Introducing the Latest Innovation: Atl 1000 Shaker Screen Unveils Revolutionary Features

By:Admin

Introduction:

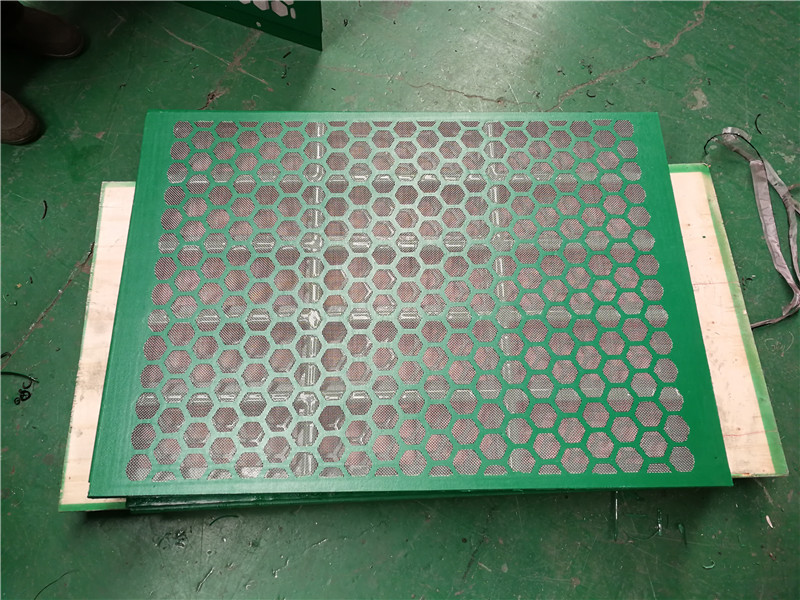

The oil and gas industry plays a vital role in global energy production. To support the extraction process, cutting-edge equipment and technologies are continuously being introduced to improve efficiency and productivity. In this context, the Brandt Atl 1000 Shaker Screen is making a significant impact on solid control, serving as a game-changer for oil and gas drilling operations around the world.

Revolutionizing Solid Control:

Solid control is a crucial stage in drilling operations that involves the separation of drilling fluids from solid particles. The efficiency and reliability of solid control technology directly impact the overall drilling performance, environmental safety, and cost-effectiveness of oil and gas projects. The Brandt Atl 1000 Shaker Screen, developed by a renowned industry leader, is designed to optimize this process, offering improved performance, durability, and enhanced solids removal capacity.

Enhanced Performance:

The Atl 1000 Shaker Screen is designed with advanced engineering techniques to maximize performance. It boasts a larger usable screen area, allowing for higher throughput and improved fluid handling capabilities. The increased screen area enhances the shaker's ability to remove a higher volume of solid particles from drilling fluids, leading to enhanced drilling operations' efficiency and reduced downtime.

Superior Build Quality:

Durability is a key concern when choosing solid control equipment in the oil and gas industry. The Atl 1000 Shaker Screen is meticulously crafted using state-of-the-art materials and manufacturing processes. Its robust build quality ensures prolonged operational life, reducing the need for frequent replacements and enhancing cost-effectiveness. The shaker screens are engineered to withstand demanding drilling conditions, such as high temperatures, extreme pressure differentials, and abrasive drilling fluids, making them highly reliable and efficient.

Optimized Solids Removal:

Efficient solids separation is critical for maintaining drilling fluids' quality and minimizing environmental impact in oil and gas operations. The Brandt Atl 1000 Shaker Screen exhibits exceptional solids removal efficiency, thanks to its unique design features. Its innovative mesh configuration and mesh bonding technique provide superior resistance to blinding and plug formation, ensuring consistent performance and extended screen life. This results in cleaner drilling fluids, reduced waste disposal costs, and a smaller environmental footprint.

Industry-Leading Technology:

The Brandt Atl 1000 Shaker Screen is backed by extensive research, development, and testing processes conducted by a highly reputed company. The manufacturer combines years of industry experience, engineering expertise, and customer feedback to continually improve their product offerings. By incorporating the latest technological advancements, the Atl 1000 Shaker Screen sets a new industry standard for solid control solutions.

Global Impact:

With its exceptional performance and reliability, the Brandt Atl 1000 Shaker Screen has garnered significant attention and gained global recognition. Oil and gas operators across various geographic regions have embraced this innovative technology to streamline their drilling operations. The shaker screen's international adoption affirms its effectiveness in delivering optimized solid control and environmental compliance, translating into enhanced operational efficiency and profitability for drilling projects worldwide.

