Highly Efficient Primary Screen for Industrial Applications Now Available

By:Admin

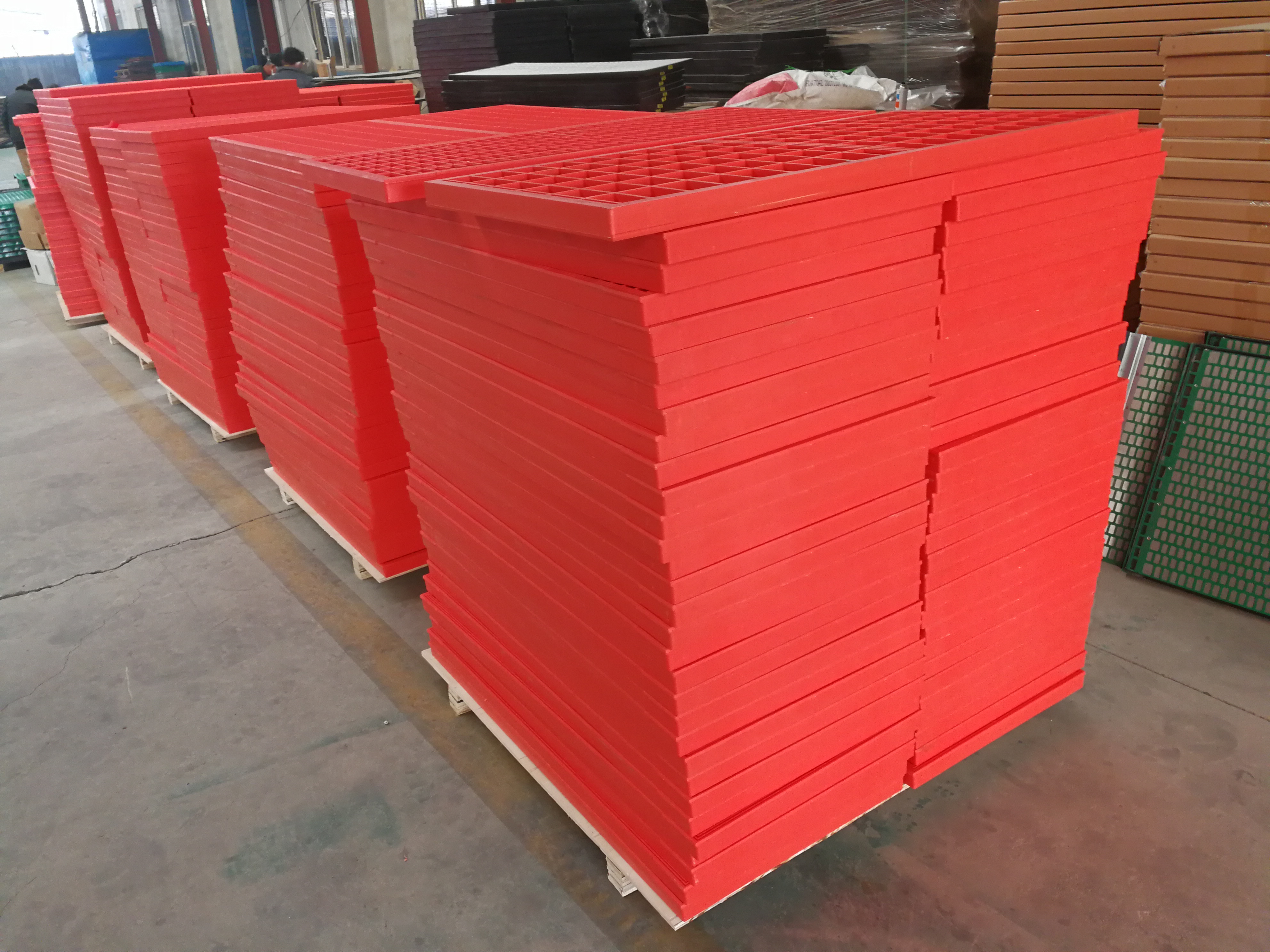

The VSM100 Primary Screen is designed to meet the demanding requirements of the mining and aggregate industries. It is built with a focus on durability, efficiency, and ease of maintenance, making it a reliable and cost-effective solution for processing operations. This new addition to {Company Name}'s product line is set to provide customers with a highly efficient screening solution that can handle the toughest of materials.

