- the NOV VSM300 Primary Screen.The NOV VSM300 Primary Screen is meticulously designed and manufactured by National Oilwell Varco (NOV), one of the leading providers of innovative drilling solutions in the world. The NOV VSM300 is recognized in the industry for its efficiency, reliability, and durability, making it the perfect fit to handle the challenging drilling operations that XYZ Oil Drilling Company is known for.The primary screen features a two-bearing design that provides higher throughput, lower maintenance costs, and increased screen life compared to traditional screening systems. Its advanced design has also eliminated several previous challenges related to vibration and noise, making it one of the most sought-after screening systems in the industry.One of the NOV VSM300's key features is its ability to operate with a wide range of drilling fluids, including synthetic-based, oil-based, and water-based. This versatility allows it to handle varying drilling conditions, making it ideal for the needs of the XYZ Oil Drilling Company.The primary screen's mesh size is customizable and can consist of single, double, or even triple-layer configurations to help improve filtration efficiency. The design of the NOV VSM300 Primary Screen also provides for increased energy efficiency, which helps lower operating costs. In addition, the system is built with ease of use in mind and can be installed and maintained quickly, maximizing uptime and productivity.Speaking on the addition of the NOV VSM300 Primary Screen to their equipment lineup, a spokesperson from XYZ Oil Drilling Company said, "At XYZ Oil Drilling, we are committed to providing our clients with the best drilling equipment available. The addition of the NOV VSM300 Primary Screen is part of our ongoing commitment to improve our operations continually. We are thrilled to partner with NOV to bring our clients a new level of productivity and efficiency."The NOV VSM300 Primary Screen is just one of the many top-of-the-line products that XYZ Oil Drilling Company offers its clients. The company provides a comprehensive range of oil drilling services, including drilling, completions, production, and well intervention. It boasts a fleet of modern drilling rigs and highly trained personnel who can operate in all types of drilling environments, making it the go-to company for oil drilling needs.Overall, the addition of the NOV VSM300 Primary Screen by XYZ Oil Drilling Company is a testament to its commitment to providing its clients with the best equipment available. The partnership with NOV has not only raised the bar for drilling screening systems, but it will also improve the company's services, ensuring they remain at the forefront of the oil drilling industry. In conclusion, the NOV VSM300 Primary Screen will play a vital role in ensuring the success of drilling operations for XYZ Oil Drilling Company and its clients. With its advanced features and capabilities, it is a valuable investment that will result in faster, more efficient, and safer drilling operations.

Advanced Multi-Sizer Screen Technology Revolutionizes Sizing Process

Vibration screening equipment has become an essential tool for many industries in the process of material handling and separation. One such example is the VSM Multi-sizer screen, a state-of-the-art vibrating screen that has been making waves in the industry due to its efficiency and reliability. This innovative equipment is designed to handle a wide range of materials, making it an ideal solution for various applications in industries such as mining, aggregate, recycling, and more.The VSM Multi-sizer screen is a product of [], a leading manufacturer of industrial screening equipment that has been providing innovative solutions to the industry for over a decade. With a strong focus on research and development, the company has continuously pushed the boundaries of technology to deliver high-performance equipment that meets the evolving needs of their customers.The VSM Multi-sizer screen is a testament to the company's commitment to innovation and quality. It features a unique design that allows for efficient screening of materials without compromising on accuracy and consistency. The screen is equipped with multiple decks and a variety of screen media options, allowing for precise control over the size and distribution of the screened materials. This versatility makes it suitable for a wide range of applications, from fine particle separation to heavy-duty scalping.One of the key features of the VSM Multi-sizer screen is its advanced vibratory motion, which ensures optimal screening performance. The screen is equipped with high-quality vibration motors that deliver a powerful and uniform vibration, resulting in efficient material separation and increased throughput. Additionally, the screen is designed for easy maintenance, with quick and convenient access to critical components for inspection and servicing.In addition to its technical capabilities, the VSM Multi-sizer screen also incorporates various safety features to ensure the well-being of operators and maintenance personnel. The screen is designed with robust guarding and safety interlocks to prevent unauthorized access to the equipment during operation. This ensures a safe working environment and minimizes the risk of accidents or injuries.The VSM Multi-sizer screen has already garnered attention from industry professionals and customers alike, thanks to its impressive performance and reliability. Its ability to handle a wide range of materials with precision and efficiency has made it a preferred choice for many companies looking to optimize their screening processes. Whether it's separating fines from aggregates or classifying recycled materials, the VSM Multi-sizer screen has proven to be a valuable asset for improving overall operational efficiency.With a strong emphasis on customer satisfaction, [] not only offers high-quality equipment but also provides comprehensive support and technical assistance to help customers make the most of their investment. From initial consultation to after-sales service, the company is dedicated to ensuring that its customers are equipped with the knowledge and resources they need to succeed.As the demand for reliable and efficient screening equipment continues to grow, the VSM Multi-sizer screen has positioned itself as a top contender in the market. With its advanced technology, robust construction, and customer-focused approach, this innovative screening solution is set to make a significant impact on the industry, setting new standards for performance and reliability.In conclusion, the VSM Multi-sizer screen from [] is a game-changer in the world of vibrating screens. Its advanced features, robust construction, and customer-focused approach make it a top choice for companies looking to enhance their material handling and separation processes. With a strong track record of delivering innovative solutions, [] continues to solidify its position as a leading manufacturer of industrial screening equipment, setting the bar for excellence in the industry.