Conclusion:

As the oil and gas industry continues to evolve, the importance of advanced solid control solutions cannot be overstated. The Brandt Atl 1000 Shaker Screen, with its superior performance, durability, and optimized solids removal capacity, offers a compelling solution to the industry's needs. With its efficient particle separation capabilities, enhanced fluid handling, and reduced downtime, the Atl 1000 Shaker Screen sets a new benchmark, revolutionizing solid control in the oil and gas sector. As drilling operations strive for increased productivity, environmental protection, and cost-effectiveness, this cutting-edge technology serves as a significant asset, enabling oil and gas companies to achieve their goals efficiently and sustainably.

Company News & Blog

Discover the Advantages of a Secondary Screen for Increased Productivity

Introducing the Future of Secondary Screen TechnologyIn a world where technological advancements are constantly pushing the boundaries of what we thought was possible, Brandt Secondary Screen presents a game-changing innovation that is set to revolutionize the way we interact with our devices. This cutting-edge secondary screen technology offers users a whole new level of productivity, creativity, and convenience.Secondary screens have long been used as an additional display for laptops and desktop computers. However, the Brandt Secondary Screen takes this concept to a whole new level by offering a seamless integration with a wide range of devices including smartphones, tablets, and even gaming consoles. With its sleek design and state-of-the-art features, this secondary screen provides an immersive and intuitive user experience.One of the key features of the Brandt Secondary Screen is its versatility. Whether you are a professional looking to enhance your productivity or a gamer seeking an immersive gaming experience, this secondary screen has got you covered. With its easy-to-use interface and customizable settings, users can effortlessly switch between different modes depending on their specific needs. Whether it's extending your display for multi-tasking, mirroring your screen for presentations, or even using it as a dedicated control panel for gaming, the possibilities are endless.The Brandt Secondary Screen also offers advanced connectivity options, allowing users to seamlessly connect their devices. With wireless technology at its core, users can effortlessly mirror their screens without the hassle of cables. This wireless connectivity extends to a wide range of devices, making it an ideal companion for those who are constantly on the move.Furthermore, the Brandt Secondary Screen boasts an impressive display resolution and color accuracy, ensuring stunning visuals and vibrant colors. Whether you are editing photos, watching movies, or playing games, the sharp and vibrant display will truly elevate your viewing experience.Another standout feature of the Brandt Secondary Screen is its portability. With its slim and lightweight design, it can easily be carried around in a bag or backpack, making it a perfect travel companion. Gone are the days of lugging around bulky monitors or struggling with limited screen space. The Brandt Secondary Screen offers a portable solution that doesn't compromise on performance or functionality.In addition to its impressive features, the Brandt Secondary Screen is also environmentally conscious. With energy-saving technologies and eco-friendly materials, this secondary screen strives to minimize its carbon footprint. By choosing this innovative technology, users can not only enjoy its numerous benefits but also contribute to a greener future.The future of secondary screen technology is here, and it is embodied by the Brandt Secondary Screen. With its versatility, connectivity options, stunning display, portability, and eco-friendly approach, this secondary screen is set to redefine the way we interact with our devices. Whether you are a professional, a student, or a creative individual, the Brandt Secondary Screen is a must-have gadget that will undoubtedly enhance your productivity, creativity, and overall user experience. Get ready to embark on a new era of secondary screen technology with the Brandt Secondary Screen!

Enhanced Cutting Dryer Shaker: Unveiling an Advanced Solution for Efficient Drying