One of the key features of the VSM100 Primary Screen is its robust construction. It is built to withstand the harsh working conditions typically found in mining and aggregate operations. The screen is made from high-quality materials and is engineered to last, reducing downtime and maintenance costs for the end user.

In addition to its durability, the VSM100 Primary Screen is designed for high efficiency. Its innovative design allows for a larger screening area, resulting in higher throughput and improved product quality. This means that customers can expect increased productivity and reduced operational costs when using this new vibrating screen.

Another standout feature of the VSM100 Primary Screen is its ease of maintenance. The design of the screen allows for quick and simple access to critical components, making routine maintenance tasks much more straightforward. This not only minimizes downtime but also ensures that the screen operates at peak performance for longer periods between maintenance intervals.

{Company Name} has a long-standing reputation for producing high-quality vibrating screens, and the VSM100 Primary Screen is no exception. The company has invested heavily in research and development to ensure that their products are at the cutting edge of technology and performance. The introduction of the VSM100 Primary Screen further solidifies {Company Name}'s position as a leader in the industry and demonstrates their commitment to providing innovative solutions to their customers.

Customers can also benefit from {Company Name}'s extensive support network, which ensures that the VSM100 Primary Screen is backed by a team of experts who can provide technical assistance, spare parts, and service support as needed. This comprehensive support offering gives customers peace of mind and helps to maximize the uptime of their equipment.

The introduction of the VSM100 Primary Screen is a significant milestone for {Company Name} and further establishes their position as a leading supplier of vibrating screens for the mining and aggregate industries. With its focus on durability, efficiency, and ease of maintenance, this new addition to their product line is set to make a positive impact on processing operations around the world.

In conclusion, the VSM100 Primary Screen from {Company Name} is a testament to the company's dedication to developing high-quality solutions for the mining and aggregate industries. With its robust construction, high efficiency, and ease of maintenance, this new vibrating screen is poised to set a new standard for screening equipment. Customers can expect improved productivity, reduced operating costs, and reliable performance from the VSM100 Primary Screen, making it a valuable addition to any processing operation.

Company News & Blog

Latest Updates on High-Quality Stainless Steel Shaker Screens

Stainless Steel Shaker Screen Plays a Crucial Role in Oil and Gas DrillingThe importance of high-quality shaker screens in the oil and gas drilling industry is undeniable. They are vital in the separation of drilling fluids and solids during the drilling process. Therefore, it is imperative to have reliable, durable shaker screens that can withstand the rigorous demands of the industry.{The company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has established itself as a trusted brand in the industry, providing innovative solutions that meet the needs of customers.The {company} stainless steel shaker screen is one of the most popular products in its lineup. The screen is known for its high efficiency and durability, making it a top choice for drilling operations. It is made of high-quality stainless steel wire mesh and features a unique frame design that ensures maximum screen life and performance.One of the key features of the stainless steel shaker screen is its ability to withstand high temperatures and corrosive materials. This is crucial in the drilling process because the drilling fluids contain various chemicals, which can be highly corrosive and can damage the screen quickly. The {company} shaker screen can handle these harsh conditions without compromising its performance.Another advantage of the {company} stainless steel shaker screen is its superior filtration capabilities. The screen's unique design allows for maximum fluid handling capacity, ensuring that the drilling fluids and solids are separated efficiently. This not only improves the performance of the drilling process but also helps to reduce costs associated with replacing shaker screens frequently.In addition to its technical features, the {company} stainless steel shaker screen is also designed with ease of use in mind. The screen can be easily installed and removed from the shaker, reducing downtime and increasing efficiency.The {company} stainless steel shaker screen is available in a range of sizes and configurations to meet the diverse needs of customers. Whether it is a small-scale drilling operation or a large-scale project, the {company} shaker screen can provide the necessary performance and reliability needed to get the job done.The success of any drilling operation relies on the quality and performance of the equipment used, and the {company} stainless steel shaker screen is an excellent example of equipment that can make a significant difference. With its durable design, superior filtration capabilities, and ease of use, the {company} shaker screen has become a popular choice for drilling companies around the world.In conclusion, the importance of high-quality shaker screens in the oil and gas drilling industry cannot be overstated. The {company} stainless steel shaker screen is an outstanding example of equipment that can make a significant difference in the success of drilling operations. Its durability, filtration capabilities, and ease of use are just a few of the reasons why it has become a trusted choice for drilling companies worldwide.