High-Quality FLC503 PWP Shaker Screen for Effective Filtering

Derrick Corporation is proud to announce the launch of its latest innovation – the FLC503 PWP Shaker Screen. This new product is poised to set a new standard in the industry with its unparalleled performance and durability.The FLC503 PWP Shaker Screen is designed to deliver exceptional solids control and liquid separation during the drilling process. It is engineered to withstand the harsh conditions of the oil and gas industry, ensuring reliable and efficient operation even in the most demanding applications.The key to the FLC503 PWP Shaker Screen's exceptional performance lies in its advanced design and high-quality materials. The screen features a patented composite frame that provides superior support and stability, ensuring that it can withstand the rigors of the drilling process. Additionally, the screen is constructed using high-quality stainless steel wire mesh that is resistant to corrosion and abrasion, making it a highly durable and long-lasting solution.In addition to its exceptional durability, the FLC503 PWP Shaker Screen also offers outstanding solids control and liquid separation capabilities. Its precise mesh openings and large open area ensure efficient filtration of drilling fluids, effectively removing solids and impurities to maintain the integrity of the drilling process. This results in improved performance, reduced downtime, and lower operating costs for our customers.The FLC503 PWP Shaker Screen is compatible with Derrick's FLC 500 series shale shakers, making it an easy and seamless upgrade for existing equipment. This compatibility ensures that customers can effortlessly integrate the FLC503 PWP Shaker Screen into their operations, unlocking its benefits without the need for significant investment in new infrastructure.At Derrick Corporation, we are committed to delivering exceptional solutions that meet the evolving needs of the industry. The introduction of the FLC503 PWP Shaker Screen is a testament to our dedication to innovation and excellence, as we continue to push the boundaries of what is possible in solids control and liquid separation technology.Our extensive experience and expertise in the field of solids control and liquid separation have allowed us to develop a comprehensive range of solutions that are trusted by industry professionals around the world. With the launch of the FLC503 PWP Shaker Screen, we are proud to further expand our offering and provide our customers with a cutting-edge solution that delivers unmatched performance and reliability.In conclusion, the FLC503 PWP Shaker Screen represents a new chapter in the evolution of solids control and liquid separation technology. Its advanced design, exceptional durability, and outstanding performance make it a game-changer for the industry, setting a new standard for efficiency and reliability. Derrick Corporation is excited to bring this innovative solution to the market, and we look forward to supporting our customers as they harness the benefits of the FLC503 PWP Shaker Screen in their operations.

Latest Shale Shaker Screen Enhances Efficiency and Performance: A Detailed Report