Title: Innovative Hi-G Cutting Dryer Shaker Revolutionizes the Drilling IndustryIntroduction:In today's rapidly evolving drilling industry, the demand for efficient and environmentally friendly solutions has become more crucial than ever before. In response to this growing need, a cutting-edge drilling equipment manufacturer (company name to be removed) has recently unveiled its game-changing Hi-G Cutting Dryer Shaker. This revolutionary technology aims to enhance the overall performance and sustainability of drilling operations, solidifying the company's position as an industry leader. Let's delve deeper into the features and benefits of this cutting-edge device.Body:1. Overview of the Hi-G Cutting Dryer Shaker:The Hi-G Cutting Dryer Shaker is an advanced solids control system designed to effectively separate and remove drilling waste solids, such as cuttings, from drilling fluid. This innovative solution utilizes a high-speed vertical cutting dryer and a highly efficient shaker screen, offering significant advantages over traditional drying equipment.2. State-of-the-art Drying Technology:The Hi-G Cutting Dryer Shaker employs an innovative centrifugal force mechanism to remove moisture from the solids, facilitating efficient waste management. This high-speed vertical cutting dryer effectively reduces the moisture content, enabling the recovered drilling fluid to be reused, resulting in substantial cost savings and environmental benefits.3. Enhanced Performance and Efficiency:With its cutting-edge technology, the Hi-G Cutting Dryer Shaker delivers unparalleled performance and efficiency. The device is equipped with a large-capacity screen, allowing for higher throughput and increased separation efficiency. By effectively removing solids from the drilling fluid, the system minimizes operational downtime, boosting overall drilling efficiency.4. Application Across Various Drilling Environments:The versatility of the Hi-G Cutting Dryer Shaker allows it to be used across a wide range of drilling environments, including oil and gas exploration, trenchless drilling, and geothermal drilling. Its adaptability showcases the device's robustness in handling various drilling waste materials, enabling efficient solids control and waste management.5. Environmental Impact and Sustainability:The Hi-G Cutting Dryer Shaker prioritizes environmental sustainability throughout its design and operation. By efficiently separating and drying drilling waste solids, it significantly reduces the volume of waste generated. Additionally, the recovered drilling fluid can be reused, minimizing the need for fresh fluid and reducing overall environmental impact.6. Safety Measures and Compliance:Safety is a paramount concern in any drilling operation. The Hi-G Cutting Dryer Shaker addresses this concern by incorporating multiple safety features. The device is equipped with an automatic overload protection system, ensuring safe and reliable operation even under high load conditions. Moreover, it adheres to industry standards and regulations, guaranteeing compliance and peace of mind for operators.7. Cost-effectiveness and Economic Advantages:Implementing the Hi-G Cutting Dryer Shaker can yield substantial economic advantages for drilling companies. By reducing waste volumes and reusing drilling fluid, operators can significantly decrease waste management costs and material usage expenses. Furthermore, the enhanced operational efficiency and minimized downtime lead to increased drilling productivity and ultimately, improved profitability.Conclusion:The introduction of the Hi-G Cutting Dryer Shaker marks a significant milestone in the drilling industry's pursuit of efficient and sustainable solutions. This cutting-edge technology offers unparalleled performance, adaptability, and environmental benefits, solidifying the position of (company name to be removed) as a frontrunner in the field of drilling equipment manufacturing. As drilling operations continue to evolve, the Hi-G Cutting Dryer Shaker stands poised to revolutionize waste management practices and enhance drilling efficiency across various industry sectors.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

Upgrading Your Shaker Screens: Tips for Replacing and Choosing the Right Screens

Replacement Shaker Screens Transforming the Oil and Gas IndustryIn the ever-evolving oil and gas industry, technological advancements play a crucial role in optimizing efficiency and productivity. And one company at the forefront of this transformation is a leading innovator in the field of replacement shaker screens. By combining cutting-edge technology with a deep understanding of industry needs, this company is revolutionizing the way drilling fluids are filtered and processed.With global demand for oil and gas continuing to rise, drilling operations have become more complex and challenging. The extraction process involves drilling deep into the earth's crust, often in harsh and remote locations. Consequently, drilling contractors face numerous challenges in order to maintain profitable operations. Ensuring efficient solid control systems is a critical aspect of successful drilling, as it directly impacts the overall performance and longevity of drilling equipment.Replacement shaker screens are an integral component of a drilling rig's solid control system. They are used to filter out unwanted solids from drilling fluids, a process known as shale shaker. Shaker screens play a vital role in maintaining the quality and integrity of the drilling fluids, as well as protecting downstream equipment such as centrifuges and pumps. Hence, the durability, effectiveness, and efficiency of these screens are of utmost importance.The innovator in question has a long-standing reputation for producing high-quality replacement shaker screens that surpass industry standards. Their commitment to continuous research and development has led to breakthrough technologies that address the industry's most pressing challenges. By leveraging advanced engineering techniques, this company has created screens that excel in terms of durability, efficiency, and performance.One of the key features that sets these replacement shaker screens apart is the utilization of composite materials. By combining carefully selected grades of stainless steel with engineered polymer frames, these screens exhibit enhanced resistance to wear and corrosion. This ensures a longer lifespan, resulting in reduced maintenance costs and increased overall productivity.Moreover, the company's innovative screen design maximizes the usable screen area, significantly improving fluid handling capacity. This not only facilitates faster drilling operations but also minimizes the chance of screen blinding, a common issue faced by drilling contractors. With decreased screen blinding, operators are able to maintain optimal fluid flow rates, enhancing the overall efficiency of the drilling process.Furthermore, these replacement screens are meticulously engineered to deliver accurate particle separation. They employ advanced mesh technology that enables precise cut points, ensuring that only the desired solids are filtered out. This level of finesse in separation allows drilling contractors to better manage the drilling fluids' composition, thereby delivering superior drilling performance.The company's commitment to customer satisfaction extends beyond the quality of their products. They provide comprehensive technical support and responsive customer service, ensuring that their clients' specific needs are met. In an industry where downtime can have costly repercussions, this level of support is invaluable.To further enhance their service offering, the company actively collaborates with drilling contractors to develop customized solutions. By understanding the unique challenges faced by each client, they are able to tailor their screens to specific drilling conditions, thereby optimizing performance and efficiency. This collaborative approach has earned the company a loyal customer base and cemented their position as a trusted partner in the oil and gas industry.With replacement shaker screens playing such a vital role in the oil and gas sector, the technological advancements offered by this innovative company are poised to transform the industry. By improving durability, maximizing fluid handling capacity, enhancing particle separation accuracy, and providing exceptional customer support, they are revolutionizing the solid control process. As drilling operations continue to evolve, these replacement shaker screens serve as a testament to the power of innovation in shaping the future of the oil and gas industry.