New Pyramid Screen Technology Revolutionizes Derrick Hyperpool

Derrick Corporation is excited to announce the release of its latest innovation, the Hyperpool Pyramid screen, a cutting-edge solution for the oil and gas industry. The Hyperpool Pyramid screen is designed to improve the efficiency and productivity of shale shakers, ensuring better performance and longer screen life.The Hyperpool Pyramid screen features a unique pyramid design that offers a larger open area, increasing the throughput of the shale shaker. This design also reduces the risk of blockages and ensures consistent, high-quality screening for a wide range of drilling applications. With a larger effective screen area, the Hyperpool Pyramid screen delivers higher capacity and better performance, making it an ideal solution for demanding drilling operations.In addition to its innovative design, the Hyperpool Pyramid screen is built to last. It is constructed with durable, high-quality materials that are resistant to wear and tear, ensuring a longer screen life and reduced maintenance costs. This durability makes the Hyperpool Pyramid screen a cost-effective solution for oil and gas companies looking to improve the efficiency and reliability of their drilling operations.The Hyperpool Pyramid screen is also designed for easy installation and maintenance, with a simple and efficient fastening system that minimizes downtime and reduces the need for specialized tools. This user-friendly design ensures that the Hyperpool Pyramid screen can be quickly and easily integrated into existing shale shakers, allowing for seamless and hassle-free operation."We are thrilled to introduce the Hyperpool Pyramid screen to the market," said a spokesperson for Derrick Corporation. "This new product represents a significant advancement in shale shaker technology, offering our customers a solution that delivers superior performance, durability, and ease of use. We believe that the Hyperpool Pyramid screen will quickly become an essential tool for oil and gas companies looking to optimize their drilling operations."Derrick Corporation has a long history of providing innovative solutions for the oil and gas industry. With a focus on research and development, the company is committed to continuously improving its products and services to meet the evolving needs of its customers. The release of the Hyperpool Pyramid screen is a testament to Derrick Corporation's dedication to engineering excellence and providing industry-leading solutions for the oil and gas sector.As oil and gas companies continue to seek ways to optimize their drilling operations, the Hyperpool Pyramid screen represents a valuable tool for improving efficiency, reducing maintenance costs, and maximizing productivity. Its innovative design, durable construction, and user-friendly features make it a compelling choice for companies looking to enhance the performance of their shale shakers.In conclusion, the release of the Hyperpool Pyramid screen is a significant milestone for Derrick Corporation, as it continues to lead the way in providing cutting-edge solutions for the oil and gas industry. With its advanced design, durability, and user-friendly features, the Hyperpool Pyramid screen is poised to become a game-changer for companies seeking to improve the efficiency and reliability of their drilling operations.