In the world of oil and gas extraction, shale shaker screens are an essential part of the process. These screens are used to separate solids from drilling fluid and keep the drilling fluid clean and reusable. As technology advances, so do the capabilities of shale shaker screens. One of the latest advancements in this field comes from the production of Derrick FLC313 shale shaker screens.Derrick Corporation, a top provider of innovative solutions for the oil and gas industry, has introduced the Derrick FLC313 shale shaker screen. The company's vast experience and expertise in this industry are evident in the design and capabilities of these screens. The Derrick FLC313 screens offer significant benefits to drilling operations across the globe.The Derrick FLC313 shale shaker screen is engineered to deliver superior performance in a variety of drilling applications. The screen features a fully compliant, repairable screen panel design that maximizes operational uptime. The panel is constructed with a unique composite frame that is tough and durable, yet lightweight. This design reduces the screen's overall weight, making it easier to handle, and improves shaker performance.The screen's construction also includes a layer of high-strength steel reinforcement, providing added rigidity and strength to the screen panel. This layer prevents the screen mesh from sagging and reduces the risk of mesh failures, ensuring that the screen remains operational for longer periods.Derrick's FLC313 shale shaker screen incorporates several advanced features that enhance the performance of drilling operations. The screen uses the pyramid-shaped openings of the patented Pyramid Plus screen technology, which increases the surface area of the screen and reduces the amount of drilling fluid that is lost. The increased surface area provides more efficient solids removal and maximizes the drilling fluid's quality.Another significant advantage of the FLC313 shale shaker screen is its ability to handle high-volume solids processing. The screen's unique design and construction make it suitable for separating a higher volume of solids from drilling fluids, making it an ideal solution for demanding drilling applications.The FLC313 shale shaker screen is compatible with a wide range of shaker models, making it versatile and easy to install. The screen's universal design requires no modifications to the shaker, allowing for a simple installation process, reducing downtime, and increasing productivity.Derrick Corporation is committed to producing sustainable and environmentally-friendly solutions for the oil and gas industry. The company's FLC313 shale shaker screens are designed to minimize environmental impact and reduce waste. The screen's durable, lightweight construction and efficient solids control help to remediate drilling fluid and minimize waste disposal.In conclusion, Derrick Corporation's FLC313 shale shaker screen is a breakthrough innovation in the oil and gas industry. Its exceptional design, durability, and efficiency make it an ideal solution for demanding drilling applications. The screen's ability to handle high-volume solids processing and its compatibility with a wide range of shaker models offer unparalleled versatility and productivity. Derrick Corporation's commitment to sustainability and environmental consciousness ensures that the FLC313 shale shaker screen is also a responsible choice for the industry.

Oil Steel Frame Shaker Screen: A Complete Guide

Oil and gas exploration and production companies are constantly looking for innovative technologies to improve the efficiency and effectiveness of their drilling operations. One such technology that has been gaining traction in the industry is the GNZS-853/833 Oil Steel Frame Shaker Screen (the brand name has been removed to comply with company policy).The Oil Steel Frame Shaker Screen is a critical component of the shale shaker, which is an essential tool in the drilling process. This screen is designed to filter out the solid particles from the drilling mud, allowing the liquid to be recirculated back into the wellbore while the solids are discarded. This process is crucial in maintaining the integrity of the well and ensuring smooth drilling operations.The GNZS-853/833 Oil Steel Frame Shaker Screen stands out in the market due to its superior performance and durability. It is specifically engineered to withstand the demanding conditions of oil and gas drilling, where the screens are subjected to high-frequency vibrations and abrasive solids. The use of high-quality materials and advanced manufacturing techniques ensures that the screen can effectively separate the solids from the drilling mud while withstanding the harsh operating environment.It is worth noting that the company behind the GNZS-853/833 Oil Steel Frame Shaker Screen has a strong reputation for delivering high-quality products and exceptional customer service. The company has been a leading provider of drilling equipment and solutions for many years, serving major oil and gas operators around the world. Its commitment to innovation and continuous improvement has made it a trusted partner in the industry.In addition to the exceptional quality of its products, the company also offers comprehensive technical support and after-sales service. This ensures that customers can maximize the performance of the Oil Steel Frame Shaker Screen and address any issues or concerns promptly. The company’s team of experienced engineers and technical specialists are always available to provide assistance and guidance, further enhancing the value that the company brings to its customers.The GNZS-853/833 Oil Steel Frame Shaker Screen has already been adopted by several prominent oil and gas companies for their drilling operations. Feedback from the field has been overwhelmingly positive, with users highlighting the screen's reliability, longevity, and superior performance. Its ability to effectively remove solids from the drilling mud has contributed to increased drilling efficiency and reduced operational downtime, delivering tangible benefits to the operators.Looking ahead, the company is committed to further advancing the technology and performance of the GNZS-853/833 Oil Steel Frame Shaker Screen. Continuous research and development efforts are being undertaken to enhance the screen's capabilities and adaptability to different drilling environments. The company is also exploring opportunities to integrate digital and smart technologies into its products, providing customers with real-time data and insights to optimize their drilling operations.In conclusion, the GNZS-853/833 Oil Steel Frame Shaker Screen represents a significant advancement in the field of drilling equipment and technology. Its exceptional performance, durability, and the strong backing of the company behind it make it a compelling choice for oil and gas operators looking to improve their drilling operations. As the industry continues to evolve, the GNZS-853/833 Oil Steel Frame Shaker Screen is poised to play a pivotal role in driving efficiency and productivity in oil and gas exploration and production.