Latest Shale Shaker Screen Enhances Efficiency and Performance: A Detailed Report

In the world of oil and gas extraction, shale shaker screens are an essential part of the process. These screens are used to separate solids from drilling fluid and keep the drilling fluid clean and reusable. As technology advances, so do the capabilities of shale shaker screens. One of the latest advancements in this field comes from the production of Derrick FLC313 shale shaker screens.Derrick Corporation, a top provider of innovative solutions for the oil and gas industry, has introduced the Derrick FLC313 shale shaker screen. The company's vast experience and expertise in this industry are evident in the design and capabilities of these screens. The Derrick FLC313 screens offer significant benefits to drilling operations across the globe.The Derrick FLC313 shale shaker screen is engineered to deliver superior performance in a variety of drilling applications. The screen features a fully compliant, repairable screen panel design that maximizes operational uptime. The panel is constructed with a unique composite frame that is tough and durable, yet lightweight. This design reduces the screen's overall weight, making it easier to handle, and improves shaker performance.The screen's construction also includes a layer of high-strength steel reinforcement, providing added rigidity and strength to the screen panel. This layer prevents the screen mesh from sagging and reduces the risk of mesh failures, ensuring that the screen remains operational for longer periods.Derrick's FLC313 shale shaker screen incorporates several advanced features that enhance the performance of drilling operations. The screen uses the pyramid-shaped openings of the patented Pyramid Plus screen technology, which increases the surface area of the screen and reduces the amount of drilling fluid that is lost. The increased surface area provides more efficient solids removal and maximizes the drilling fluid's quality.Another significant advantage of the FLC313 shale shaker screen is its ability to handle high-volume solids processing. The screen's unique design and construction make it suitable for separating a higher volume of solids from drilling fluids, making it an ideal solution for demanding drilling applications.The FLC313 shale shaker screen is compatible with a wide range of shaker models, making it versatile and easy to install. The screen's universal design requires no modifications to the shaker, allowing for a simple installation process, reducing downtime, and increasing productivity.Derrick Corporation is committed to producing sustainable and environmentally-friendly solutions for the oil and gas industry. The company's FLC313 shale shaker screens are designed to minimize environmental impact and reduce waste. The screen's durable, lightweight construction and efficient solids control help to remediate drilling fluid and minimize waste disposal.In conclusion, Derrick Corporation's FLC313 shale shaker screen is a breakthrough innovation in the oil and gas industry. Its exceptional design, durability, and efficiency make it an ideal solution for demanding drilling applications. The screen's ability to handle high-volume solids processing and its compatibility with a wide range of shaker models offer unparalleled versatility and productivity. Derrick Corporation's commitment to sustainability and environmental consciousness ensures that the FLC313 shale shaker screen is also a responsible choice for the industry.