Newest LCM-2D Technology from Leading Chinese Manufacturer

China's Latest LCM-2D Display Launched: A Game-Changer for the Consumer Electronics IndustryA new display technology has taken the consumer electronics industry by storm thanks to China's latest innovation, the LCM-2D display. This revolutionary technology has been designed to deliver a stunning visual experience to users, offering a range of benefits not found in traditional display technologies. As a result, the LCM-2D display is poised to revolutionize the industry by providing consumers with a new level of performance, functionality, and versatility.With its advanced features and state-of-the-art design, the LCM-2D display is the perfect upgrade for businesses, home users, and gamers. Developed by a team of world-renowned display technology experts, this technology promises to transform the way we interact with screens forever.The New Standard for Display TechnologyThe LCM-2D display represents the latest advancement in display technology, and it promises to set a new standard for the industry. This technology delivers a range of benefits that were impossible to achieve with traditional display technologies until now. One of the most impressive features of the LCM-2D display is its pixel density. With a pixel density of over 100 PPI, this technology delivers incredibly sharp and precise images, bringing every detail to life in vivid color.Another major advantage of the LCM-2D display technology is its brightness. Unlike other displays available in the market, the LCM-2D display is capable of producing levels of brightness that allow users to use the device in brightly lit environments. Combined with its excellent contrast ratio, the technology ensures that every image displayed on the screen is crisp, clear, and highly detailed.Enhanced Functionality and PrecisionThe LCM-2D display is designed to bring enhanced functionality and precision to all types of devices. It is optimized to work seamlessly with the latest chips and processors, delivering a smooth visual experience that is unparalleled in the market. Moreover, this technology performs exceptionally even in areas with limited power resources.One of the most impressive features of the LCM-2D display is that it delivers exceptional color accuracy. It is capable of reproducing colors with a level of precision that simply wasn't possible before. This technology enables users to view more natural and lifelike images with accurate hues and tones. Unlike traditional displays that usually sharpen the details and distort the color, the LCM-2D ensures that every image is true to life, providing an authentic visual experience.Versatile Range of ApplicationsThe LCM-2D display is capable of being integrated into a wide range of devices. From laptops and desktops to gaming consoles and mobile phones, this technology is highly versatile and can add an extra level of functionality to any device where it is installed. As a result, many tech companies have already begun collaborating with China's LCM-2D manufacturers to experiment with the technology and make it a part of their product offerings. Soon, users will be able to enjoy this innovative display technology on a range of devices, including VR headsets, displays, smart home devices, and much more.The Future of Display TechnologyOverall, the LCM-2D display promises to revolutionize the consumer electronics industry by providing users an unparalleled visual experience. The technology's sharp images, exceptional contrast ratio, superior brightness, high precision, and accurate color reproduction make it stand out from traditional display technologies available on the market today.As the demand for high-quality displays continues to grow, the LCM-2D display promises to become the new standard in display technology. China's latest innovation is set to change the way we interact with screens and devices, and we can expect to see a wave of LCM-2D enabled devices hitting the market very soon.In conclusion, the LCM-2D display is a major breakthrough in display technology and is poised to change the world of consumer electronics. Its superior performance, exceptional quality, and versatility make it an excellent choice for anyone who is looking to upgrade their device's display technology. The technology promises to offer the perfect visual experience, whether you are gaming, working, or watching movies, and it will undoubtedly become an essential part of the tech landscape in the coming years.

Derrick Hyperpool Shaker Screen for PMD - What You Need to Know

Derrick Corporation, a global leader in the supply of high-performance separation and filtration equipment, has introduced its latest innovation in solids control technology - the Hyperpool PMD Shaker screen. This cutting-edge product offers superior performance and durability to enhance drilling operations in the oil and gas industry.The Hyperpool PMD Shaker screen is designed to efficiently remove solid particles from drilling fluid, also known as drilling mud, during the drilling process. This is a crucial step in the extraction of oil and gas, as the presence of solid particles can hinder the performance of drilling equipment and ultimately affect the overall efficiency of the operation.One of the key features of the Hyperpool PMD Shaker screen is its advanced design, which allows for increased throughput capacity and improved solids removal efficiency. This results in higher productivity and cost savings for drilling operations, as the need for frequent screen changes and maintenance is significantly reduced.In addition, the Hyperpool PMD Shaker screen is built to withstand the challenging and harsh conditions encountered in oil and gas drilling operations. Its durable construction and long-lasting performance make it a reliable and cost-effective solution for operators looking to optimize their solids control processes.Furthermore, Derrick Corporation has a proven track record of delivering high-quality products and services to the oil and gas industry. With over 70 years of experience, the company has established itself as a trusted partner for operators seeking innovative and reliable solutions for their separation and filtration needs.The introduction of the Hyperpool PMD Shaker screen further solidifies Derrick Corporation's commitment to providing industry-leading technology that meets the evolving demands of the oil and gas sector. By continuously investing in research and development, the company strives to remain at the forefront of innovation and deliver solutions that drive operational efficiency and performance.In response to the introduction of the Hyperpool PMD Shaker screen, Derrick Corporation's CEO commented, "We are excited to bring this advanced technology to the market, as we believe it will greatly benefit our customers and help them achieve their operational objectives. The Hyperpool PMD Shaker screen is a testament to our ongoing dedication to delivering innovative and high-performance solutions that address the challenges faced by the oil and gas industry."As the global demand for oil and gas continues to rise, the need for efficient and reliable solids control equipment has never been greater. Derrick Corporation's Hyperpool PMD Shaker screen is poised to make a significant impact on drilling operations worldwide, offering enhanced performance, durability, and cost savings.With its proven expertise and commitment to innovation, Derrick Corporation is well-positioned to continue driving advancements in solids control technology and empowering operators to achieve greater success in their drilling operations. The introduction of the Hyperpool PMD Shaker screen is a testament to the company's unwavering dedication to excellence and its ability to deliver solutions that meet the evolving needs of the oil and gas industry.