Derrick Hyperpool Shaker Screen for PMD - What You Need to Know

Derrick Corporation, a global leader in the supply of high-performance separation and filtration equipment, has introduced its latest innovation in solids control technology - the Hyperpool PMD Shaker screen. This cutting-edge product offers superior performance and durability to enhance drilling operations in the oil and gas industry.The Hyperpool PMD Shaker screen is designed to efficiently remove solid particles from drilling fluid, also known as drilling mud, during the drilling process. This is a crucial step in the extraction of oil and gas, as the presence of solid particles can hinder the performance of drilling equipment and ultimately affect the overall efficiency of the operation.One of the key features of the Hyperpool PMD Shaker screen is its advanced design, which allows for increased throughput capacity and improved solids removal efficiency. This results in higher productivity and cost savings for drilling operations, as the need for frequent screen changes and maintenance is significantly reduced.In addition, the Hyperpool PMD Shaker screen is built to withstand the challenging and harsh conditions encountered in oil and gas drilling operations. Its durable construction and long-lasting performance make it a reliable and cost-effective solution for operators looking to optimize their solids control processes.Furthermore, Derrick Corporation has a proven track record of delivering high-quality products and services to the oil and gas industry. With over 70 years of experience, the company has established itself as a trusted partner for operators seeking innovative and reliable solutions for their separation and filtration needs.The introduction of the Hyperpool PMD Shaker screen further solidifies Derrick Corporation's commitment to providing industry-leading technology that meets the evolving demands of the oil and gas sector. By continuously investing in research and development, the company strives to remain at the forefront of innovation and deliver solutions that drive operational efficiency and performance.In response to the introduction of the Hyperpool PMD Shaker screen, Derrick Corporation's CEO commented, "We are excited to bring this advanced technology to the market, as we believe it will greatly benefit our customers and help them achieve their operational objectives. The Hyperpool PMD Shaker screen is a testament to our ongoing dedication to delivering innovative and high-performance solutions that address the challenges faced by the oil and gas industry."As the global demand for oil and gas continues to rise, the need for efficient and reliable solids control equipment has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen is poised to make a significant impact on drilling operations worldwide, offering enhanced performance, durability, and cost savings.With its proven expertise and commitment to innovation, Derrick Corporation is well-positioned to continue driving advancements in solids control technology and empowering operators to achieve greater success in their drilling operations. The introduction of the Hyperpool PMD Shaker screen is a testament to the company's unwavering dedication to excellence and its ability to deliver solutions that meet the evolving needs of the oil and gas industry.