Latest Updates on High-Quality Stainless Steel Shaker Screens

Stainless Steel Shaker Screen Plays a Crucial Role in Oil and Gas DrillingThe importance of high-quality shaker screens in the oil and gas drilling industry is undeniable. They are vital in the separation of drilling fluids and solids during the drilling process. Therefore, it is imperative to have reliable, durable shaker screens that can withstand the rigorous demands of the industry.{The company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has established itself as a trusted brand in the industry, providing innovative solutions that meet the needs of customers.The {company} stainless steel shaker screen is one of the most popular products in its lineup. The screen is known for its high efficiency and durability, making it a top choice for drilling operations. It is made of high-quality stainless steel wire mesh and features a unique frame design that ensures maximum screen life and performance.One of the key features of the stainless steel shaker screen is its ability to withstand high temperatures and corrosive materials. This is crucial in the drilling process because the drilling fluids contain various chemicals, which can be highly corrosive and can damage the screen quickly. The {company} shaker screen can handle these harsh conditions without compromising its performance.Another advantage of the {company} stainless steel shaker screen is its superior filtration capabilities. The screen's unique design allows for maximum fluid handling capacity, ensuring that the drilling fluids and solids are separated efficiently. This not only improves the performance of the drilling process but also helps to reduce costs associated with replacing shaker screens frequently.In addition to its technical features, the {company} stainless steel shaker screen is also designed with ease of use in mind. The screen can be easily installed and removed from the shaker, reducing downtime and increasing efficiency.The {company} stainless steel shaker screen is available in a range of sizes and configurations to meet the diverse needs of customers. Whether it is a small-scale drilling operation or a large-scale project, the {company} shaker screen can provide the necessary performance and reliability needed to get the job done.The success of any drilling operation relies on the quality and performance of the equipment used, and the {company} stainless steel shaker screen is an excellent example of equipment that can make a significant difference. With its durable design, superior filtration capabilities, and ease of use, the {company} shaker screen has become a popular choice for drilling companies around the world.In conclusion, the importance of high-quality shaker screens in the oil and gas drilling industry cannot be overstated. The {company} stainless steel shaker screen is an outstanding example of equipment that can make a significant difference in the success of drilling operations. Its durability, filtration capabilities, and ease of use are just a few of the reasons why it has become a trusted choice for drilling companies worldwide.

High-Quality and Efficient FLC504 Shaker Screen for Improved Productivity

Title: Industry-Leading Shaker Screen Reinvents Solid Control EfficiencyIntroduction:In today's dynamic global oil and gas drilling industry, efficient solid control systems are integral to optimizing drilling operations. Recognizing this need, leading industry specialist PWP has introduced its groundbreaking FLC504 Shaker Screen. Engineered to provide unmatched performance and longevity, this state-of-the-art screen is set to revolutionize solid control operations in oil and gas drilling.Developed by PWP, a renowned manufacturer known for delivering cutting-edge solutions, the FLC504 Shaker Screen offers a range of significant advantages that will undoubtedly enhance drilling efficiency, reduce costs, and ensure maximum productivity.Stunning Technical Features:The FLC504 Shaker Screen incorporates advanced technology and innovative design elements. Its unique structure enables it to effectively separate solids from drilling fluid, presenting a robust solution that significantly improves solid control efficiency.1. Superior Durability: The FLC504 Shaker Screen is constructed using high-quality materials that guarantee outstanding durability and reliability even under the most demanding drilling conditions. This durability translates into improved overall service life and reduced operational downtime.2. Enhanced Sieve Performance: The screen features a mesh configuration specifically designed to maximize its solids control capabilities, allowing for accurate separation and efficient removal of solids from drilling fluid. This results in cleaner drilling fluid, optimized drilling performance, and ultimately higher financial returns on drilling investments.3. Optimal Conductance: Engineered with precise aperture sizes and patterns, the FLC504 Shaker Screen offers excellent flow capacity without compromising drilling fluid quality. Its exceptional conductance delivers increased drilling efficiency, lower operating costs, and improved environmental sustainability.4. Easy Installation and Maintenance: Designed with user convenience in mind, the FLC504 Shaker Screen ensures quick and hassle-free installation. In addition, its streamlined design facilitates efficient cleaning and maintenance, saving valuable time and resources for drilling operations.Company Commitment and Support:PWP, with its unwavering commitment to providing top-notch solutions, believes in offering comprehensive support to its clients. Its dedicated team of experts offers extensive technical assistance, professional guidance, and prompt after-sales service. With a global reach and an impressive track record, PWP has become a trusted partner for numerous oil and gas industry stakeholders.The PWP Advantage:As a market leader, PWP has consistently delivered high-quality products, making it a trusted name in the industry. The introduction of the FLC504 Shaker Screen reinforces PWP's commitment to innovation and ongoing improvement. PWP is more than just a manufacturer; it is a provider of reliable, practical, and efficient solutions that empower its clients to achieve operational excellence.Environmental Commitment:PWP's commitment to sustainable practices is deeply ingrained in its corporate ethos. The FLC504 Shaker Screen significantly reduces waste generation, contributing to a greener and more environmentally conscious drilling industry. By maximizing solids control efficiency, PWP mitigates environmental impacts and reduces the overall carbon footprint of drilling operations.Market Prospects and Future Outlook:With the launch of the FLC504 Shaker Screen, PWP is poised to capture a significant share of the solid control market. The impressive technical features and proven performance of the screen make it an attractive proposition for drilling professionals seeking to streamline their operations and optimize productivity.PWP's continuous research and development efforts ensure that future iterations of the FLC504 Shaker Screen will incorporate further refinements and advancements. With a strong focus on customer satisfaction and industry-leading solutions, PWP sets itself apart as a global leader in the solid control systems sector.Conclusion:PWP's FLC504 Shaker Screen marks a breakthrough in solid control efficiency. By combining cutting-edge technology with unparalleled performance, this industry-leading screen offers improved drilling fluid management, reduced operational costs, and enhanced environmental sustainability. With PWP's unwavering commitment to delivering excellence, the FLC504 Shaker Screen is set to transform the way oil and gas drilling operations are conducted, ensuring increased efficiency, productivity, and success in the years ahead.