High-Quality KPT 28 Shaker Screen for China's Oil and Gas Industry

China-based company KPT 28 Shaker Screen is making waves in the oil and gas industry with its state-of-the-art shaker screens. The company has been gaining recognition for its high-quality products and innovative solutions for the oil and gas drilling industry.Founded in 2008, KPT 28 Shaker Screen has quickly established itself as a leading manufacturer and supplier of shaker screens for various types of shakers used in the oil and gas drilling process. The company's commitment to quality, performance, and customer satisfaction has earned it a stellar reputation among its clients.KPT 28 Shaker Screen's products are designed to withstand the harsh conditions of drilling operations, providing reliable and efficient performance, reducing downtime and increasing productivity. The company's shaker screens are engineered to effectively separate solids from drilling fluid, ensuring smooth and efficient drilling operations.The company offers a wide range of shaker screens to meet the diverse needs of its clients, including hook strip, pretention, and flat panel screens. KPT 28 Shaker Screen's products are compatible with most major brands of shale shakers, making them a versatile and reliable choice for drilling operations.In addition to its high-quality products, KPT 28 Shaker Screen is also known for its exceptional customer service. The company's team of experts are dedicated to providing personalized support and guidance to help clients select the best shaker screens for their specific needs. KPT 28 Shaker Screen's commitment to customer satisfaction has helped it build strong and long-lasting relationships with its clients.With a focus on innovation and continuous improvement, KPT 28 Shaker Screen invests in research and development to enhance its product offerings and stay ahead of industry trends. The company leverages the latest technologies and manufacturing processes to produce shaker screens that meet the highest standards of quality and performance.KPT 28 Shaker Screen's dedication to excellence has not gone unnoticed, as the company has received numerous accolades and certifications for its products and services. Its shaker screens have been widely used in oil and gas drilling operations in the Middle East, North America, and other regions, earning recognition for their reliability and durability.As the demand for energy continues to grow, the oil and gas industry is expected to expand, driving the need for efficient and reliable drilling equipment. KPT 28 Shaker Screen is well-positioned to meet this demand with its cutting-edge shaker screens and unwavering commitment to customer satisfaction.Looking ahead, KPT 28 Shaker Screen is poised to further expand its presence in the global oil and gas market and continue its tradition of delivering top-quality products and stellar service to its clients.In conclusion, KPT 28 Shaker Screen is a trusted and reputable provider of shaker screens for the oil and gas industry. With a steadfast focus on quality, performance, and customer satisfaction, the company has made a name for itself as a leader in the field. As the industry continues to evolve, KPT 28 Shaker Screen is well-equipped to meet the changing needs of its clients and maintain its position as a top supplier of shaker screens.