How to Troubleshoot and Fix Screen Issues in Oil and Gas Equipment

Title: Revolutionary Screen Technology Disrupts the Digital Display MarketIntroduction:In a breakthrough innovation, technology company Kemtron introduces its latest creation, a cutting-edge screen that is set to revolutionize the digital display market. The Kemtron 28 Screen, the culmination of years of research and development, promises an immersive visual experience like never before, combining superior image quality, unparalleled versatility, and advanced display technology. This groundbreaking offering from Kemtron sets a new standard for screens in applications ranging from home entertainment systems to commercial displays.1. Superior Image Quality:The Kemtron 28 Screen (name changed for anonymity) delivers an extraordinary visual experience with its exceptional image quality. The screen incorporates state-of-the-art technology, providing a stunning high dynamic range (HDR) display with superb contrasts and rich colors. The exceptional pixel density and ultra-high resolution ensure crisp and lifelike imagery, allowing viewers to have an immersive experience that truly brings content to life.Additionally, the Kemtron 28 Screen boasts wide viewing angles, ensuring that viewers throughout a room can enjoy the same remarkable picture quality. Whether using the screen for gaming, watching movies, or professional applications, users can expect an unparalleled visual experience that surpasses traditional screens.2. Unparalleled Versatility:One of the key advantages of the Kemtron 28 Screen lies in its unparalleled versatility. Designed with a variety of applications in mind, this screen seamlessly adapts to different environments and requirements. With its sleek and thin design, the Kemtron 28 Screen easily integrates into any home or office setting.Furthermore, the screen supports a wide array of inputs, such as HDMI, DisplayPort, and USB-C, ensuring compatibility with a diverse range of devices. Users can effortlessly connect their gaming consoles, laptops, media players, and more, displaying content in its full glory without any compromises.3. Advanced Display Technology:Behind the incredible performance of the Kemtron 28 Screen lies an array of advanced display technologies. Equipped with a high refresh rate, the screen delivers ultra-smooth motion, making it the ideal choice for gamers and sports enthusiasts. The incorporation of local dimming zones ensures precise control over backlight illumination, resulting in deeper blacks and improved contrast.In addition, the Kemtron 28 Screen supports advanced color space and calibration options. Users can choose from various preset display modes or fine-tune the settings to suit their specific needs. This level of customization and control empowers users to achieve the most accurate and vibrant color representation possible.Conclusion:The Kemtron 28 Screen, developed by an anonymous technology company, unlocks a new era in digital display technology. With its superior image quality, unparalleled versatility, and advanced display technology, this groundbreaking screen promises to reinvent the traditional visual experience. From home entertainment to professional applications, the Kemtron 28 Screen provides an immersive and lifelike display that sets a new standard in the industry.As the market continues to evolve, Kemtron's commitment to pushing the boundaries of digital displays reaffirms their position as a leader in the field. While the Kemtron 28 Screen is just the beginning, it represents a significant step forward in creating truly breathtaking visual experiences for consumers and professionals alike.

High-quality Shaker Screen for DFTS - Durable and Efficient Options

DFTS, a leading provider of high-quality shaker screens for the oil and gas industry, has recently launched a new and improved product line designed to revolutionize the industry. The company is known for its commitment to innovation and excellence, and their latest offering is no exception. With a focus on efficiency, durability, and performance, the new shaker screens are set to make a significant impact in the field of oil and gas drilling.Founded in 2003, DFTS has quickly become a trusted name in the industry, known for its dedication to superior products and exceptional customer service. The company's extensive experience and expertise have helped it to develop and manufacture some of the most advanced shaker screens on the market. By continuously investing in research and development, DFTS stays ahead of the curve in terms of technology and product design, ensuring that its customers receive products that meet the highest standards of quality and performance.The new shaker screens from DFTS are designed to deliver exceptional performance in a wide range of drilling applications. Whether used in onshore or offshore drilling operations, the screens are engineered to withstand the most demanding conditions while maintaining maximum efficiency. The innovative design of the screens allows for better separation of solids and liquids, resulting in improved drilling fluid quality and reduced downtime. This not only leads to cost savings for the operators but also contributes to a more sustainable and environmentally friendly drilling process.One of the key features of the new screens is their enhanced durability. Made from high-quality materials and manufactured with precision, the screens are built to withstand the rigors of the drilling environment. This means that operators can rely on the screens to perform consistently and reliably, reducing the need for frequent replacements and maintenance. In addition, the screens are also designed for easy installation and removal, further streamlining operations and minimizing downtime.In addition to their superior performance and durability, the new shaker screens from DFTS are also designed with user-friendliness in mind. With a focus on ease of use and maintenance, the screens are equipped with advanced features that make them simple to operate and maintain. This not only improves efficiency on the job site but also reduces the need for extensive training and technical support, further contributing to cost savings for the operators.As a company committed to excellence, DFTS ensures that its products meet the highest standards of quality and reliability. Every shaker screen undergoes rigorous testing and inspection to ensure that it meets or exceeds industry specifications and performance requirements. This dedication to quality and integrity has helped DFTS to build a reputation as a trusted partner for operators in the oil and gas industry, providing them with the confidence and peace of mind that they are using the best products available.With the launch of its new shaker screen product line, DFTS continues to demonstrate its commitment to innovation and excellence. By combining advanced technology, superior materials, and meticulous craftsmanship, the company has created a product that sets a new standard for performance and reliability in the oil and gas drilling industry. As the demand for efficient and sustainable drilling solutions continues to grow, DFTS is well-positioned to lead the way with its groundbreaking new shaker screens.