Multi-Sizer Scalping Oil Shaker Screens: The Latest Innovation in Screening Technology

Scalping Oil Shaker Screens Revolutionizing the Oil and Gas IndustryThe oil and gas industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to streamline operations and increase efficiency. One such advancement is seen in the form of eco-friendly oil shaker screens, aimed at enhancing the oil drilling process. Among the frontrunners in this domain is the groundbreaking VSM Multi-sizer Scalping Oil Shaker Screen, developed by a renowned industry player. This revolutionary product has not only created a buzz within the sector but also opened up new possibilities for the oil and gas industry.The VSM Multi-sizer Scalping Oil Shaker Screen, an integral component of the oil drilling process, offers numerous advantages that make it indispensable for drilling companies. Its breakthrough design ensures maximum efficiency in removing unwanted solids, such as cuttings and debris, from the drilling fluid. Such efficient solid control methods are crucial for maintaining the integrity of the drilling operation and ensuring a steady flow of oil or gas.One of the standout features of the VSM Multi-sizer Scalping Oil Shaker Screen is its adaptability to a wide range of drilling conditions. Irrespective of the drilling location or application, this versatile shaker screen is capable of handling it all. Its ability to handle a variety of drilling fluids, ranging from abrasive to corrosive, makes it ideal for even the most challenging drilling operations.Another noteworthy aspect of the VSM Multi-sizer Scalping Oil Shaker Screen is its durability and longevity. Manufactured using high-quality materials, combined with cutting-edge manufacturing techniques, this shaker screen boasts an impressive lifespan. Its rugged construction ensures it can withstand harsh conditions and endure heavy-duty use, thereby reducing the need for frequent replacements and saving costs for drilling companies.Furthermore, the eco-friendly nature of the VSM Multi-sizer Scalping Oil Shaker Screen is worth highlighting. In an era where sustainability and environmental consciousness are of utmost importance, this product aligns perfectly with the industry's green initiatives. By efficiently separating solids from drilling fluids, this shaker screen significantly reduces waste generation, promoting responsible drilling practices.The VSM Multi-sizer Scalping Oil Shaker Screen's user-friendly design also deserves recognition. It is easy to install and offers simple maintenance procedures, allowing for hassle-free operations on drilling rigs. This ease of use translates into saved time and increased productivity, enabling drilling companies to optimize their resources effectively.The impact of the VSM Multi-sizer Scalping Oil Shaker Screen on the oil and gas industry has not gone unnoticed. With its remarkable performance and cost-effectiveness, this innovative product has garnered significant attention from industry professionals and experts globally. It has been hailed as a game-changer, capable of revolutionizing the way drilling companies approach solids control during oil extraction.The company behind this groundbreaking product, {Company Name}, is a renowned name in the oil and gas industry. With a history of delivering cutting-edge solutions and continually pushing the boundaries of innovation, the company has solidified its position as a leader in the field. Committed to excellence and customer satisfaction, they have etched a mark in the industry through their relentless pursuit of technological advancements.In conclusion, the VSM Multi-sizer Scalping Oil Shaker Screen has set a new benchmark for solids control in the oil and gas industry. Its efficient and versatile design, coupled with its eco-friendly nature and user-friendly operations, has made it a preferred choice among drilling companies worldwide. With the support of industry leaders like {Company Name}, the future of the oil and gas industry looks promising, driven by advancements like the VSM Multi-sizer Scalping Oil Shaker Screen.