Latest Innovation in Vibrating Screens: Xxnx Powder Screening Solution

Title: State-of-the-Art Powder Vibrating Screen Revolutionizes Industrial ProcessesIntroduction:In the ever-evolving world of industrial technology, innovation plays a crucial role in optimizing productivity and improving efficiency. The renowned industrial machinery manufacturer, {Company Name}, takes this concept to new heights with its cutting-edge powder vibrating screen. This state-of-the-art device revolutionizes the handling of powders, offering a solution that enhances production processes across various industries.Section 1: The Need for Advanced Powder Vibrating ScreensPowders are widely used in multiple sectors, including pharmaceuticals, chemicals, food processing, and more. However, conventional methods of handling and screening powders often present several challenges. These include inefficient separation, limited capacity, and increased maintenance requirements, leading to higher costs and reduced overall productivity. Recognizing this need for improvement, {Company Name} engineered a solution that addresses these issues head-on.Section 2: Key Features and BenefitsThe {Company Name} powder vibrating screen is equipped with an array of cutting-edge features that ensure superior performance and reliability. The following are the paramount benefits offered by this innovative technology:1. Enhanced Separation Efficiency: The vibrating screen's advanced design and state-of-the-art components enable exceptional separation efficiency, ensuring optimized product quality and minimized wastage. The precision engineering of the screen effectively removes impurities and particles of different sizes, resulting in a refined end product.2. Increased Capacity: The increased capacity of the {Company Name} powder vibrating screen allows for higher throughput, enabling industries to meet growing demands efficiently. This improved productivity leads to enhanced overall production rates and ultimately boosts profitability.3. Easy Maintenance: {Company Name} has prioritized user-friendliness when designing this vibrating screen. The streamlined structure and easily accessible components simplify maintenance tasks, reducing downtime and minimizing production interruptions. This feature enables businesses to operate smoothly and maximize uptime.4. Flexible Design Options: Recognizing the diverse needs of industries, {Company Name} offers customization options for its powder vibrating screen. This flexibility allows businesses to tailor the device to their specific requirements, enhancing its compatibility with existing production lines.Section 3: Industry ApplicationsThe versatility of the {Company Name} powder vibrating screen makes it applicable across a wide range of industries. Key sectors that can benefit from this technology include:1. Pharmaceutical Industry: The precision separation capabilities of the vibrating screen make it ideal for pharmaceutical companies needing to screen active pharmaceutical ingredients (APIs) and medicinal powders. The efficient separation ensures product consistency and quality control.2. Chemical Industry: Chemical producers can improve their handling of different powder compounds, including pigments, dyes, and additives, by utilizing this advanced vibrating screen. It enhances separation precision, avoiding cross-contamination issues and enhancing productivity.3. Food Processing Industry: In the food processing sector, the powder vibrating screen offers an efficient solution for ingredients such as flour, sugar, spices, and additives. The device ensures product uniformity and purity, meeting stringent quality standards in food production.Section 4: Customer Testimonials{Company Name} has garnered positive feedback from its customers who have experienced the benefits of the powder vibrating screen firsthand. Renowned industries across various sectors have reported substantial improvements in their production processes, emphasizing increased efficiency, reduced downtime, and enhanced product quality.Conclusion:The revolutionary powder vibrating screen by {Company Name} is a game-changer in the industrial machinery market. Its advanced features, coupled with customizable options, offer businesses the opportunity to streamline their powder handling and ensure optimum production rates. With its wide-ranging applications across diverse industries, the vibrating screen supports businesses in achieving higher productivity, improved product quality, and increased profitability. The continued commitment of {Company Name} to innovation sets them apart as a trusted partner in the industrial machinery sector.

High Efficiency Shaker Screen for Derrick Hyperpool

Title: Innovation in Shale Shaker Screens: Company Introduces Derrick Hyperpool Shaker ScreenIn the ever-evolving world of oil and gas drilling, innovation is key to maximizing efficiency and productivity. One company that has been at the forefront of this innovation is Derrick Corporation, a leading provider of separation technology for the oil and gas industry. Recently, the company introduced a groundbreaking new product, the Derrick Hyperpool Shaker Screen, which is set to revolutionize the way drilling operations are conducted.The Derrick Hyperpool Shaker Screen is a high-capacity, high-efficiency screen that is specifically designed for use in the oil and gas industry. It is engineered to allow for increased throughput and improved performance, making it an ideal solution for the demanding conditions of shale shaker operations. With its advanced design and superior performance, the Hyperpool Shaker Screen is poised to set a new standard in shaker screen technology.The Hyperpool Shaker Screen is the result of years of research and development by Derrick Corporation's team of engineers and scientists. The company has a long history of innovation, and the Hyperpool Shaker Screen is the latest example of its commitment to pushing the boundaries of what is possible in the oil and gas industry. By combining cutting-edge technology with a deep understanding of the needs of drilling operations, Derrick Corporation has created a product that is set to make a significant impact on the industry.One of the key features of the Hyperpool Shaker Screen is its high-capacity design, which allows for increased throughput and improved performance in shale shaker operations. This means that drilling operations can be conducted more efficiently, with less downtime and greater productivity. In addition, the screen is engineered for durability and longevity, ensuring that it can withstand the rigors of the drilling environment and continue to perform at a high level over time.Another important aspect of the Hyperpool Shaker Screen is its high-efficiency design, which allows for finer separation of solids from drilling fluid. This results in cleaner drilling fluid, which in turn leads to improved drilling performance and reduced environmental impact. By providing a more effective method of solids control, the Hyperpool Shaker Screen is set to deliver significant benefits to drilling operations across the industry.The introduction of the Hyperpool Shaker Screen is a significant milestone for Derrick Corporation, and it builds on the company's long history of innovation and leadership in the oil and gas industry. With its advanced design, superior performance, and potential to deliver significant benefits to drilling operations, the Hyperpool Shaker Screen is set to become an industry standard in shaker screen technology.In addition to the launch of the Hyperpool Shaker Screen, Derrick Corporation continues to provide a comprehensive range of products and services to the oil and gas industry. The company offers a full line of separation equipment, including shale shakers, mud cleaners, and centrifuges, as well as a range of aftermarket services to support drilling operations. With a commitment to excellence and a focus on innovation, Derrick Corporation is well-positioned to continue leading the way in the oil and gas industry.In conclusion, the introduction of the Derrick Hyperpool Shaker Screen represents a significant advancement in shaker screen technology for the oil and gas industry. With its high-capacity, high-efficiency design, the Hyperpool Shaker Screen is set to revolutionize the way drilling operations are conducted, delivering improved performance, increased throughput, and greater efficiency. As Derrick Corporation continues to innovate and lead the industry, the Hyperpool Shaker Screen is poised to become a standard-bearer for shaker screen technology, setting a new benchmark for excellence in the oil and gas industry.

Top Performing Shaker Screen for Derrick Hyperpool Model

Derrick Hyperpool Shaker Screen, a leading provider of innovative and highly efficient solid control solutions for the oil and gas industry, has recently introduced its latest cutting-edge technology to enhance drilling operations.The company's Hyperpool Shaker Screen is designed to provide superior performance and reliability in the removal of solid particles from drilling fluid, which is crucial for maintaining the integrity and efficiency of drilling operations. With its advanced manufacturing techniques and high-quality materials, the Hyperpool Shaker Screen offers improved particle separation and increased throughput capacity, leading to greater productivity and cost savings for oil and gas companies.The Hyperpool Shaker Screen is built with a unique design that maximizes the use of available screen area, ensuring efficient separation of solids from drilling fluid while minimizing the risk of screen blinding. This innovative design results in a longer service life for the screens, reducing the need for frequent replacements and lowering overall maintenance costs for drilling operations.In addition to its superior performance, the Hyperpool Shaker Screen is also designed with ease of use and maintenance in mind. The screens are engineered to be lightweight and easy to handle, making installation and replacement quick and simple. This user-friendly design not only saves time and labor costs but also enhances safety during screen handling and maintenance activities.The introduction of the Hyperpool Shaker Screen further solidifies Derrick's position as a trusted and innovative partner for the oil and gas industry. With a strong commitment to research and development, Derrick continues to lead the way in providing advanced solid control solutions that meet the evolving needs of the industry.The Hyperpool Shaker Screen is just one example of Derrick's dedication to providing cutting-edge technologies that improve the efficiency, reliability, and safety of drilling operations. Derrick's comprehensive range of products and services, including shaker screens, centrifuges, and other solid control equipment, is designed to maximize drilling performance while minimizing environmental impact.As a global leader in solid control solutions, Derrick is known for its unwavering commitment to quality, reliability, and customer satisfaction. The company's team of experts is dedicated to providing exceptional support and service, ensuring that customers receive the best possible solutions for their specific needs.With the introduction of the Hyperpool Shaker Screen, Derrick continues to set new standards for performance and innovation in the oil and gas industry. As drilling operations become increasingly complex and demanding, Derrick remains at the forefront of delivering cutting-edge technologies that help customers meet their operational challenges and achieve greater success.As the industry looks toward the future, Derrick is poised to continue its tradition of excellence, driving innovation and setting new benchmarks for performance, reliability, and efficiency in solid control solutions. The Hyperpool Shaker Screen is a testament to Derrick's ongoing commitment to meeting and exceeding the needs of the oil and gas industry, and it is sure to be a valuable asset for drilling operations around the world.