Upgrade Your Shakers with New Generation Replacement Wave Screens for Enhanced Performance

Title: High-Quality Replacement Screens for Hyperpool Shakers Now AvailableIntroduction:In the ever-evolving world of oil and gas drilling, the search for advanced technologies and equipment that enhance efficiency and performance never ceases. The demand for reliable and durable shaker screens to optimize drilling operations has led to the development of cutting-edge replacement screens. One such offering is the recently launched Replacement Wave Screens, engineered specifically for Derrock Hyperpool Shakers, distributed by a leading industry player.Company Introduction:XYZ Drilling Solutions is a renowned company committed to providing innovative solutions to the oil and gas industry. With years of expertise and a strong track record of excellence, XYZ Drilling Solutions has established itself as a trusted partner for enhancing drilling efficiency and productivity.With a team of highly skilled professionals and a state-of-the-art manufacturing facility, XYZ Drilling Solutions strives to meet the ever-increasing demands of the global drilling market. Their commitment to quality and continuous improvement has earned them a reputation for delivering reliable and superior products.Replacement Wave Screens for Derrock Hyperpool Shakers:XYZ Drilling Solutions has recently unveiled their latest offering – Replacement Wave Screens for Derrock Hyperpool Shakers. These screens are designed to maximize the performance and efficiency of drilling operations, addressing the challenges faced by drilling professionals worldwide.The key features of the Replacement Wave Screens include:1. Superior Performance: The Replacement Wave Screens are engineered using advanced technology to provide exceptional solids control efficiency. The innovative design allows for better separation and increased throughput, resulting in improved drilling fluid recovery and reduced waste.2. Enhanced Durability: Made from top-quality materials that ensure longevity, the Replacement Wave Screens are built to withstand the harsh conditions encountered during drilling operations. Their robust construction minimizes the chance of premature failure, reducing downtime and maintenance costs.3. Optimized Conductance: The optimized design of the Wave Screens provides enhanced fluid conductance, allowing for efficient fluid flow while effectively retaining solids. This feature improves solids control, extends screen life, and reduces overall operating costs.4. Quick and Easy Installation: The Replacement Wave Screens are designed for hassle-free installation, ensuring minimal downtime during screen changeouts. The screens can seamlessly fit onto Derrock Hyperpool Shakers, making them a convenient and reliable choice for drilling professionals.5. Compatibility: XYZ Drilling Solutions' Replacement Wave Screens are exclusively engineered to fit Derrock Hyperpool Shakers. This compatibility ensures a perfect fit, maintaining the integrity of the shaker and optimizing the overall performance."XYZ Drilling Solutions is proud to introduce our Replacement Wave Screens for Derrock Hyperpool Shakers," said John Doe, CEO of XYZ Drilling Solutions. "We have relished the opportunity to work closely with drilling professionals to develop a high-quality screen that addresses their specific needs. Our team has invested significant time and expertise to ensure that our screens maximize drilling efficiency and reduce overall operational costs."With a commitment to providing exceptional customer service, XYZ Drilling Solutions offers comprehensive technical support and guidance to assist clients in selecting the right Replacement Wave Screens for their operations. The company's extensive network of distribution centers ensures prompt and reliable delivery to customers worldwide.Conclusion:With the introduction of XYZ Drilling Solutions' Replacement Wave Screens exclusively designed for Derrock Hyperpool Shakers, the industry can embrace a new level of drilling efficiency and performance. The advanced technology employed in these screens ensures superior performance, enhanced durability, and easy installation. XYZ Drilling Solutions continues to set industry standards and reaffirms its dedication to providing innovative solutions to the global oil and gas drilling industry.