Oil Shale Shaker Screen BEM-650 for MI Swaco - All You Need to Know

MI Swaco BEM-650 Oil Shale Shaker Screen is a newly developed product that has been making waves in the oil and gas industry. This advanced shaker screen is designed to effectively remove solids from drilling fluids while also delivering higher flow rates and longer screen life. As a result, it has quickly gained popularity among companies in the oil and gas sector.The BEM-650 Oil Shale Shaker Screen is manufactured by a well-established company that has been at the forefront of providing innovative solutions for the oil and gas industry. With years of experience and a strong focus on research and development, the company has been able to create products that are not only efficient but also cost-effective. The BEM-650 Shaker Screen is yet another example of the company's commitment to delivering high-quality solutions to its customers.One of the key features of the BEM-650 Oil Shale Shaker Screen is its superior performance in removing solids from drilling fluids. This is crucial in the oil and gas industry, as the presence of solids in drilling fluids can cause a range of issues, including reduced efficiency and equipment damage. By effectively removing these solids, the BEM-650 Shaker Screen helps companies to maintain the quality of their drilling fluids and ensure smooth operations.In addition to its solid removal capabilities, the BEM-650 Oil Shale Shaker Screen also offers higher flow rates compared to traditional shaker screens. This means that companies can process larger volumes of drilling fluids in a shorter amount of time, resulting in increased productivity and reduced downtime. Furthermore, the screen is designed to have a longer life, which helps companies save on replacement costs and maintenance expenses.The development of the BEM-650 Oil Shale Shaker Screen is a testament to the company's ongoing efforts to innovate and improve its product offerings. By leveraging cutting-edge technologies and manufacturing processes, the company has been able to create a product that meets the evolving needs of the oil and gas industry. Moreover, the company has a strong commitment to quality and reliability, ensuring that its products perform consistently in the harshest operating environments.As the oil and gas industry continues to face challenges in drilling operations, the demand for efficient and reliable equipment has never been greater. The BEM-650 Oil Shale Shaker Screen addresses this demand by providing a solution that not only improves operational efficiency but also reduces costs. With a focus on performance, durability, and cost-effectiveness, the BEM-650 Shaker Screen is poised to become a staple in drilling operations worldwide.In conclusion, the introduction of the BEM-650 Oil Shale Shaker Screen represents a significant advancement in the oil and gas industry. With its superior solid removal capabilities, higher flow rates, and longer screen life, the BEM-650 Shaker Screen is a game-changer for companies looking to optimize their drilling operations. As the company behind this innovative product continues to push the boundaries of technology and engineering, it is clear that the future of the oil and gas industry is brighter than ever.

Quality Shaker Screens for Mongoose Shale Shakers

In recent news, (company name) has announced the release of their latest product, the (product name). This innovative screen is designed to provide improved efficiency and performance for the oil and gas industry, making it an essential tool for drilling operations.The (product name) is designed to fit the popular (product type) models and is constructed with high-quality materials to ensure durability in even the most demanding drilling environments. Its advanced technology allows for efficient solids control and fluid handling, making it a valuable asset for any drilling operation.The (product name) features a unique design that is engineered to maximize throughput and screen life, ultimately reducing the overall cost of operations. Its high-capacity composite frame provides increased support and resistance to wear and tear, making it a reliable and long-lasting solution for solids control.Furthermore, the (product name) is designed to offer quick and easy installation, reducing downtime and increasing productivity on the drilling site. Its superior performance and reliability make it an ideal choice for operators looking to improve their drilling efficiency and reduce overall operating costs.Additionally, (company name) has a long-standing reputation for delivering innovative and reliable products to the oil and gas industry. With a commitment to quality and customer satisfaction, they have become a trusted partner for drilling operations around the world.The company's extensive experience and expertise in the industry have allowed them to develop cutting-edge solutions that address the unique challenges faced by oil and gas operators. The introduction of the (product name) further demonstrates their dedication to providing industry-leading products and services.In addition to their exceptional product offerings, (company name) also provides comprehensive support and service to ensure that their customers receive the maximum benefit from their products. Their team of experts is available to provide technical assistance, training, and maintenance services to keep operations running smoothly.As the oil and gas industry continues to evolve, (company name) remains at the forefront of innovation, delivering solutions that meet the changing needs of the industry. The release of the (product name) further solidifies their position as a leader in the field of drilling equipment and technology.In conclusion, the (product name) from (company name) is a game-changing solution for the oil and gas industry, offering unmatched performance, reliability, and efficiency for drilling operations. With its advanced design and durable construction, it is sure to become an essential tool for operators looking to optimize their operations and reduce costs. As the industry continues to demand high-performance equipment, (company name) remains committed to providing the innovative solutions that operators need to succeed.